Patents

Literature

68results about How to "The processing technology is easy to operate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Y reinforced Mg-Zn-Y-Zr system magnesium alloy with effective utilization of rare earth element and production method

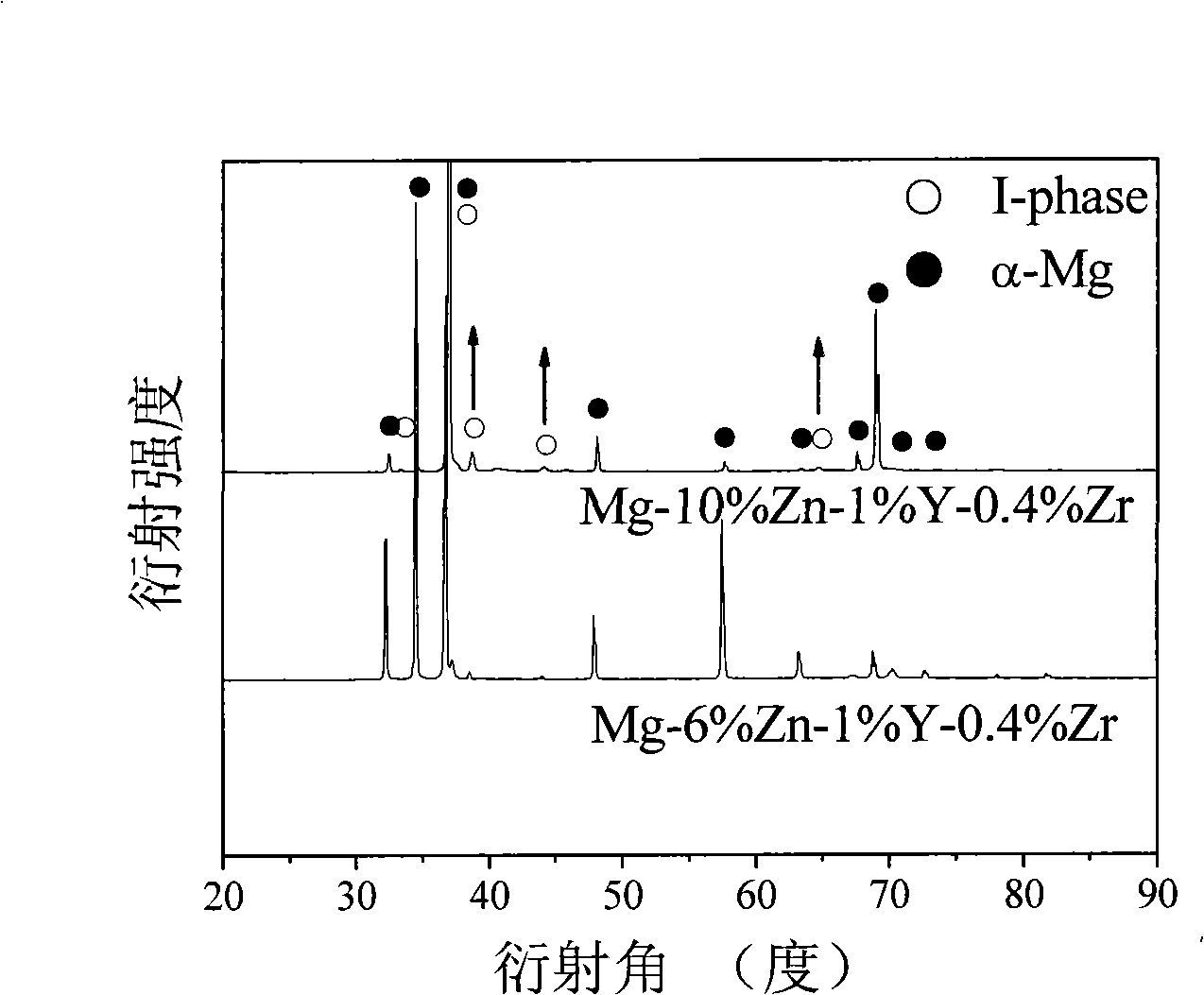

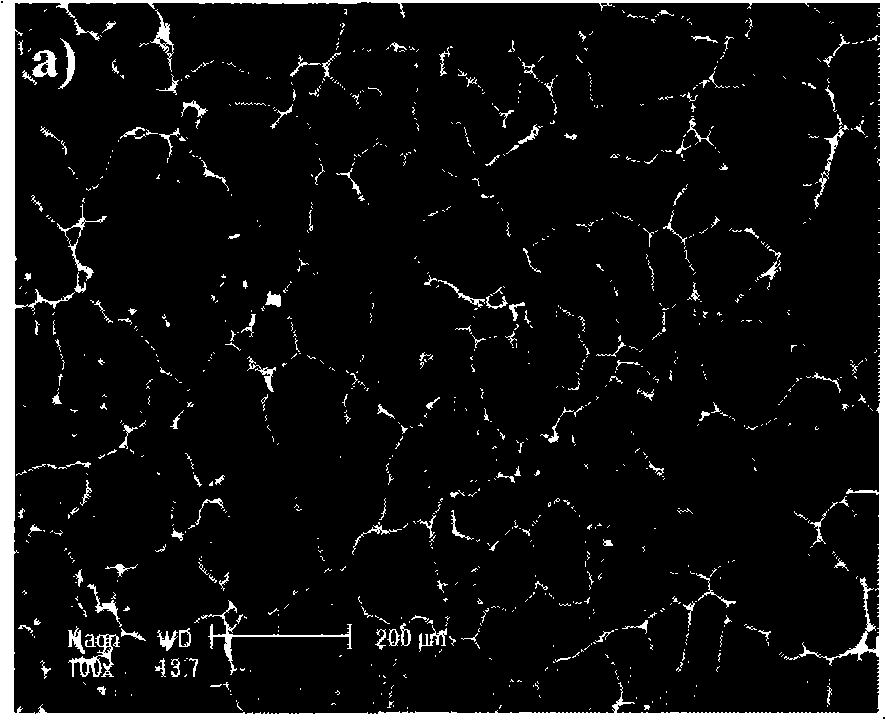

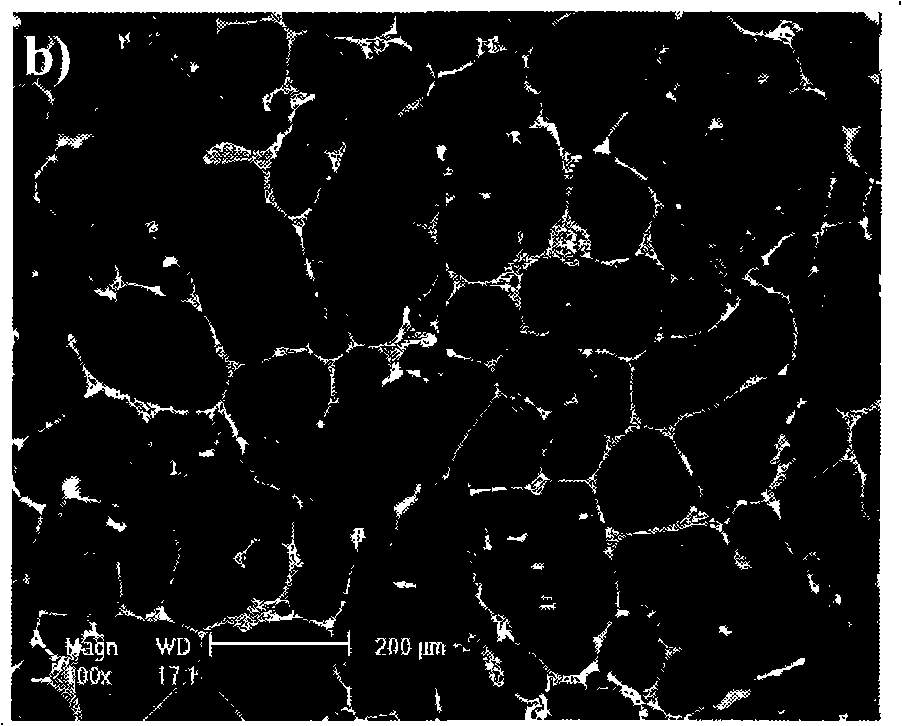

The invention relates to a lanthanon Y which is utilized to strengthen magnesium alloy effectively and a preparation technology thereof, in particular to a quasicrystal phase which is utilized to strengthen Mg-Zn-Y-Zr magnesium alloy and a preparation method thereof, and the problems such as magnesium alloy strengthening, etc. are solved. On the premise of definite Y contents, the volume percentage of the quasicrystal phase which is led into a magnesium alloy matrix to reach the maximum through reasonably choosing the rate between Zn and Y in the alloy (the rate between Zn and Y ranges from 6 to 15), so as to prepare the Mg-Zn-Y-Zr magnesium alloy with low density, high strength and better plasticity. The magnesium alloy material has the components and the contents thereof as follows: the content of zinc (Zn) ranges from 5 to 30 percent; the content of yttrium (Y) ranges from 0.5 to 5 percent; the content of zirconium (Zr) ranges from 0.3 to 0.8 percent, and the others are magnesium (Mg); all the percentage are weight percentage. The magnesium alloy material are processed through alloy melting and subsequent hot extrusion processing and deformed into products, and the operation of the processing technology is simple and convenient. The tensile strength of the material satisfies that Sigma (b) ranges from 290 to 360MPa, the yield stress delta0.2 ranges from 175 to 260MPa, the unit extension Delta ranges from 10 to 18 percent, and the density is 1.84 to 2.73g / cm<3>.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

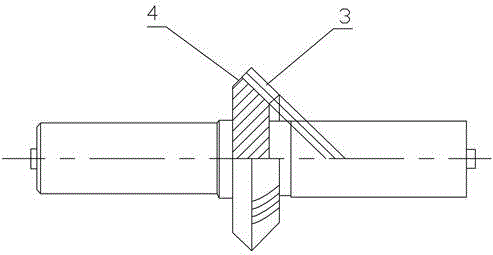

Integrated bevel gear machining method

The invention discloses an integrated bevel gear machining method. The integrated bevel gear machining method comprises the steps: material preparing, boring of central holes in the two ends of a blank, rough turning till polishing, crack detection, heating, rough turning, blank re-inspection, semi-fine turning, tooth rough milling, chamfering, heating, shot blasting, fine turning, rough grinding, tooth fine milling, coloring and rolling detecting, detecting, fine grinding and final detecting. The invention aims at providing an integrated bevel gear machining method with great structure stability and high machining precision.

Owner:CHONGQING ZHIZHAN GEAR TRANSMISSION

High-strength Mg-Li-Al-Y-Ca alloy and preparation method thereof

InactiveCN106521274AImprove mechanical propertiesThe processing technology is easy to operateHigh intensityMetal

The invention belongs to the technical field of metal materials and relates to a high-strength Mg-Li-Al-Y-Ca alloy and a preparation method thereof. The alloy is prepared from components in percentage by weight as follows: 4wt%-12wt% of Li, 2wt%-6wt% of Al, 1wt%-3wt% of Y, 0.5wt%-1.5wt% of Ca and the balance of Mg and impurity elements including Si, Fe, Cu and Ni, and the total quantity of the impurity elements is smaller than 0.02wt%. The alloy is prepared with the method comprising steps as follows: (1) material baking, (2) material addition, (3) casting, (4) plastic deformation, and (5) heat treatment technology. Certain mass of Y elements and certain mass of Ca elements are added to a Mg-Li-Al alloy, a strengthening phase having the high heat stability is introduced into an alloy solidification structure; meanwhile, the solidification structure is promoted to be refined; and the high-strength Mg-Li-Al-Y-Ca alloy has the relatively low density and the excellent mechanical property through plastic deformation and the heat treatment technology.

