High-elasticity and high-strength titanium alloy and preparing method and application thereof

A titanium alloy, high-elasticity technology, applied in the field of high-elasticity and high-strength oxygen-containing titanium alloys and their preparation, can solve problems such as increasing preparation cost, element segregation, and influence on alloy properties, achieving important theoretical significance and engineering value, reducing The effect of preparation cost and reduction of smelting difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of as-rolled Ti-14.6Nb-0.16O alloy

[0030] (1) Prepare high-purity Ti ingot, Nb ingot, TiO 2 Powder raw materials, and according to the ratio of the above alloy components, the raw materials are subjected to steps such as ultrasonic cleaning and pickling to remove surface impurities. The raw materials are put into a vacuum non-consumable electric arc furnace for smelting, and smelted into TiNbO ingots.

[0031] (2) Homogenize the TiNbO ingot at 1100° C. for 2 hours, and then perform hot forging at 600° C. to obtain an alloy plate.

[0032] (3) Hot-rolling the above-mentioned alloy plate at 600° C., with a rolling amount of 80%.

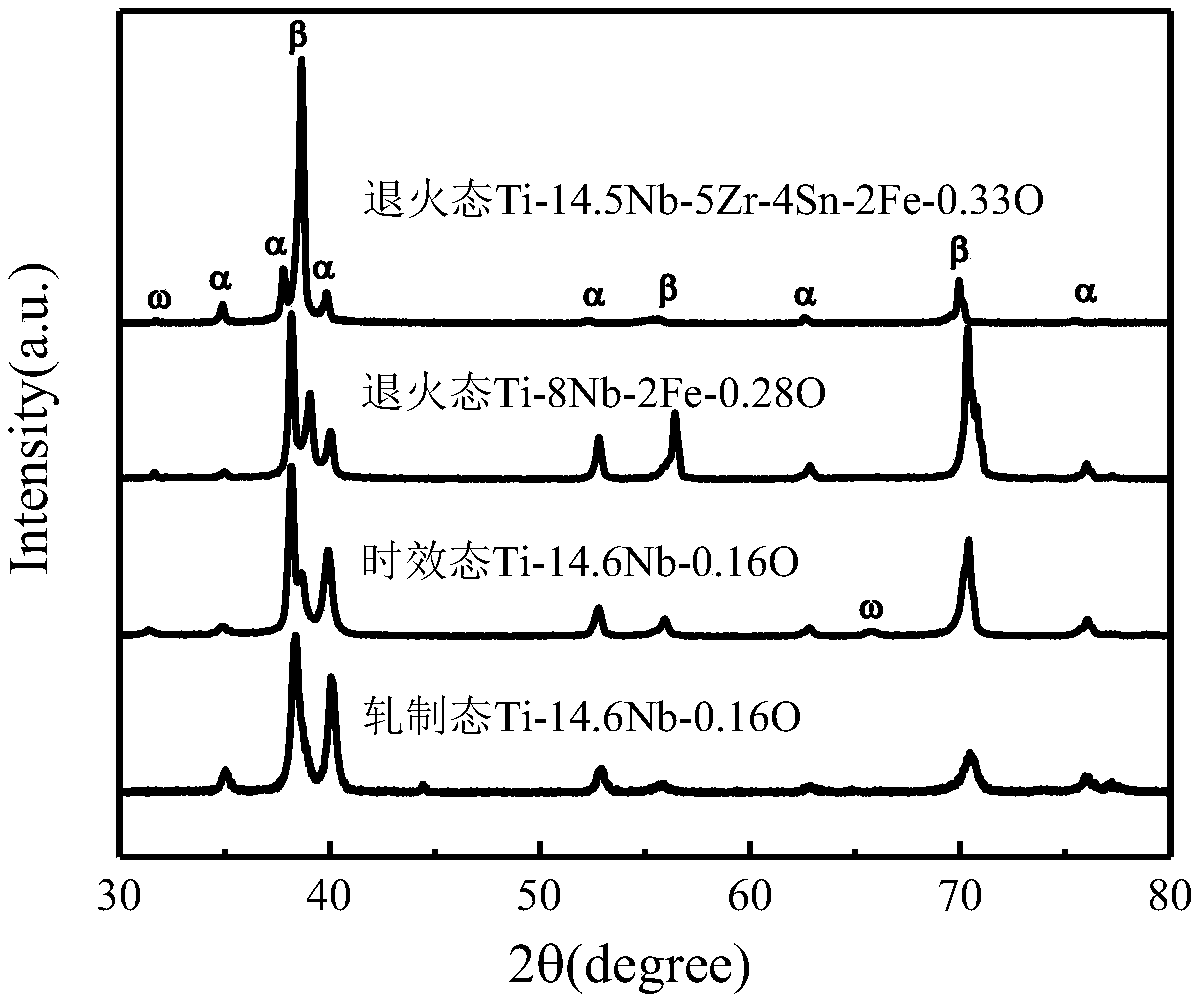

