Preparation method for ZnO nanomaterial with hierarchical porous structure

A nanomaterial, hierarchical porous technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex reaction and high cost, and achieve uniform macropore distribution, low cost and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

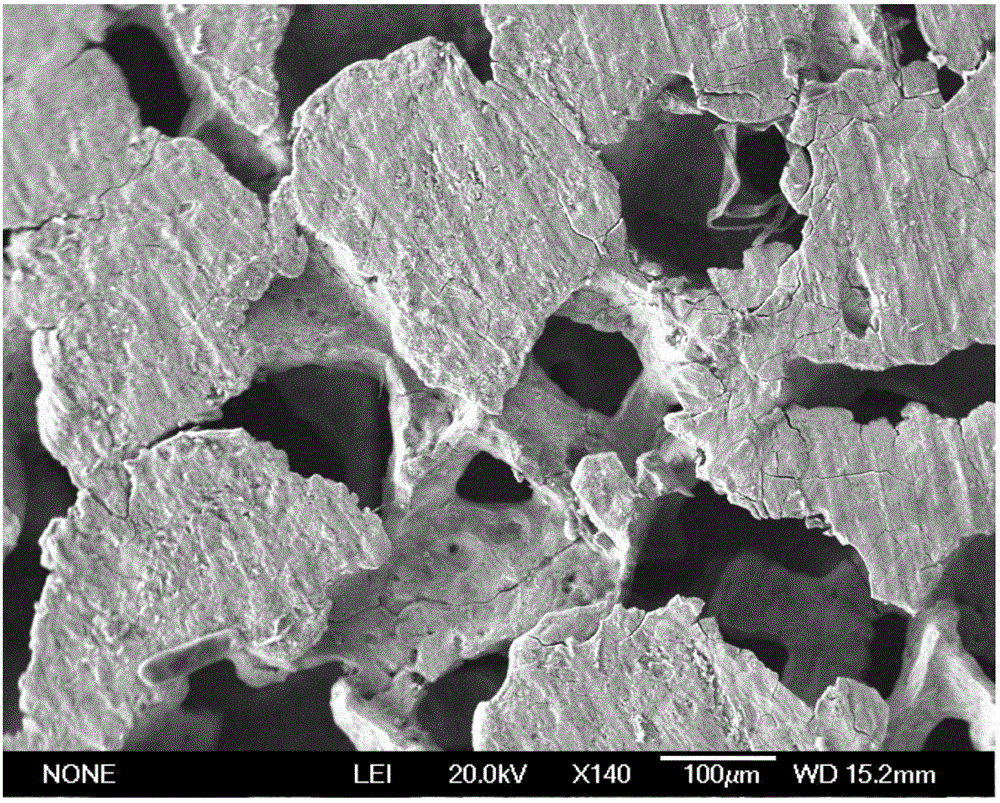

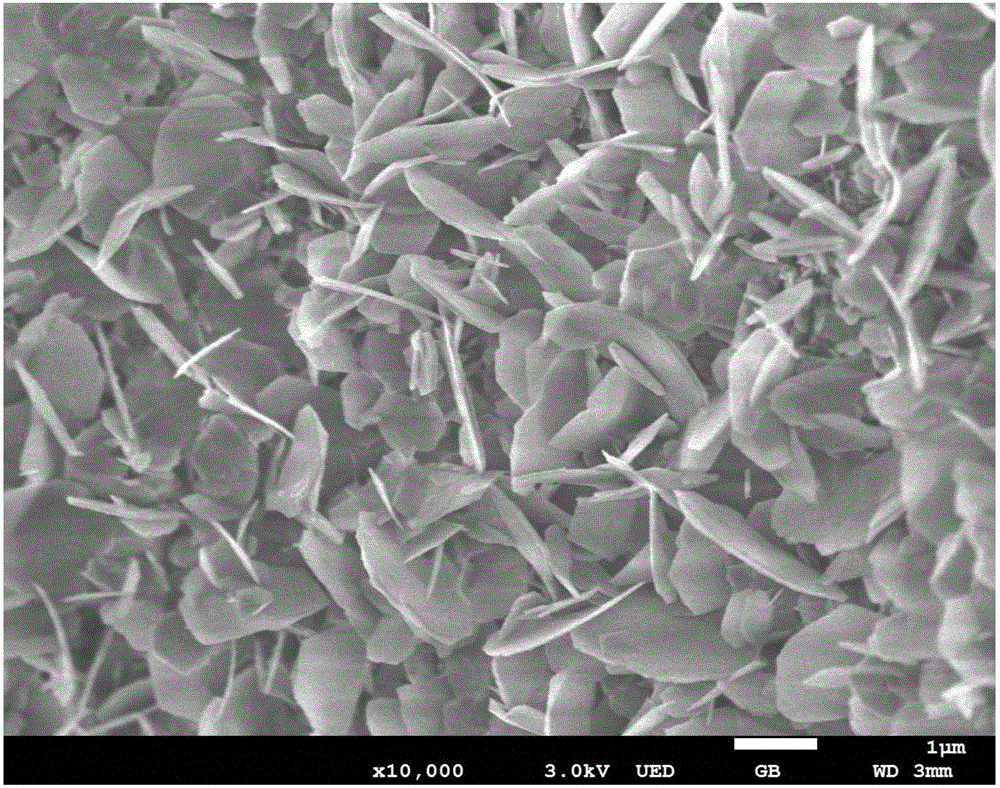

[0034] A kind of preparation method of the ZnO nanometer material with hierarchical porous structure provided by the invention, concrete operation steps are as follows:

