Low-alloyed degradable miniature inner fixed assembly, magnesium alloy preparation method and magnesium alloy material

A technology of fixing components and magnesium alloys, applied in the direction of fixators, fastening devices, internal bone synthesis, etc., can solve the adverse effects of cell proliferation and osseointegration around bone screws, aggravated corrosion of pure magnesium, and decreased mechanical properties of bone screws, etc. problems, to achieve the effect of solving the problem of galvanic corrosion, low impurity content and low alloying element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

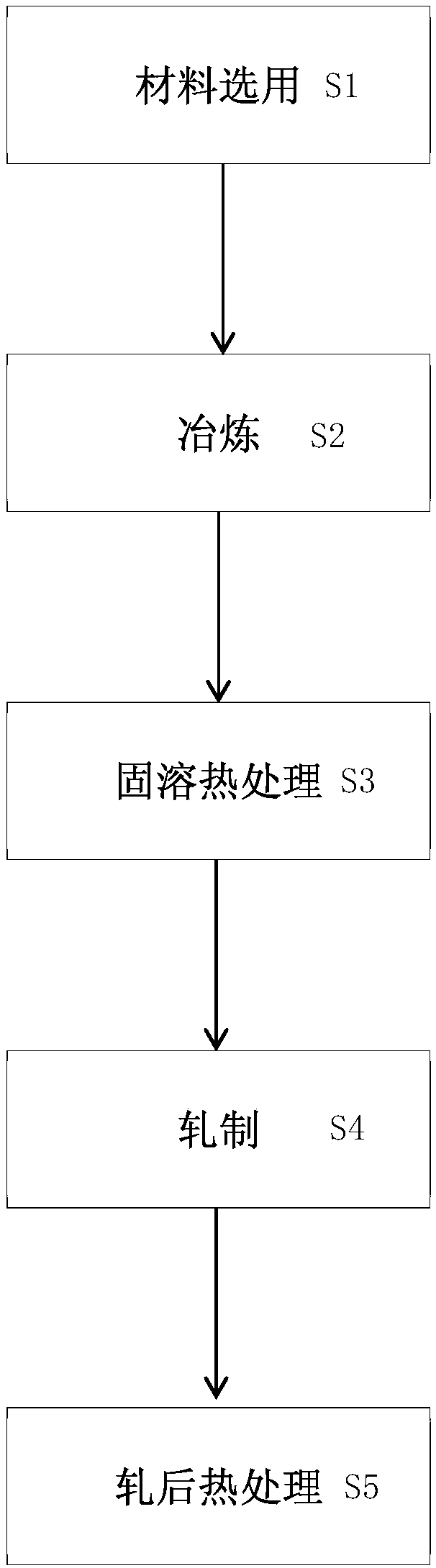

[0044] Such as figure 1 As shown, the present invention is a low-alloy degradable miniature internal fixation component, a magnesium alloy preparation method and a magnesium alloy material. The preparation method of the magnesium alloy includes material selection S1, smelting S2, solution heat treatment S3, rolling S4, post-rolling heat treatment S5 and other steps.

[0045] Material selection step S1: using pure magnesium ingot with a purity greater than 99.99% as the magnesium raw material, using zinc particles with a purity greater than 99.9% as the zinc raw material, and using a magnesium-calcium master alloy with a purity greater than 99.99% as the calcium raw material to prepare calcium (Ca) The mass fraction is 0.01% to 0.1%, the mass fraction of zinc (Zn) is 0.8% to 2.5%, the rest is magnesium, the individual content of aluminum, iron, copper, manganese, silicon, nickel and other impurities does not exceed 0.005%, and the total content of impurities does not exceed 0.0...

Embodiment 1

[0058] First carry out raw material configuration according to the following alloy raw materials: magnesium ingot with a purity greater than 99.99% as the magnesium raw material, magnesium-5.97% calcium master alloy (Mg-Ca) master alloy with a purity greater than 99.99% as the calcium raw material, zinc with a purity greater than 99.9% pellets as zinc raw material.

[0059] The smelting process is as follows: clean the pure magnesium ingot and the Mg-Ca master alloy in a 5% hydrochloric acid ethanol solution to remove the surface oxide layer, dry them under an argon protective atmosphere, put them into a graphite crucible, and pure zinc particles Place in secondary hopper. Vacuumize until the vacuum degree of the vacuum furnace is lower than 0.01Pa, then fill it with high-purity argon until the vacuum pressure gauge shows -0.03MPa, then carry out two times of filling and washing the furnace, and then heat the raw materials in the crucible, after the magnesium ingot and the int...

Embodiment 2

[0071] First carry out raw material configuration according to the following alloy raw materials: magnesium ingot with a purity greater than 99.99% is used as a magnesium raw material, a magnesium-2.6% calcium master alloy (Mg-Ca) master alloy with a purity greater than 99.99% is used as a calcium raw material, and zinc with a purity greater than 99.9% pellets as zinc raw material.

[0072] The smelting process is as follows: clean the pure magnesium ingot and (Mg-Ca) master alloy in a 5% hydrochloric acid ethanol solution to remove the surface oxide layer, dry it under an argon protective atmosphere, put it into a graphite crucible, and pure The zinc pellets are put into the secondary feeding hopper. Vacuumize until the vacuum degree of the vacuum furnace is lower than 0.01Pa, then fill it with high-purity argon until the vacuum pressure gauge shows -0.03MPa, then carry out two times of filling and washing the furnace, and then heat the raw materials in the crucible, after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com