Indium or niobium epoxide apatite type lanthanum silicate mixed solid electrolyte material and preparation method thereof

A technology of oxyapatite and solid electrolyte, applied in solid electrolyte fuel cells, circuits, fuel cells, etc., can solve the problems of high cost, easy formation of second phase, high temperature and other problems of sol-gel method, and reduce energy consumption , reduce the sintering temperature and holding time, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

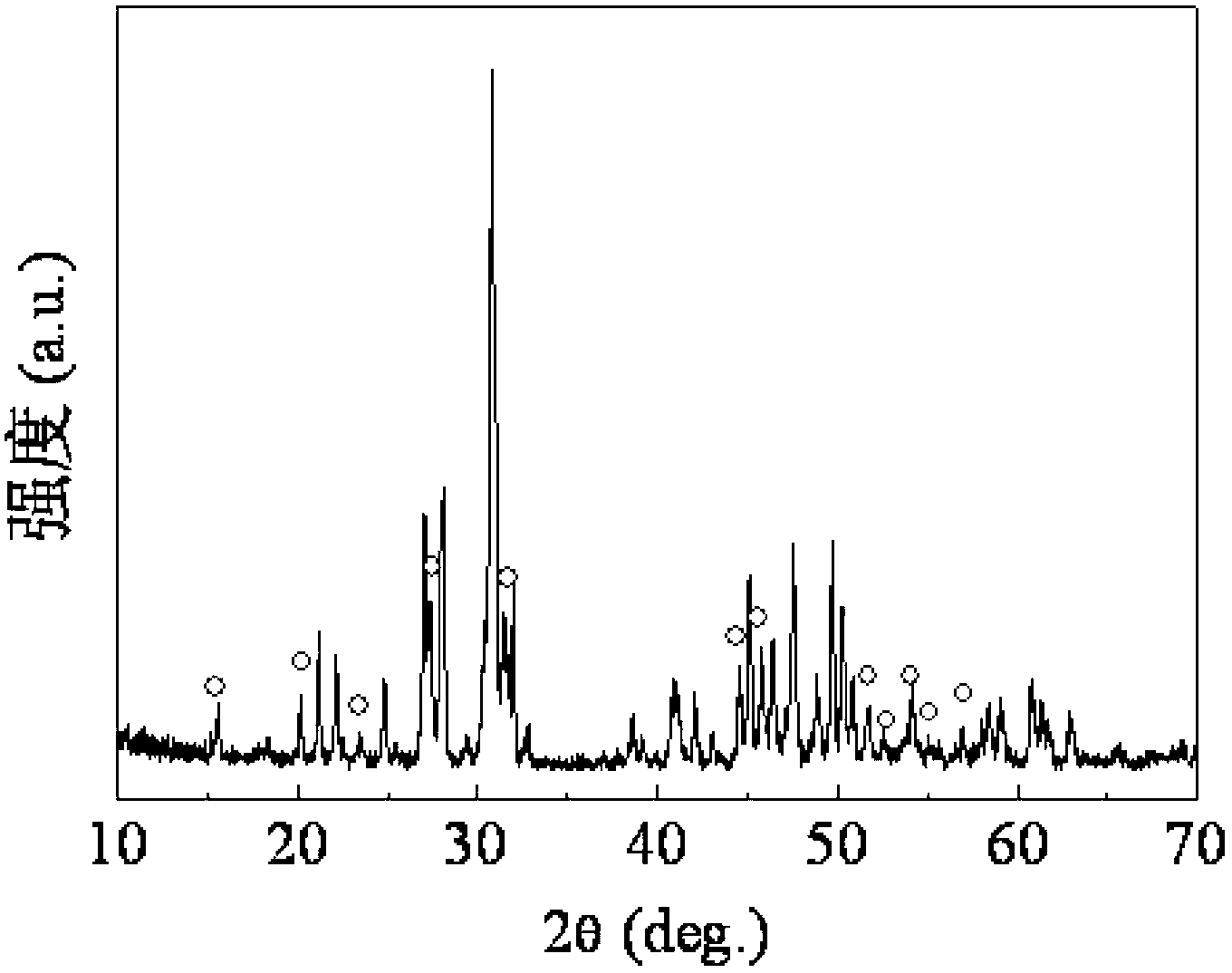

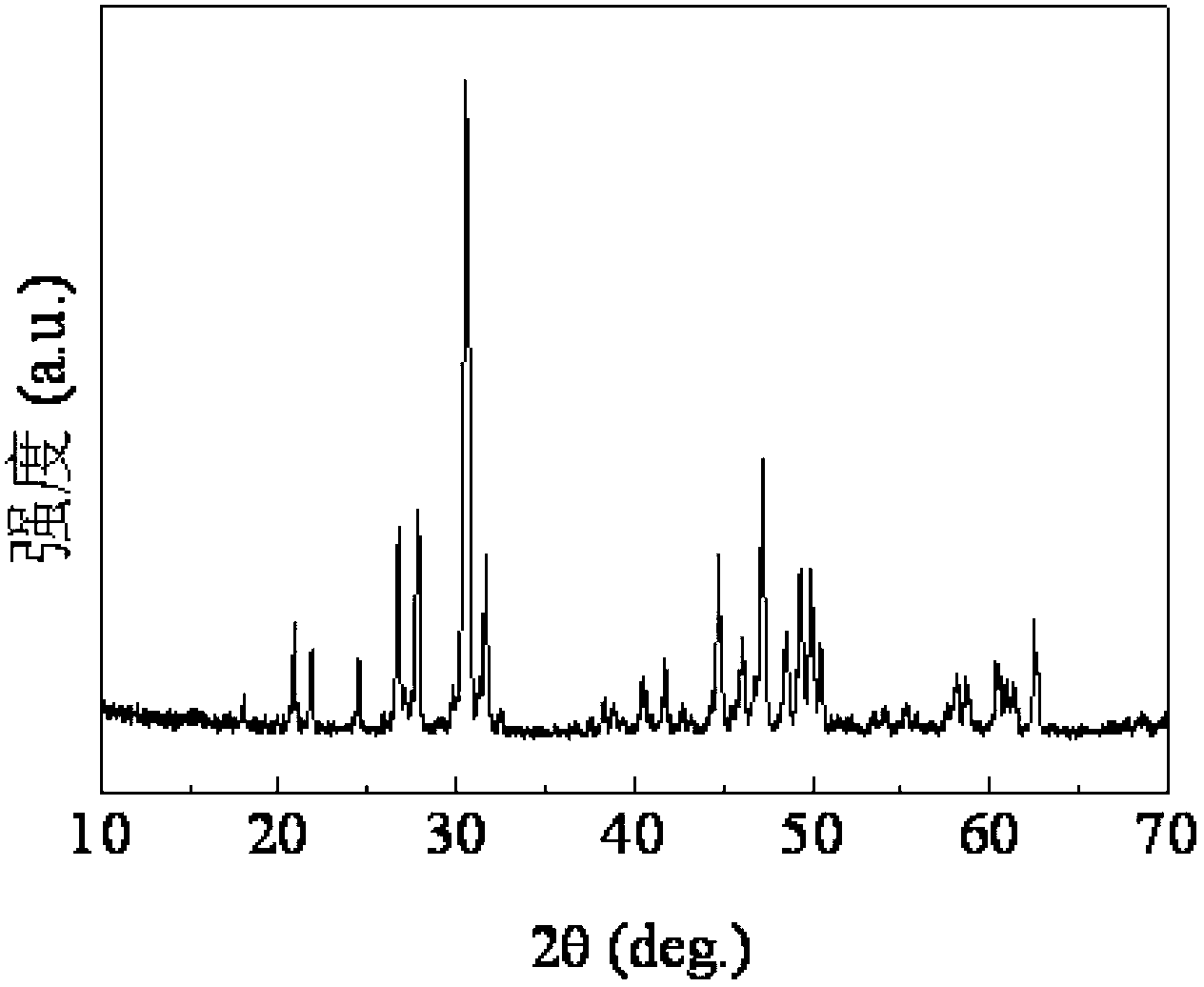

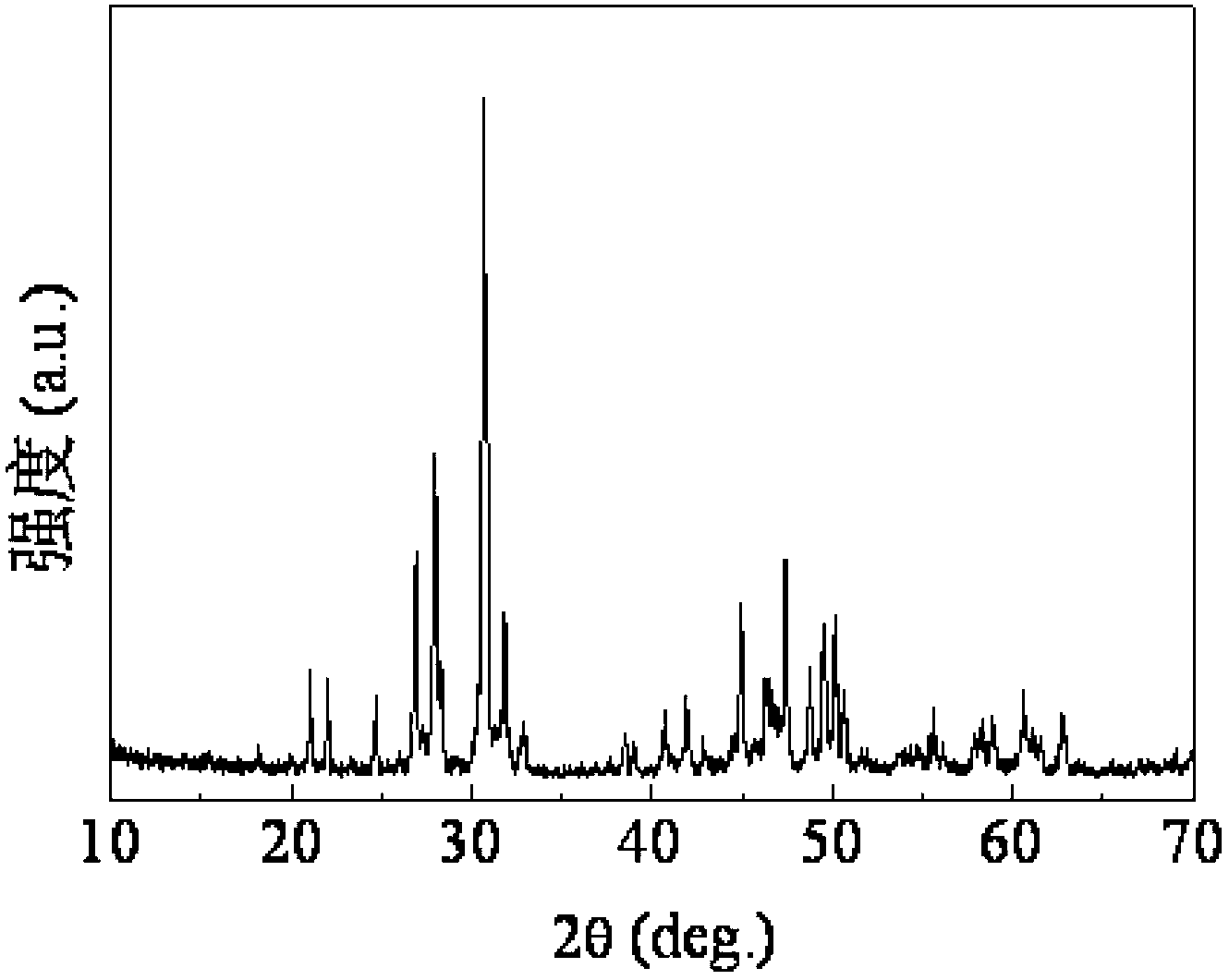

Image

Examples

specific Embodiment approach 1

[0026] Embodiment 1: In this embodiment, the chemical formula of the indium or niobium-doped oxyapatite-type lanthanum silicate solid electrolyte material is La 10 Si 6-x In x o 27-x / 2 or La 10 Si 6-x Nb x o 27+x / 2 , where the value range of x is 0<x≤2.

