Candle processing technology and demolding device

A technology of processing technology and demoulding device, which is applied to candle preparation devices, candles, and fatty acid production, etc., can solve the problems of poorly controlled air pressure, the candle body flying out of the mold, and damage, etc., and achieves easy operation and processing of the processing technology. The effect of simple process and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The present invention will be described in further detail below in conjunction with the accompanying drawings.

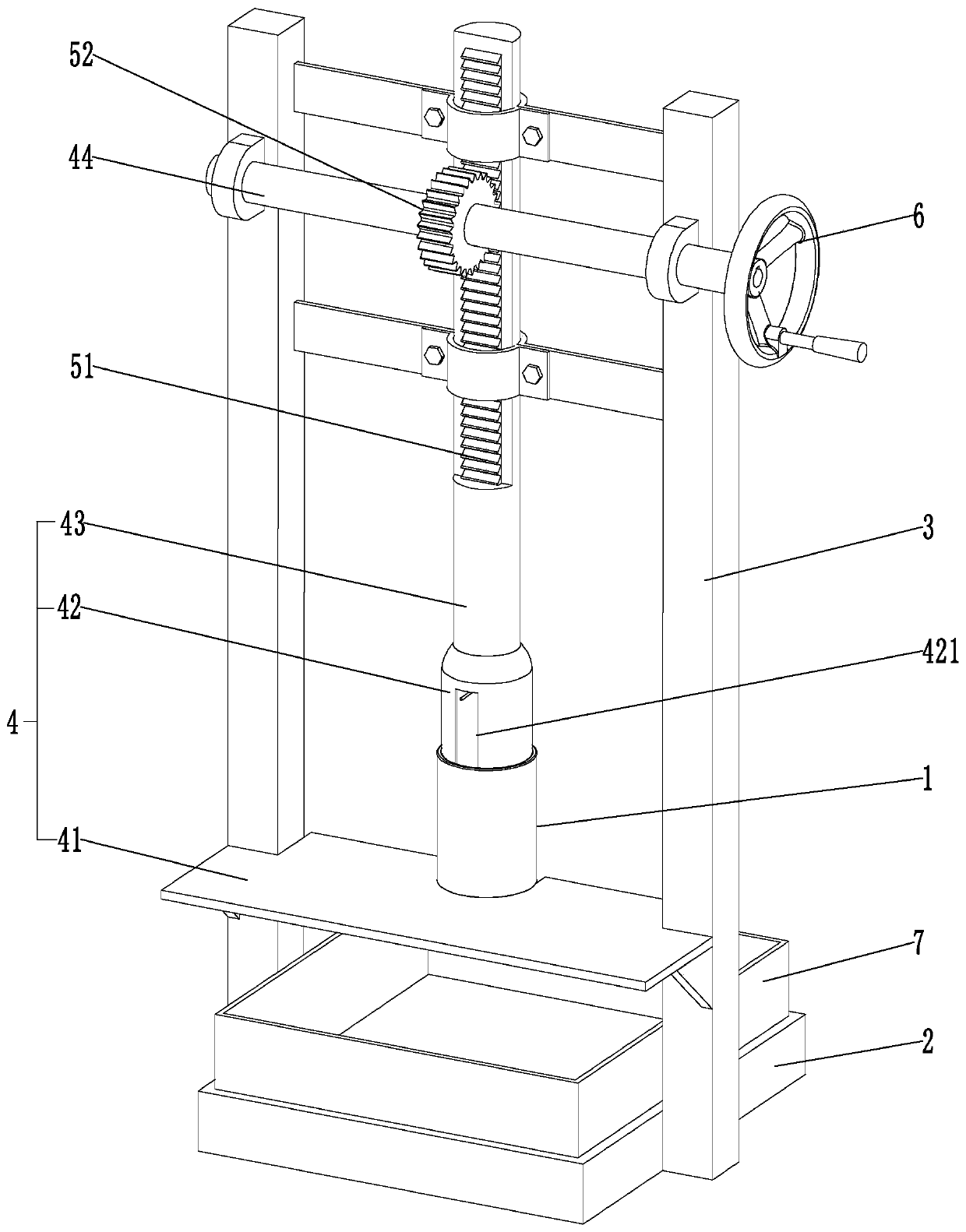

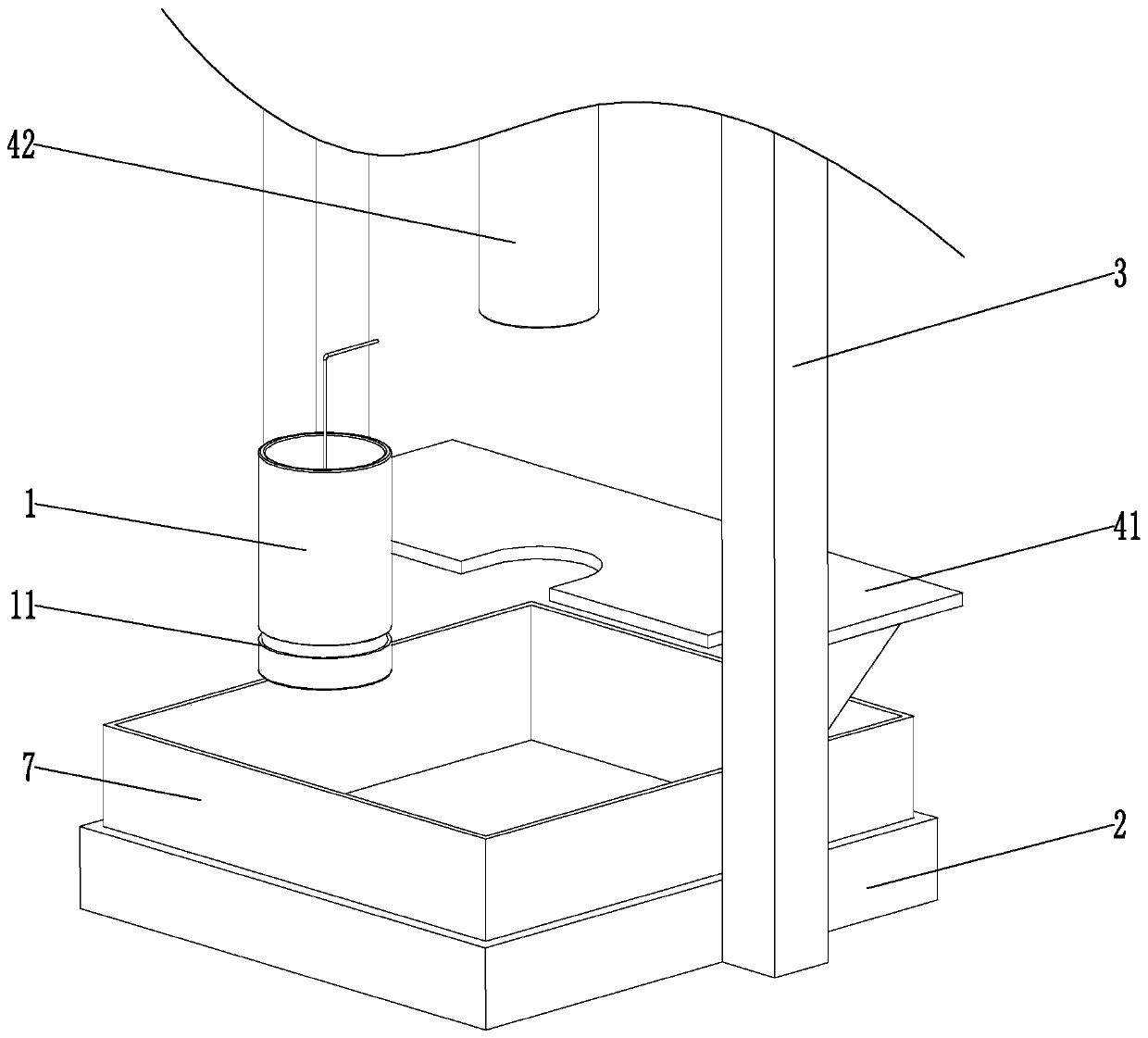

[0047] refer to figure 1 , is a candle demoulding device disclosed in the present invention, comprising a base 2, a support frame 3 arranged on the base 2, and a mold-taking mechanism 4 arranged on the support frame 3. Connected sequentially from bottom to top, the support frame 3 plays a supporting role, supports the mold taking mechanism 4, places the mold 1 in the mold taking mechanism 4, and takes out the candle body from the mold 1.

