Heat treatment process for inhibiting plastic instability of quasi-crystal reinforced magnesium lithium alloys

A magnesium-lithium alloy and plastic instability technology, applied in the field of magnesium-lithium alloys, can solve the problems of plastic deformation and instability of magnesium-lithium alloys, and achieve the effects of high yield and tensile strength, and simple processing and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, the heat treatment method for suppressing the plastic instability of the quasicrystal-strengthened magnesium-lithium alloy mainly includes the following steps:

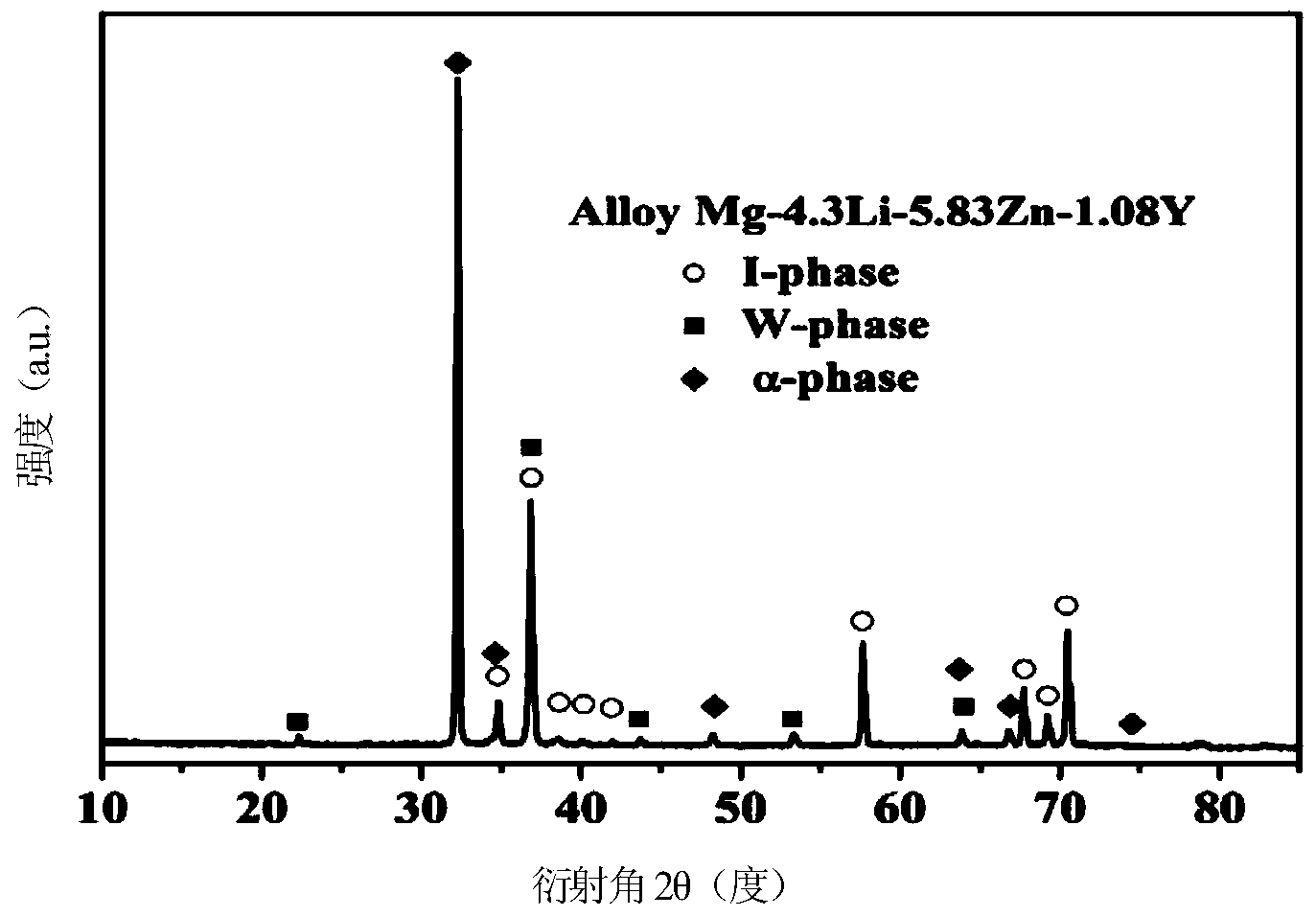

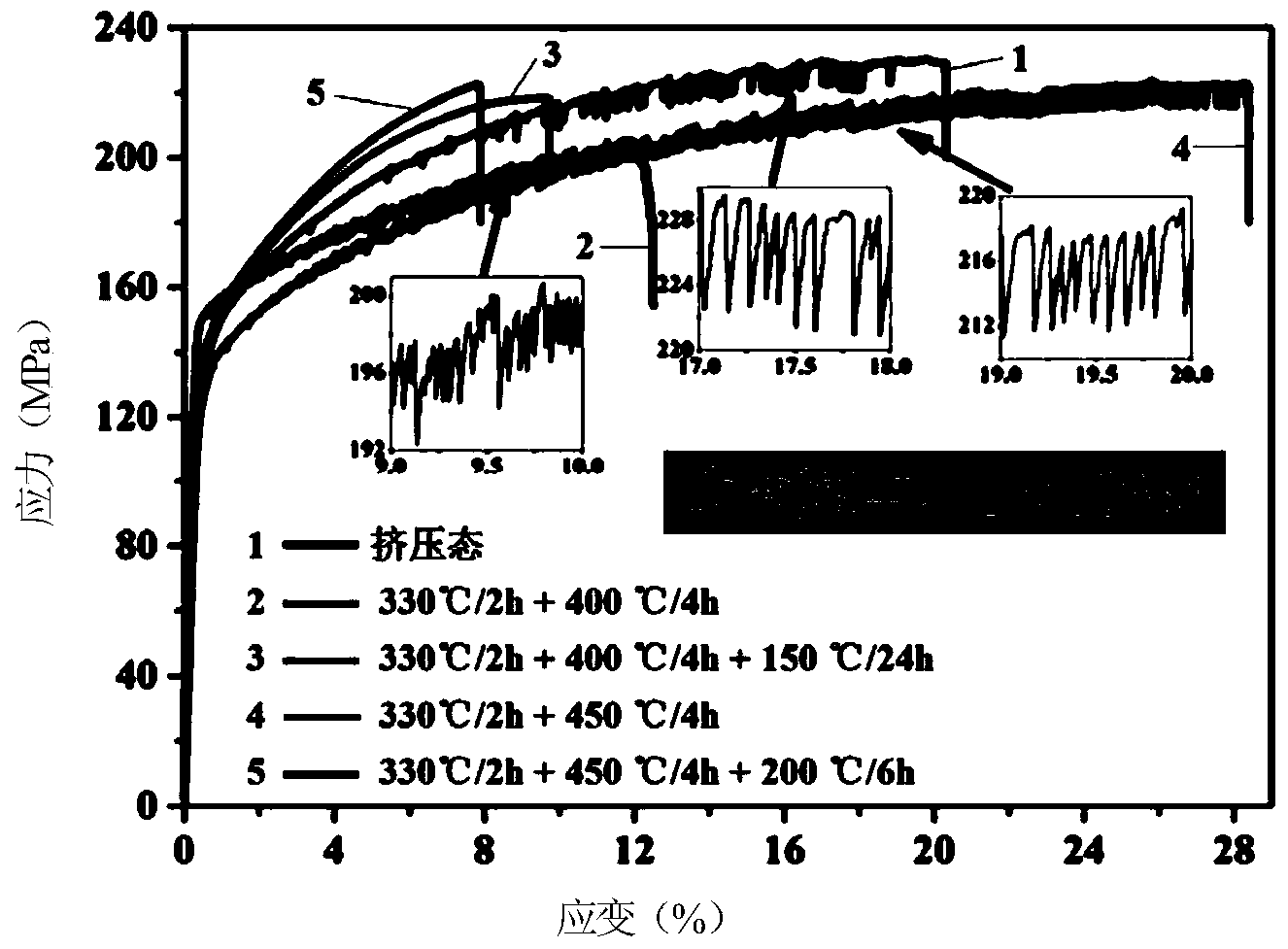

[0022] Ⅰ), the magnesium-lithium alloy composition that adopts: use extruded state quasi-crystal strengthened Mg-Li-Zn-Y magnesium alloy, its chemical composition (weight percentage content) is: 4.3% Li, 5.83% Zn, 1.08% Y, The rest is Mg; the room temperature tensile properties of the extruded quasicrystalline strengthened Mg-Li-Zn-Y magnesium alloy are shown in the curve 1 of Figure 2(a), and its performance index is: the sawtooth amplitude fluctuation range is between 4 and 8 MPa .

[0023] Ⅱ) Solid solution treatment process: tightly wrap the extruded quasicrystalline strengthened magnesium alloy sheet with aluminum foil, solid solution at 330°C for 2 hours, then raise the temperature to 400°C, keep it warm for 4 hours, and cool it to room temperature by water quenching. The tensile perf...

Embodiment 2

[0030] The difference from Example 1 is:

[0031] Ⅰ), alloy composition

[0032] With reference to the composition ratio of Example 1, the room temperature tensile properties of the extruded state quasicrystalline strengthened Mg-Li-Zn-Y magnesium alloy are shown in the curve 1 of Fig. 2 (a), and its performance index is: the sawtooth amplitude fluctuation range is Between 4 ~ 8MPa.

[0033] Ⅱ), solid solution treatment process

[0034] The extruded quasicrystalline strengthened magnesium alloy sheet is tightly wrapped with aluminum foil, solidified at 330°C for 2 hours, then the temperature is raised to 450°C, kept for 4 hours, and cooled to room temperature by water quenching. The tensile performance at room temperature is shown in the curve 4 of Figure 2(a), and its performance index is: the sawtooth amplitude fluctuation range is between 4 and 6 MPa.