[0027] The beneficial effects of this embodiment are:

[0028] 1. Doping oxides reduces the content of the second phase and improves the density of the oxyapatite-type lanthanum silicate solid electrolyte material;

[0029] 2. Compared with the undoped oxyapatite-type lanthanum silicate solid electrolyte, the indium or niobium-doped oxyapatite-type lanthanum silicate solid electrolyte synthesized by the present invention can be used at medium and low temperatures (873-1073K) The conductivity of the solid oxide fuel cell has more than doubled, which is conducive to improving the service life of the solid oxide fuel cell.

specific Embodiment approach 2

[0030] Specific embodiment two: In this embodiment, the preparation method of indium or niobium-doped oxyapatite-type lanthanum silicate solid electrolyte material is carried out according to the following steps:

[0031] 1. The oxide powder La 2 o 3 , SiO 2 and A are respectively placed in three crucibles, and then the crucibles are placed in a high-temperature furnace at a temperature of 100-300K h -1 The heating rate is raised to 873~1273K, and after 1~4h of heat preservation, the temperature is increased to 100~500K·h -1 The cooling rate drops to room temperature; where A represents In 2 o 3 or Nb 2 o 5 ;

[0032] 2. Weigh the La processed in step 1 2 o 3 , SiO 2 and A, where La 2 o 3 with SiO 2 The ratio of the amount of substances is 5: (5.5 ~ 5.9), La 2 o 3The ratio of the amount of substance to A is 5: (0.05~0.25);

[0033] 3. Take the La that was weighed in step 2 2 o 3 , SiO 2 and A are placed in a ball mill jar, add absolute ethanol and balls, and...

specific Embodiment approach 3

[0042] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step one, use 150~250K·h -1 The heating rate is increased to 973 ~ 1173K, and the temperature is kept for 2 ~ 3 hours. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com