[0035] Step 1, preparation of pore-forming agent

[0036] Sodium chloride is selected as the macroporous pore-forming agent, and sodium chloride is placed in a crucible for sintering, and the sintered sodium chloride is fully ground with a mortar, and the ground sodium chloride is sub-sieved to obtain 100 -120 purpose spare;

[0037] Step 2, alloy melting

[0038] Weigh 40g of industrial pure Al and 60g of industrial pure Zn, place the configured raw materials in a crucible and heat them in a heating furnace at 700°C for alloy melting, stir continuously to mix the molten alloy evenly, and keep it in a molten state for later use;

[0039] Step 3, Alloy Suction Casting

[0040] Put the treated 100-120 mesh sodium chloride obtained in step 1 into a glass tube, and perform suction casting with a vacuum pump un...

Embodiment 2

[0048] A kind of preparation method of the ZnO nanometer material with hierarchical porous structure provided by the invention, concrete operation steps are as follows:

[0049] Step 1, preparation of pore-forming agent

[0050] The macroporous pore-forming agent is sodium chloride, which is placed in a crucible for sintering, and the sintered sodium chloride is fully ground with a mortar, and the ground sodium chloride is sub-sieved to obtain < 100 purpose spare;

[0051] Step 2, alloy melting

[0052] Weigh 70g of industrially pure Al and 30g of industrially pure Zn, place the configured raw materials in a crucible and heat the alloy at 700°C in a heating furnace, stir continuously to mix the molten alloy evenly, and keep it in a molten state for later use;

[0053] Step 3, Alloy Suction Casting

[0054] Put the treated <100 mesh sodium chloride obtained in step 1 into a glass tube, and use a vacuum pump to suction-cast the alloy liquid in molten state until the molten al...

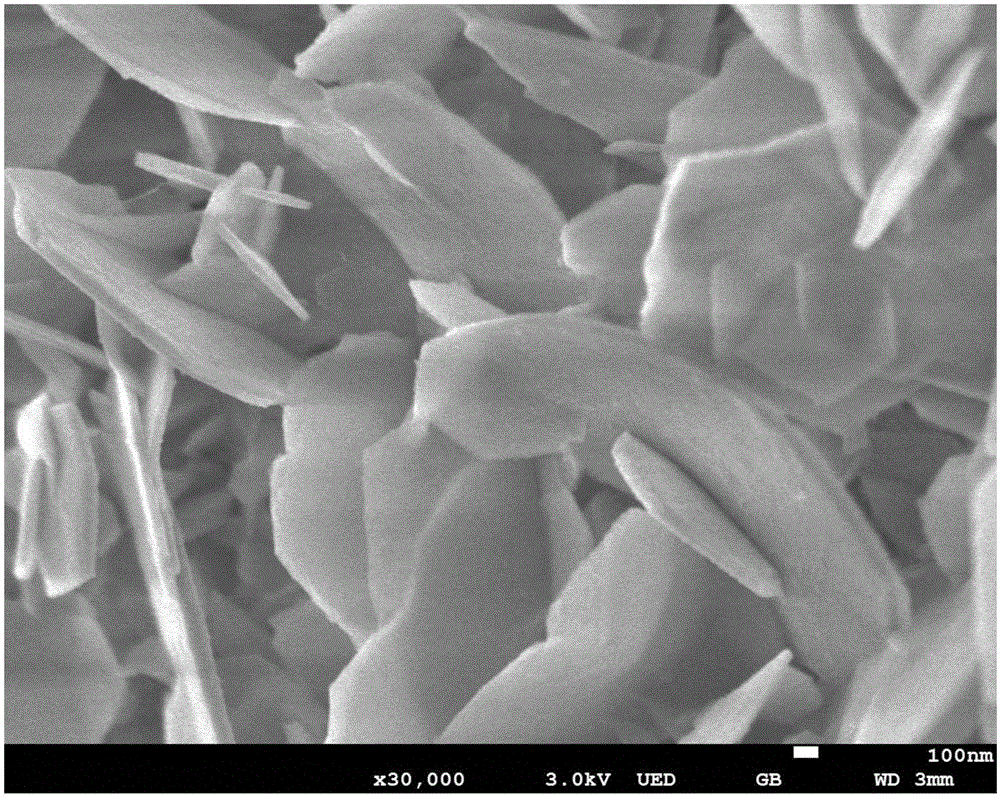

Embodiment 3

[0062] A kind of preparation method of the ZnO nanometer material with hierarchical porous structure provided by the invention, concrete operation steps are as follows:

[0063] Step 1, preparation of pore-forming agent

[0064] Sodium chloride is selected as the macroporous pore-forming agent, and sodium chloride is placed in a crucible for sintering, and the sintered sodium chloride is fully ground with a mortar, and the ground sodium chloride is sub-sieved to obtain 100 -150 purpose spare;

[0065] Step 2, alloy melting

[0066] Weigh 60g of industrial pure Al and 40g of industrial pure Zn, place the configured raw materials in a crucible and heat them in a heating furnace at 700°C for alloy melting, stir continuously to mix the molten alloy evenly, and keep it in a molten state for later use;

[0067] Step 3, Alloy Suction Casting

[0068] Put the treated 100-150 mesh sodium chloride obtained in step 1 into a glass tube, and perform suction casting with a vacuum pump un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com