Method for preparing high-strength and high-thermal-conductivity silicon nitride ceramic through two-step sintering

A technology of silicon nitride ceramics and high thermal conductivity, which is applied in the field of two-step sintering to prepare high-strength and high thermal-conductivity silicon nitride ceramics, can solve the problems of low content of sintering aids, high content of second phase, low thermal conductivity of ceramics, etc. The effect of reducing the content of the second phase, improving the thermal conductivity of ceramics, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

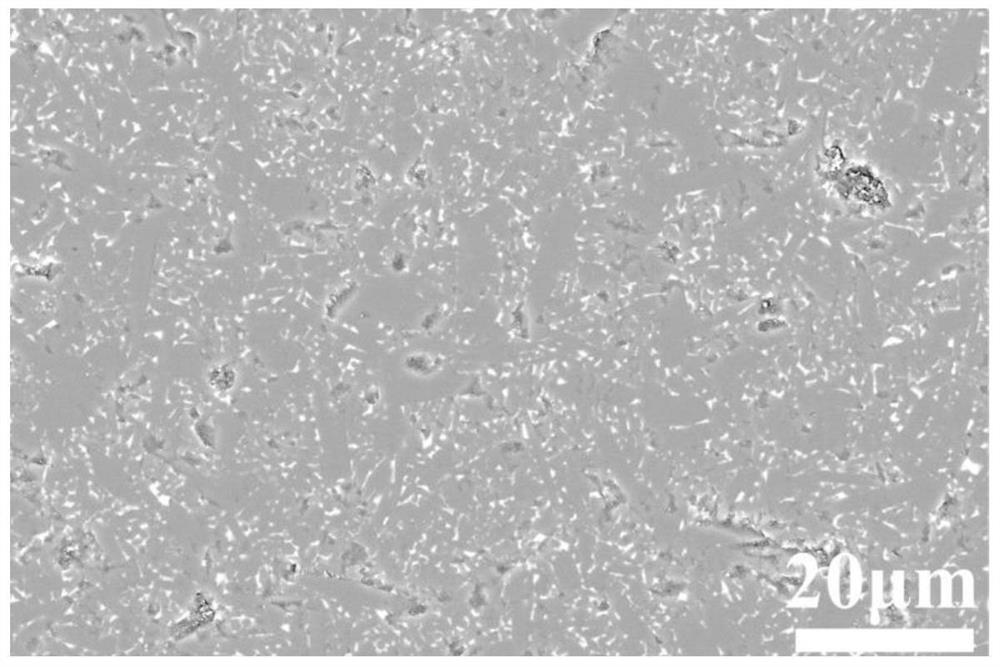

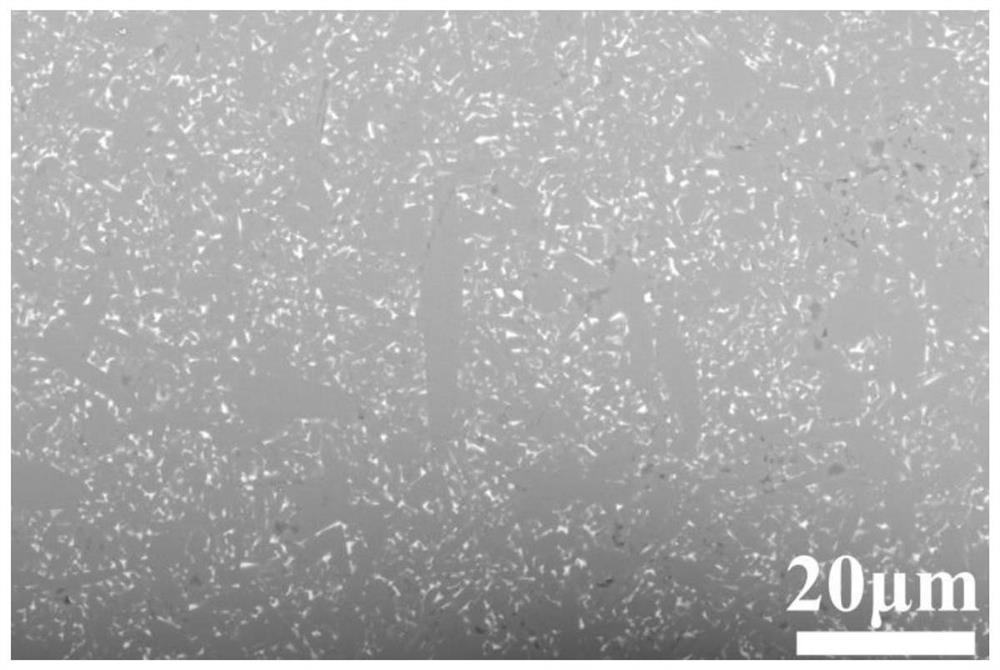

Image

Examples

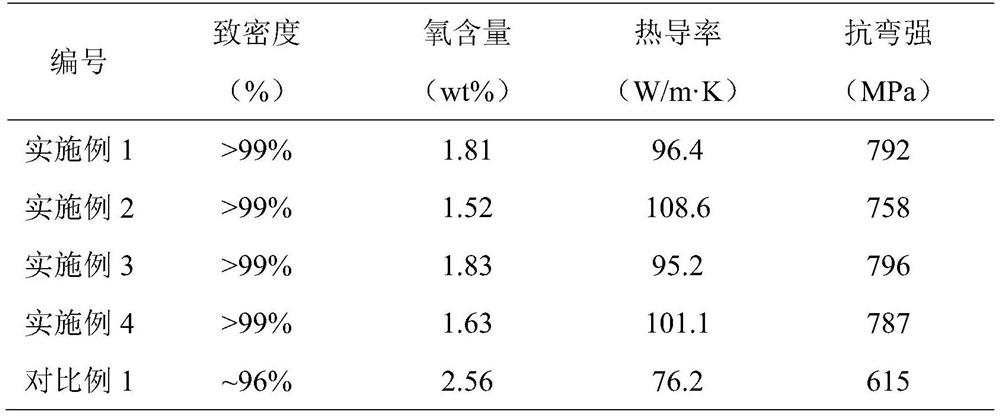

Embodiment 1

[0027] 1. Weigh 920g of silicon nitride powder with an oxygen content of 1.0wt%, 24g of magnesium oxide and 56g of ytterbium oxide, ball mill them with a binder in absolute ethanol, and mix them uniformly to obtain a slurry;

[0028] 2. Spray granulate the above slurry to obtain a granulated powder with a particle size of 60 μm;

[0029] 3. Press the granulated material into a square plate of 100×100×2 mm, and then carry out isostatic pressing at 200 MPa for 15 minutes to obtain a green body.

[0030] 4. Degrease the green body at 600°C; then perform two-step sintering, raise the temperature to 1350°C at 5°C / min for 2 hours, accompanied by a nitrogen flow rate of 1L / min; continue to heat up to 1900°C for 5 hours, and the nitrogen pressure to 1.2 MPa;

[0031] 5. Grinding and polishing the sintered product to obtain the final silicon nitride ceramic. Its ceramic thermal conductivity is 96.4W / m·K, and its bending strength is 792Mpa.

Embodiment 2

