Compact type easily-maintained tooth holder

An easy-to-maintain and compact technology, used in the field of pick-tooth holders, it can solve the problems of reduced coal-loading performance of drums, reduced cutting performance, and drop-off of tooth sleeves, and achieves reduced external dimensions, extended service life, and reliable connections. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

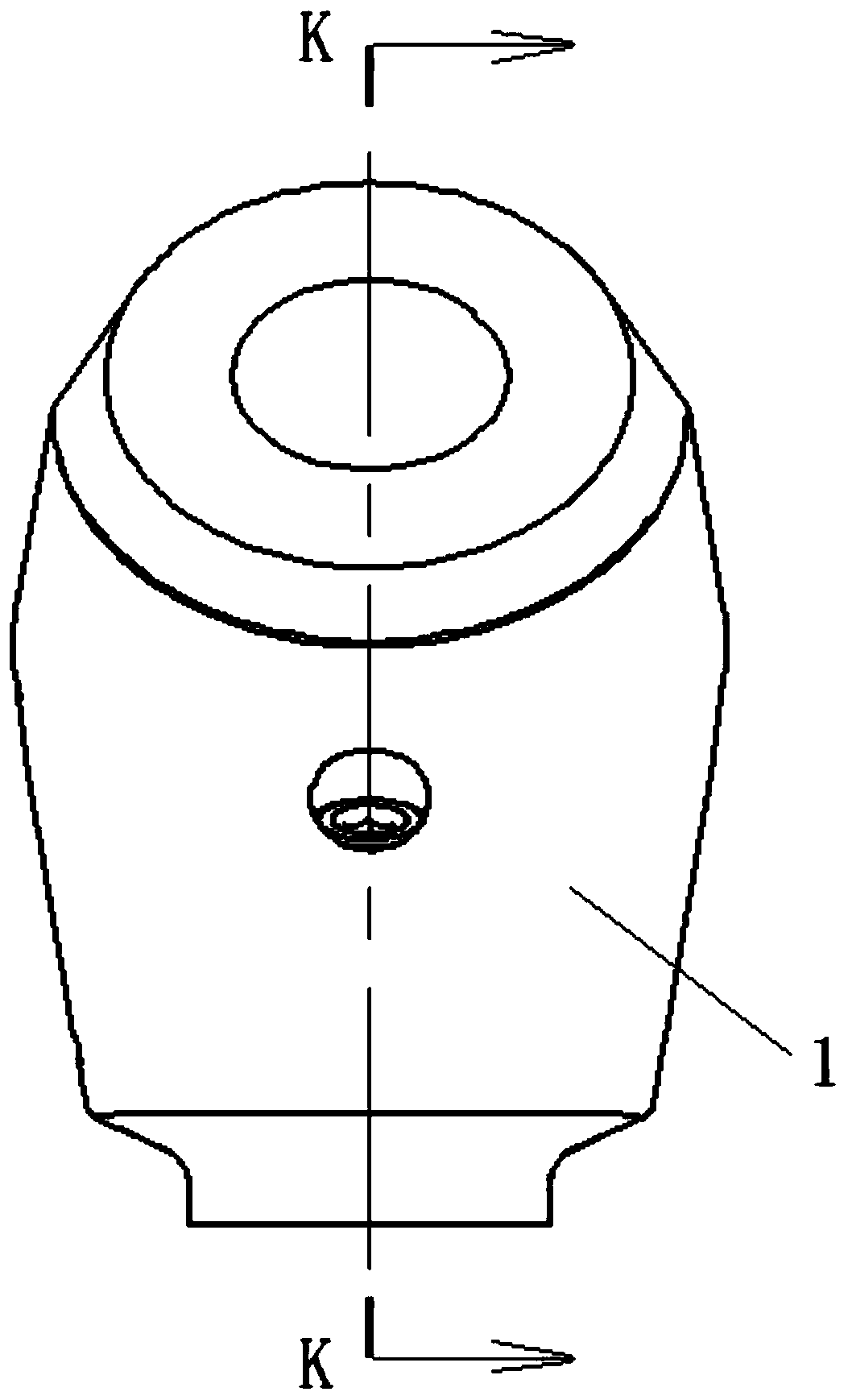

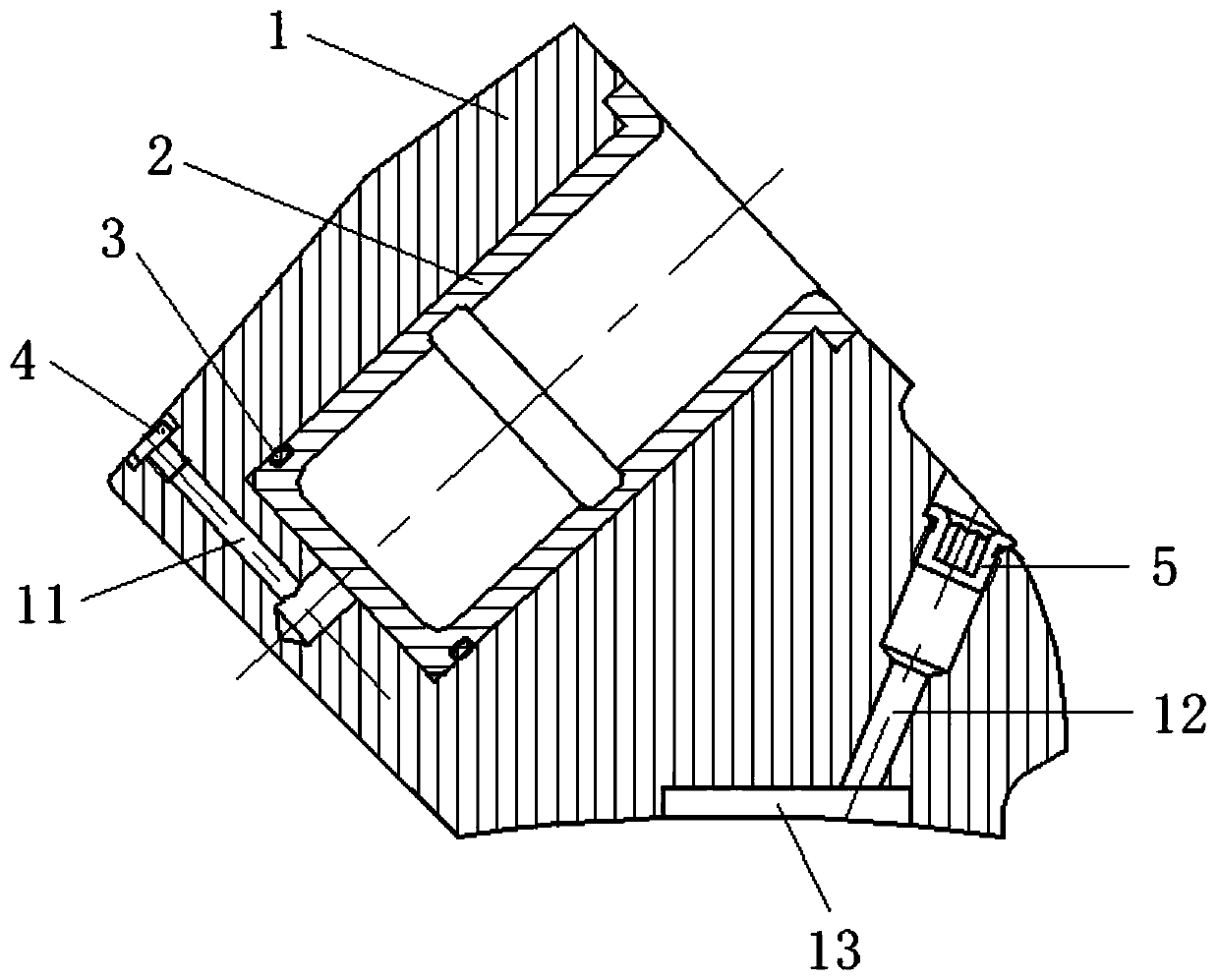

[0022] The invention discloses a compact and easy-to-maintain gear seat, such as figure 1 , 2 As shown, it includes a tooth seat body 1 and a tooth sleeve 2, and the tooth sleeve is tightly fitted in the main hole on the tooth seat body, so that the connection between the tooth seat body and the tooth sleeve is more reliable, and the stability of the tooth seat body can also be improved. service life. The wall thickness of the gear sleeve is in the range of 3-5mm, which is a typical thin-wall gear sleeve. Compared with the existing gear sleeve with a wall thickness of 8-10mm, the outer diameter of the gear sleeve is reduced by about 1 / 3, correspondingly , The outer dimensions of the tooth seat body are also greatly reduced. Since the height direction of the tooth seat body and the axial direction of the main hole form an acute angle, the thinning of the wall thickness of the tooth sleeve reduces the size of the tooth seat body of the present invention in the radial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com