Environment-friendly and high-weather-resistance PVC profile particles and processing technology thereof

A processing technology and high weather resistance technology, applied in the field of environmentally friendly and high weather resistance PVC profile particles and their processing technology, can solve the problems of thermal degradation of PVC, decrease of impact strength and tensile strength, bending and twisting of thermal expansion and contraction rate, etc. , to achieve the effect of extending service life, good heat resistance and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

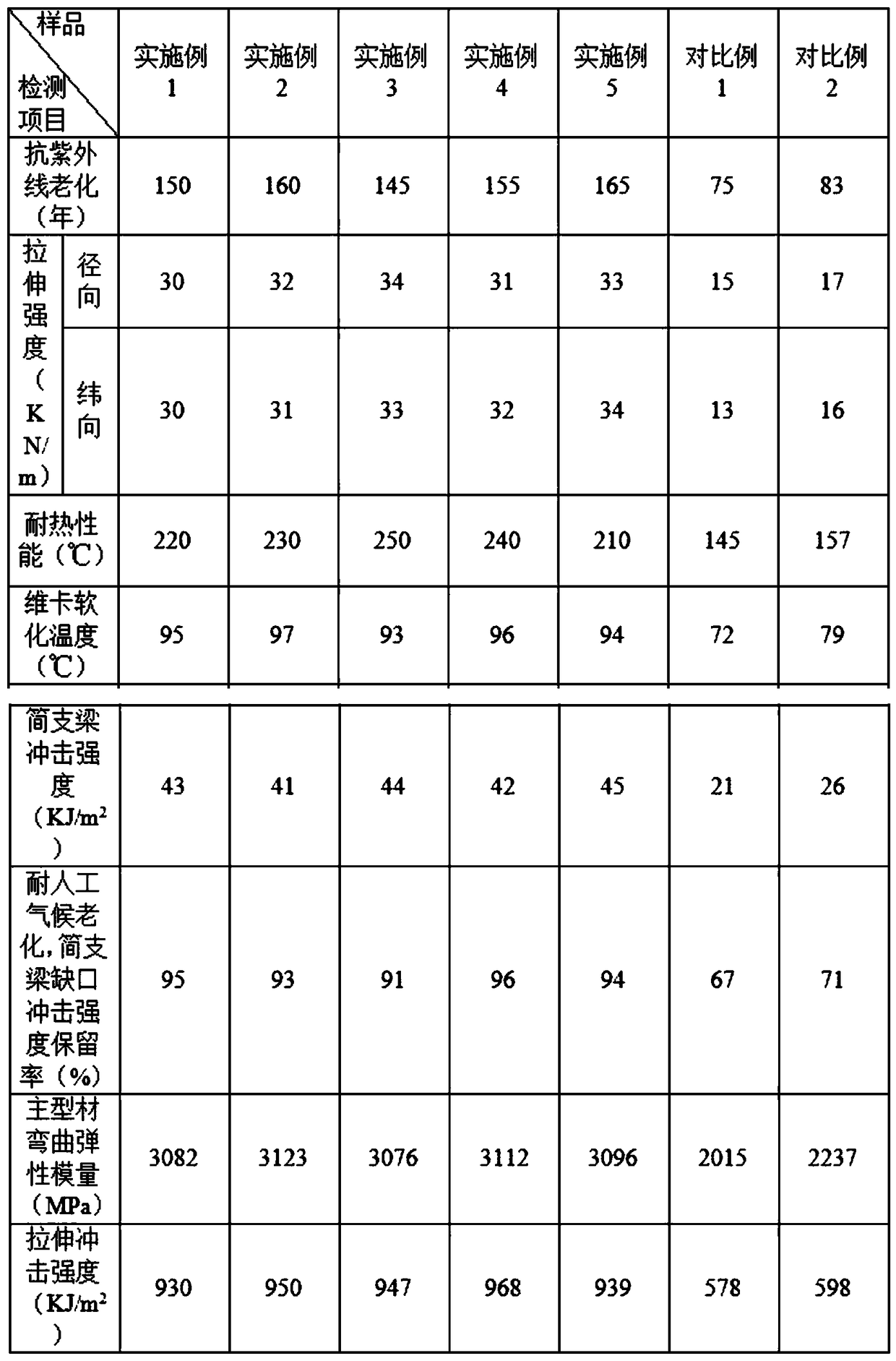

Examples

Embodiment 1

[0055] An environmentally friendly and highly weather-resistant PVC profile granule, the PVC profile granule includes the following components in parts by weight: 80 parts of PVC resin, 2 parts of heat stabilizer, 1 part of auxiliary heat stabilizer, 0.5 part of light stabilizer, auxiliary light stabilizer 0.1 part of anti-oxidant, 0.1 part of ultraviolet light absorber, 0.1 part of antioxidant, 0.1 part of auxiliary antioxidant, 0.1 part of toughening agent and 0.1 part of lubricant.

[0056] The thermal stabilizer in the above-mentioned PVC profile particle raw material is the mixture of zinc stearate, lanthanum salicylate and phosphite, and the mass ratio of zinc stearate, lanthanum salicylate and phosphite in the mixture is 1:0.2: 1; the auxiliary heat stabilizer is stearyl benzoyl methane; the light stabilizer is 2,4-dihydroxybenzophenone; the auxiliary light stabilizer is nano silicon dioxide; the antioxidant is 2,6-ditertiary Butyl-4-cresol; auxiliary antioxidant is cys...

Embodiment 2

[0063] An environmentally friendly and highly weather-resistant PVC profile granule, the PVC profile granule includes the following components in parts by weight: 90 parts of PVC resin, 2.5 parts of heat stabilizer, 1.2 parts of auxiliary heat stabilizer, 0.6 part of light stabilizer, auxiliary light stabilizer 0.2 parts of anti-oxidant, 0.2 parts of ultraviolet light absorber, 0.2 parts of antioxidant, 0.15 parts of auxiliary antioxidant, 0.15 parts of toughening agent and 0.15 parts of lubricant.

[0064] The thermal stabilizer in the above-mentioned PVC profile particle raw material is the mixture of zinc stearate, cerium salicylate and phosphite, and the mass ratio of zinc stearate, cerium salicylate and phosphite in the mixture is 1:0.4: 1.5; the auxiliary heat stabilizer is dibenzoylmethane; the light stabilizer is 2-hydroxyl-4-methoxybenzophenone; the auxiliary light stabilizer is nano silicon dioxide; the antioxidant is four (3,5 Di-tert-butyl-4-hydroxyphenyl) pentaery...

Embodiment 3

[0071] An environmentally friendly and highly weather-resistant PVC profile granule, the PVC profile granule includes the following components in parts by weight: 100 parts of PVC resin, 3 parts of heat stabilizer, 1.4 parts of auxiliary heat stabilizer, 0.7 parts of light stabilizer, auxiliary light stabilizer 0.3 parts of anti-oxidant, 0.3 parts of ultraviolet absorber, 0.3 parts of antioxidant, 0.2 parts of auxiliary antioxidant, 0.2 parts of toughening agent and 0.2 parts of lubricant.

[0072] The thermal stabilizer in the above-mentioned PVC profile particle raw material is the mixture of zinc stearate, lanthanum salicylate and phosphite, and the mass ratio of zinc stearate, lanthanum salicylate and phosphite in the mixture is 1:0.6: 2; the auxiliary heat stabilizer is oleoylbenzoylmethane; the light stabilizer is 2-hydroxy-4-n-octyloxybenzophenone; the auxiliary light stabilizer is nano-silica; Dilauryl propionate; auxiliary antioxidant is phytic acid; ultraviolet absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com