[0035] Ⅲ), aging treatment process

[0036] The magnesium alloy after solution treatment was aged at 200° C. for 6 hou...

Embodiment 3

[0042] The difference from Example 1 is:

[0043] Ⅰ), alloy composition

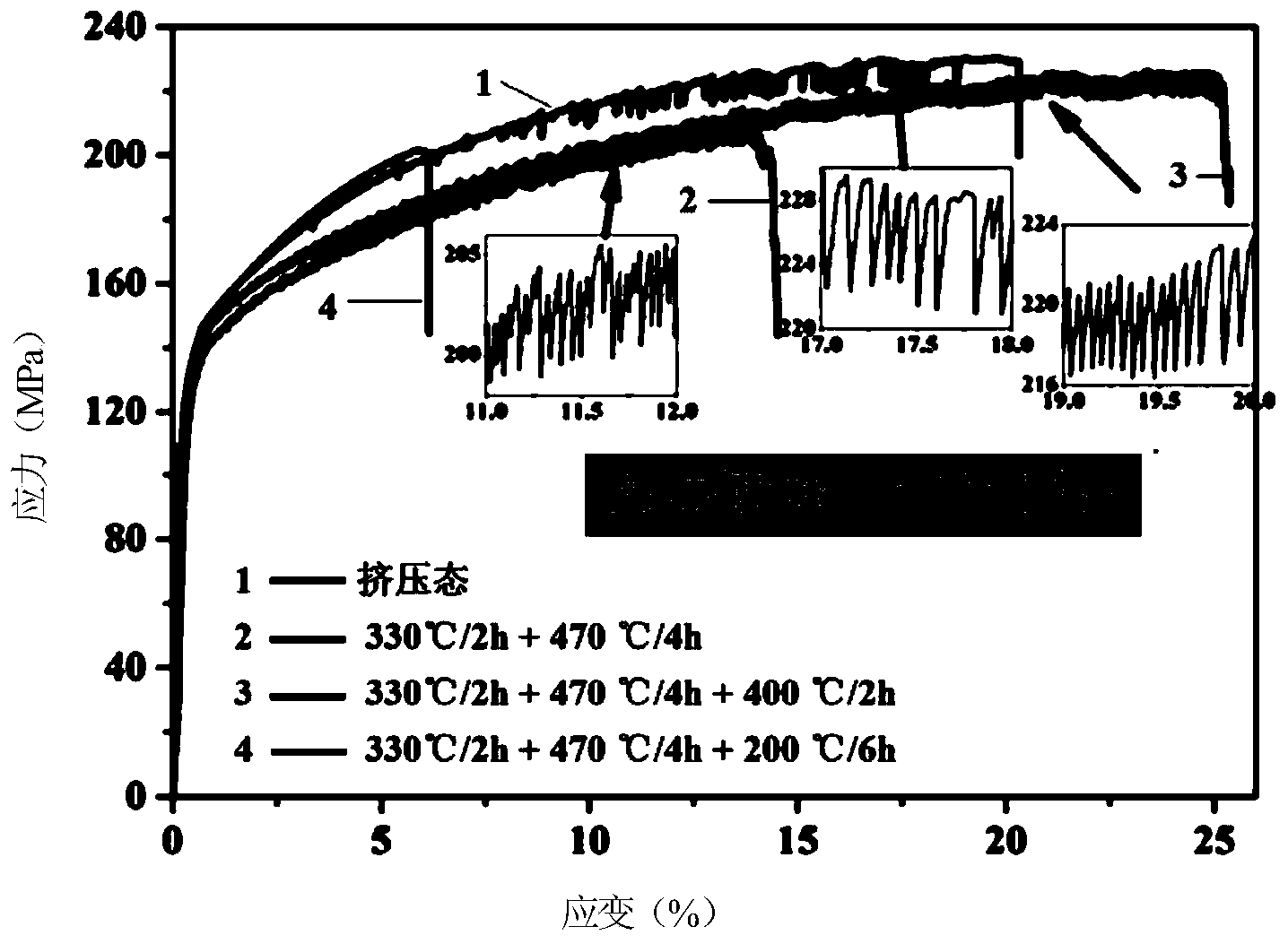

[0044] With reference to the composition ratio of Example 1, the room temperature tensile properties of the extruded state quasicrystalline strengthened Mg-Li-Zn-Y magnesium alloy are shown in curve 1 of Fig. 2 (b), and its performance index is: the sawtooth amplitude fluctuation range is Between 4 ~ 8MPa.

[0045] Ⅱ), solid solution treatment process

[0046] The extruded quasicrystalline strengthened magnesium alloy sheet is tightly wrapped with aluminum foil, solid solutioned at 330°C for 2 hours, then the temperature is raised to 470°C, kept for 4 hours, and cooled to room temperature by water quenching. The tensile performance at room temperature is shown in the curve 2 of Figure 2(b), and its performance index is: the sawtooth amplitude fluctuation range is between 2 and 5 MPa.

[0047] Alternatively, the solution treated magnesium alloy is aged at 400° C. for 2 hours, and then water quenched to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com