An effective method to control the corrosion rate of magnesium alloy

A corrosion rate, magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems of uncontrollable, too fast corrosion rate of magnesium alloys, etc., and achieve the effect of simple equipment, low cost, and simple processing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Ⅰ), alloy selection

[0022] Use commercial AZ31 wrought magnesium alloy bar, its chemical composition (mass percentage composition) is: 3% Al, 1% Zn, the rest is Mg;

[0023] Ⅱ), deformation processing

[0024] The alloy was hot-extruded at 400°C for 4 hours, and the extrusion ratio was 5:1.

[0025] Ⅲ), stress relief annealing

[0026] The extruded alloy was kept at 400°C for 1 hour, and stress relief annealing was performed to eliminate the influence of residual stress on the corrosion anisotropy of the alloy.

[0027] Ⅴ) Microstructure characterization

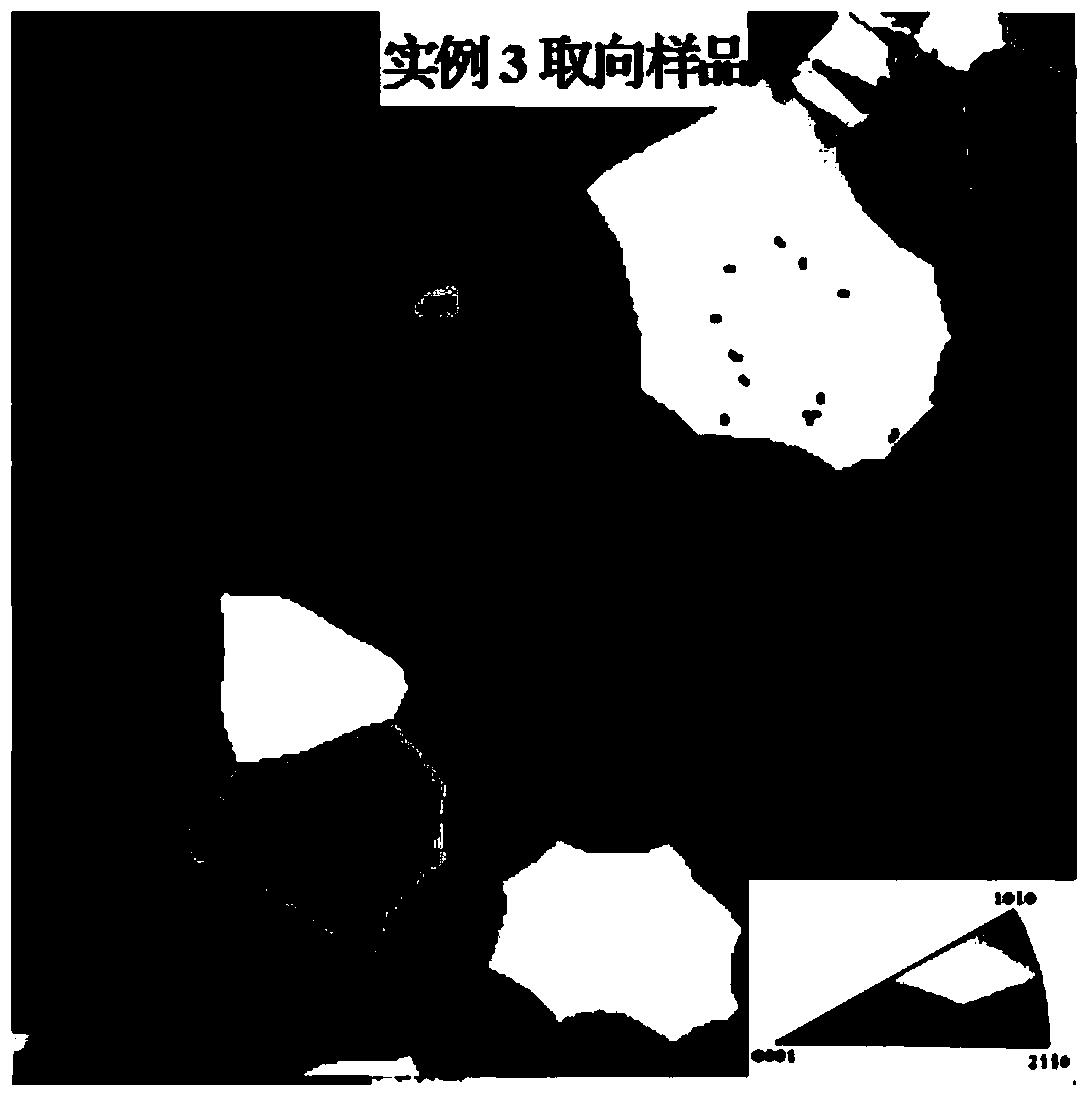

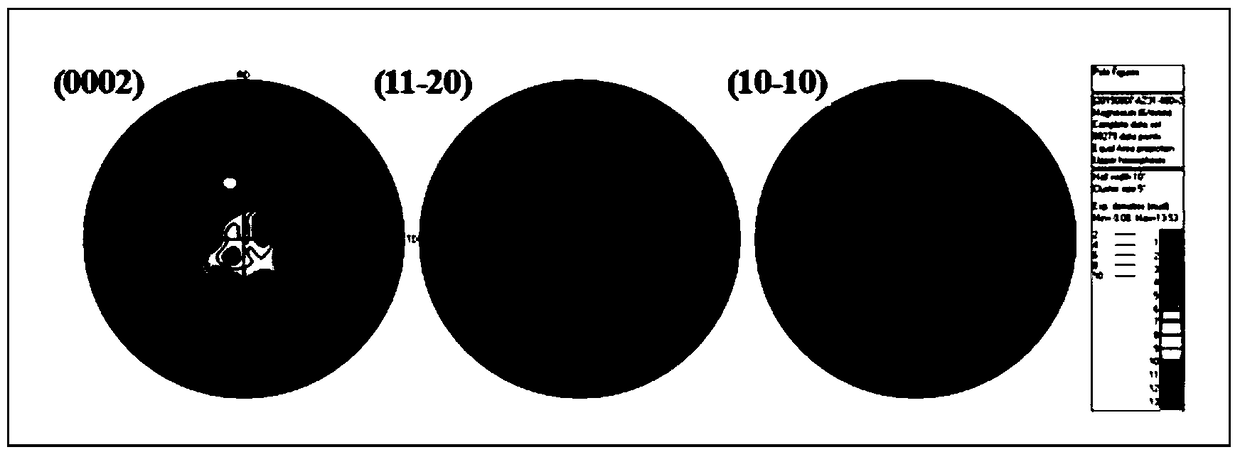

[0028] The preparation process of the sample for microstructure observation is as follows: use No. 1000 silicon carbide water-grinding paper to grind the surface; then use oil-based diamond abrasive paste to mechanically polish; EBSD analysis results show that the texture of the alloy is a typical basal texture, and the corresponding graph and ( 0002), (11-20) and (10-10) pole figures are shown in Figure 1, whic...

Embodiment 2

[0032] Same as Example 1 in that:

[0033] Ⅰ), alloy selection

[0034] Ⅱ), deformation processing

[0035] Ⅲ), stress relief annealing

[0036] Ⅴ) Microstructure characterization

[0037] The difference from Example 1 is:

[0038] Ⅳ), Sampling location and corrosion performance test

