Processing technology for double-faced antistatic coating film

A processing technology and anti-static technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of uneven surface coating, poor anti-static effect of anti-static coating film, etc., to save the substrate, Good effect, good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

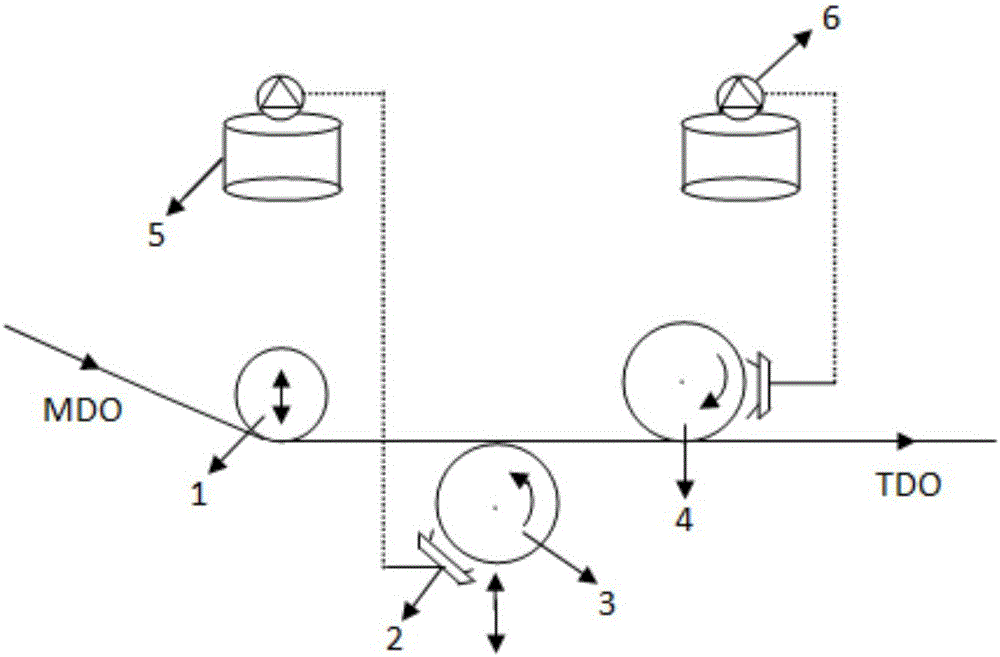

[0041] The processing technology of a double-sided antistatic coating film is shown in the accompanying drawing. The material film stretched 3.0 times by MDO and with a thickness of 75 μm passes through the guide roller 1 and first contacts with the coating roller Ⅰ3 for single-sided coating, and then with the coating Cloth roll II4 is in contact with the other side for coating, and finally preheated and stretched at TDO 105°C for 3.8 times to obtain a double-sided antistatic coating film; coating roll I3 and coating roll II4 are gravure rolls, coating roll I3 and coating The diameter of the roller II4 is 300mm, and the coating roller I3 and the coating roller II4 are respectively located in different coating chambers 2, and the horizontal center distance between the coating roller I3 and the coating roller II4 is 75mm, and the coating roller I3 and the coating roller The rotation direction of the cloth roller II4 is opposite to the feeding direction of the material film. The c...

Embodiment 2

[0044] A processing technology of double-sided antistatic coating film, the material film stretched 3.1 times by MDO and with a thickness of 75 μm is firstly contacted with coating roll I for one-sided coating through the guide roll, and then contacted with coating roll II for the other Coating on one side, and finally preheating and stretching at TDO107°C for 3.85 times to obtain a double-sided antistatic coating film; coating roll I and coating roll II are gravure rolls, and the diameter of coating roll I and coating roll II is 310mm. Coating roller Ⅰ and coating roller Ⅱ are respectively located in different coating chambers, the horizontal center distance between coating roller Ⅰ and coating roller Ⅱ is 62mm, and the rotation direction of coating roller Ⅰ and coating roller Ⅱ is the same as that of the material film The material feeding direction is opposite, the coating liquid in the middle tank enters the coating chamber through the pump and is scraped on the coating roll...

Embodiment 3

[0047] A processing technology for double-sided antistatic coating film. The material film stretched 3.3 times by MDO and with a thickness of 75 μm is firstly contacted with coating roll I for one-sided coating through the guide roll, and then contacted with coating roll II for the other side. Coating on one side, and finally preheating and stretching at TDO110°C for 3.9 times to obtain a double-sided antistatic coating film; coating roll I and coating roll II are gravure rolls, and the diameter of coating roll I and coating roll II is 320mm. Coating roller Ⅰ and coating roller Ⅱ are located in different coating chambers, the horizontal center distance between coating roller Ⅰ and coating roller Ⅱ is 80mm, and the rotation direction of coating roller Ⅰ and coating roller Ⅱ is in line with the material film The material feeding direction is opposite, the coating liquid in the middle tank enters the coating chamber through the pump and is scraped on the coating roller I and coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com