Axle housing steel for cold stamping of 590mpa thick specification and preparation method thereof

A thick-gauge, cold-stamping technology, applied in the field of 590MPa thick-gauge cold-stamping axle housing steel and its preparation, can solve the problems of high production cost of high-strength axle housing steel, achieve improved welding performance, good structure uniformity, and reduce carbon equivalent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0047] Example 1-2: Smelting to obtain slabs according to the data in Table 1, and processing the slabs, specifically: the heating temperature is 1200-1240°C, and the heating time is 190-400min; The reduction amount is ≥ 19%, the full length of the odd pass is descaled, and the thickness of the intermediate billet is 53-57mm; after 7 passes of finishing rolling, the reduction rates of the last three stands are 18%, 13% and 10%, respectively. Cooling water between 3 stands, finishing rolling temperature ≤1030℃, finishing rolling temperature 830-870℃, coiling temperature 550-590℃; laminar cooling after rolling, using front-end cooling mode, specific process parameters are shown in the table 2 shown.

[0048] Table 2 embodiment 1,2 preparation process parameters

[0049]

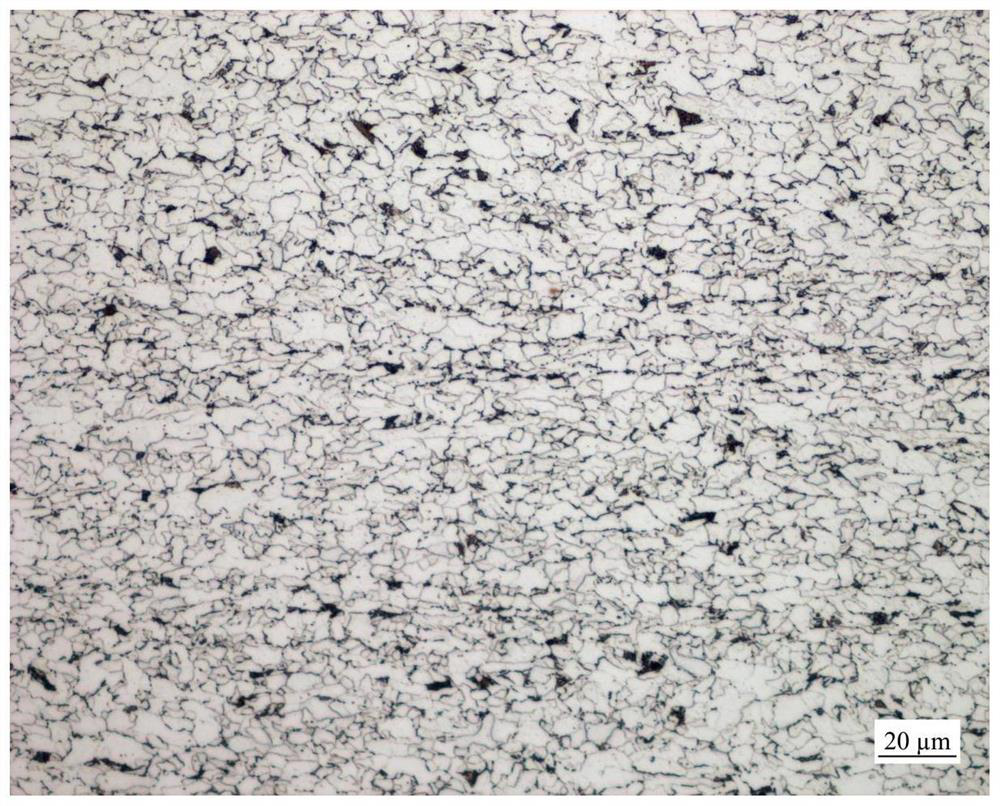

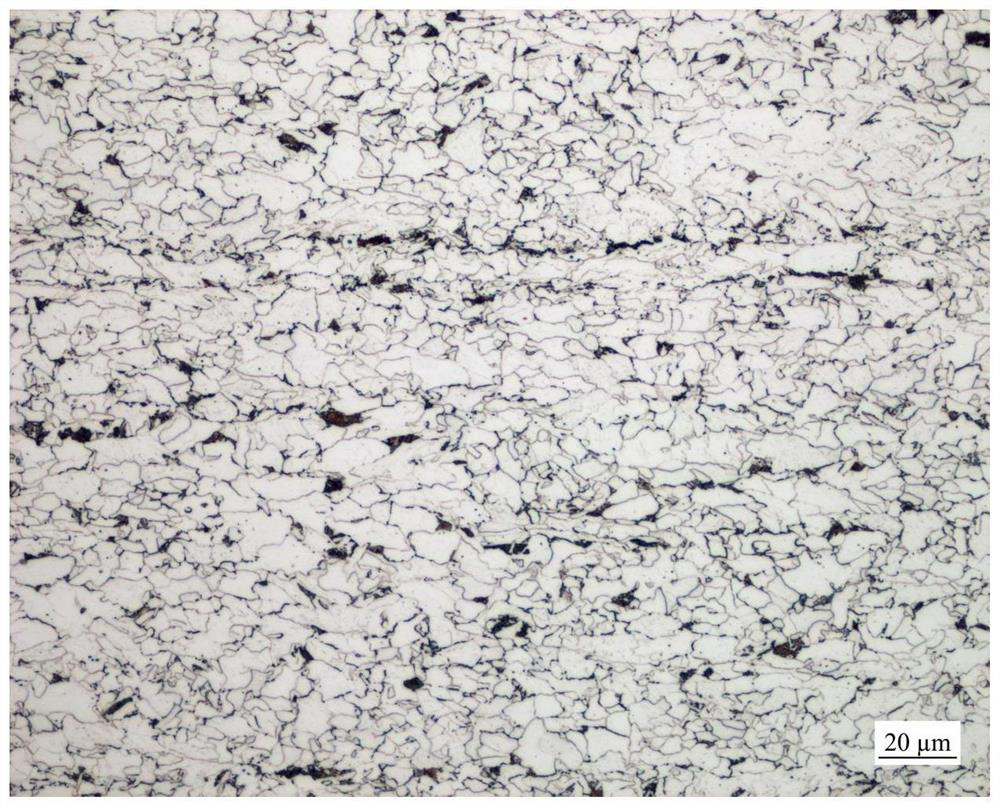

[0050] figure 1 It is the typical edge structure in the thickness direction of the axle housing steel for cold stamping with a thickness of 590 MPa prepared in Example 1 of the present invention; figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com