Owner:JIANGSU UNIV OF TECH

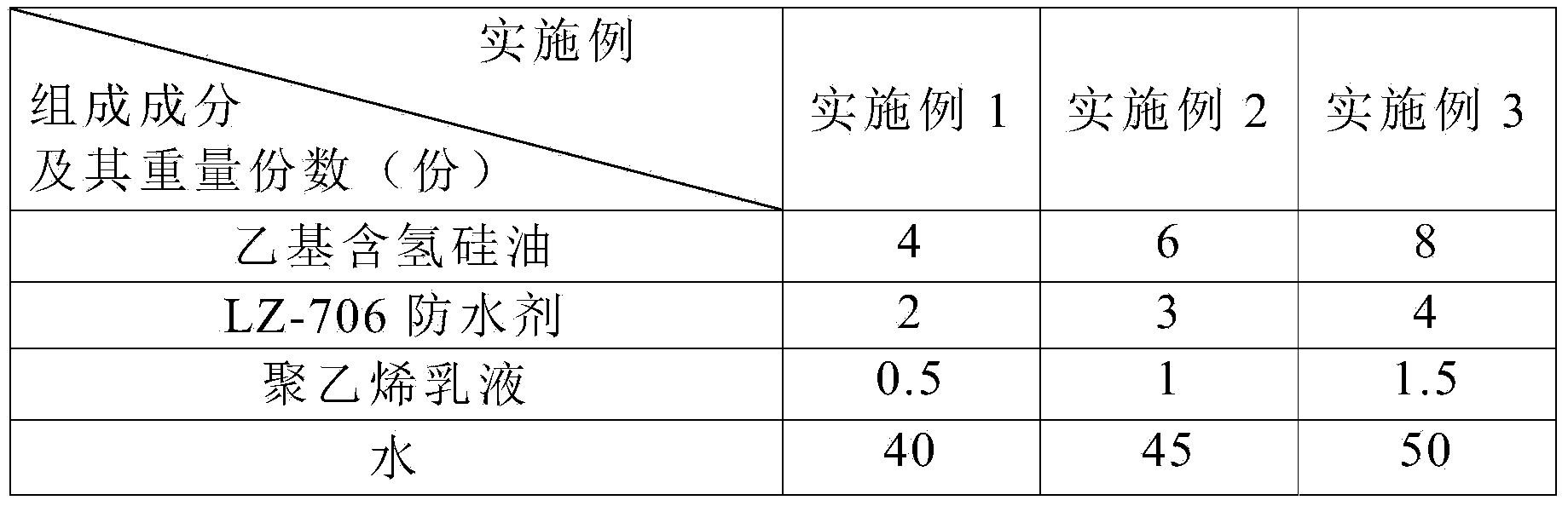

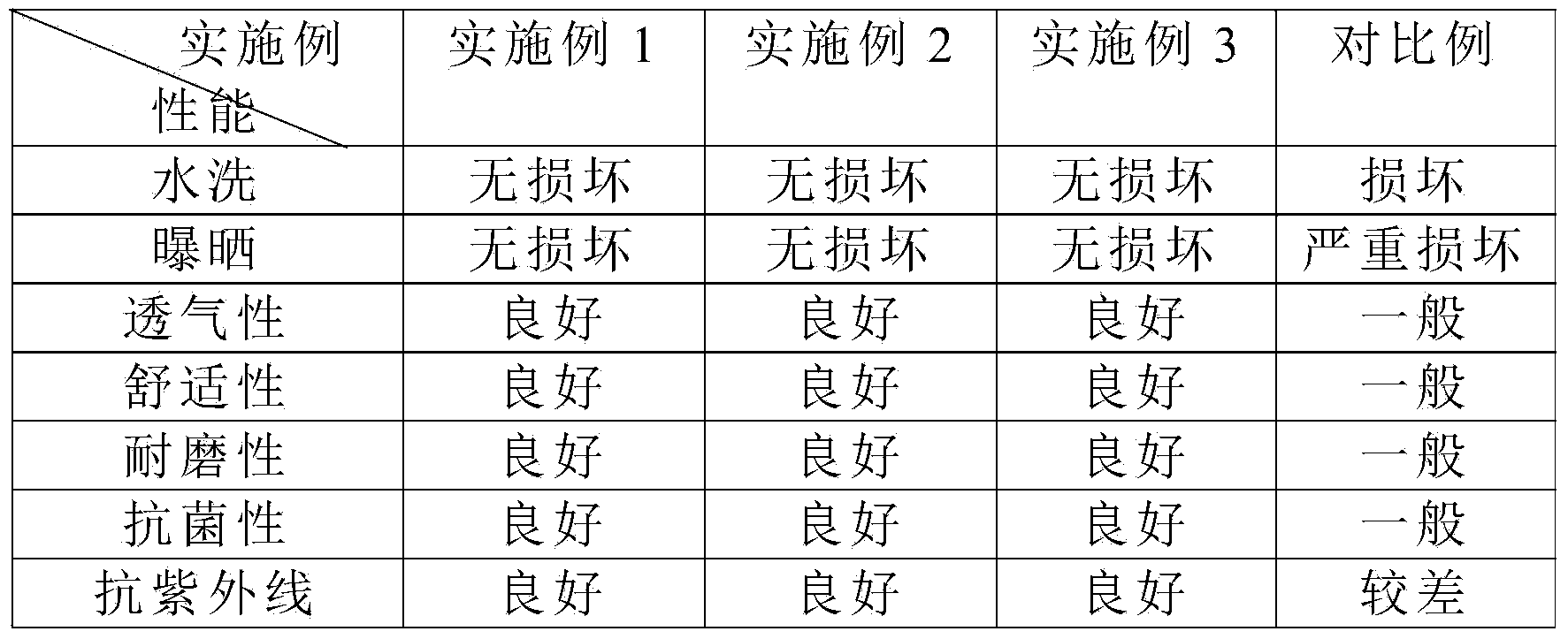

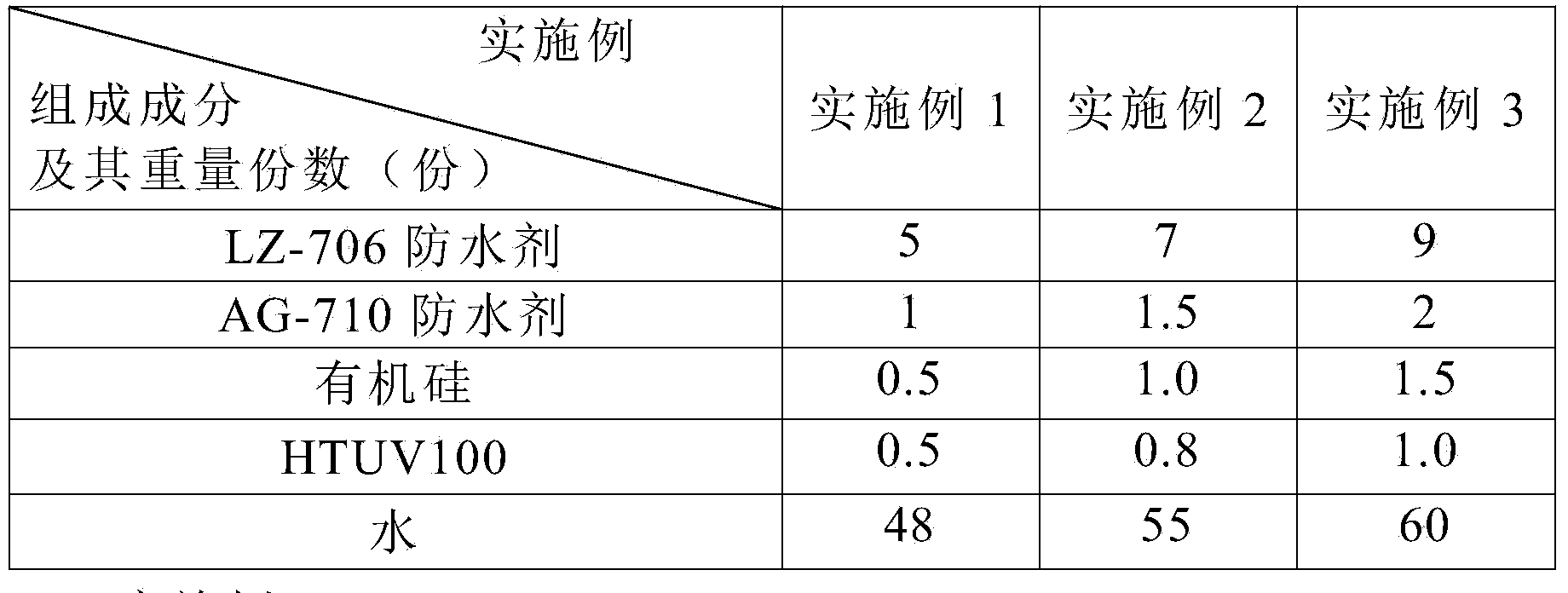

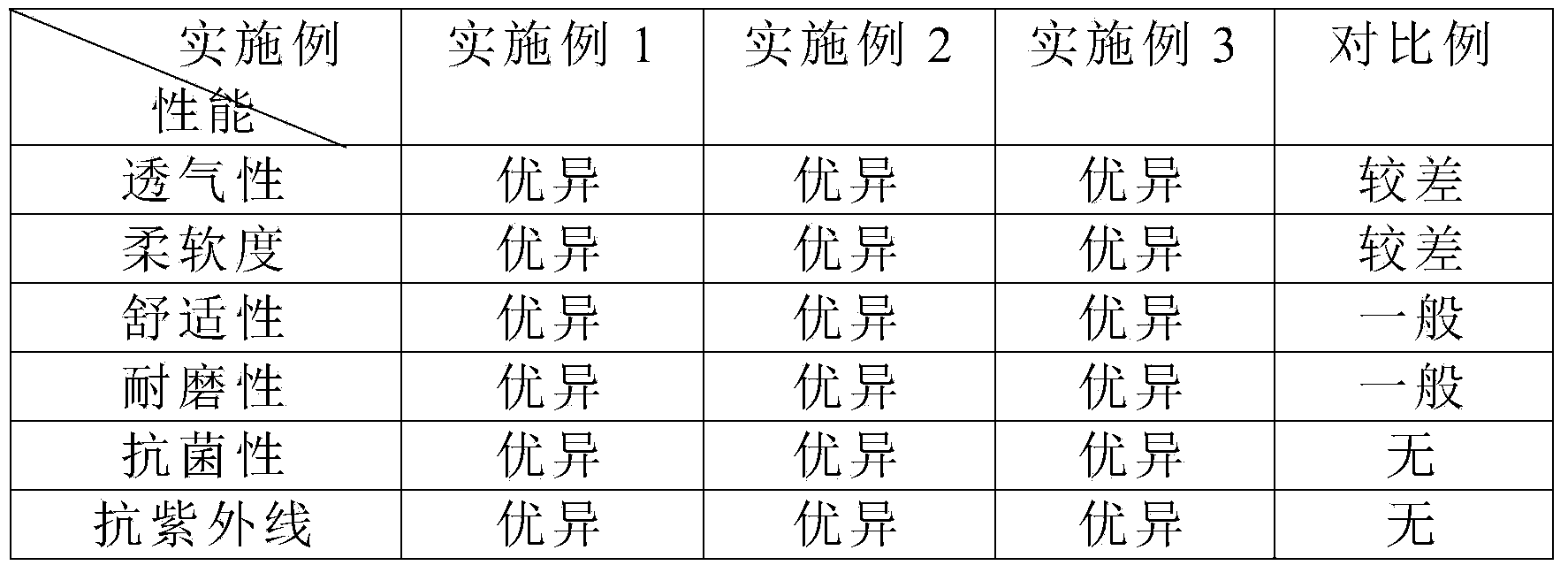

Processing technique for China-Hemp and paper straw mixed mat

ActiveCN104207561AGood hygroscopicityImprove antibacterial propertiesBed-coversWear resistantPulp and paper industry

The invention relates to a processing technique for mats and particularly relates to a processing technique for a China-Hemp and paper straw mixed mat. The processing technique comprises the following steps: cutting waterproof paper into sheets according to specifications of the mat, then wrapping straws with sheety waterproof paper so as to form ropy paper and then reeling to form wefts, and taking China-Hemp as warps for knitting, so as to obtain a mat main body; spraying water by using an atomizer of a pressing machine, heating, pressing polish and carrying out shrinking treatment on the mat main body, so as to obtain a semi-finished mat; soaking the semi-finished mat into a waterproof agent solution with a pH value of 4.5 to 6.5, and then placing the semi-finished mat into a drying oven for drying; arranging well cut lining cloth on peripheries of the dried semi-finished mat, wrapping the semi-finished mat by using the lining cloth, enabling the lining cloth to be symmetric on upper and lower surfaces of the mat, compacting, then carrying out edge covering treatment on the mat, and finally obtaining a finished mat. The mat prepared by using the processing technique provided by the invention are not only nice and cool, air-permeable, wear-resistant, sun-proof and has soft feel, but also has the advantages of bacteriostasis, uvio-resistance and the like, and is long in service life.

Owner:宁波黄古林工艺品有限公司

Processing technology of stir-fried semen trichosanthis

InactiveCN106174348AIncrease flavor concentrationIncrease the fragranceFood ingredient as taste affecting agentCooking & bakingAdditive ingredient

The present invention relates to a processing technology of stir-fried semen trichosanthis and belongs to the field of snack food processing. The processing technology comprises the following steps: screening, washing, air-drying, soup material preparing, soaking and flavoring, drying, baking, secondarily soaking, baking, sterilizing and bagging, etc. By conducting the soaking for twice and the air-drying for multiple times, the accessory materials are fully permeated into the semen trichosanthis, which improves the concentration of the flavoring materials of the semen trichosanthis and increases the fragrance. In the processing processes, the baking is firstly conducted and then the baking is conducted. During the stir-frying process, the own fragrance of the semen trichosanthis can be extracted out and the outer shells of the semen trichosanthis have the fragrances of the accessory materials. After the soaking for twice and then the baking, the fragrance mellowness of the semen trichosanthis outer shells are further improved. The mellow fragrance and mouthfeel of the processed semen trichosanthis are utilized. Almost all the nutritional ingredients of the semen trichosanthis are kept and the stir-fried semen trichosanthis is safe in consumption. The processing technology is simple in operations and conductive for an extensive promotion.

