A heat treatment process for suppressing the plastic instability of quasicrystal-strengthened magnesium-lithium alloys

A magnesium-lithium alloy, plastic instability technology, applied in the field of magnesium-lithium alloy, can solve the problems of magnesium-lithium alloy plastic deformation and instability, achieve high yield and tensile strength, eliminate the problem of plastic deformation and instability, and eliminate chemical composition instability The effect of the uniform area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, the heat treatment method for suppressing the plastic instability of the quasicrystal-strengthened magnesium-lithium alloy mainly includes the following steps:

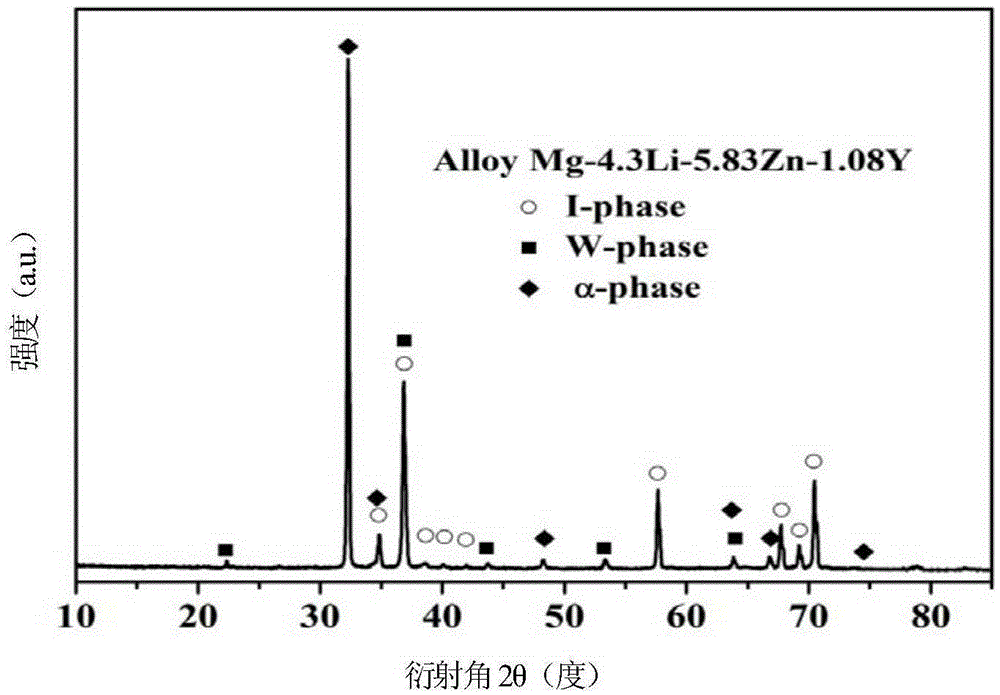

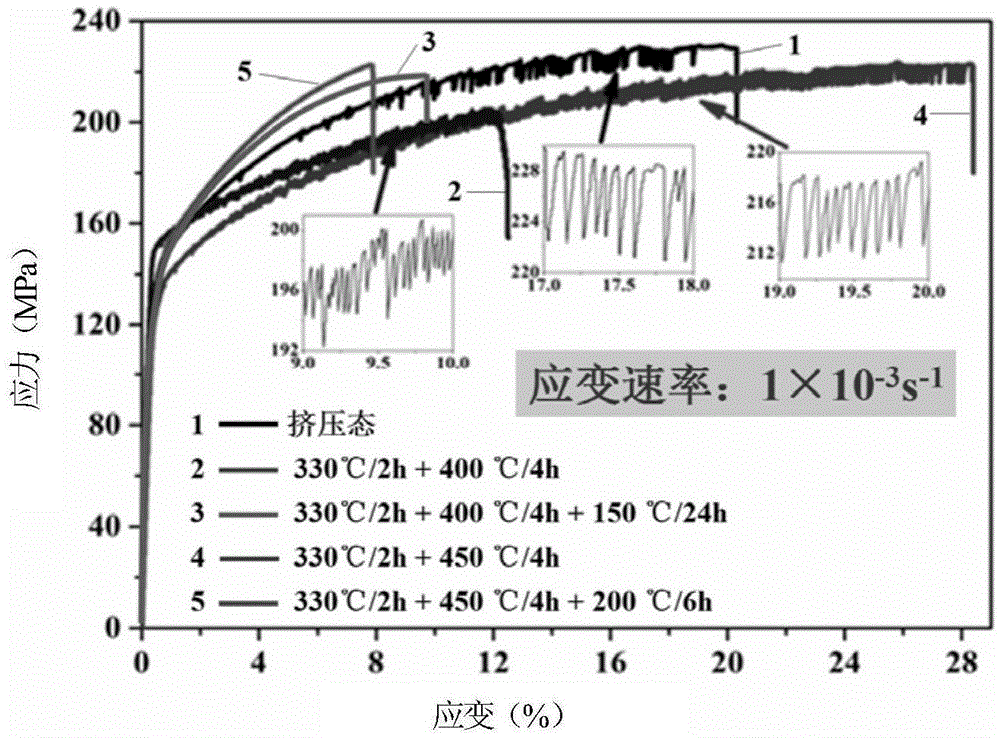

[0022] Ⅰ), the magnesium-lithium alloy composition that adopts: use extruded state quasi-crystal strengthened Mg-Li-Zn-Y magnesium alloy, its chemical composition (weight percentage content) is: 4.3% Li, 5.83% Zn, 1.08% Y, The rest is Mg; the room temperature tensile properties of the extruded quasicrystalline strengthened Mg-Li-Zn-Y magnesium alloy are shown in the curve 1 of Figure 2(a), and its performance index is: the sawtooth amplitude fluctuation range is between 4 and 8 MPa .

