Weather-resistant steel and preparing method thereof

A technology for weathering steel and billet, applied in metal rolling and other directions, can solve the problems of increasing the cost and difficulty of smelting and the influence of steel forming properties, and achieve the effect of suitable promotion and use, reducing the difficulty of smelting, reducing the cost and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing the above-mentioned weathering steel, comprising the following steps:

[0025] a. Melt steel is smelted into steel slabs; the composition of molten steel is: by weight percentage, C: 0.06-0.08%, Si: 0.30-0.45%, Mn: 1.10-1.25%, P≤0.020%, S≤0.005%, Cu: 0.20~0.30%, Cr: 0.50~0.60%, Ni: 0.20~0.30%, Nb: 0.020~0.030%, Sb: 0.03~0.05%, Al: 018~0.20%, the balance is Fe and unavoidable impurities;

[0026] b. Hot rolling the steel slab smelted in step a. The temperature before hot rolling is 1220-1260°C. Rough rolling is carried out in 5 passes, the deformation of each pass is ≥ 20%, the whole length is descaled, and finally The rolling temperature is 840~880℃;

[0027] c. Pre-cooling after hot rolling;

[0028] d. The cooled steel is coiled, and the coiling temperature is 560-600° C., and the weather-resistant steel is obtained after coiling.

[0029] Wherein, in the above-mentioned preparation method of weathering st...

Embodiment 1~3

[0034] Embodiment 1~3 prepares weathering steel of the present invention

[0035] The specific operation steps are as follows:

[0036] a, by the composition shown in table 1, molten steel is smelted into billet;

[0037] b. Hot rolling the steel slab smelted in step a. The temperature before hot rolling is 1220°C. Rough rolling is carried out in 5 passes. The deformation of each pass is ≥ 20%. The whole length is descaled. The rolling temperature is 850~880℃;

[0038] c. Sparse cooling after hot rolling;

[0039] d. The cooled steel is coiled at a temperature of 600° C. to obtain weathering steel.