[0039] A sample with a size of 5 mm (length) × 5 mm (width) × 3 mm (thickness) was cut by wire cutting, and the surface of the sample was at an angle of 45 degrees to the axis of the extruded rod. The specific orientation diagram is shown in Figure 1. The resin was used for cold mounting, and the surface was polished; then, the sample was placed in a NaCl solution with a molar concentration of 0.1M at room temperature for immersion and electrochemical experiments. The hydrogen collection experiment was carried out under the open circuit potential, and the specific hydrogen evolution curve is shown in the appendix figure 2 . It can be seen that the hydrogen evolution rate of the oriented ...

Embodiment 3

[0041] Same as Example 1 in that:

[0042] Ⅰ), alloy selection

[0043] Ⅱ), deformation processing

[0044] Ⅲ), stress relief annealing

[0045] Ⅴ) Microstructure characterization

[0046] The difference from Example 1 is:

[0047] Ⅳ), Sampling location and corrosion performance test

[0048]Use wire cutting to cut a sample with a size of 5mm (length) × 5mm (width) × 3mm (thickness). The surface of the sample is in the center layer of the extruded bar and parallel to the axis of the extruded bar. The specific orientation diagram is shown in the attached drawing 1. The resin was used for cold mounting, and the surface was polished; then, the sample was placed in a NaCl solution with a molar concentration of 0.1M at room temperature for immersion and electrochemical experiments. The hydrogen collection experiment was carried out under the open circuit potential, and the specific hydrogen evolution curve is shown in the appendix figure 2 . It can be seen that the hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com