Owner:TONGCHENG GUNIUBEI AGRI DEV

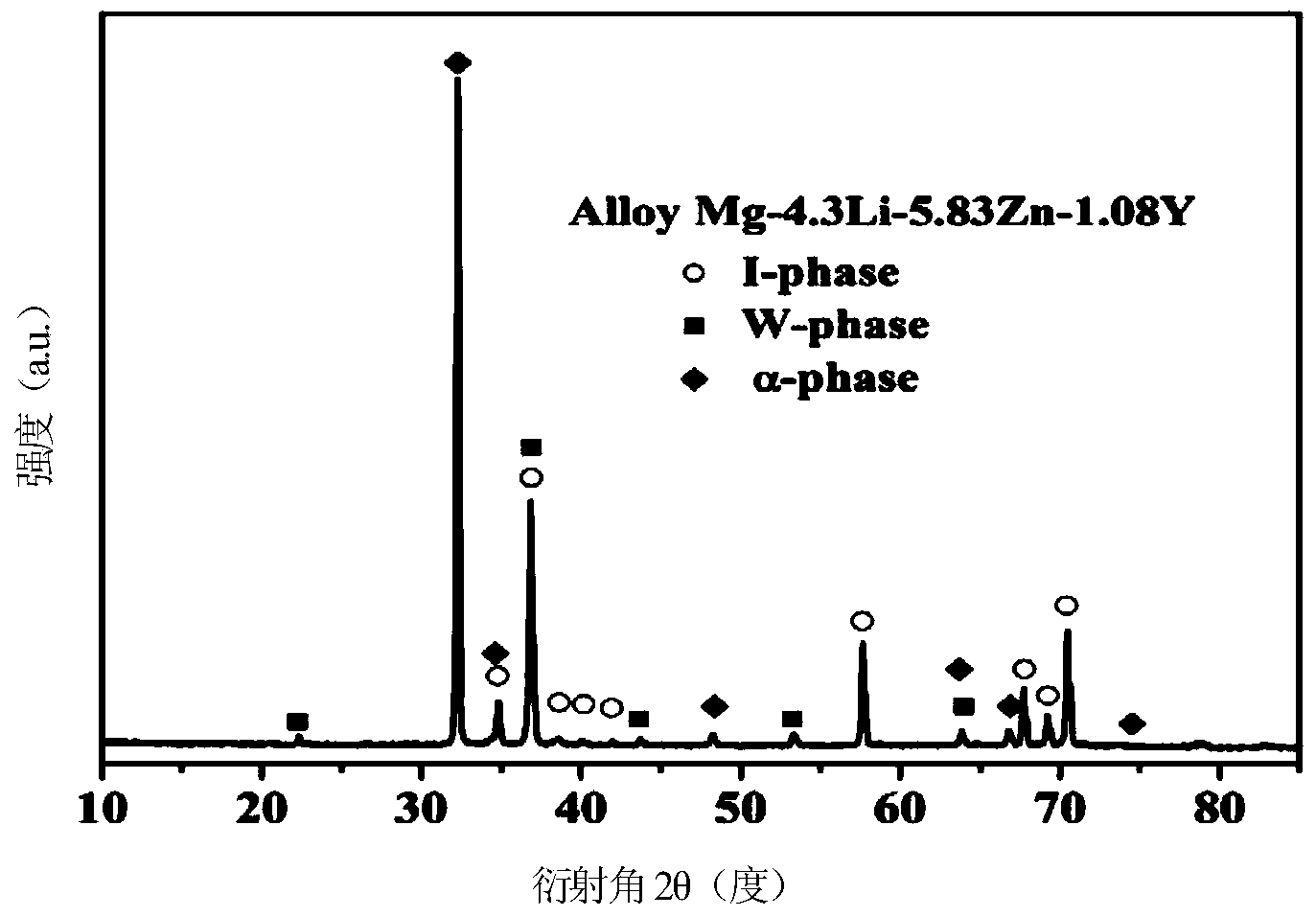

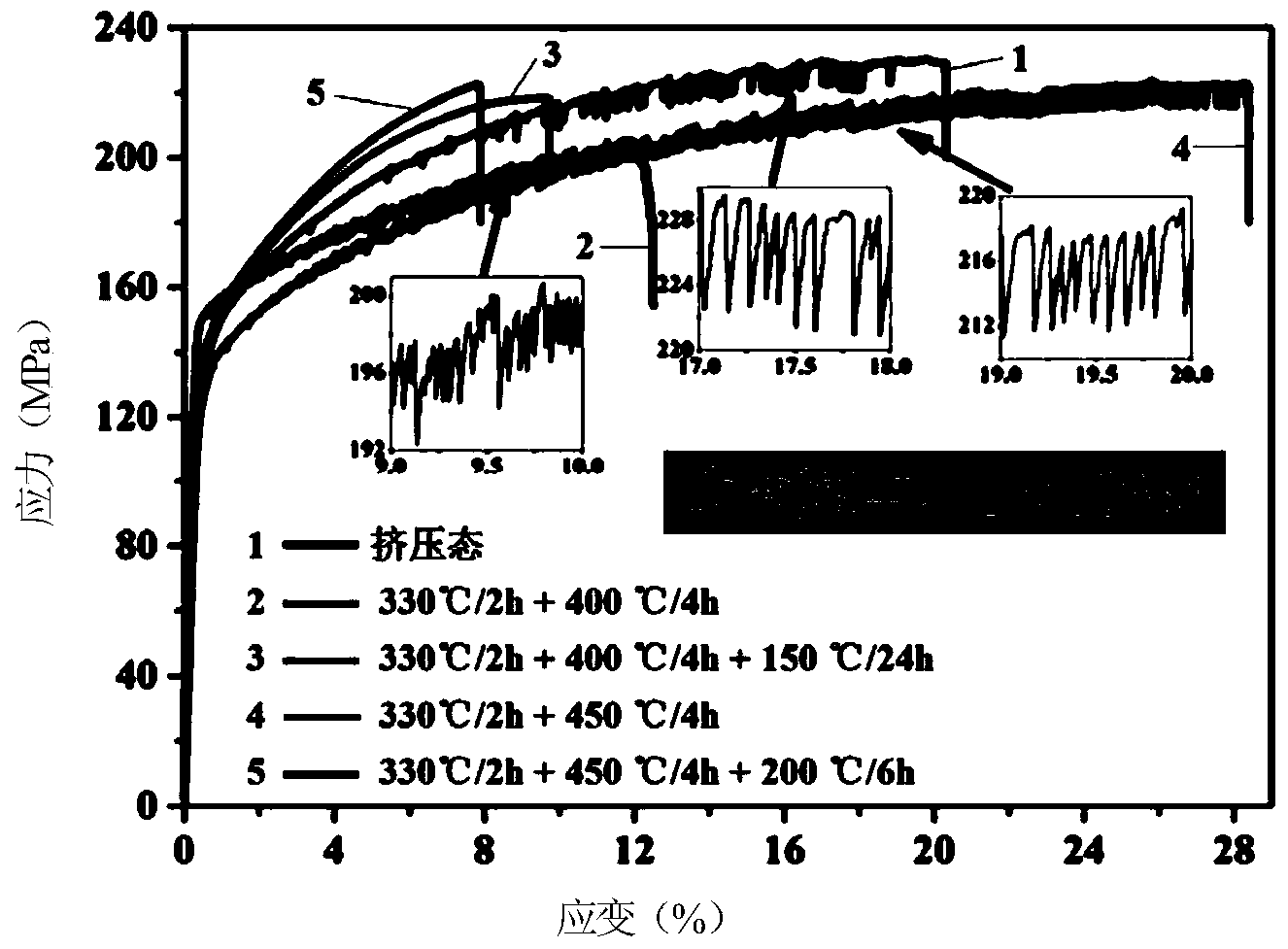

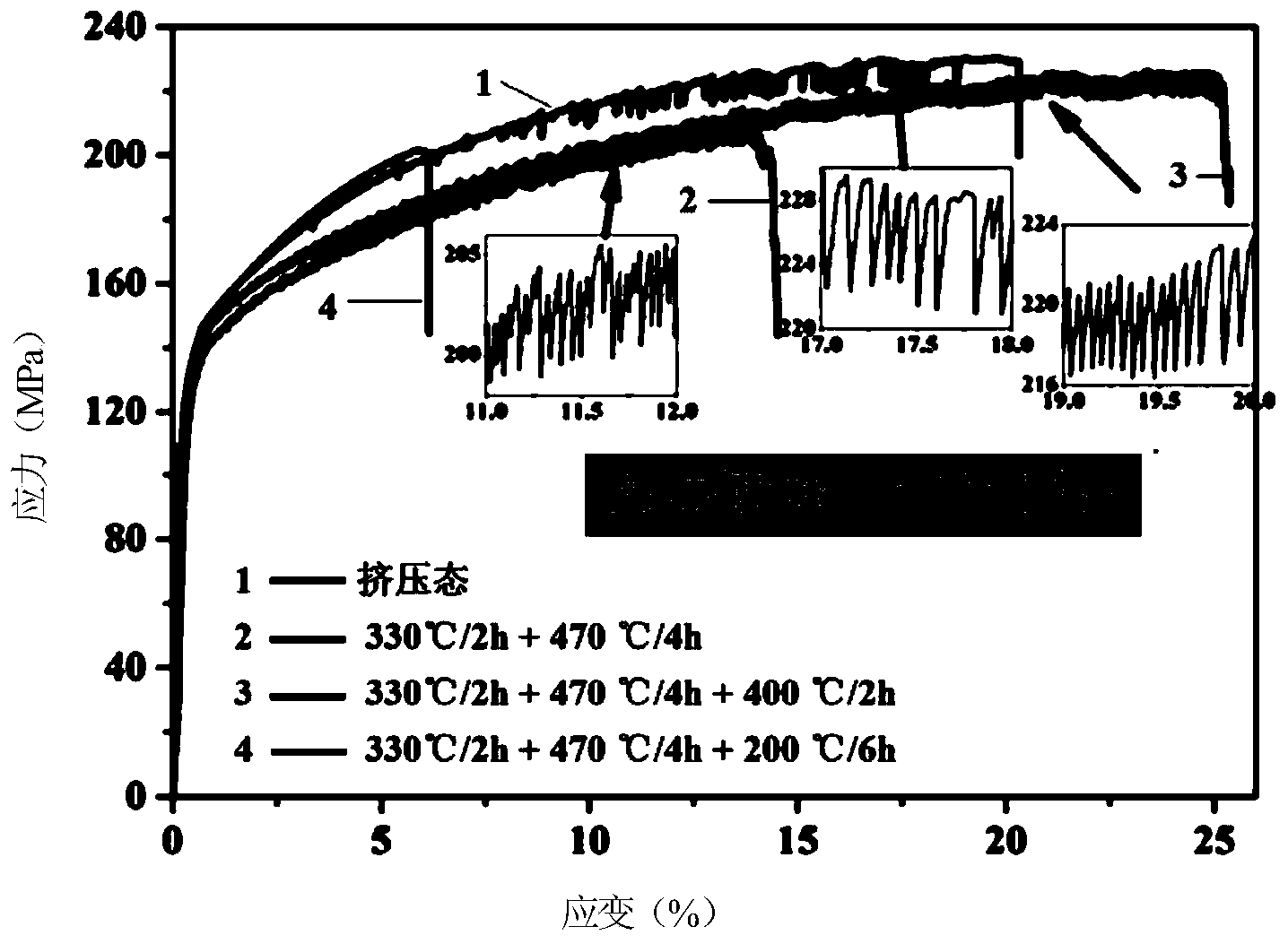

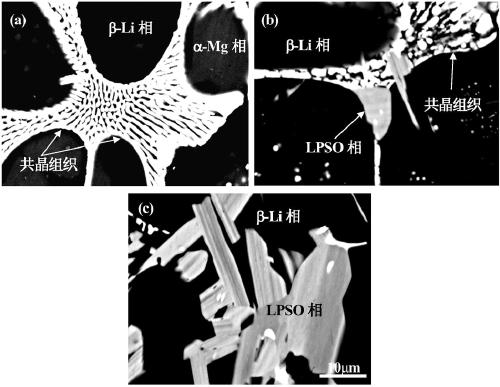

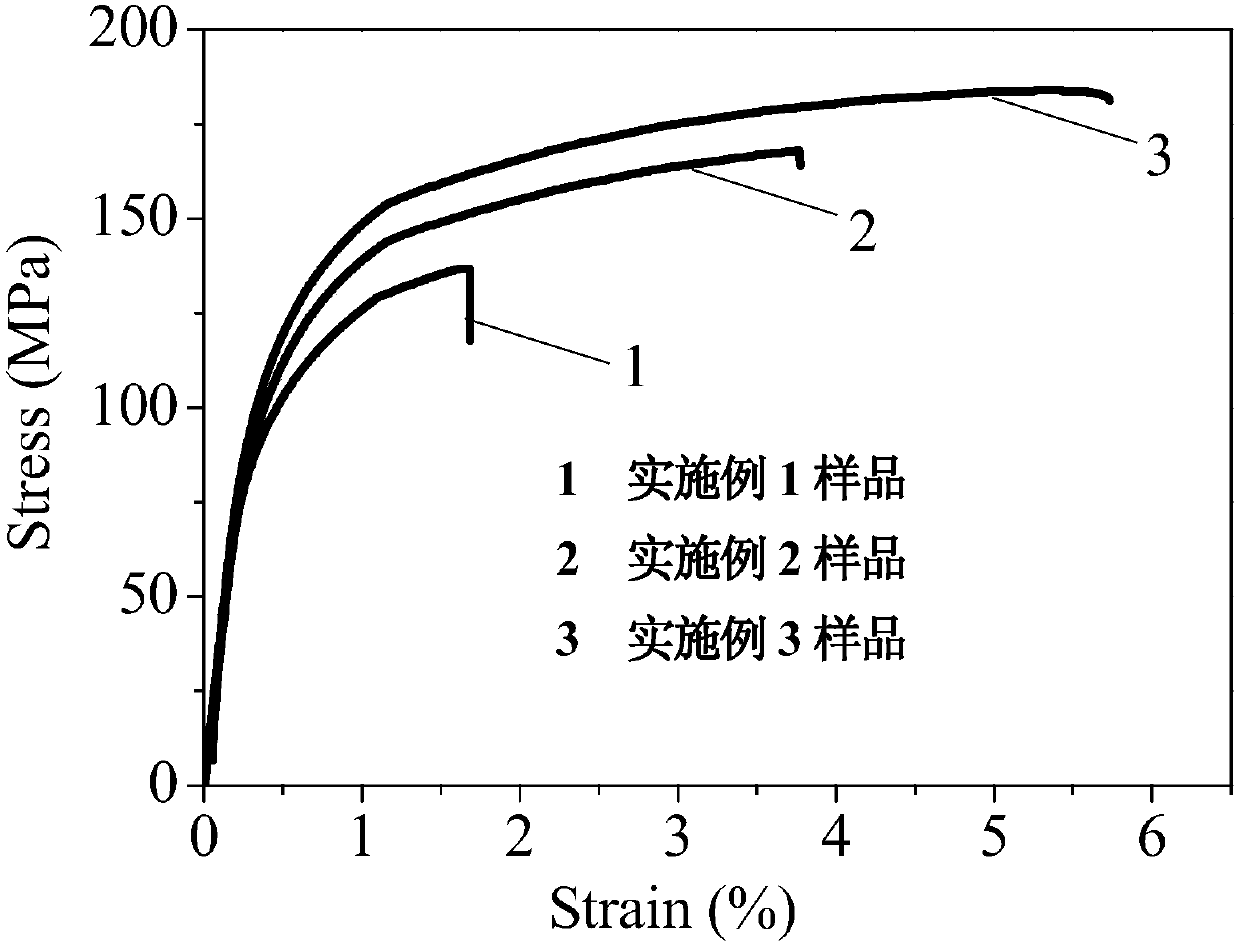

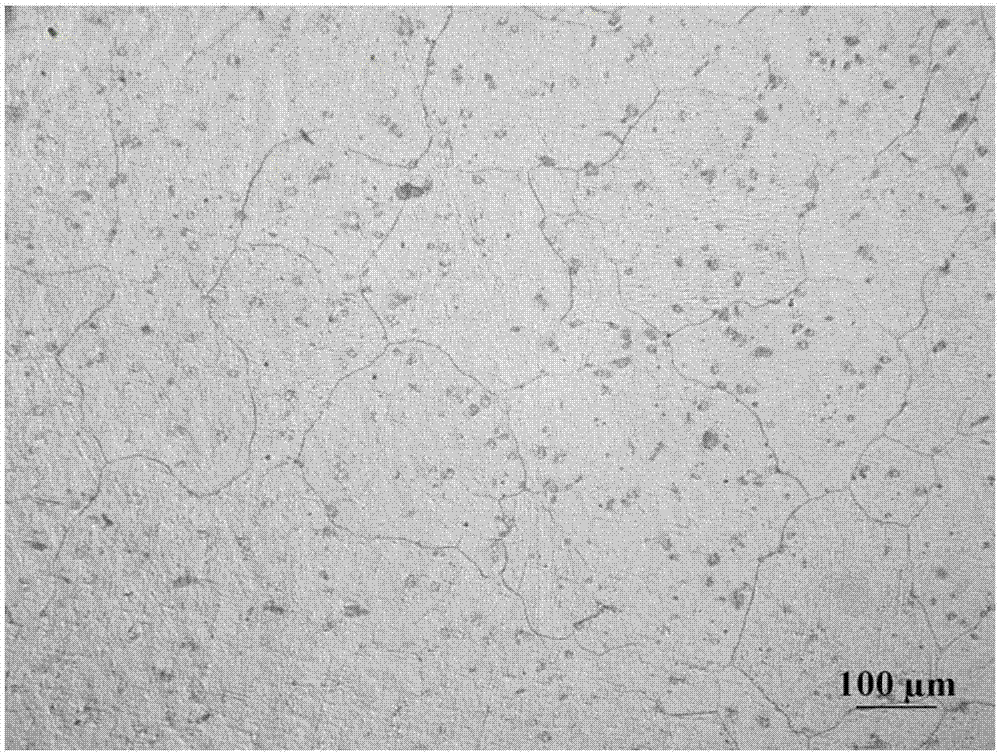

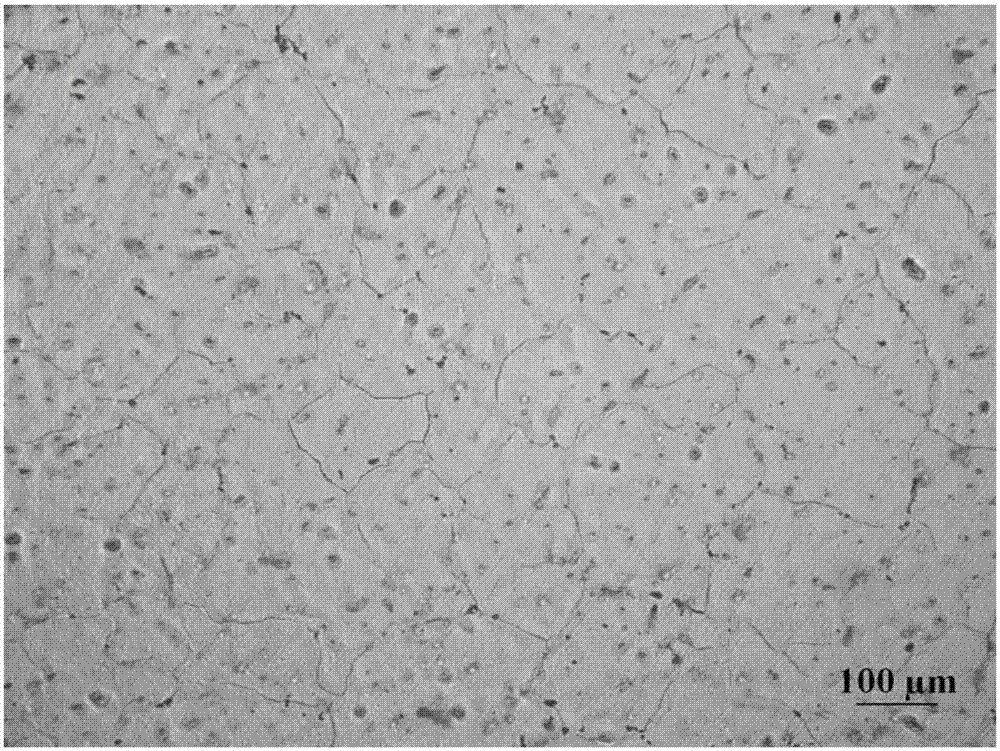

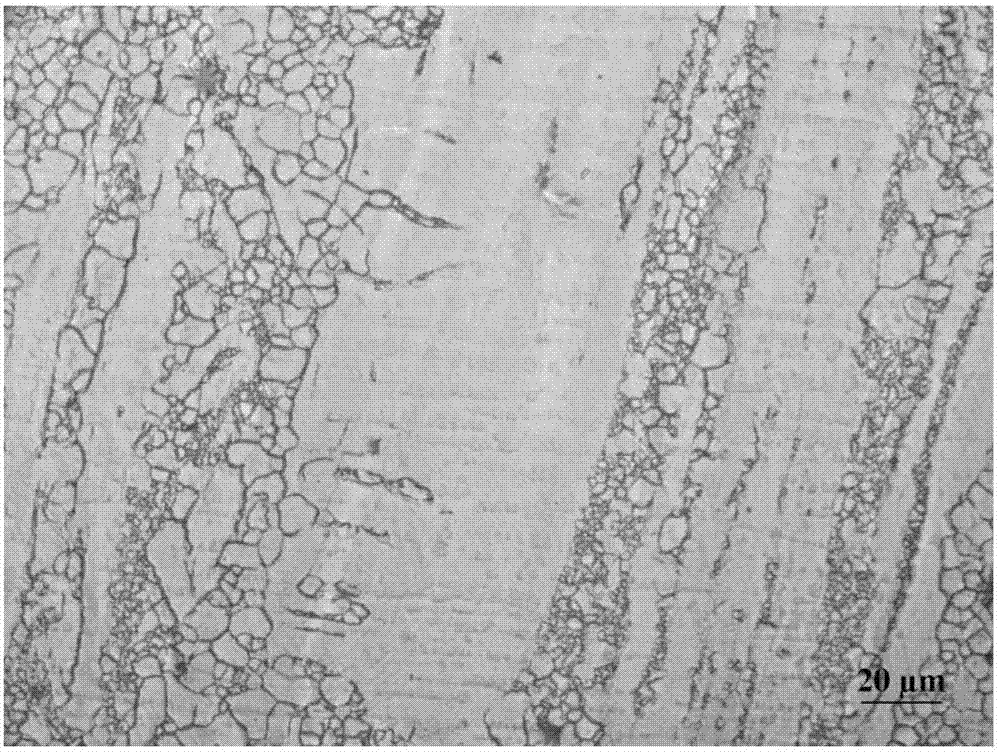

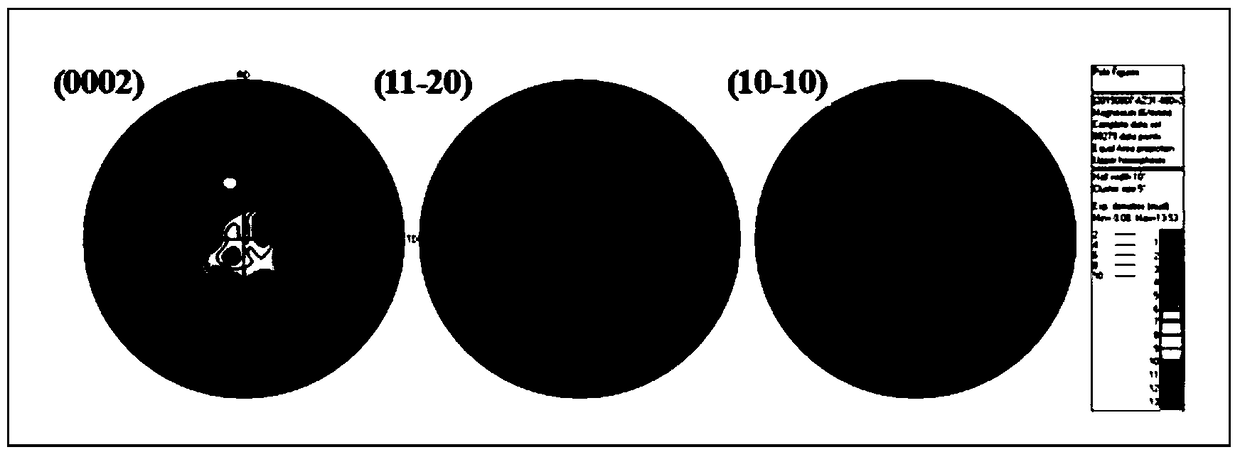

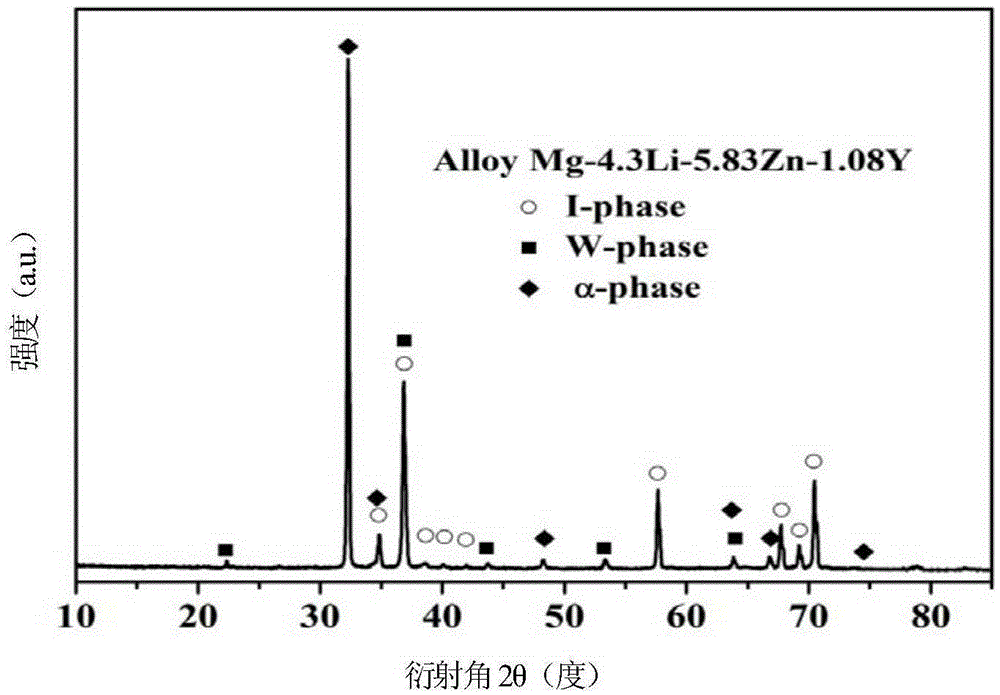

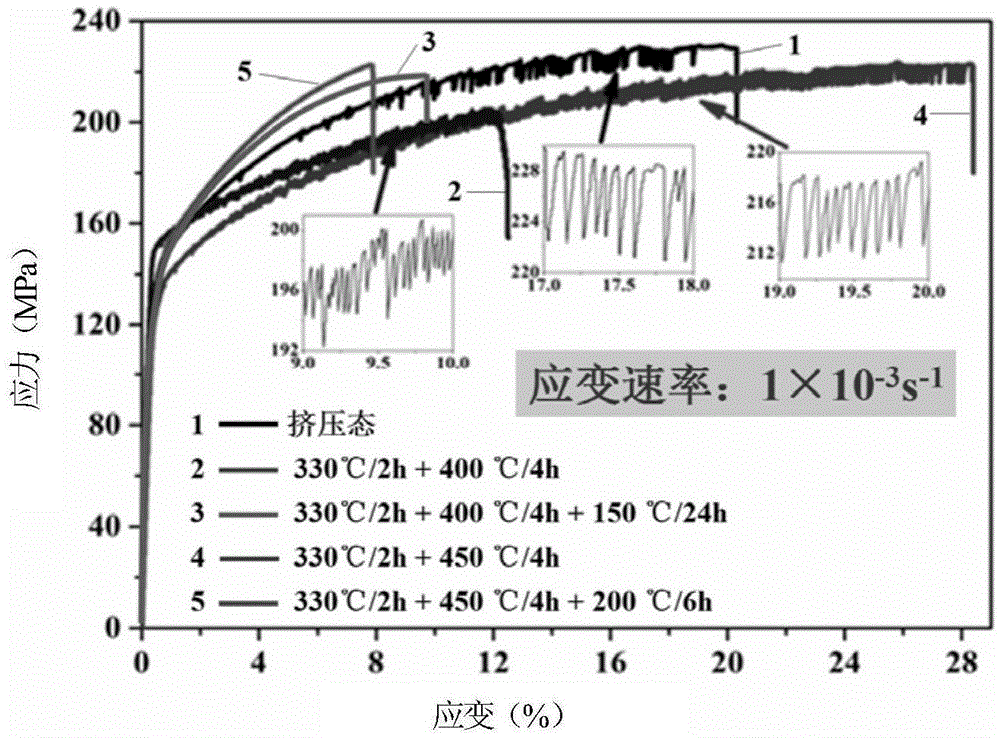

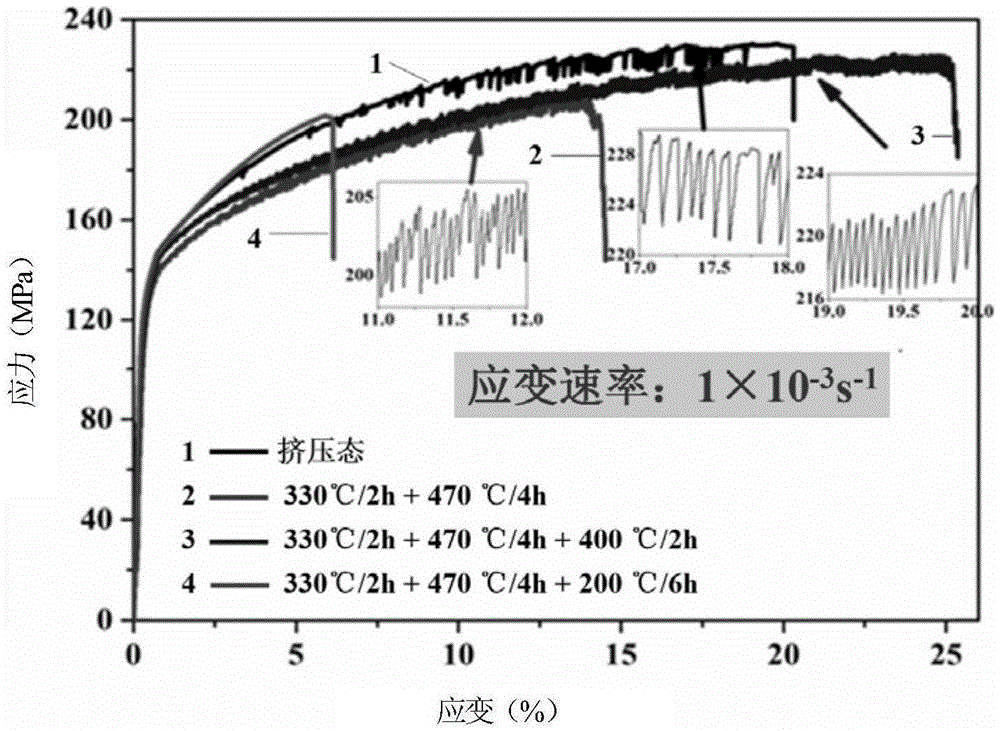

Heat treatment process for inhibiting plastic instability of quasi-crystal reinforced magnesium lithium alloys

ActiveCN104131247AEliminate the problem of plastic deformation instabilityEliminates jagged yieldingLithiumInstability

The invention relates to the field of magnesium lithium alloys, and particularly relates to a heat treatment process for inhibiting the plastic instability of quasi-crystal reinforced magnesium lithium alloys. The process comprises the following steps: tightly wrapping a variable-form magnesium lithium alloy with an aluminum foil, carrying out solid solution treatment on the obtained object at a temperature of 330-470 DEG C, carrying out heat preservation for 4-8 hours, cooling the obtained product to room temperature by water quenching, ageing the obtained product for 12-24 hours at a temperature of 100-200 DEG C, and cooling the obtained product to room temperature by water quenching again. According to the invention, the plastic instability phenomenon of a quasi-crystal reinforced magnesium lithium alloy can be significantly inhibited, and the high yield strength and tensile strength of the alloy are retained, thereby solving the serrated yielding problem (occurring along with the tensile process) of plasticity of the magnesium lithium alloy. An alloy applicable to the heat treatment process disclosed by the invention comprises the following compositions by percent: 1.0-11.5% of Li, 5-10% of Zn, 0.5-2% of Y, and the balance of Mg. The process disclosed by the invention is simple in used equipment, low in cost, and simple and convenient to operate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

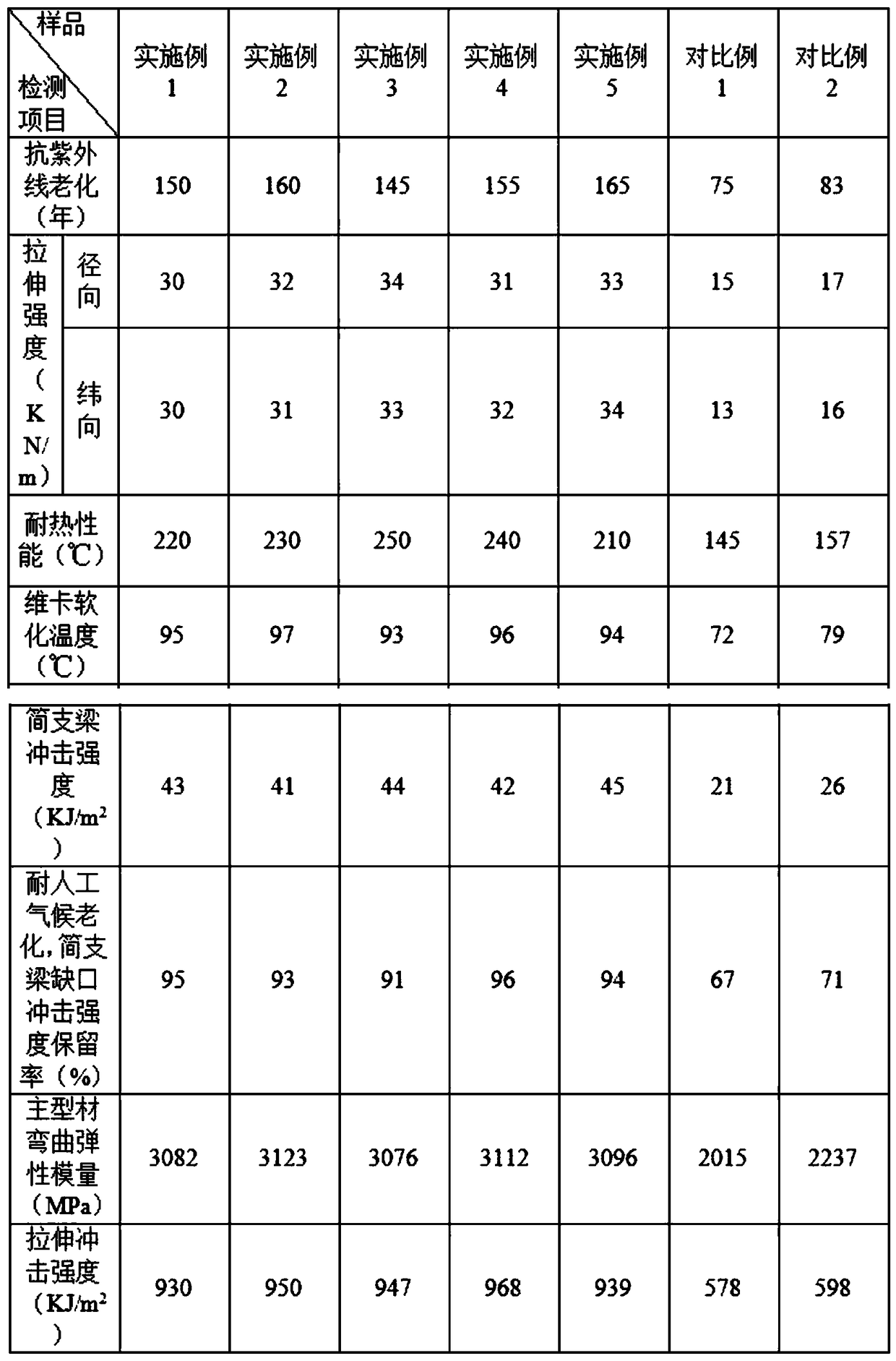

Environment-friendly and high-weather-resistance PVC profile particles and processing technology thereof

