Integrated bevel gear machining method

A processing method and bevel gear technology, applied in the field of gear manufacturing, can solve the problems of reduced production efficiency, cumbersome processing, and precision errors, and achieve the effects of improving productivity, ensuring overall precision, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

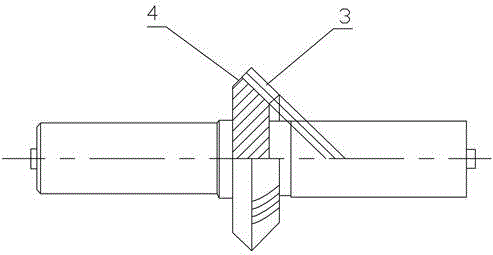

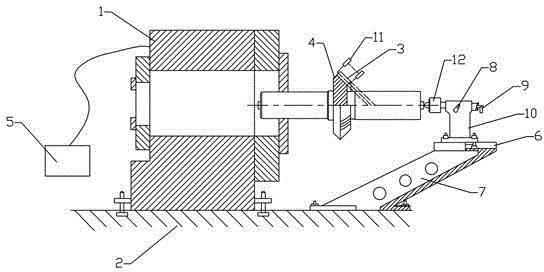

[0039] Such as figure 1 , figure 2 The specific embodiment of the processing method of integral bevel gear of the present invention is shown, comprising the following steps:

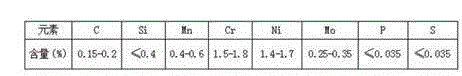

[0040] A. Material preparation: forging blank, forging ratio = 4, provide material report and flaw detection report, heat the blank to 930°C for 3 hours after normalizing, cool it to room temperature in the air, and then heat it to 680°C for 3 hours. Finally, the resulting workpiece is cooled to room temperature in air;

[0041] B. Drill the center hole at both ends of the blank forged in step A, and select the B5 center hole;

[0042] C. Rough turning: Clamp the workpiece obtained in step B on the lathe, turn the outer circle of each step of the workpiece with the turning tool, and remove the oxide skin on the surface of the workpiece, and keep it to the maximum size;

[0043] D. Flaw detection: The workpiece after rough turning in step C is subjected to ultrasonic flaw detection, so that the workpi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com