Low-carbon and high-chromium steel slab and continuous efficient production method thereof

A production method and technology of high chromium steel, applied in the direction of improving process efficiency, etc., can solve problems such as large temperature loss, unfavorable converter furnace condition stability and forward movement, long process flow, etc., to achieve continuous and efficient casting without self-leading The effect of pouring and reducing the difficulty of smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

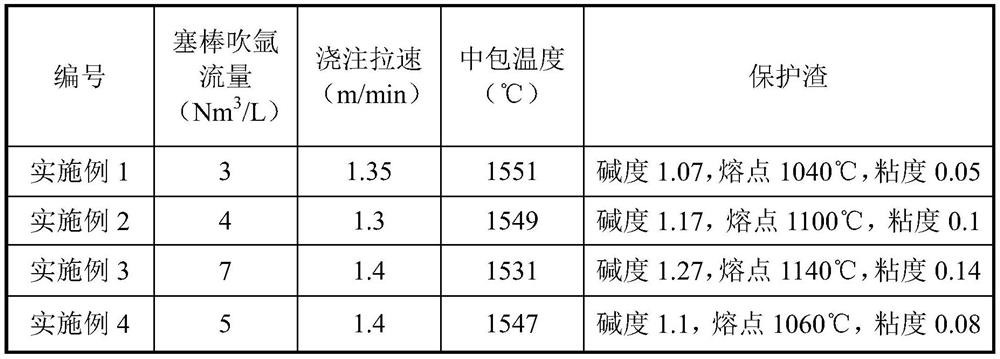

[0030] The chemical composition of the steel slabs of the various embodiments of the present invention is as shown in Table 1, and the composition detection is carried out according to GB / T 4336 "Measurement of Multi-element Content in Carbon Steel and Medium and Low Alloy Steel by Spark Discharge Atomic Emission Spectroscopy (conventional method)" .

[0031] Table 1 Chemical composition (%) of low-carbon ultra-high chromium weathering steel

[0032] Sample serial number C Si mn P S als Ti Ni Cu Cr Example 1 0.02 0.20 0.2 0.009 0.0006 0.040 0.018 0.30 0.37 4.19 Example 2 0.04 0.30 0.5 0.02 0.005 0.06 0.03 0.4 0.5 4.7 Example 3 0.028 0.21 0.35 0.012 0.0008 0.043 0.028 0.2 0.36 4.0 Example 4 0.022 0.10 0.34 0.012 0.003 0.02 0.01 0.35 0.3 4.40

[0033] The continuous high-efficiency production method of low-carbon high-chromium steel slabs in this embodiment adopts the smelting process of mo...

Embodiment 2

[0042] The chemical composition of the steel slab of this embodiment is as shown in Table 1, and its production method is also basically the same as that of Example 1, the difference is that some process parameters are adjusted in the actual operation:

[0043] In the converter smelting process, the strong bottom blowing process is adopted, the carbon and oxygen product is 0.0018%, the tapping carbon: 0.02%, and the oxygen: 600ppm;

[0044] In the converter smelting process, 7.3kg / t of copper plates and 5.6kg / t of nickel plates are added to the head of the scrap steel hopper; the total loading capacity of the converter is controlled to 308t, and the molten steel volume of the ladle is 290t when tapping; the end point temperature of the converter is controlled at 1670°C, The amount of steel lime added is 1806kg; the rated capacity of Shenggang ladle is 300 tons, and the amount of drainage sand added is 50kg;

[0045] In the RH vacuum treatment process, the RH decarburization ti...

Embodiment 3

[0050] The chemical composition of the steel slab of this embodiment is as shown in Table 1, and its production method is also basically the same as that of Example 1, the difference is that some process parameters are adjusted in the actual operation:

[0051] In the converter smelting process, the strong bottom blowing process is adopted, the carbon and oxygen product is 0.0016%, the tapping carbon: 0.02%, and the oxygen: 550ppm;

[0052] In the converter smelting process, 7kg / t of copper plates and 6kg / t of nickel plates are added to the head of the scrap steel hopper; the total load of the converter is controlled to 304t, and the amount of molten steel in the ladle is 285t when tapping; the end point temperature of the converter is controlled at 1660°C, and the lime The addition amount is 1500kg; the rated capacity of Shenggang ladle is 350 tons, and the addition amount of drainage sand is 50kg;

[0053] In the RH vacuum treatment process, the RH decarburization time is 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com