The invention discloses environment-friendly and high-weather-resistance PVC profile particles and a processing technology thereof. The PVC profile particles are prepared from components including PVCresin, a heat stabilizer, an auxiliary heat stabilizer, a light stabilizer, an auxiliary light stabilizer, an ultraviolet absorber, an antioxidant, an auxiliary antioxidant, a toughening agent and alubricant. The processing technology of the PVC profile particles comprises the steps as follows: firstly, mixing the PVC resin, the heat stabilizer and the auxiliary heat stabilizer, then, adding thelight stabilizer, the auxiliary light stabilizer, the ultraviolet absorber, the antioxidant and the auxiliary antioxidant for mixing, finally, adding the toughening agent and the lubricant for mixing, and performing melt extrusion and granulation to obtain the environment-friendly and high-weather-resistance PVC profile particles. The PVC profile particles have excellent ultraviolet aging resistance, heat resistance, tensile strength and excellent weather resistance. No harmful intermediate products are produced in the preparation process of the PVC profile particles, and the whole processingprocess is simple to operate, short in time and high in efficiency.

Owner:GUANGDONG SHUNDE JIANGSUN MAGNETIC CO LTD

High-strength and high-elastic-modulus magnesium lithium base composite material and preparation method thereof

The invention discloses a high-strength and high-elastic-modulus magnesium lithium base composite material and a preparation method thereof. A magnesium lithium alloy comprises the following basal body components in percentage by mass: 11-16 wt% of Li, 1-5 wt% of Zn, 0.5-2.5 wt% of Gd, 0-1 wt% of Si, and the balance of Mg. The magnesium lithium alloy Mg-Li-Zn-Gd-Si is used a parent body, and is added with 1-10 wt% of Al2Ca or Al2Y. The preparation method of the high-strength and high-elastic-modulus magnesium lithium base composite material comprises two processes of smelting and plastic deformation, wherein the smelting process comprises the steps of: baking, Mg and Si melting, Zn and Gd adding, Li adding, reinforced particle adding, and casting; and the plastic deformation process comprises homogenization and plastic deformation. Zn and Gd are synchronously added in a magnesium lithium alloy solidification structure to form a quasi-crystal reinforcing phase, and Si is added to form a heat-resistance second phase, so that the heat stability of the alloy is improved; and meanwhile, the reinforced particles are introduced in the basal body of the magnesium lithium alloy to form the composite material, so that the strength and the rigidity are comprehensively improved, the material density is guaranteed to be lower than 1.55 g / cm3, and the ultralight high-performance magnesium lithium base composite material is obtained.

