Preparation method of GH4698 high-temperature alloy mold

A high-temperature alloy and mold technology, which is applied in the field of GH4698 high-temperature alloy mold preparation, can solve the problems of high cost, reduced life, temper softening, etc., and achieve the effects of wide chemical composition range, reduced manufacturing cost, and reduced smelting difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] For solving technical problem of the present invention, GH4698 superalloy mold preparation method of the present invention comprises:

[0031] a. Heating the ingot to 1160-1180°C for the first forging, the total deformation in the forging process is less than 20%;

[0032] b. Heating the ingot after the first forging to 1160-1180°C for the second forging, the total deformation in the forging process is less than 25%;

[0033] c. Heating the ingot after the second forging to 1160-1180°C for the third forging, the total deformation in the forging process is less than 35%;

[0034] d. peeling the ingot after forging for the third time in step c to obtain a bar stock;

[0035] e. The bar material obtained in step d is subjected to three-fire upsetting to complete the module manufacturing. When the three-fire upsetting bar is upsetting, the deformation amount does not exceed 40%, and after the upsetting is completed, it is rounded to eliminate the influence of the belly;

...

Embodiment 1

[0054] Determine the selected mold specification according to the external dimension of the die forging, and then add the machining allowance to the maximum external dimension of the mold to determine the size of the module blank, and add the amount of damage in the process of ingot opening, the amount of skin peeling in bar processing, and the damage of the upsetting process. Quantity, and finally determine the required GH4698 superalloy ingot size.

[0055] The mold specification required for a certain forging is φ920×370mm. According to the conversion, the required GH4698 superalloy ingot specification is φ610×905mm.

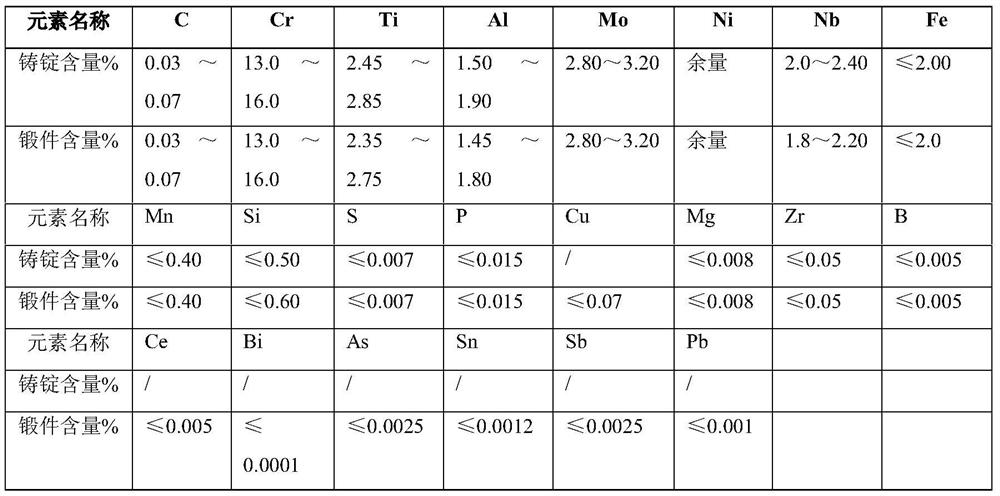

[0056] The composition of the ingot is: C 0.049%; Cr 14.69%; Ti 2.57%; Al 1.7%; Mo 3.06%; Ni balance; Nb 2.06%; Fe0.46%; Mn0.02%; Si0.06%; .001%; P0.006%; Mg≤0.008%; Zr0.033%; B0.003%.

[0057] The GH4698 superalloy ingot billet forging equipment is a 45MN fast forging machine, the forging temperature is 1170±10°C, and it is heated by a natural gas furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com