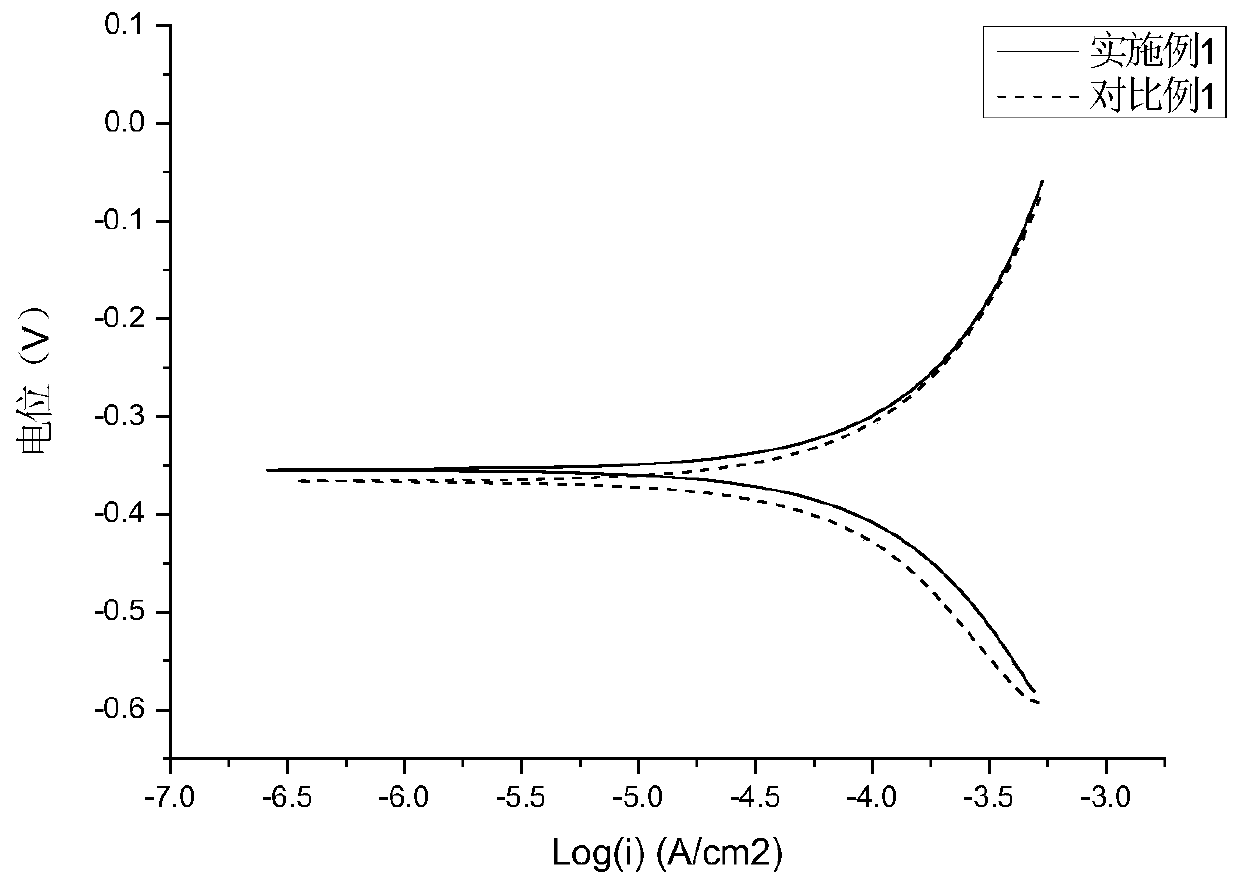

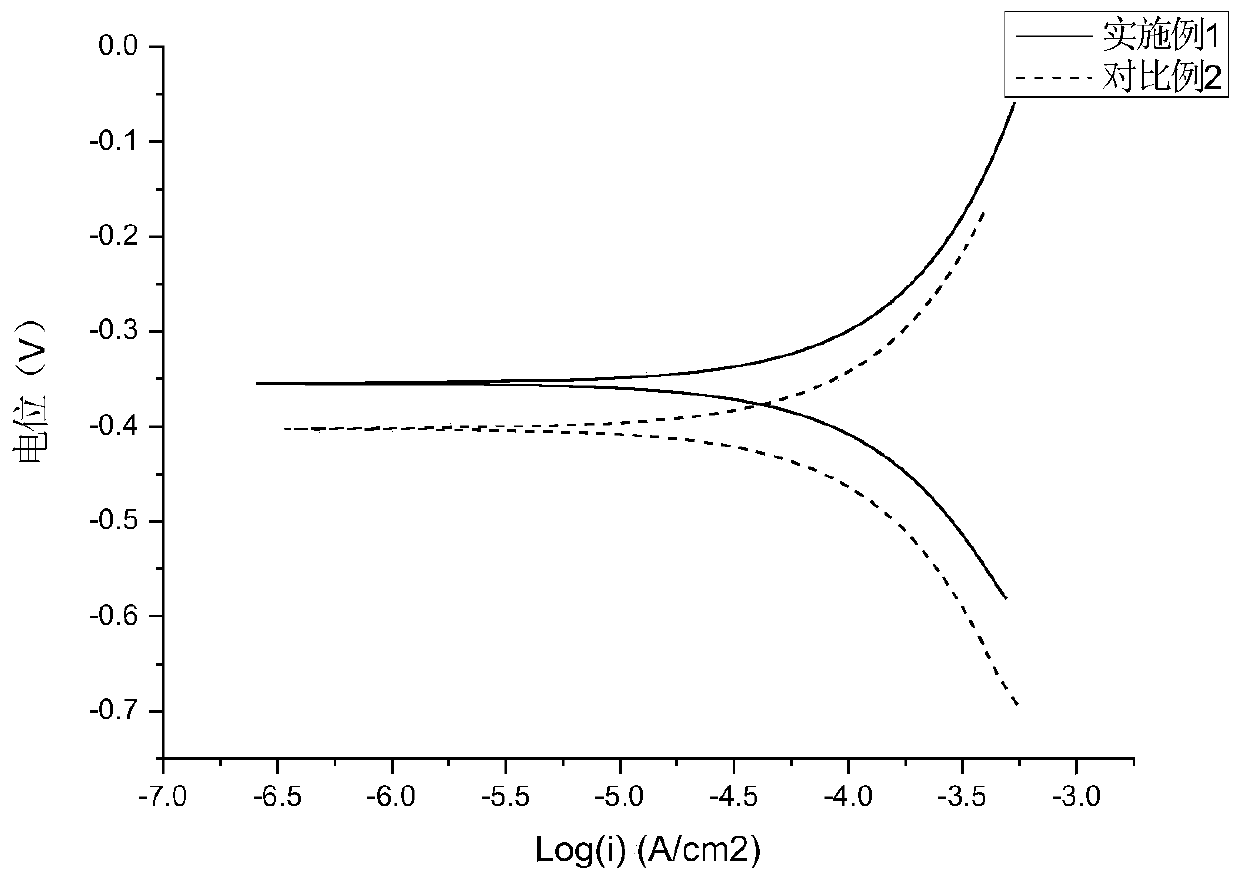

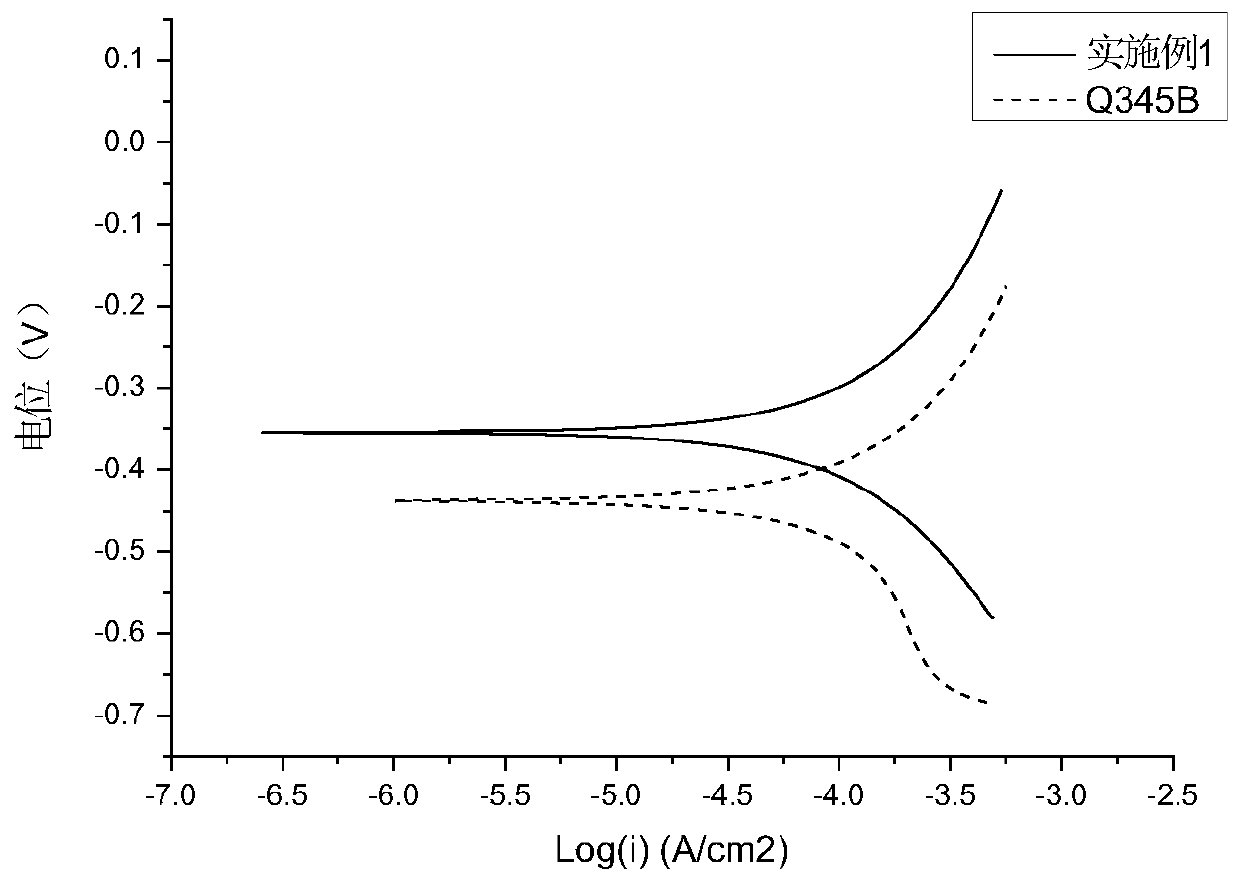

[0040] Comparative example 1, 2 prepares the weathering steel of existing composition

[0041] The weather-resistant steel with high Cr content was selected as Comparative Example 1, and the weather-resistant steel with high Sb content was selected as Comparative Example 2. The specific components are shown in Table 1 below. In Comparative Examples 1 and 2, the smelting and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com