Owner:苏州轻金三维科技有限公司

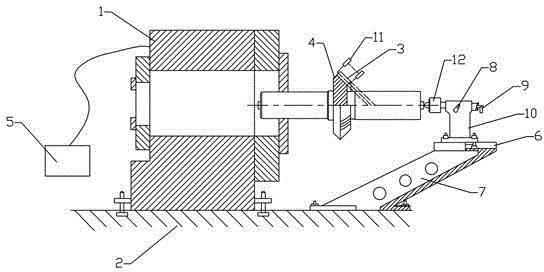

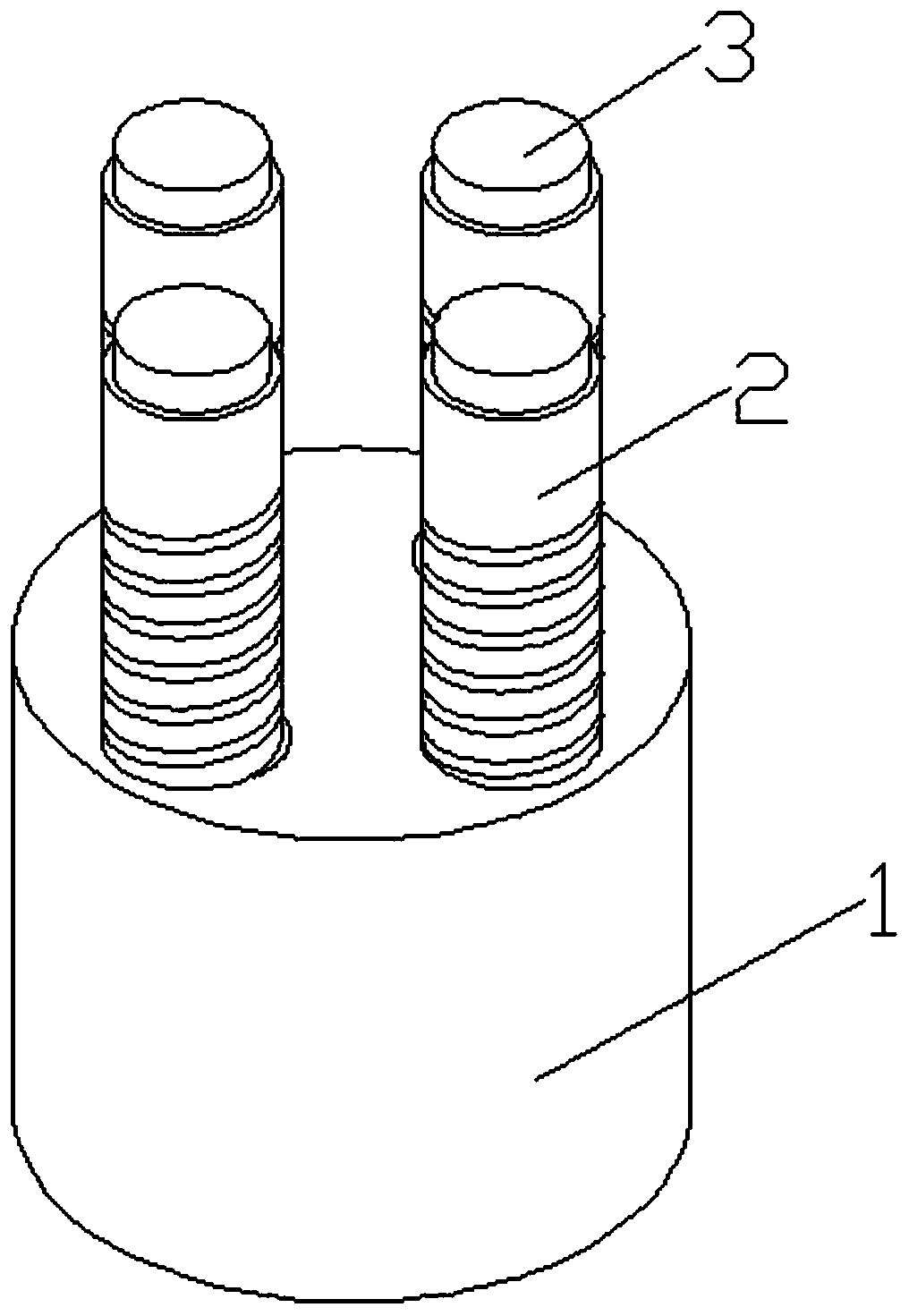

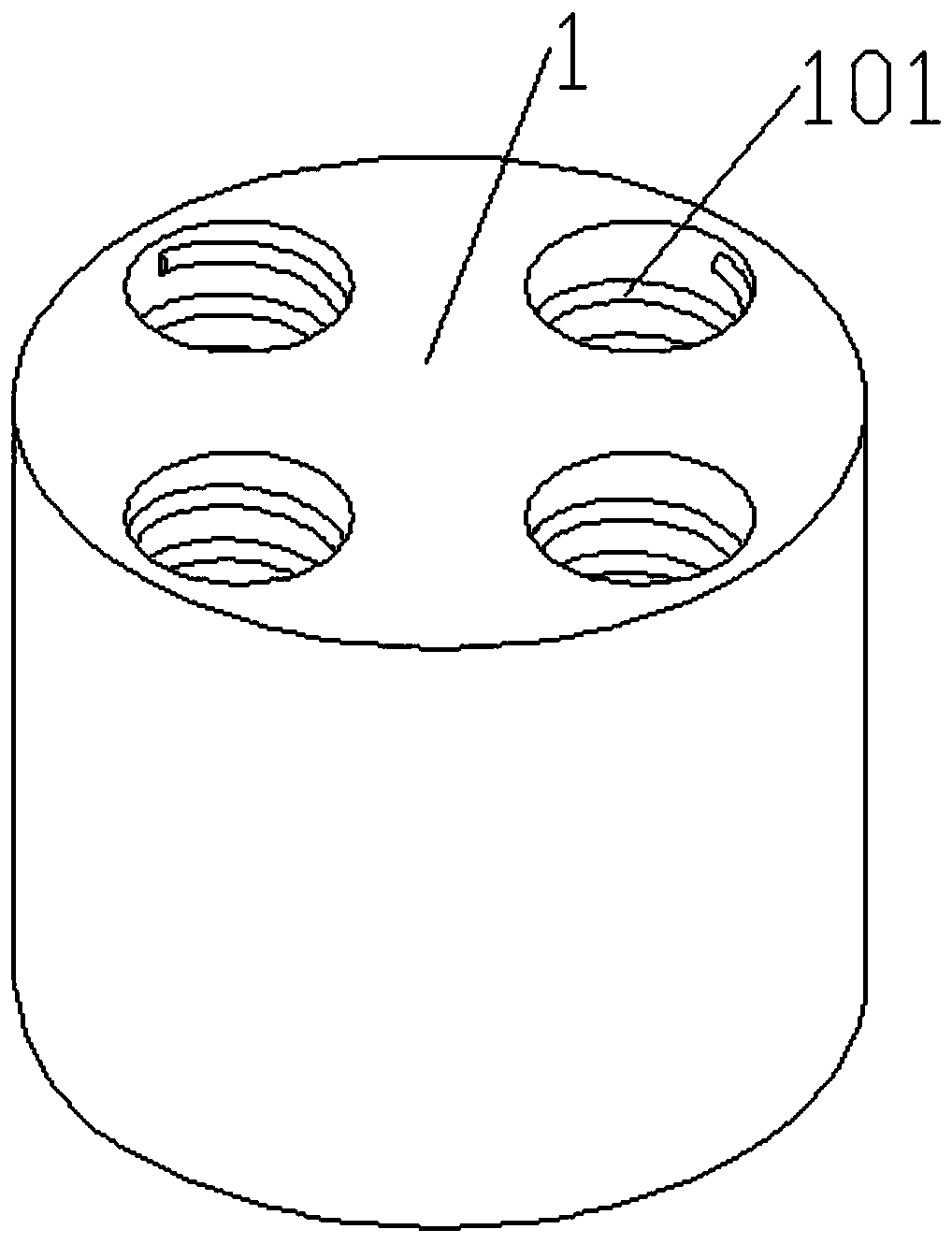

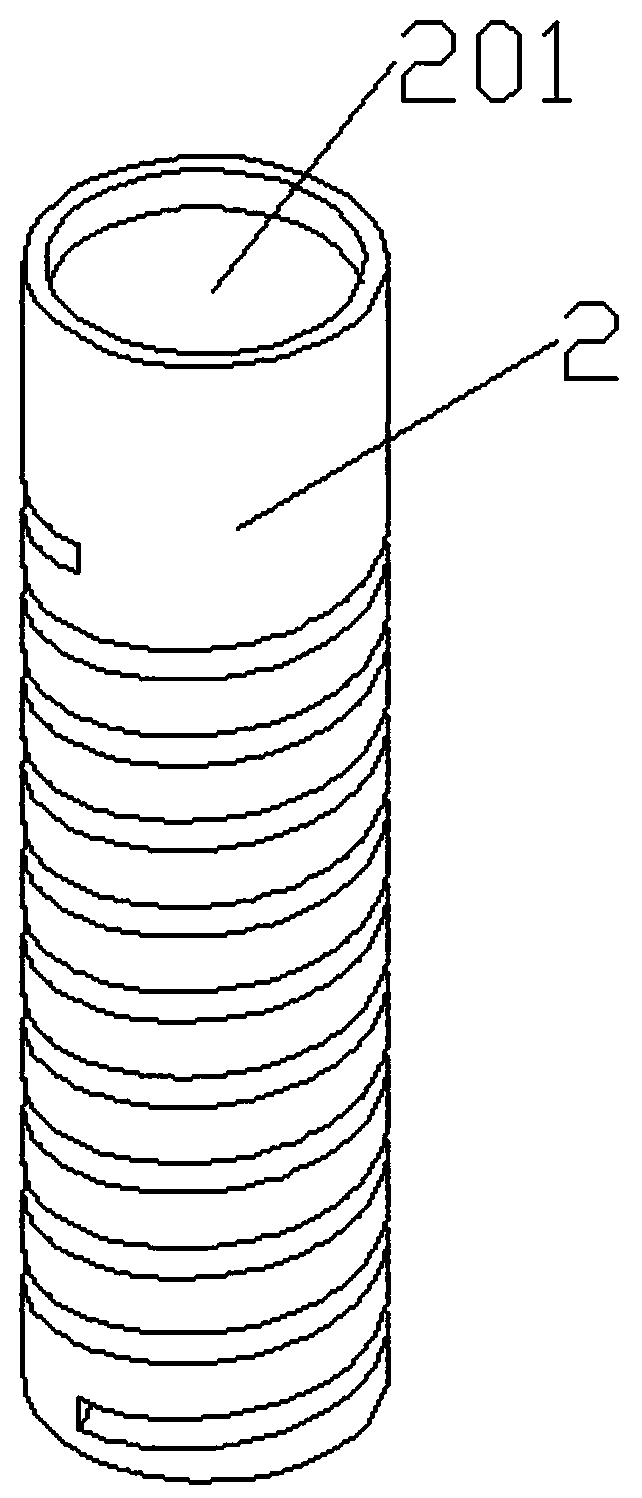

Observation aid for high-temperature laser scanning confocal microscope samples and using method thereof

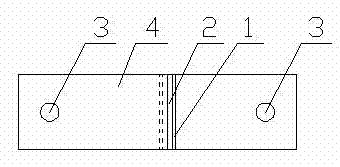

PendingCN110632075ASimple structureThe processing technology is easy to operatePreparing sample for investigationMaterial analysis by optical meansRoom temperatureLaser scanning

The invention discloses an observation aid for high-temperature laser scanning confocal microscope samples and a using method thereof. The aid comprises a seat body, bolts and a wafer sample, whereinthe seat body is cylindrical; a plurality of through threaded holes are circumferentially and uniformly formed in the seat body; the bolts are meshed in the threaded holes; the bolts are formed by topping and grinding traditional bolts; placing grooves are formed in the top surfaces of the bolts; and wafer samples are fixedly connected in the placing grooves. The using method comprises the steps of sample mounting, sampling grinding and sample observation. The observation aid has the following beneficial effects that the cylindrical seat body is easy to be handheld for polishing, so that the grinding and polishing of multiple wafer samples at one time are convenient and benefit is brought to improve the surface quality and flatness of the wafer samples; and the fingers are prevented from being in direct contact with the samples and the wafer samples are easier to be uniformly stressed in the grinding process, so that the thickness uniformity of the samples is ensured. The aid is capable of observing the surface grinding corrosion conditions of multiple samples at the same time under a high-temperature laser confocal room-temperature microscope.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

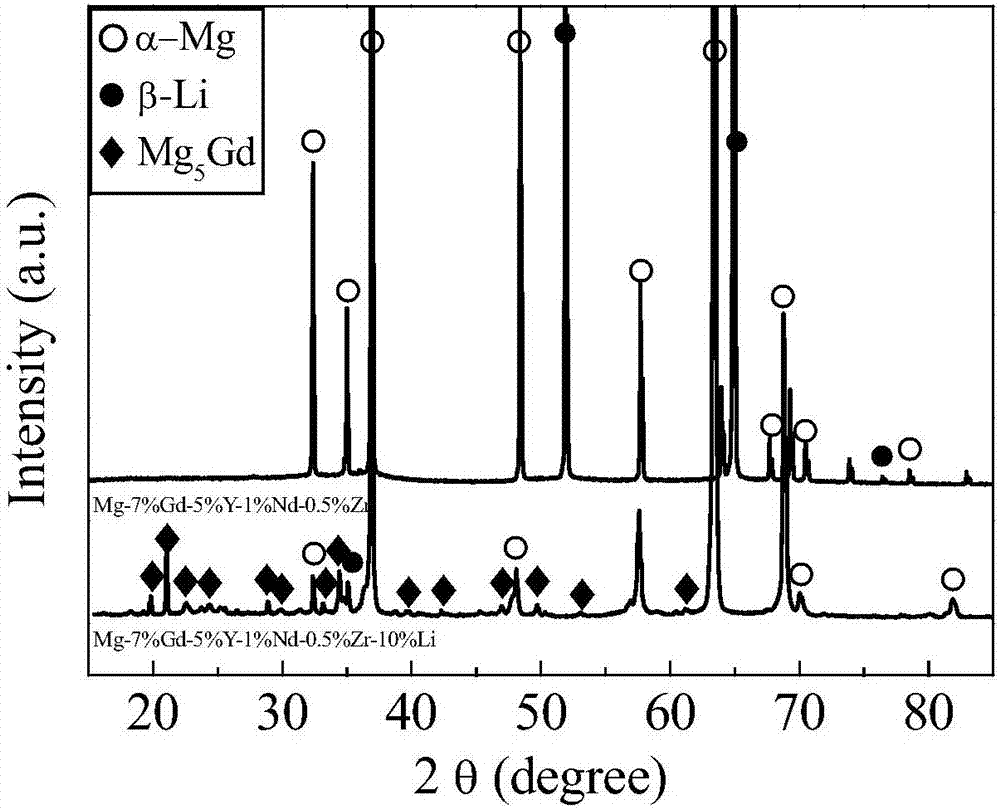

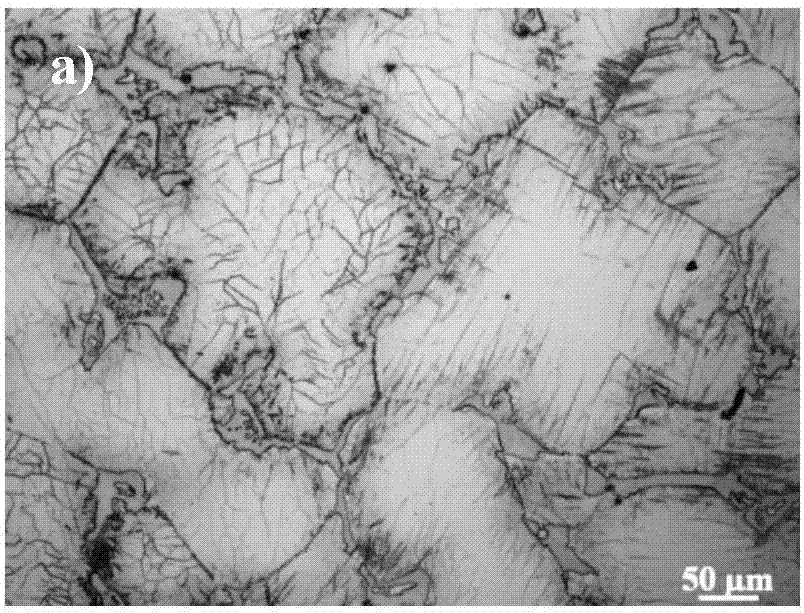

Effective method for improving plastic molding capacity of high-strength Mg-Gd-Y-Nd-Zr magnesium alloy

ActiveCN107964602AImproved coordination of plastic deformationImprove plastic processing and forming abilityPlastic moldingZr alloy

The invention relates to the field of plasticity improvement of high-strength magnesium alloys, in particular to a method for improving plastic molding cavity of a high-strength Mg-Gd-Y-Nd-Zr magnesium alloy by effectively using an element Li, and solves the problem of weaker high-strength plasticity. Under the precondition of keeping relative contents of all elements in the alloy invariable, 5-20weight% of Li element is added to form a beta-Li phase with higher plasticity deformation capacity in the alloy; the volume fraction (20-90%) of forming the beta-Li phase is controlled to prepare a lithium-contained Mg-Gd-Y-Nd-Zr alloy with high strength and better plasticity; the alloy is smelted and hot rolled subsequently to prepare a plate; and the machining process is simple and convenient to operate. The tensile strength of the material under cast-state condition is ob=120-250 MPa, the yield strength is o0.2=80-150 MPa, the ductility is delta=10-30%, and the density is 1.50-1.89 g / cm3;and the plate cannot generate the edge cracking phenomenon after deformation with 40% of rolling quantity at room temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

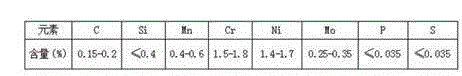

Precision bearing ring for automobile and machining technology thereof

The invention belongs to the technical field of manufacturing of precision bearings matched with important main machines, and particularly relates to a machining technology for a precision bearing ring for an automobile. The machining technology comprises the following steps that (a) a blank is heated by adopting a medium-frequency induction heating furnace; (b) forging is carried out by adoptinga high-speed upsetting forging machine according to a mold ring; (c) spheroidizing annealing is carried out in a continuous nitrogen-based protective atmosphere furnace after demolding; (d) shot blasting is carried out; (e) cold rolling is carried out for 7-10 seconds; (f) carrying out cleaning treatment; and (g) appearance sorting is carried out after cold rolling. The machining technology has the beneficial effects that the machining technology can be improved by combining a forging technology and a cold rolling technology, optimizing the technological conditions and performing automatic operation, and the hardness, the wear resistance and other performances of the bearing outer ring can be further improved; no tiny waste exists on the bearing outer ring through cleaning treatment, and therefore the cleanliness can be improved, the service life of the precision bearing outer ring can be prolonged, and the grade requirement of a precision bearing workpiece can be met.

