High-strength and high-plasticity medium manganese cold-roll steel sheet and manufacturing method thereof

A technology of cold-rolled steel sheet and manufacturing method, which is applied to high-strength and high-plasticity medium-manganese cold-rolled steel sheet and its manufacturing field, can solve the problems of poor combination of strength and plasticity, high production cost, complicated process, etc., and achieve excellent mechanical properties, The effect of increased strength and plastic product, simple and economical ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

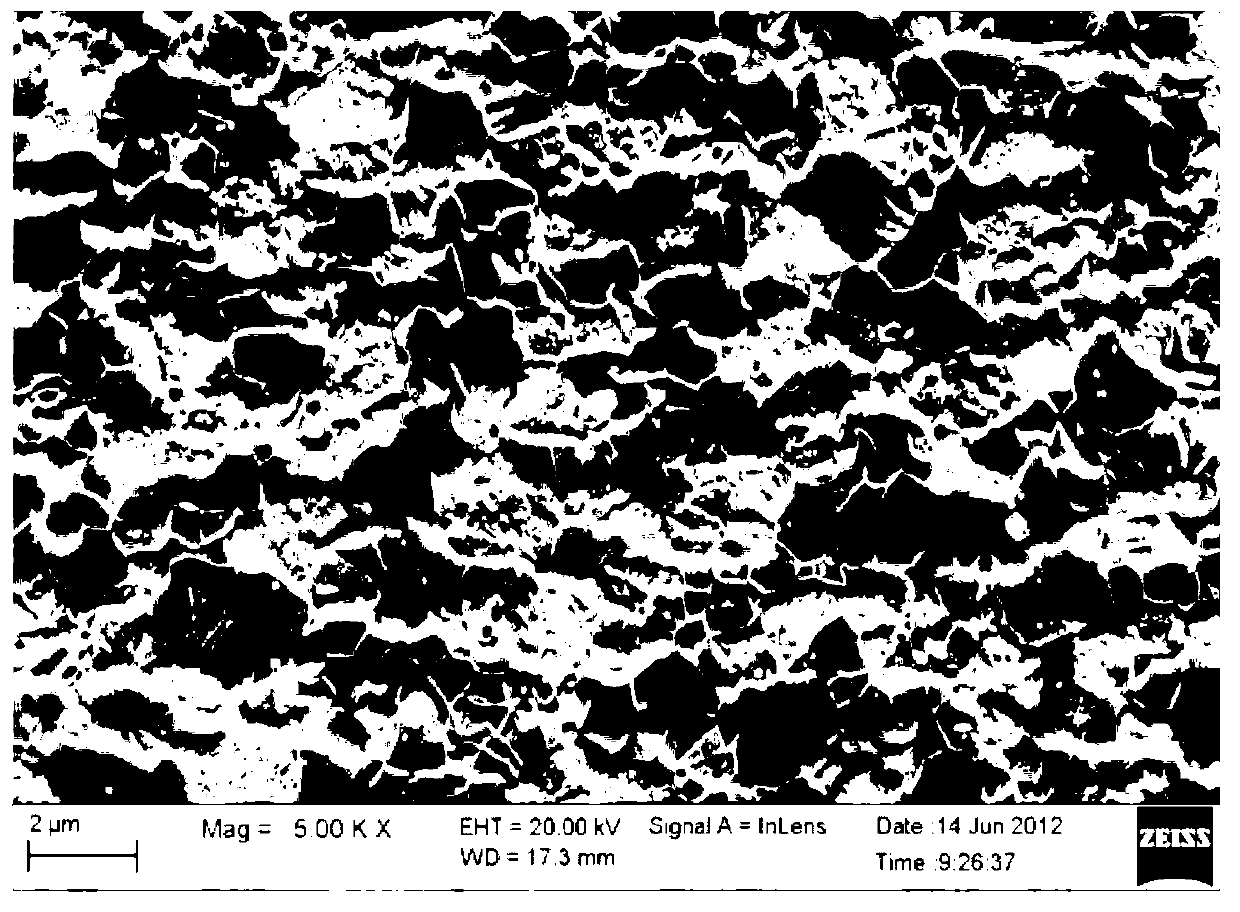

Image

Examples

Embodiment 1

[0025] The composition mass percentage of this high-strength, high-plasticity low-carbon medium-manganese cold-rolled steel sheet is: C: 0.19%, Mn: 7.5%, Si: 1.6%, Al: 0.03%, P: 0.015%, S: 0.0071% , and the rest is Fe.

[0026] After smelting, casting and forging, the steel billet is heated to 1200°C for 1 hour to complete austenitization, and then rolling is started. The starting temperature of rough rolling is 1150°C. The rolling start temperature is 1000°C, after 3 passes of finish rolling, the finish rolling temperature is 800°C, and air-cooled to room temperature after rolling. The hot rolling reduction rate is 91.7%.

[0027] Heat the hot-rolled sheet to 680°C for 10 hours, then take it out of the furnace and air cool it to room temperature. The annealed sheet was pickled and then cold-rolled in the first stage with a reduction of 36%. The first-stage cold-rolled sheet is annealed at 680°C for 16 hours, air-cooled to room temperature, pickled and then second-stage col...

Embodiment 2

[0030] The difference from Example 1 is that the annealing time of the final heat treatment is 0.5h. After the final heat treatment, the mechanical properties of the steel plate are tested according to the national standard. The tensile strength is 1085MPa, the elongation is 39.48%, and the strong-plastic product reaches 42.9GMPa*%.

Embodiment 3

[0032] The composition mass percentage of this high-strength, high-plasticity low-carbon medium-manganese cold-rolled steel sheet is: C: 0.21%, Mn: 7.0%, Si: 1.6%, Al: 0.02%, P: 0.012%, S: 0.0074% , and the rest is Fe.

[0033] After smelting, casting and forging, the steel billet is heated to 1200°C for 1 hour to complete austenitization, and then rolling is started. The starting temperature of rough rolling is 1150°C. The rolling start temperature is 1000°C, after 3 passes of finish rolling, the finish rolling temperature is 780°C, and air-cooled to room temperature after rolling. The hot rolling reduction rate is 87.5%.

[0034] Heat the hot-rolled sheet to 680°C for 12 hours, then take it out of the furnace and air cool it to room temperature. After pickling, the annealed sheet is cold-rolled in the first stage with a reduction of 45%. The first-stage cold-rolled sheet is annealed at 700°C for 12 hours, air-cooled to room temperature, pickled and then second-stage cold-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com