Threaded element, connection assembly comprising the element and method of manufacturing both

A technology of threaded elements and connecting components, applied in the direction of connecting components, threaded fasteners, screws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

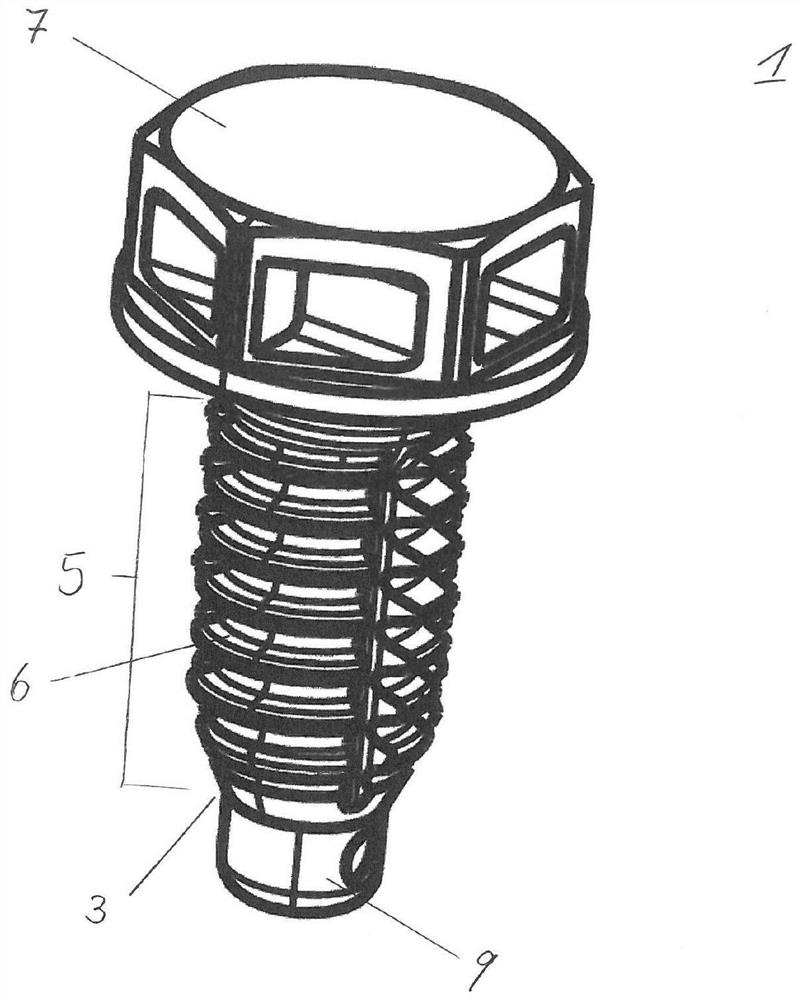

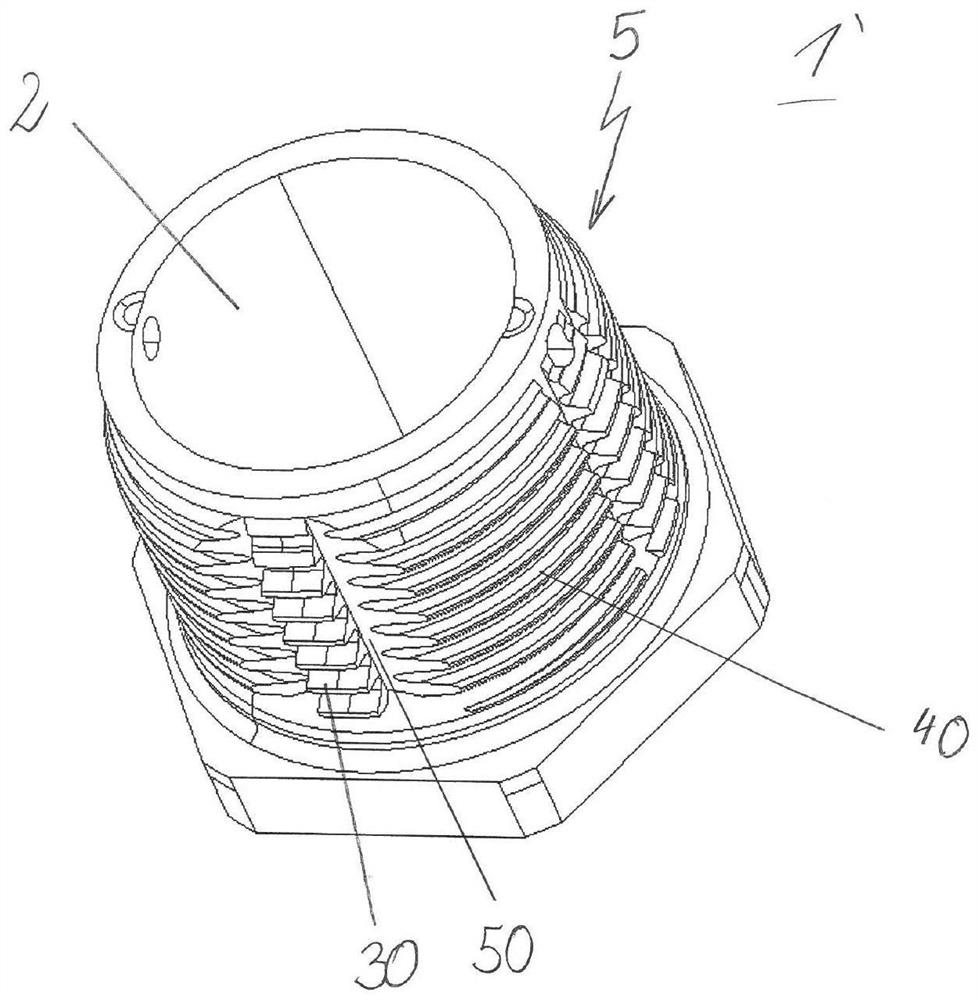

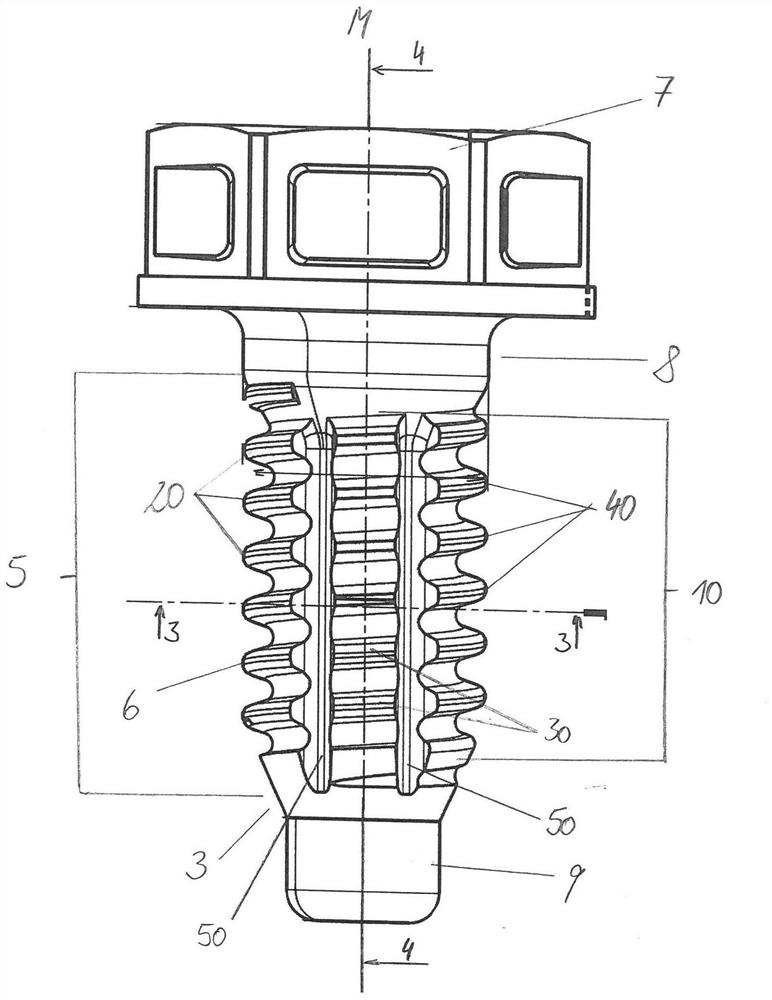

[0032] A preferred embodiment of the inventive threaded element in the form of a screw 1 made of plastic is in Figure 1A shown in . Preferably, the threaded element can also be realized as a screw insert or threaded insert 2 made of plastic, such as Figure 1B shown.

[0033] According to the invention, the external thread 5 of the plastic screw 1 or plastic insert 2 is preferably configured such that when inserted into the receiving opening of the support part, it optimally forms a reverse thread on the inner wall of the receiving opening. The reverse thread can be formed by a cutting process or by material deformation or by a combination of the above two processes.

[0034] A preferred screw 1 according to the invention shown exemplarily in FIG. External thread 5, transition zone 8 between the screw shank 3 and the screw head 7, the drive member at the screw head 7, and the tip 9 at the core of the screw 1 or the end of the screw shank 3 opposite the screw head 7. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com