Owner:江苏保捷精锻有限公司

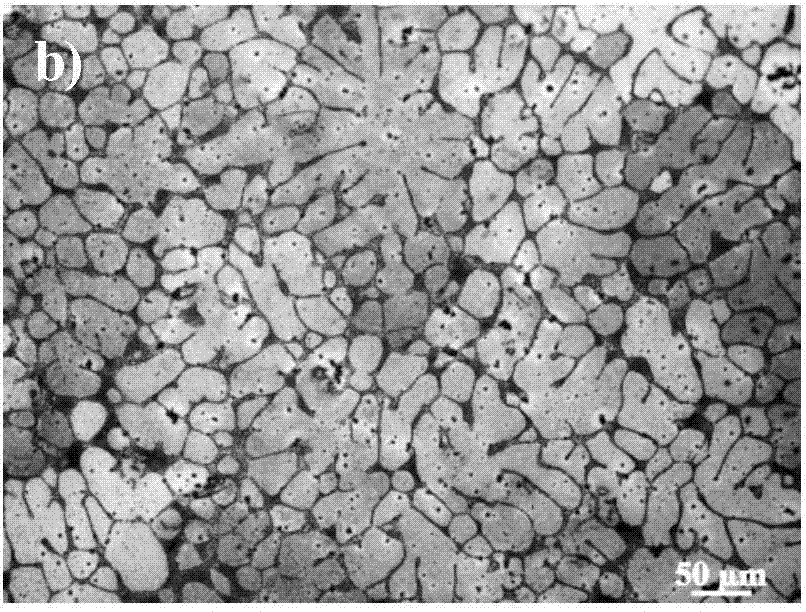

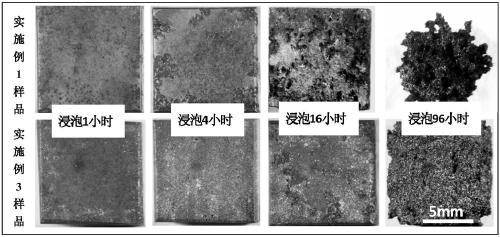

Heat treatment process to improve the performance of long-range structural ordered phase strengthened dual-phase magnesium-lithium alloy

The invention relates to the field of magnesium alloy performance optimization, in particular to a heat treatment process for remarkably improving using performance of long-range structure ordered phase enhanced bi-phase magnesium lithium alloy. The heat treatment process comprises the following steps that solid solution treatment is conducted on as-cast long-range structure ordered phase enhanced Mg-Li-Zn-Y alloy, heat preservation is conducted for 1-20 hours at 350-550 DEG C, and then water quenching cooling is conducted to room temperature. According to the heat treatment process, the corrosion resistance of the alloy can be remarkably improved, and the problem of the poor corrosion resistance of the long period phase enhanced magnesium lithium alloy is solved; and meanwhile, the strength and plasticity of the alloy are further improved, and the practical engineering application of this kind of high-strength magnesium lithium alloy is widened.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High strength AZ31-CaO magnesium alloy and preparing method thereof

The invention belongs to the technical field of metal materials, and relates to a high strength AZ31-CaO magnesium alloy and a preparing method thereof. According to the allot, a certain mass of CaO is added into an AZ31 magnesium alloy, refining, casting, homogenization treatment and plastic deformation are carried out, and the AZ31-CaO magnesium alloy is obtained. By means of the alloy, casting state crystalline grains are refined, the strengthening phase with the high temperature stability is formed, the strengthening effect is achieved, the newly-generated high temperature stabilization strengthening phase during plastic deformation promotes recrystallization, and therefore the AZ31-CaO alloy has the excellent mechanical property, and the strength of extension is greatly improved under the condition that the ductility is basically kept unchanged.

Owner:JIANGSU UNIV OF TECH

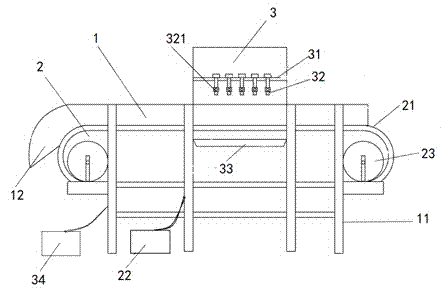

Processing technology for double-faced antistatic coating film

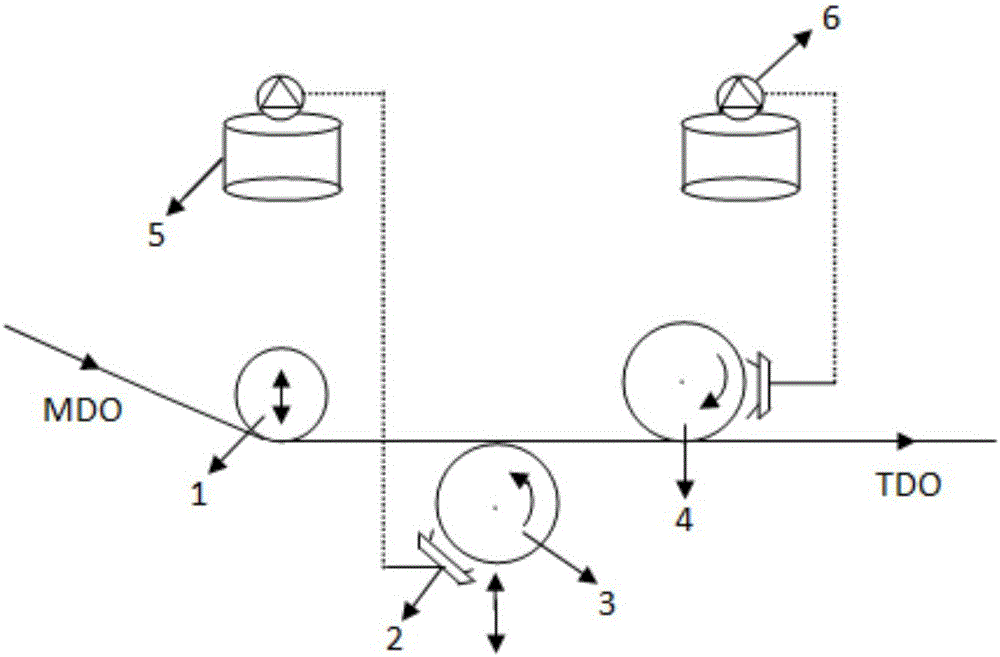

ActiveCN106799328ANo jitterUniform coatingLiquid surface applicatorsCoatingsMetallurgyMaterials science

The invention relates to a processing technology for a double-faced antistatic coating film. A material film stretched through MDO firstly makes contact with a coating roller I through a guiding roller so that single face coating can be carried out, then, the material film makes contact with a coating roller II so that coating of the other face can be carried out, and finally TDO preheating stretching is carried out; the coating roller I and the coating roller II are gravure rollers, the horizontal center distance between the coating roller I and the coating roller II is 1 / 5-1 / 4 of the diameter of each coating roller, the diameter of each coating roller ranges from 300 mm to 350 mm, the coating roller diameter refers to the diameter of the coating roller I or the diameter of the coating roller II, and the diameter of the coating roller I is equal to the diameter of the coating roller II; and the rotating direction of the coating roller I and the rotating direction of the coating roller II are opposite to the material feeding direction of the material film, and the coating weight of the coating roller I and the coating weight of the coating roller II on the surface of the material film ranges from 3 g / m<2> to 6 g / m<2>. By means of the processing technology, the occurrence of winding bar shaking in the coating process can be effectively avoided, uniform coating of antistatic coating is achieved, and the finally obtained product is uniform in surface coating and has an excellent antistatic effect.

Owner:YINGKOU KANGHUI PETROCHEM

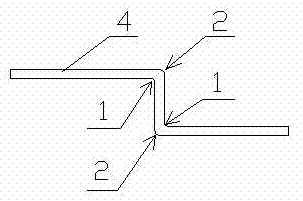

Ramie and paper straw mix-woven mat and processing technology thereof

InactiveCN104382430AStrong adsorption capacityEliminate bad smellHeating/cooling textile fabricsWoven fabricsAnti bacterialCotton thread

The invention relates to a mat and a processing technology thereof, in particular to a ramie and paper straw mix-woven mat and the processing technology thereof. The ramie and paper straw mix-woven mat is formed by weaving ramie and paper straws in a mixed way. The processing technology of the ramie and paper straw mix-woven mat comprises the following steps of firstly manufacturing the paper straws into paper, cutting the paper into pieces according to the specification of the ramie and paper straw mix-woven mat, then taking the pieces as weft threads by rolling the pieces into rope shapes or core-spun cotton threads in the pieces to form the rope shapes, obtaining ramie fiber by carrying out chemical degumming on the ramie, soaking the ramie fiber by nano-silver antibiotic finishing agent solution of which the PH is 5.0-6.5, and taking the ramie fiber as warp threads for weaving after the ramie fiber is dried, so as to obtain a mat main body; obtaining a mat semi-finished product by carrying out water spraying, heating, press polishing and shrinkage treatment on the mat main body by a press atomizer; finally, drying the mat semi-finished product after soaking the mat semi-finished product is soaked in a waterproof agent of which the PH is 4.3-6.2 for 5-10 minutes, and obtaining a mat finished product by carrying out edge covering treatment. According to the ramie and paper straw mix-woven mat and the processing technology, disclosed by the invention, the processing technology is simple, and the ramie and paper straw mix-woven mat which is obtained through the processing technology not only has excellent performance of moisture-absorption air permeability, anti-bacterial deodorization performance, health and environment protection performance and the like, but also is comfortable in hand feeling, is washable and foldable and is long in service life.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

Processing craft for thermoplastics pipes of copper bar suit

A processing craft for thermoplastics pipes of copper bar suit is characterized in that the length of each end of the thermoplastics pipes is 10mm shorter than that of the copper bars when the thermoplastics pipes are sleeved on the copper bars, and an air heater operates at a second gear at 630 DEG C in the processes of baking, heating, contracting and forming each section of the thermoplastics pipe sleeved on each section of the copper bar by using a heat gun, wherein the hot blast rate is 28-300 liters per minute. By overcoming the prejudice of the prior art and saving raw materials of the thermoplastics pipes with simple operation, the processing craft for thermoplastics pipes of copper bar suit disclosed by the invention has the advantages that the phenomena of overlarge local contraction amount or burning and burning through are barely caused when the sleeved thermoplastics pipes are baked, heated, contracted and formed by the heat gun, the abnormally-shaped copper bars containing bending angles are not easy to generate folds during thermal shrinkage, redundant noses of the thermoplastics pipes are removed from two ends of the copper bars after the sleeved thermoplastics pipes are baked, heated, contracted and formed so that the thermoplastics pipes are easily gathered in the thermoplastics pipe cutting process, and is simple in cutting operation and high in production efficiency.

Owner:HEBEI ELECTRIC POWER EQUIP

High-strength magnesium-neodymium-zinc-zirconium-lithium alloy and preparation method thereof

The invention belongs to the technical field of metal material, and relates to a high-strength magnesium-neodymium-zinc-zirconium-lithium alloy and a preparation method thereof. The alloy comprises, by weight, 2 to 4 wt% of Nd, 0.2 to 1 wt% of Zn, 0.2 to 0.8 wt% of Zr, 0.5 to 1.5 wt% of Li, and the balance of Mg and the impurity elements Si, Fe, Cu and Ni, and the total amount of the impurity elements is less than 0.02 wt%. The alloy is prepared by the following steps of 1) drying material; 2) feeding; 3) casting; 4) heat treatment. By adding a certain amount of lithium to the magnesium-neodymium-zinc-zirconium alloy, the precipitation of the strengthening phase during the aging process is promoted, the time required for the aging treatment is shortened or the aging treatment temperature is reduced, the performance of the high-strength magnesium zinc-zirconium-lithium alloy is improved, and the density of the alloy is reduced.

Owner:JIANGSU UNIV OF TECH

Refrigeration type production method for improving water preserving capability of abalones

The invention relates to the technical field of processing marine products, in particular to a refrigeration type production method for improving the water preserving capability of abalones. The refrigeration type production method disclosed by the invention comprises the following steps: (a) cleaning the abalones, and blanching the cleaned abalones for 1-5 minutes at a constant temperature in water of which the temperature is 50-80 DEG C; (b) draining the moisture of the surfaces of the blanched abalones, and cooling the drained abalones; (c) quickly refrigerating the cooled abalones until the core temperature of muscles of the abalones reaches minus 18-minus 30 DEG C. According to the processing method provided by the invention, through detection, after the refrigerated abalones are cooked and boiled, the quality of the muscles of the cooked abalones is close to that of fresh abalones; the processing loss is small, the yield rate is high, the processing technology is simple, the operability is good, and the production method has extremely good industrial application prospects.

Owner:夏雪飞

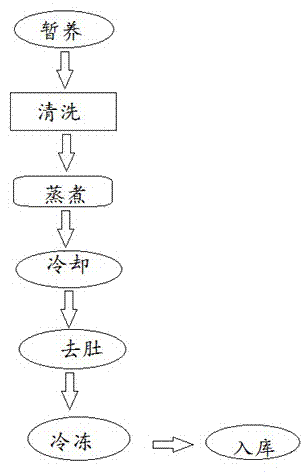

Ultralow-temperature frozen abalone processing method

The invention relates to the technical field of processing of aquatic products, and in particular relates to an ultralow-temperature frozen abalone processing method. The ultralow-temperature frozen abalone processing method is characterized by comprising the following steps: (1), cleaning captured abalones on a self-made high-pressure cleaning device in a manner that of the meat surfaces of the abalones are upwardly placed; (2), stewing, namely arranging the cleaned abalones of same sizes in a dish matched with a stewing pot one by one, and putting in the stewing pot for stewing after arranging; (3), cooling, namely instantly putting the stewed abalones in cooling water for cooling; (4), removing internal organs after taking out the abalones processed in the step (4); and (5), freezing, namely putting the abalones arranged in the step (5) in monomer quick-freezing equipment to freeze rapidly. The ultralow-temperature frozen abalone processing method disclosed by the invention is easy to operate and applied to industrial production; the nutritional components of the abalones are retained to the most extent; and the original flavour of the abalones is kept.

Owner:XIAMEN DAOZHIYUAN BIOTECH

High-strength and heat-resistance Mg-Zn-Al-Y-Sb magnesium alloy and preparation method thereof

The invention relates to the technical field of magnesium alloy materials, in particular to a high-strength and heat-resistance Mg-Zn-Al-Y-Sb magnesium alloy and a preparation method thereof. The high-strength and heat-resistance Mg-Zn-Al-Y-Sb magnesium alloy comprises the following components: 2-4 wt.% of Zn, 2-4 wt.% of Al, 0.5-2 wt.% of Y, 0.2-1 wt.% of Sb, the total quantity of impurity elements Si, Fe, Cu and Ni less than 0.02 wt.%, and the balance of Mg. The preparation method of the high-strength and heat-resistance Mg-Zn-Al-Y-Sb magnesium alloy comprises two processes of smelting and heat treatment, wherein the smelting process comprises the steps of material baking, Mg smelting, Zn and Al adding, Y adding, Sb adding, refining and casting; and the heat treatment process comprises solid solution treatment and aging. The Sb elements with a certain mass are added in a Mg-Zn-Al-Y alloy, so that the casting structure of the alloy is effectively improved, and grains are refined; anda compact second phase with high melting point and high heat stability is formed, so that the room-temperature and high-temperature mechanical performances of the alloy are improved.

Owner:JIANGSU UNIV OF TECH

Machining technology of ultrahigh-surface-density foam nickel

ActiveCN106319584AThe processing technology is easy to operateReduce production process costsElectroplatingHeat treating

The invention discloses a machining technology of ultrahigh-surface-density foam nickel, and belongs to the field of special foam nickel. Firstly, foam is subject to conductive treatment, preparing before electroplating is carried out, the foam obtained after conductive treatment is electroplated under the state that the four sides have certain tension, hot pressing treatment is carried out after electroplating, secondary electroplating and heat treatment are carried out, the machining technology is easy to operate, the production technology is low in cost, the problems that due to the fact that the density is too high, uneven electroplating appears in electroplating, the stress is too large and deformation is too large, products are poor are solved, the use problem brought by uneven electroplating also can be solved in the technology, and the use rate of the products is greatly improved.