[0033] 1. Weigh 920g of silicon nitride powder with an oxygen content of 1.0wt%, 24g of magnesium oxide and 56g of ytterbium oxide, ball mill them with a binder in absolute ethanol, and mix them uniformly to obtain a slurry;

[0034] 2. Spray granulate the above slurry to obtain a granulated powder with a particle size of 60 μm;

[0035] 3. Press the granulated material into a square plate of 100×100×2 mm, and then carry out isostatic pressing at 200 MPa for 15 minutes to obtain a green body.

[0036] 4. Degrease the green body at 600°C; then perform two-step sintering, heat at 1350°C at 5°C / min for 2 hours, accompanied by a nitrogen flow rate of 1L / min; continue to heat up to 1900°C for 10 hours, and nitrogen pressure to 1.2 MPa;

[0037] 5. Grinding and polishing the sintered product to obtain the final silicon nitride ceramic. Its ceramic thermal conductivity is 108.6W / m·K, and its bending strength is 758Mpa.

Embodiment 3

[0039] 1. Weigh 920g of silicon nitride powder with an oxygen content of 1.0wt%, 24g of magnesia and 56g of yttrium oxide, ball mill them with a binder in absolute ethanol, and mix them uniformly to obtain a slurry;

[0040] 2. Spray granulate the above slurry to obtain a granulated powder with a particle size of 80 μm;

[0041] 3. Press the granulated material into a square plate of 100×100×2mm, and then perform isostatic pressing at 200MPa for 15 minutes to obtain a green body;

[0042] 4. Degrease the green body at 600°C; then perform two-step sintering, raise the temperature to 1350°C at 5°C / min for 2 hours, accompanied by a nitrogen flow rate of 1L / min; continue to heat up to 1900°C for 5 hours, and the nitrogen pressure to 1.2 MPa;

[0043] 5. Grinding and polishing the sintered product to obtain the final silicon nitride ceramic. Its ceramic thermal conductivity is 95.2W / m·K, and its bending strength is 796Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com