A kind of cake-shaped grain deep-drawing dual-phase steel plate and preparation method thereof

A technology of steel plate and grain, which is applied in the field of pie-shaped grain ferrite plus martensitic dual-phase steel plate for deep drawing and its preparation, high-strength cold rolling, which can solve the problem of deteriorating deep drawing formability and affecting the r value of steel In order to solve the problems of deep drawing performance and high production cost, it can achieve the effects of improved tensile strength and secondary processing brittleness, good plate shape and surface quality, and strong anti-aging stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

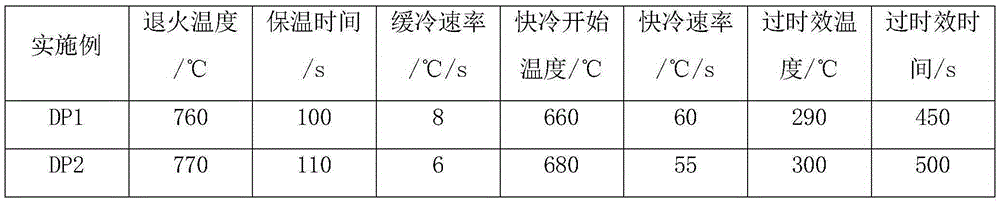

[0032] The chemical composition of pie-shaped grain deep-drawn dual-phase steel plates (steel plate numbers DP1, DP2) is shown in Table 1.

[0033] Table 1 Chemical composition (mass percentage) of pie-shaped grain deep-drawn dual-phase steel plate

[0034] Numbering

C

Si

mn

Cr

P

S

als

N

DP1

0.027

0.18

1.52

0.23

0.016

0.004

0.052

0.0043

DP2

0.038

0.26

1.65

0.27

0.012

0.0043

0.047

0.0046

[0035] According to the chemical composition in Table 1, the smelting and forging are carried out. In order to make the AlN particles completely dissolve in the hot rolling process, the hot rolling adopts the "three highs and one low" process system, that is, the forging billet is heated to 1230 °C and put into the furnace for 2 hours. Hot rolling is carried out on a 450mm two-roller hot rolling mill. The forged billet is quickly hot rolled after it comes out of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com