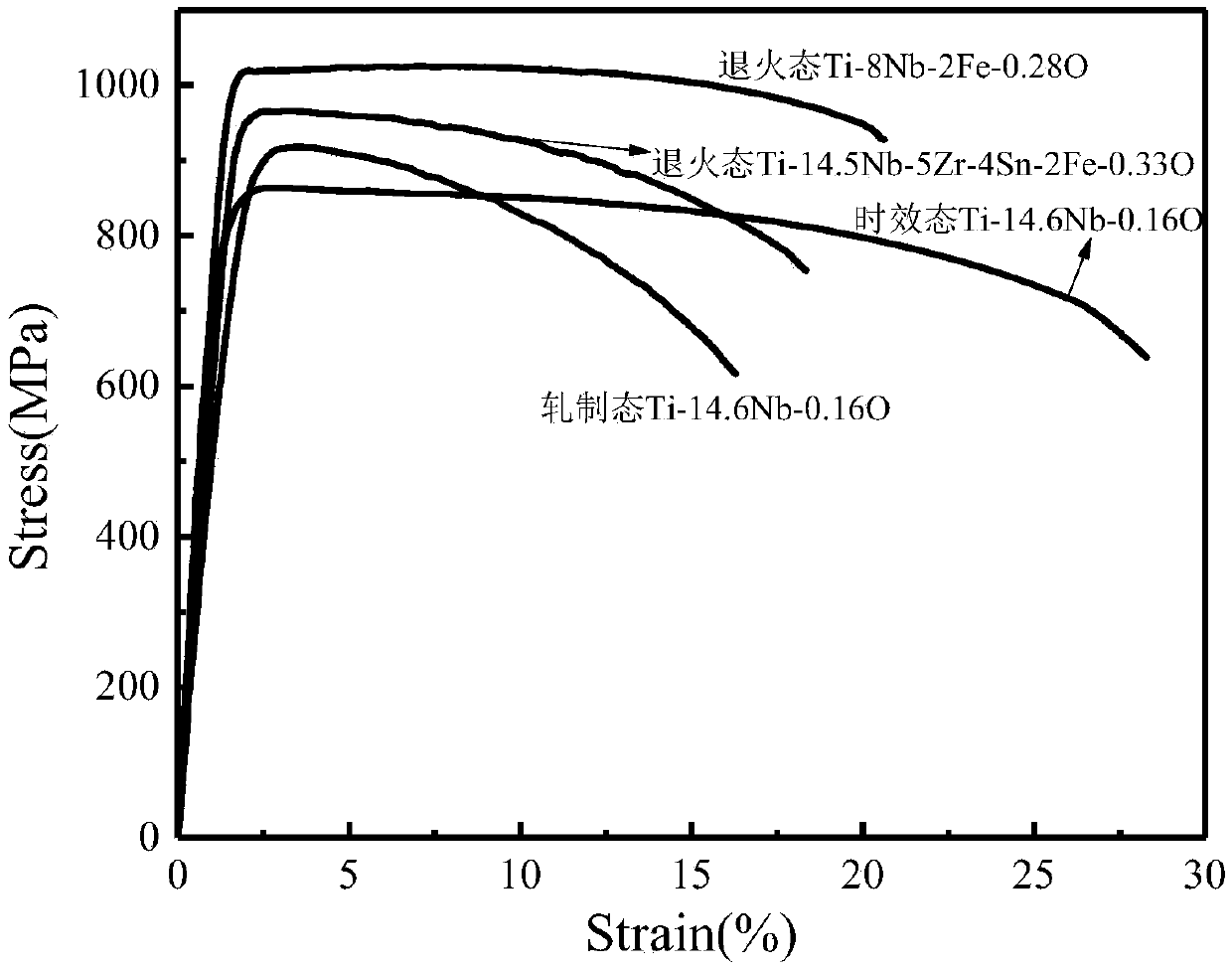

[0033] The Ti-14.6Nb-0.16O alloy prepared in this implementation is 2.44, is 2.81 and e / a is 4.09. From figure 1 It can be seen from the XRD patterns of the obtained alloys that they are mainly α and β phases. Pass the tensile test (see figure 2 Shown), the modulus of elasticity of the titanium alloy is 80GPa,...

Embodiment 2

[0034] Example 2: Preparation of aged Ti-14.6Nb-0.16O alloy

[0035] (1) Prepare high-purity Ti ingot, Nb ingot, TiO 2 Powder raw materials, and according to the ratio of the above alloy components, the raw materials are subjected to steps such as ultrasonic cleaning and pickling to remove surface impurities. The raw materials are put into a vacuum non-consumable electric arc furnace for smelting, and smelted into TiNbO ingots.

[0036] (2) Homogenize the ingot at 1100°C for 2 hours, and then perform hot forging at 600°C to obtain an alloy plate;

[0037] (3) hot-rolling the above-mentioned alloy plate at 600°C, with a rolling capacity of 80%;

[0038] (4) annealing the above-mentioned rolled plate at 600° C. for 60 minutes, and air cooling;

[0039] (5) The above alloy was aged at 350° C. for 60 minutes, and air-cooled.

