Method for manufacturing thick hot-rolled dual-phase steel based on CSP (Compact Strip Production) process

A technology for hot-rolled dual-phase steel and a manufacturing method, which is applied in the field of manufacturing hot-rolled dual-phase steel with a low-cost thickness specification of 590 MPa, can solve the problem that it is difficult to achieve stable matching of chemical composition-process window-structure and properties, and it is impossible to achieve dual-phase steel. Industrial production and application problems, to achieve the effect of reducing the difficulty of smelting, low cost, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

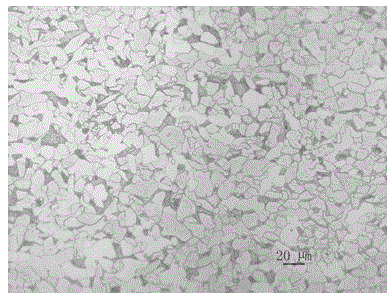

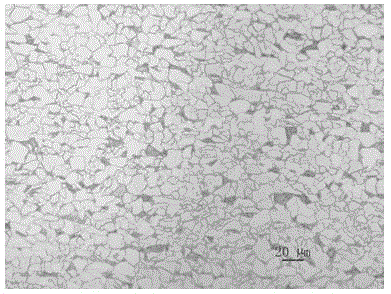

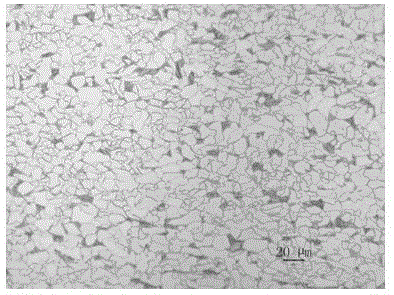

Image

Examples

Embodiment Construction

[0022] The following is a specific embodiment of the present invention. The embodiment is used to explain the present invention and is not used to limit the scope of the present invention.

[0023] The components of the actual molten steel in the embodiment are shown in Table 1 in terms of mass percentage.

[0024] The molten steel with the components of Examples 1 to 3 shown in Table 1 is pretreated → converter top and bottom composite blowing → LF refining treatment → thin slab continuous casting → tunnel furnace soaking → F1~F7 seven-stand hot continuous rolling mill continuous rolling →Laminar cooling system→Super fast cooling system→Reeling.

[0025] Table 1 Chemical composition of specific examples of the present invention (Wt.%)

[0026]

[0027] The continuous casting billet in the tunnel furnace soaking time is 10~25min, control and control the discharge temperature ≥1130℃, the opening temperature ≥1010℃, the F1 rolling mill stand reduction rate ≥40%, the F2 stand reduction r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com