[0023] Ⅱ) Solid solution treatment process: tightly wrap the extruded quasicrystalline strengthened magnesium alloy sheet with aluminum foil, solid solution at 330°C for 2 hours, then raise the temperature to 400°C, keep it warm for 4 hours, and cool it to room temperature by water quenching. The tensile perf...

Embodiment 2

[0030] The difference from Example 1 is:

[0031] Ⅰ), alloy composition

[0032] With reference to the composition ratio of Example 1, the room temperature tensile properties of the extruded state quasicrystalline strengthened Mg-Li-Zn-Y magnesium alloy are shown in the curve 1 of Fig. 2 (a), and its performance index is: the sawtooth amplitude fluctuation range is Between 4 ~ 8MPa.

[0033] Ⅱ), solid solution treatment process

[0034] The extruded quasicrystalline strengthened magnesium alloy sheet is tightly wrapped with aluminum foil, solidified at 330°C for 2 hours, then the temperature is raised to 450°C, kept for 4 hours, and cooled to room temperature by water quenching. The tensile performance at room temperature is shown in the curve 4 of Figure 2(a), and its performance index is: the sawtooth amplitude fluctuation range is between 4 and 6 MPa.

[0035] Ⅲ), aging treatment process

[0036] The magnesium alloy after solution treatment was aged at 200° C. for 6 hou...

Embodiment 3

[0042] The difference from Example 1 is:

[0043] Ⅰ), alloy composition

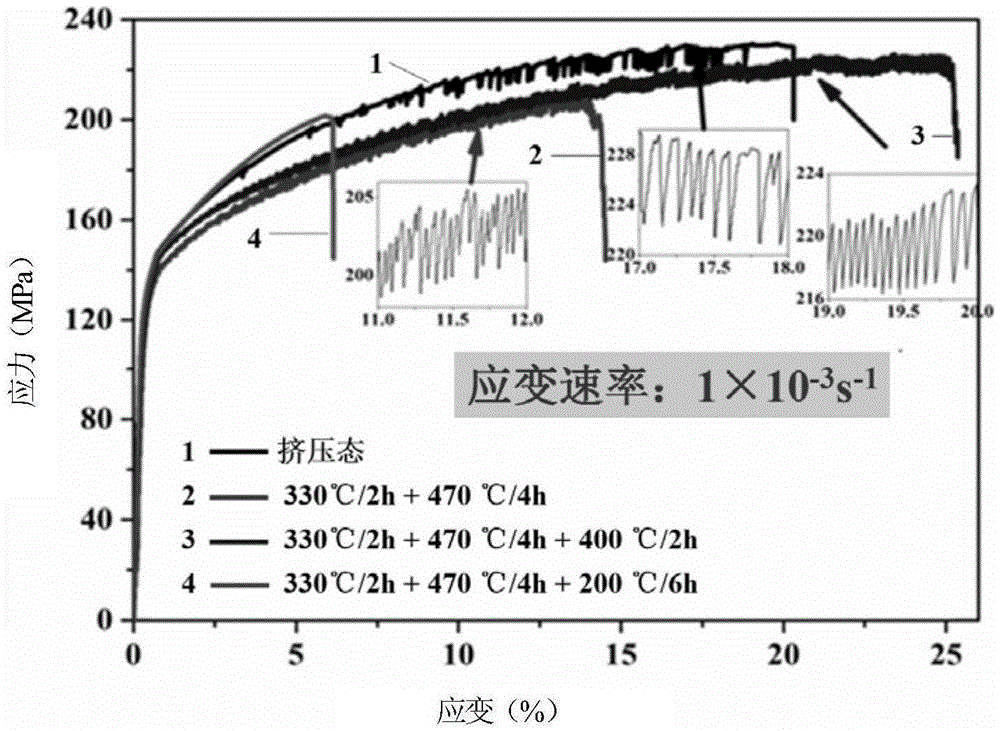

[0044] With reference to the composition ratio of Example 1, the room temperature tensile properties of the extruded state quasicrystalline strengthened Mg-Li-Zn-Y magnesium alloy are shown in curve 1 of Fig. 2 (b), and its performance index is: the sawtooth amplitude fluctuation range is Between 4 ~ 8MPa.

[0045] Ⅱ), solid solution treatment process

[0046] Wrap the extruded quasicrystalline strengthened magnesium alloy sheet tightly with aluminum foil, solid solution at 330°C for 2 hours, then raise the temperature to 470°C, keep it warm for 4 hours, and cool it to room temperature by water quenching. The tensile performance at room temperature is shown in the curve 2 of Figure 2(b), and its performance index is: the sawtooth amplitude fluctuation range is between 2 and 5 MPa.

[0047] Alternatively, the solution treated magnesium alloy is aged at 400° C. for 2 hours, and then water quenched to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com