Owner:ADVANCED TECH MATERIALS DALIAN

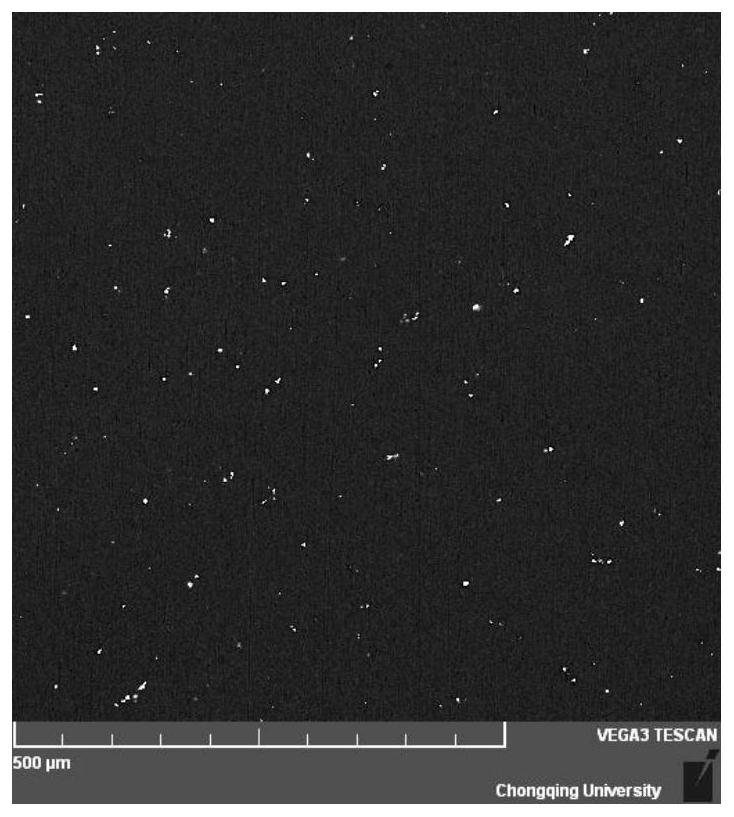

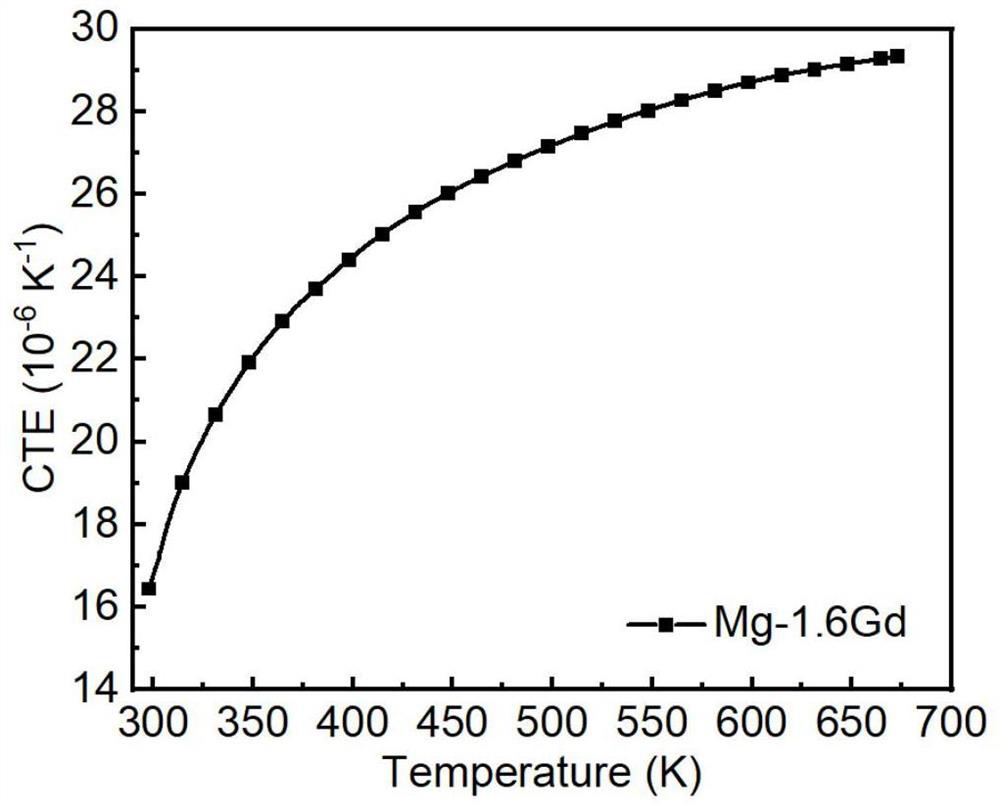

Novel low-expansion binary magnesium alloy and preparation method thereof

ActiveCN114672711AReduce the content of the second phaseReduce stress concentrationSolution treatmentThermal dilatation

The invention discloses a novel low-expansion binary magnesium alloy and a preparation method thereof, the magnesium alloy comprises the following components in percentage by mass: 1.6-15.5% of Gd and the balance of magnesium and inevitable impurity elements, and the thermal expansion coefficient of the magnesium alloy at room temperature is 15.7 * 10 <-6 > K <-1 >-16.4 * 10 <-6 > K <-1 >. By adopting the mode of combining accurate control of the content of the Gd element and the solution treatment process, the content of a second phase in the alloy is greatly reduced, meanwhile, a large number of phase interfaces are prevented from being generated with a magnesium matrix, and the thermal expansion coefficient of the magnesium alloy is effectively reduced. The Mg-Gd alloy not only has a low thermal expansion coefficient, but also has good plastic processing performance, the potential of the Mg-Gd alloy serving as a repair welding material or an electronic element material is greatly improved, the engineering field where magnesium alloy can be applied is expanded, meanwhile, a new research direction is provided for research on preparation of low-expansion magnesium alloy, and the Mg-Gd alloy has great significance.

Owner:CHONGQING UNIV

High-performance magnesium alloy and preparation method thereof

The invention provides high-performance magnesium alloy and a preparation method thereof. The alloy comprises the specific ingredients in percentage by weight: 1wt% of Al, 0.3wt% of Ca, 0.3wt% of Mn,0 to 0.6wt% of Zn and the balance of Mg. The preparation method comprises the steps of preparing all elements according to an alloy weight ratio, and carrying out vacuum smelting, pouring, homogenizing treatment and plastic deformation, thereby obtaining the alloy. Through adding a certain weight of element zinc into magnesium-aluminum-calcium-manganese alloy, an alloy structure can be refined, astrengthening phase with high-temperature stability is formed, the action of strengthening the alloy is exerted, and the aim of improving properties of the material is achieved.

Owner:JIANGSU UNIV OF TECH

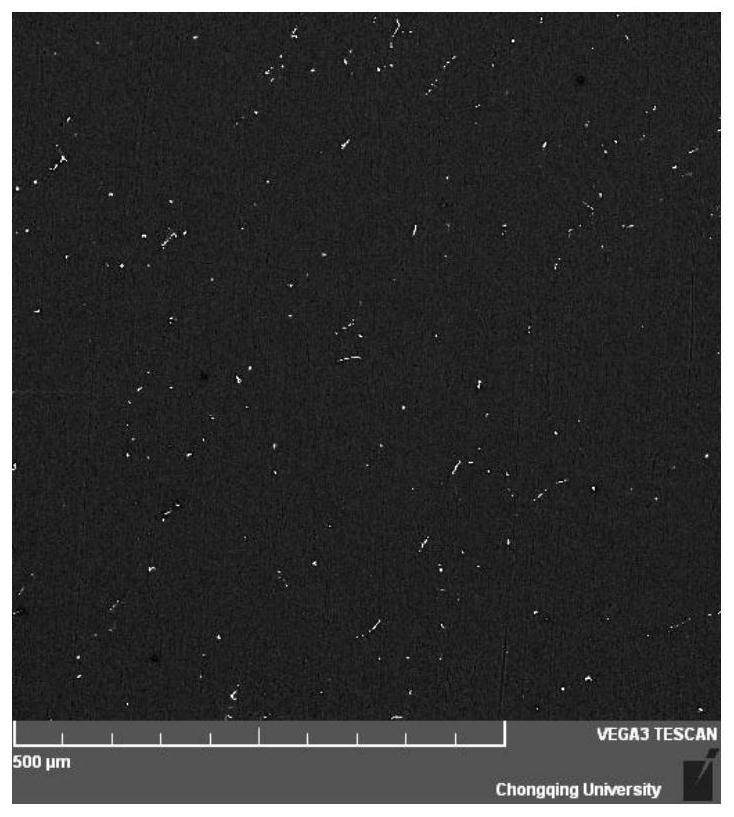

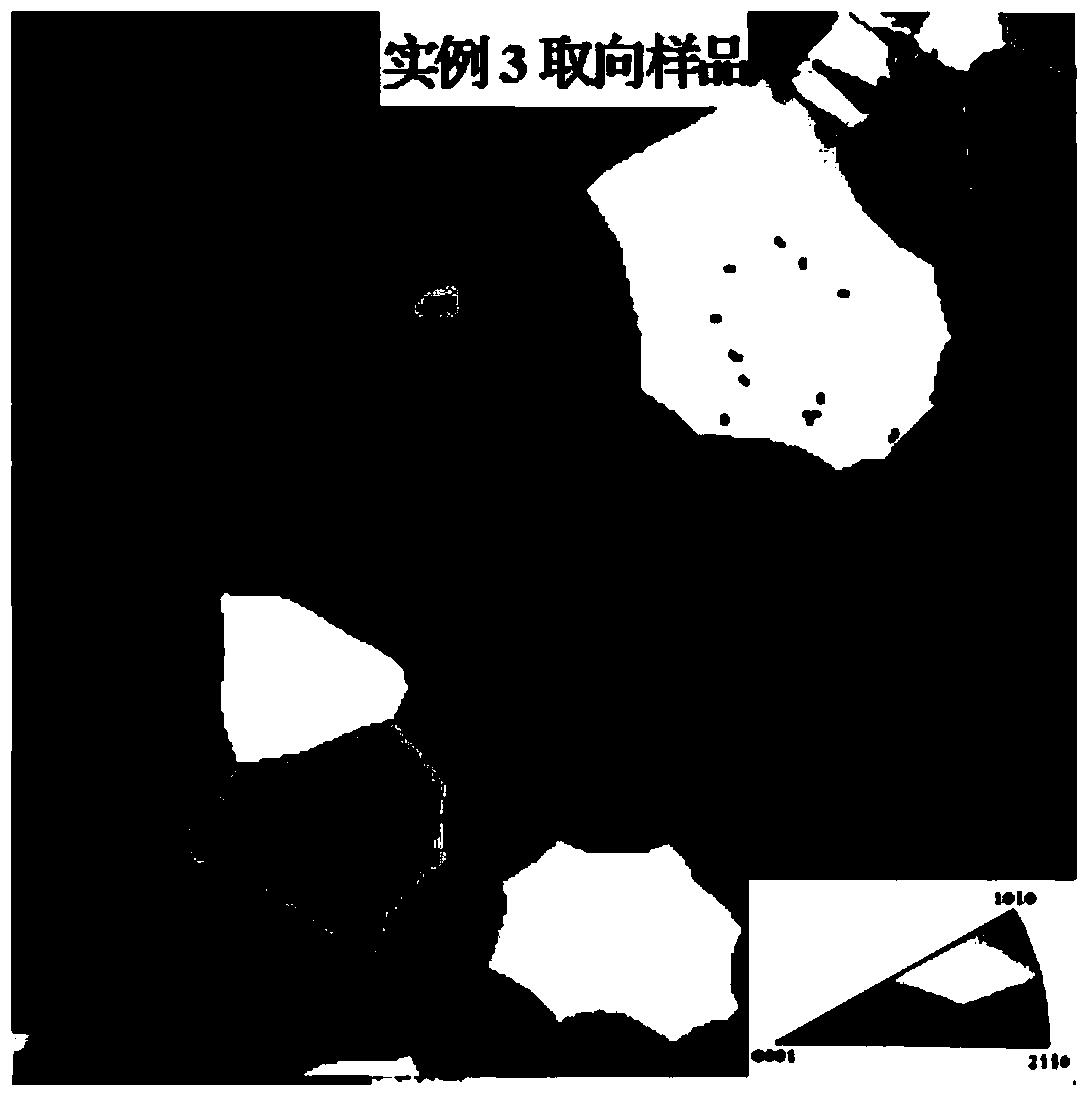

An effective method to control the corrosion rate of magnesium alloy

ActiveCN106811706BBiodegradation Rate ControlRaise the potentialLarge deformationBiological materials

The invention relates to the field of magnesium alloys and in particular to an effective method of regulating the corrosion rate of a magnesium alloy. The effective method is suitable for effectively regulating the corrosion rates of various deformed magnesium alloys and processing and preparing and meets the demand of biodegradation rate of a magnesium alloy implant material in different human body parts. The method comprises the following steps: in a condition of 300-400 DEG C, performing annealing treatment on a deformed magnesium alloy of a strong basic face structure for 0.5-2 hours to eliminate the residual stress caused by large deformation; and then cutting and sampling the alloy with different orientations and strictly controlling components and proportions of crystallographic surfaces contained on the surface of the sample. The effective method provided by the invention can obviously regulate the corrosion resistance of the magnesium alloy, solves the problem of regulating the corrosion rate of the magnesium alloy and achieves the demand of the magnesium alloy on different biodegradation rates in the medical field, so that the competitiveness of the magnesium alloy as a human body implant biological material is obviously enhanced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

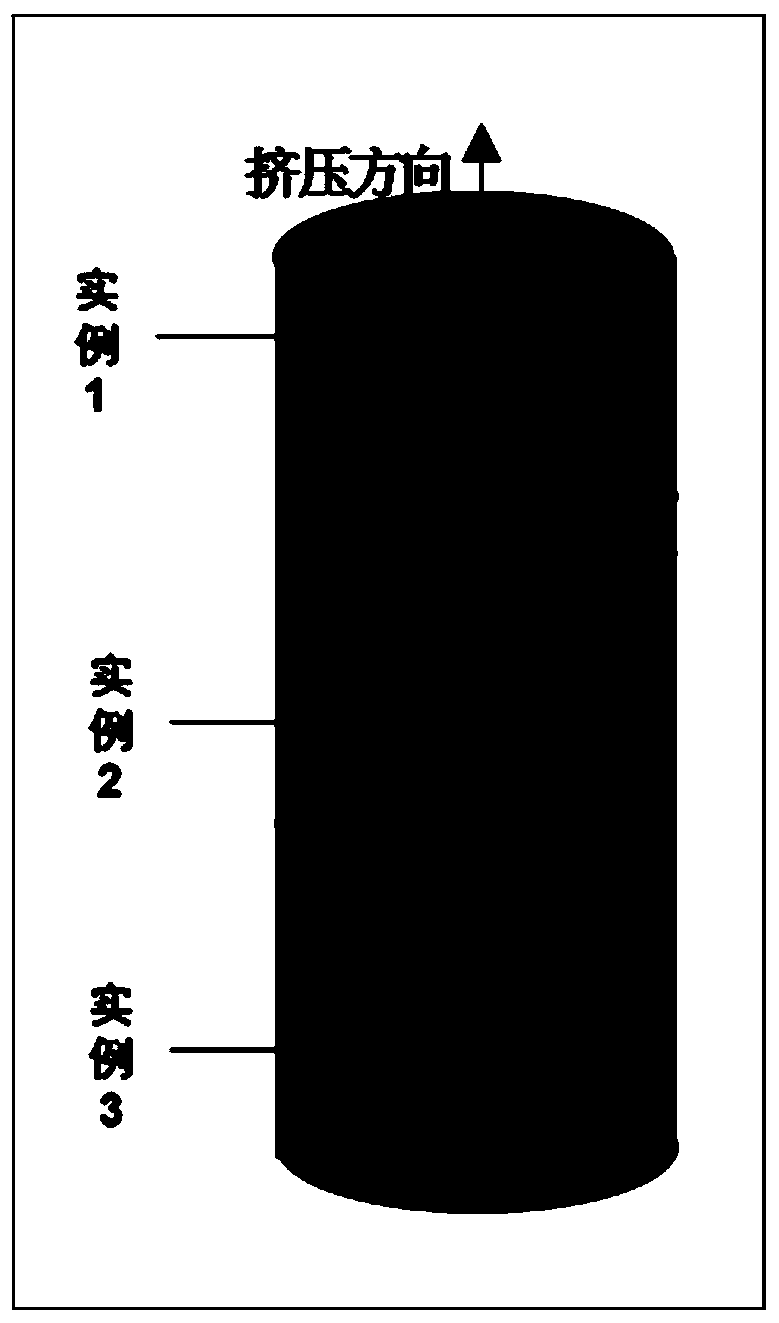

A kind of preparation method of high-strength magnesium-lithium alloy

The invention discloses a method for preparing high strength magnesium-lithium alloy. The magnesium-lithium alloy comprises following components by weight percent: 6-10wt% of Li, 2.5-7.5wt% of Zn, 1-3wt% of Gd, 0.2-0.6wt% of Zr, less than 0.02wt% of impurity elements like Si, Fe, Cu and Ni, and the balance of Mg. The method comprises three steps of smelting, plastic deformation and thermal treatment, wherein the smelting comprises the steps of drying the materials, melting magnesium, adding Zn and Gd, adding Zr, adding Li and casting; the plastic deformation comprises the steps of homogenization treatment and plastic deformation processing; and the thermal treatment comprises the step of aging treatment. As elements like Zn and Gd are added into the magnesium-lithium alloy, quasi-crystal is taken as a strengthening phase to be introduced into the solidification structure of the magnesium-lithium alloy, and the added Zr is taken as a grain refiner, low density and high strength magnesium-lithium alloy is obtained after subsequent steps of plastic deformation and thermal treatment.

