Ultralow carbon copper-containing automobile high-strength cold-rolled steel plate and manufacturing method thereof

A technology of cold-rolled steel sheet and manufacturing method, which is applied in the field of ultra-low carbon copper-containing high-strength cold-rolled steel sheet for automobiles and its heat treatment, can solve the problems of increasing steel cost and the like, so as to reduce smelting cost, save gas cost and reduce smelting difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

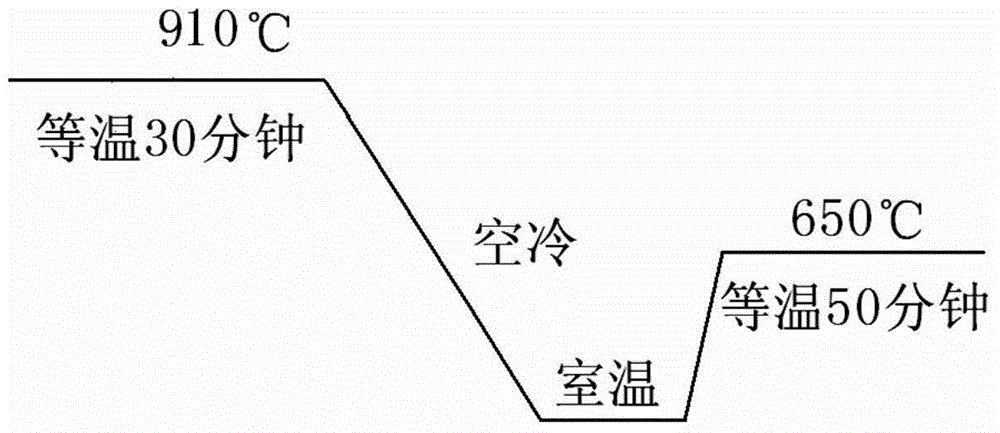

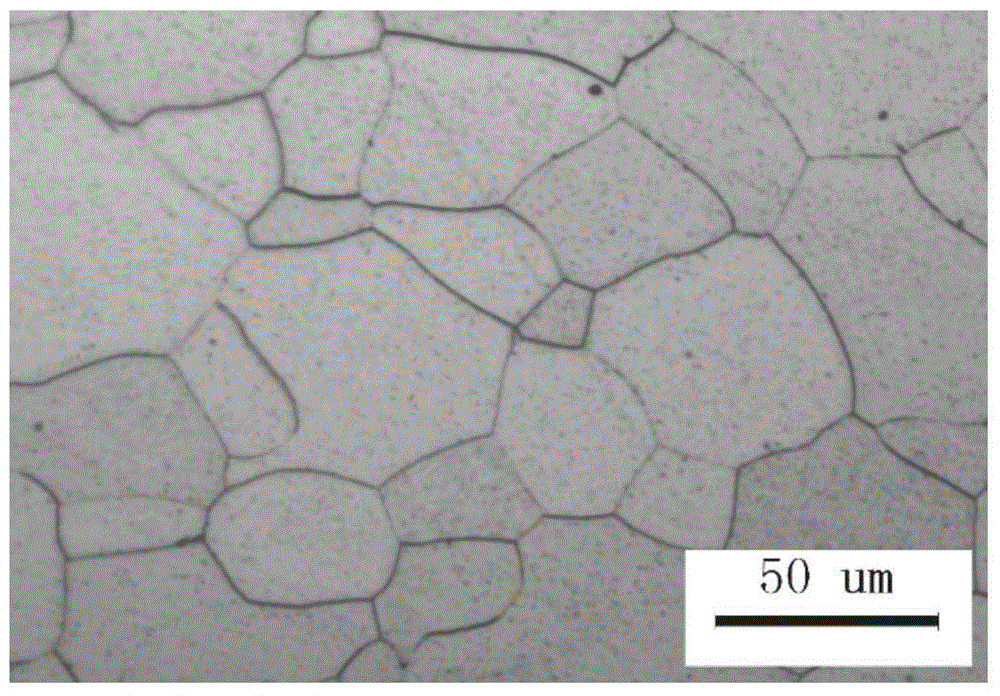

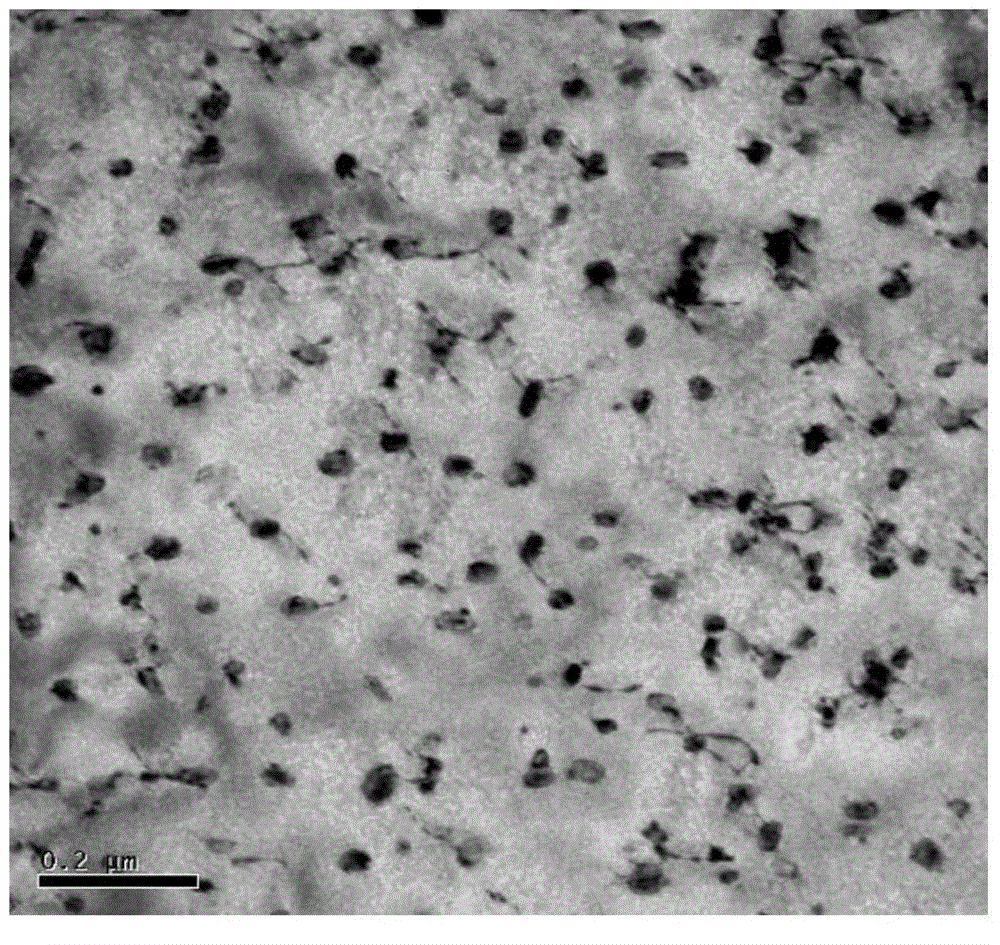

[0028] The chemical composition of the ultra-low carbon copper-containing high-strength cold-rolled steel sheet for automobiles of the present invention is: C: 0.004% to 0.006%, N: 0.001% to 0.003%, Si: 0.2% to 1.0%, Mn: 0.2% to 1.0%, P≤0.015%, S≤0.015%, Als: 0.02%-0.04%, Cu: 1.2%-2.4%, and the balance is Fe and unavoidable impurities. The thickness of the continuous casting slab is controlled below 350mm; the heating temperature for hot rolling is 980-1050°C, and the heat preservation is 30-60min; The cold rolling reduction rate is not less than 65%. The annealing heating temperature is 890-920°C, heat preservation for 20-40min, cooling to room temperature at a speed of not less than 20°C / s, and then aging at 550-680°C for 30-60min.

[0029] The following examples are used to specifically illustrate the contents of the present invention and embody the obtained effects. These embodiments are only general descriptions of the content of the present invention, and do not limit t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com