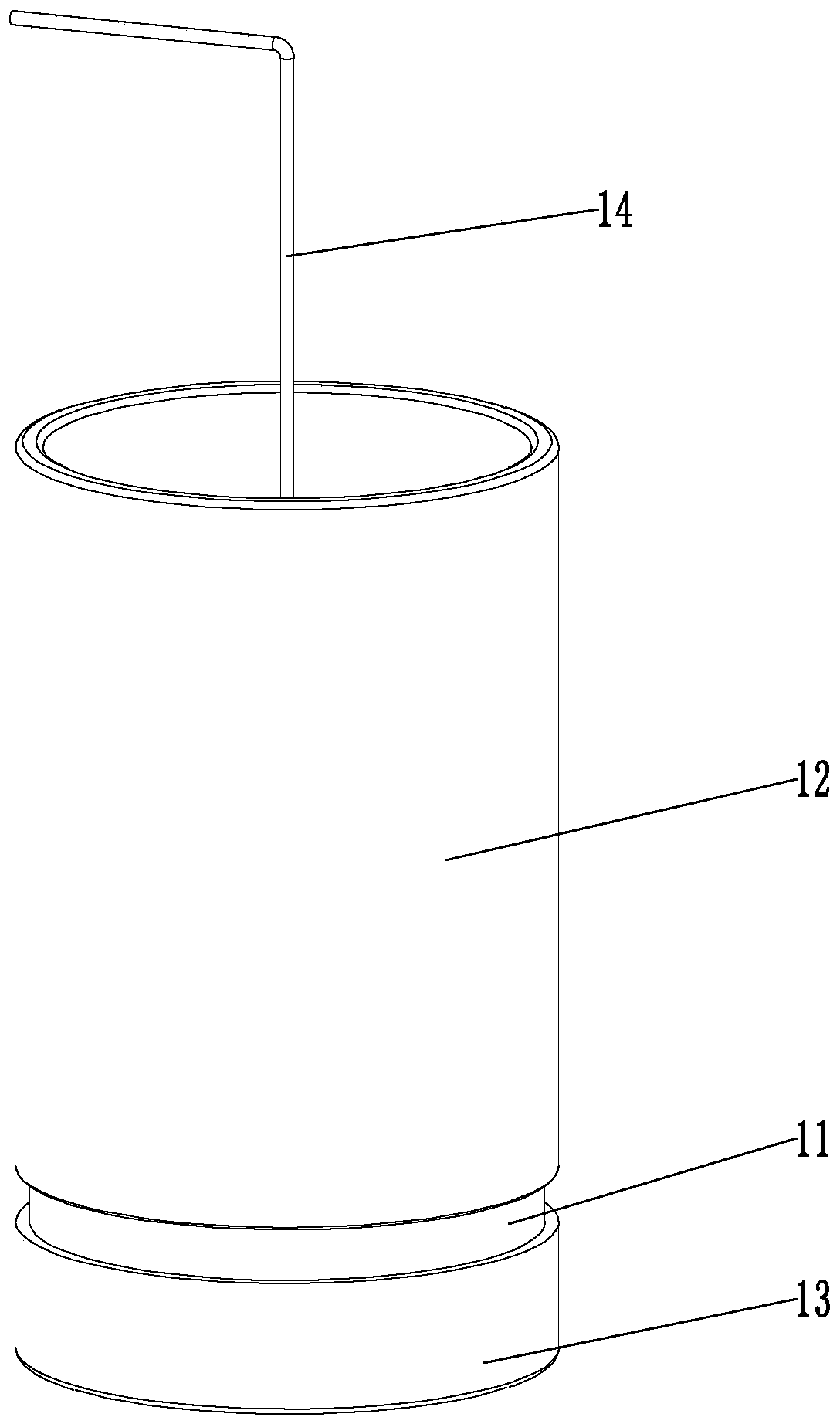

[0048] refer to figure 2 , the mold 1 includes a cylinder body 12, a bottom support 13 detachably connected to the lower end of the cylinder body 12 and a piercing rod 14 arranged in the cylinder body 12, the piercing rod 14 is directly placed inside the cylinder body 12, and When pouring raw materials in 12 , insert the through rod 14 into the cylinder 12 and insert it to the center along the axis direction of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com