Heat treatment process to improve the performance of long-range structural ordered phase strengthened dual-phase magnesium-lithium alloy

A technology of orderly structure and magnesium-lithium alloy, applied in the field of heat treatment process, can solve the problems of corrosion and the reduction of alloy corrosion rate, and achieve the effects of simple equipment, improved strength and plasticity, and high corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Ⅰ), the composition of the magnesium-lithium alloy used

[0023] The as-cast long-range structure ordered phase is used to strengthen the dual-phase Mg-Li-Zn-Y alloy, and its chemical composition (mass percentage content) is: lithium content is 8%; zinc content is 3%; yttrium content is 6%; magnesium margin.

[0024] Ⅱ), alloy smelting

[0025] The alloy is smelted in a vacuum smelting furnace under the protection of argon, and after being kept at 770°C for 2 hours, it is cast in the furnace.

[0026] Ⅲ), solid solution treatment

[0027] The as-cast long-range structural ordered phase strengthened dual-phase Mg-Li-Zn-Y alloy was kept at 400°C for 2 hours.

[0028] Ⅴ) Microstructure characterization

[0029] The preparation process of the sample for tissue observation is as follows: use No. 1000 silicon carbide water abrasive paper to grind the surface, and then use oil-based diamond grinding paste to mechanically polish; SEM observation results show that before the...

Embodiment 2

[0033] Same as Example 1 in that:

[0034] Ⅰ), the composition of the magnesium-lithium alloy used

[0035] Ⅱ), alloy smelting

[0036] The difference from Example 1 is:

[0037] Ⅲ), solid solution treatment

[0038] The as-cast long-range structural ordered phase strengthened dual-phase Mg-Li-Zn-Y alloy was kept at 400°C for 4 hours.

[0039] Ⅴ) Microstructure characterization

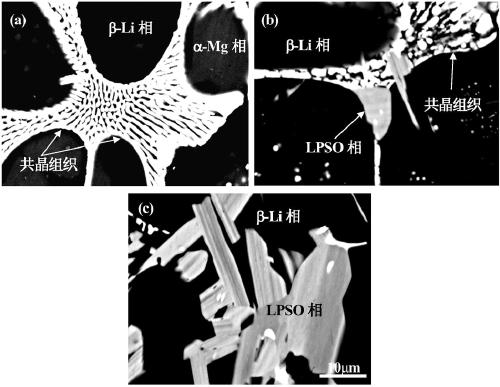

[0040] Refer to the tissue observation method of Example 1. After solution treatment, the alloy phases in the sample of Example 2 are LPSO phase, residual dendritic eutectic structure, β-Li and α-Mg matrix phase magnesium matrix, and the corresponding photos are shown in the attached figure 2 . It is worth noting that in order to reflect the existence of the LPSO phase and the residual dendrite eutectic structure, the observation magnification is high, and the α-Mg matrix phase cannot be included in the photo.