[0040] The Ti-14.6Nb-0.16O alloy prepared in this implementation is 2.44, is 2.81 and e / a is 4.09. The alloy is mainly α and β phase, and contains a ...

Embodiment 3

[0041] Example 3: Preparation of annealed Ti-8Nb-2Fe-0.28O alloy

[0042] (1) Prepare high-purity Ti ingot, Nb ingot, Fe ingot, TiO 2 Powder raw materials, and according to the ratio of the above alloy components, the raw materials are subjected to steps such as ultrasonic cleaning and pickling to remove surface impurities. The raw materials are put into a vacuum non-consumable electric arc furnace for smelting, and smelted into ingots.

[0043] (2) Homogenize the ingot at 1100° C. for 2 hours, and then perform hot forging at 600° C. to obtain an alloy plate.

[0044] (3) Hot-rolling the above-mentioned alloy plate at 600° C., with a rolling amount of 80%.

[0045] (4) Anneal the above-mentioned rolled plate at 700° C. for 30 minutes, and then water-cool it.

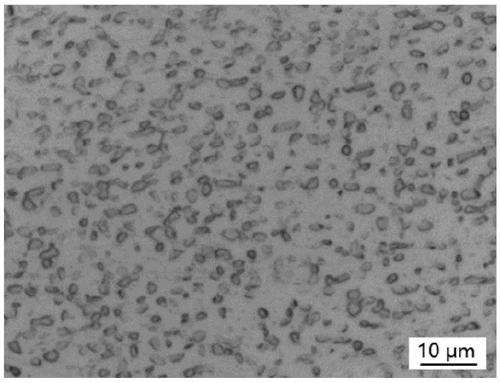

[0046] The Ti-8Nb-2Fe-0.28O alloy prepared in this implementation is 2.41, is 2.79 and e / a is 4.12. The alloy is mainly α and β phase, and a small amount of ω phase (see figure 1 shown). Such as image 3 As sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com