Owner:SHANGHAI JIAO TONG UNIV

Wood processing technology

InactiveCN111941579AThe processing technology is easy to operateImprove toughnessImpregnation spraying apparatusCleaning using liquidsCold airCarbonization

The invention discloses a wood processing technology. The wood processing technology comprises the following steps that A, firstly, the surface of wood is polished; B, the surface of the polished woodis cleaned; C, the cleaned wood is put into a drying box to be dried; D, the dried wood is taken out and then cooled in a ventilated place; E, the treated wood is put into a sealed carbonization furnace to be subjected to high-temperature carbonization; F, the carbonized wood is cooled through cold air blowing of a cold air fan; G, the cooled wood is subjected to drilling treatment according to design requirements; And H, finally, a layer of antioxidant is sprayed to the surface of the drilled wood. The adopted wood processing technology is easy to operate, the overall toughness and strengthof the wood can be improved, and wood products processed by using the wood possess excellent impact resistance, deformation resistance and oxidation resistance and are long in service life.

Owner:常宁市腾鑫家具研发有限公司

A heat treatment process for suppressing the plastic instability of quasicrystal-strengthened magnesium-lithium alloys

The invention relates to the field of magnesium lithium alloys, and particularly relates to a heat treatment process for inhibiting the plastic instability of quasi-crystal reinforced magnesium lithium alloys. The process comprises the following steps: tightly wrapping a variable-form magnesium lithium alloy with an aluminum foil, carrying out solid solution treatment on the obtained object at a temperature of 330-470 DEG C, carrying out heat preservation for 4-8 hours, cooling the obtained product to room temperature by water quenching, ageing the obtained product for 12-24 hours at a temperature of 100-200 DEG C, and cooling the obtained product to room temperature by water quenching again. According to the invention, the plastic instability phenomenon of a quasi-crystal reinforced magnesium lithium alloy can be significantly inhibited, and the high yield strength and tensile strength of the alloy are retained, thereby solving the serrated yielding problem (occurring along with the tensile process) of plasticity of the magnesium lithium alloy. An alloy applicable to the heat treatment process disclosed by the invention comprises the following compositions by percent: 1.0-11.5% of Li, 5-10% of Zn, 0.5-2% of Y, and the balance of Mg. The process disclosed by the invention is simple in used equipment, low in cost, and simple and convenient to operate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

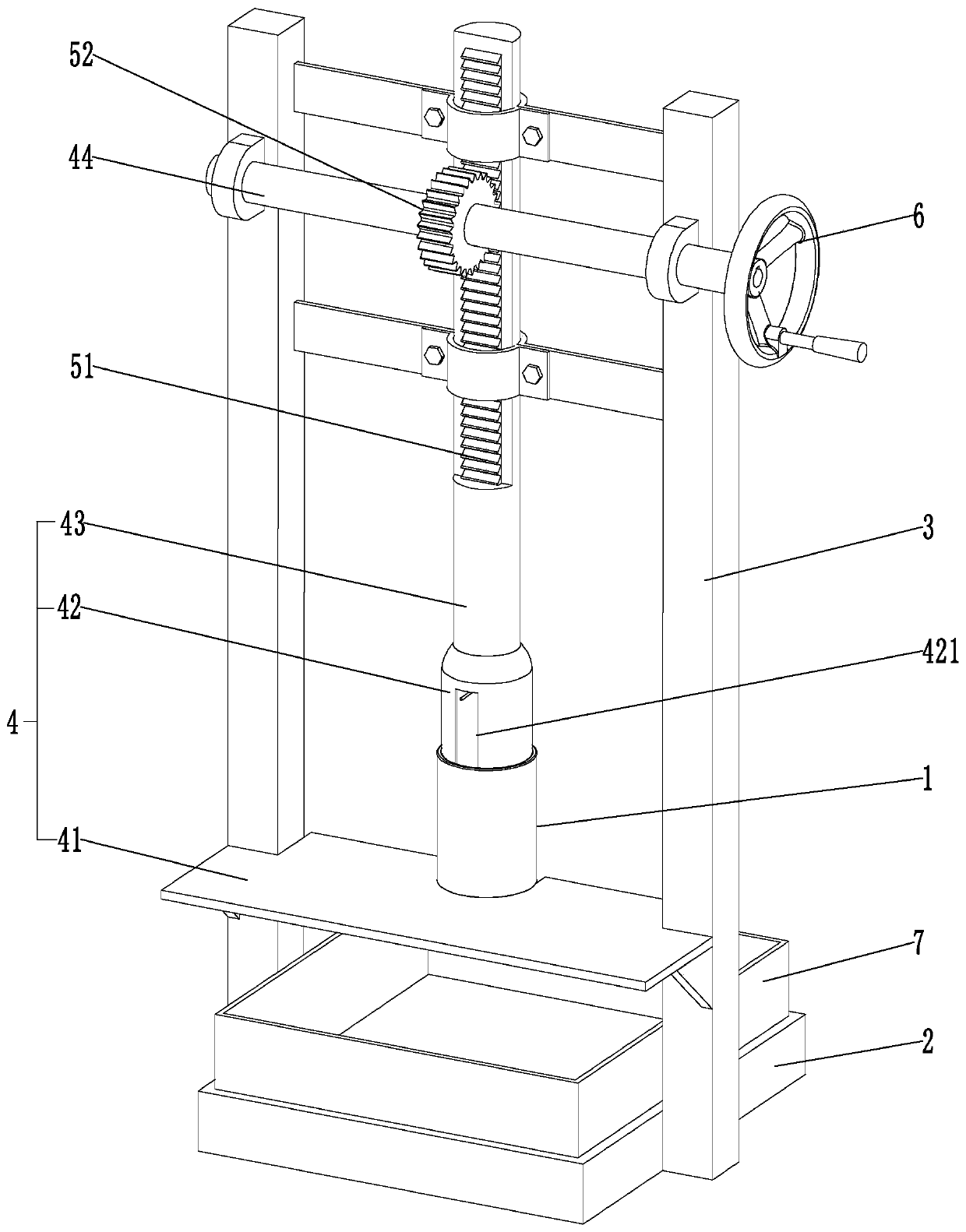

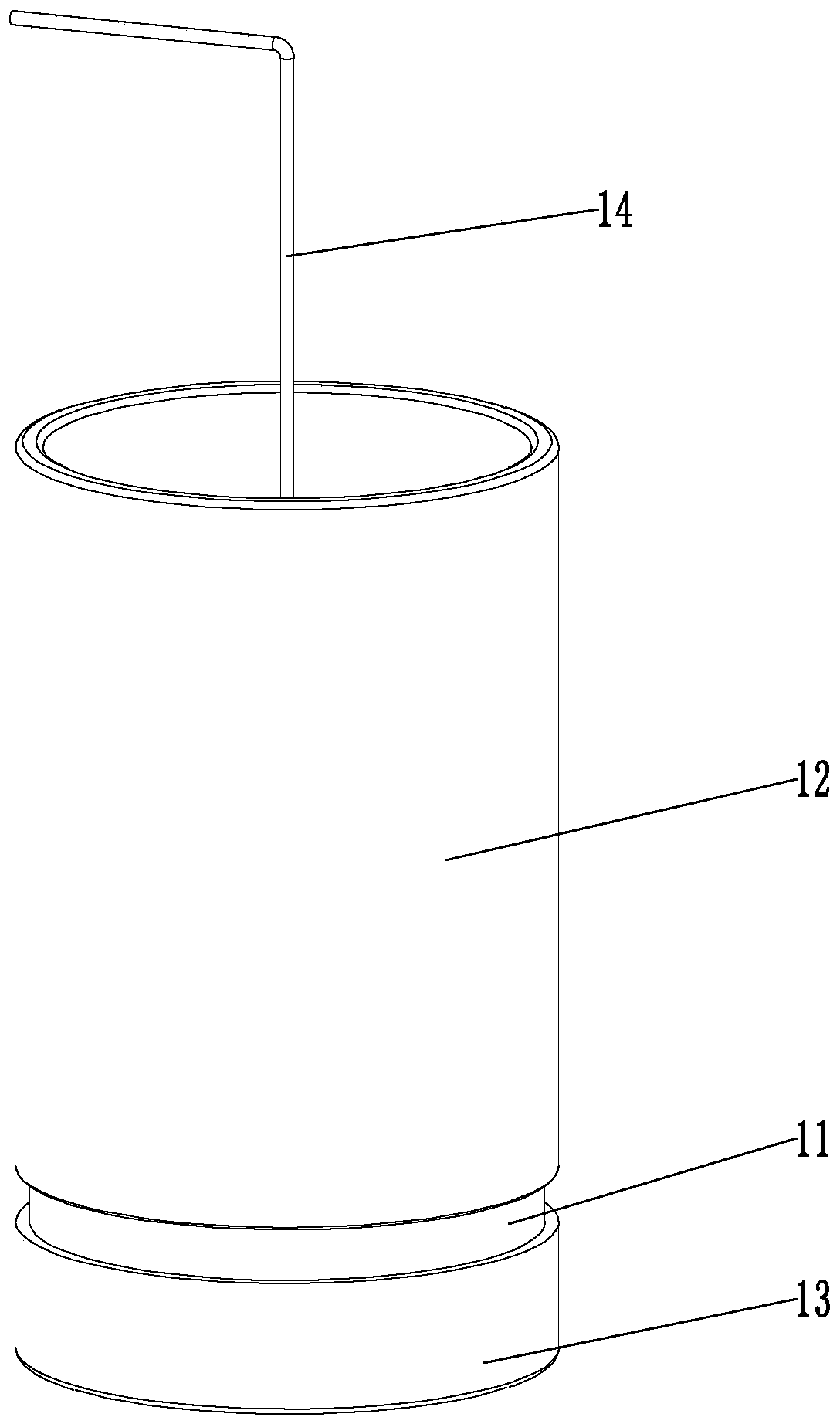

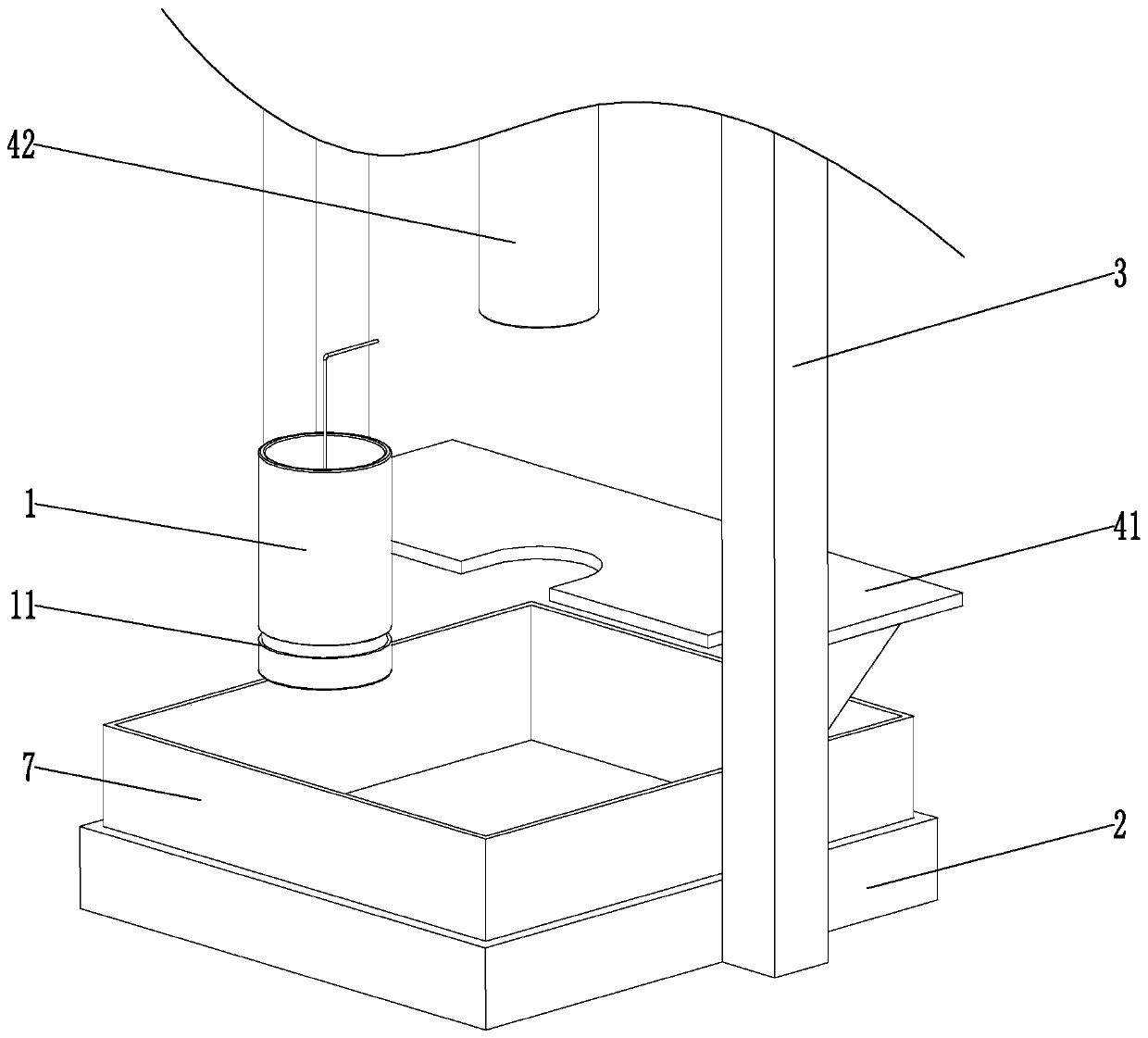

Candle processing technology and demolding device

PendingCN111019766ASimple processing technologyThe processing technology is easy to operateCandle preparation apparatusParaffin waxProcess engineering

The invention relates to a candle processing technology and a demoulding device,wherein the candle processing technology comprises the steps: step 1, heating and melting any one or more of paraffin, beeswax, powdered adipocere and palm wax, filtering, and uniformly stirring; step 2, pouring the uniformly stirred raw materials into a mold, and inserting a center penetrating rod into the axis area of the mold to the bottom of the mold; step 3, placing the mold and the raw materials at the room temperature, and cooling to form a candle body; step 4, demolding the candle body, and taking the candle body and the core penetrating rod out of the mold through a demolding device; step 5, taking the center penetrating rod out of the candle body; and step 6, inserting a candlewick into the candle body. The candle processing technology is simple and convenient, the steps are simple and easy to understand and operate, the candle body in the mold can be completely taken out in the fourth step, operation is convenient, the mold taking step is simplified, the candle body is completely taken out, and the working efficiency is improved.

Owner:石家庄市藁城区燃亮烛业有限公司

Processing technology of rose-scented fabric

InactiveCN104988593AThe processing technology is easy to operateLong lasting fragranceMelt spinning methodsUndergarmentsDistillationRoom temperature

The invention discloses a processing technology of a rose-scented fabric. The technology comprises the following steps: 1, selecting fresh rose petals, placing the fresh rose petals in a distillation container, and processing to obtain rose essential oil; 2, selecting attapulgite, roasting attapulgite, cooling to room temperature, and adding the rose essential oil to prepare a rose mixture; 3, adding the rose mixture to polyamide resin, and uniformly mixing to obtain a resin mixture; 4, adding the resin mixture into a double screw extruder, mixing, extruding, and granulating to prepare rose-scented nylon master batches; and 5, mixing the rose-scented nylon master batches with nylon slices, spinning, oiling, drawing, and texturing to obtain the rose-scented fabric. The processing technology of the rose-scented fabric is simple to operate, and the obtained fabric naturally generates scent in the use process, and has the advantages of long scent timeliness, high washing fastness and good breathability.

Owner:APPROACH SUZHOU GARMENT

Bottle blowing processing technology for hand cream blow molding bottle without butt joint at bottom

The invention discloses a bottle blowing processing technology of a hand cream blow molding bottle without a butt joint at the bottom. The bottle blowing processing technology comprises the following steps of A, mixing raw materials, adding the mixed raw materials into a drying tank, uniformly stirring and drying the mixed raw materials; B, adding the dried raw materials into an injection molding machine, melting the dried raw materials through a screw of the injection molding machine to obtain a melt, injecting the melt into an injection mold, and cooling to obtain a bottle blank; C, putting the bottle blank into a blowing mold, and heating and softening the bottle blank in a hot air blowing manner; D, pulling the softened bottle blank, so that the bottle blank is attached to the blow molding mold; E, blowing air through an air blowing system of a bottle blowing machine, and carrying out one-time blow molding on the bottle blank to form the hand cream blow molding bottle; and F, checking the quality of the blow molding bottle, and classifying the blow molding bottle. The processing technology is easy to operate, one-time blow molding is achieved, the uniformity of the wall thickness of the blow molding bottle can be guaranteed, meanwhile, the bottom of the blow molding bottle is free of the butt joint, the overall strength is high, and deformation and damage are not likely to happen.

Owner:南通瑞卓模塑有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com