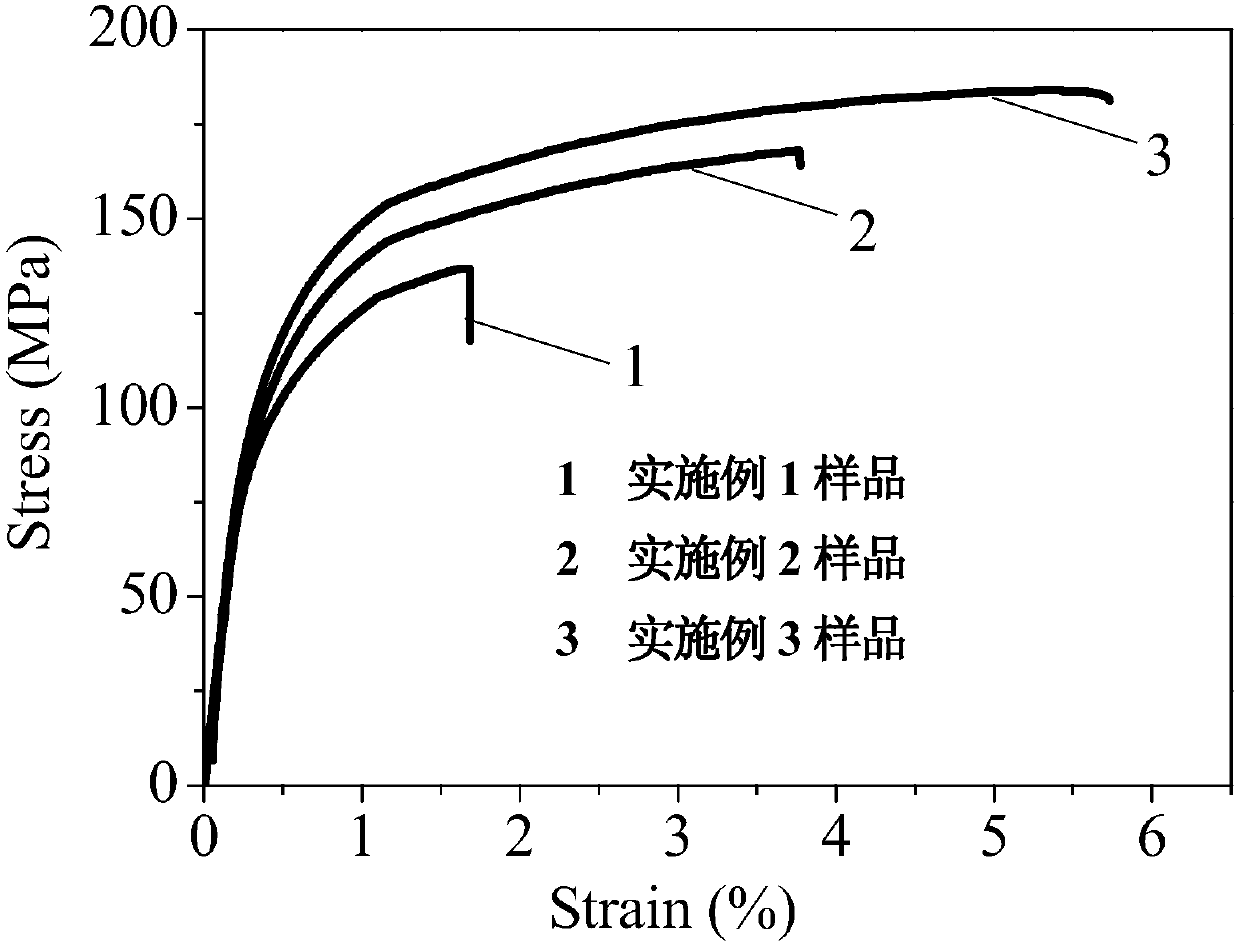

[0041] Ⅳ), corrosion and mechanical properties test

[0042] Refer to the corrosion...

Embodiment 3

[0044] Same as Example 1 in that:

[0045] Ⅰ), the composition of the magnesium-lithium alloy used

[0046] Ⅱ), alloy smelting

[0047] The difference from Example 1 is:

[0048] Ⅲ), solid solution treatment

[0049] The as-cast long-range structural ordered phase strengthened dual-phase Mg-Li-Zn-Y alloy was kept at 400°C for 8 hours.

[0050] Ⅴ) Microstructure characterization

[0051] Refer to the tissue observation method of Example 1. After solution treatment, the alloy phases in the sample of Example 3 are LPSO phase, β-Li and α-Mg matrix phases, and the corresponding photos are shown in the attached figure 1 . It is worth noting that in order to reflect the existence of the LPSO phase, the observation magnification is high, and the α-Mg matrix phase cannot be included in the photo.

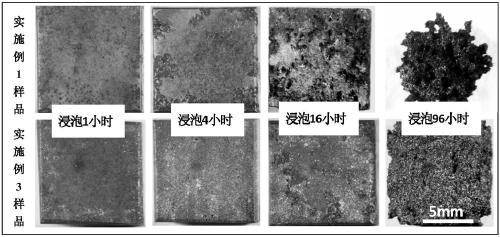

[0052] Ⅳ), corrosion and mechanical properties test

[0053] Refer to the corrosion and mechanical property test method of Example 1. After solid solution treatment, the corrosion p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com