Earthworking tool and method for earthworking

A technology of work and equipment, which is applied in the direction of earth drilling, drilling equipment and methods, earth movers/shovels, etc., can solve the problems of time, operation and cost intensive, and achieve the improvement of operation accuracy and high efficiency of soil engineering. Operation, collision avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

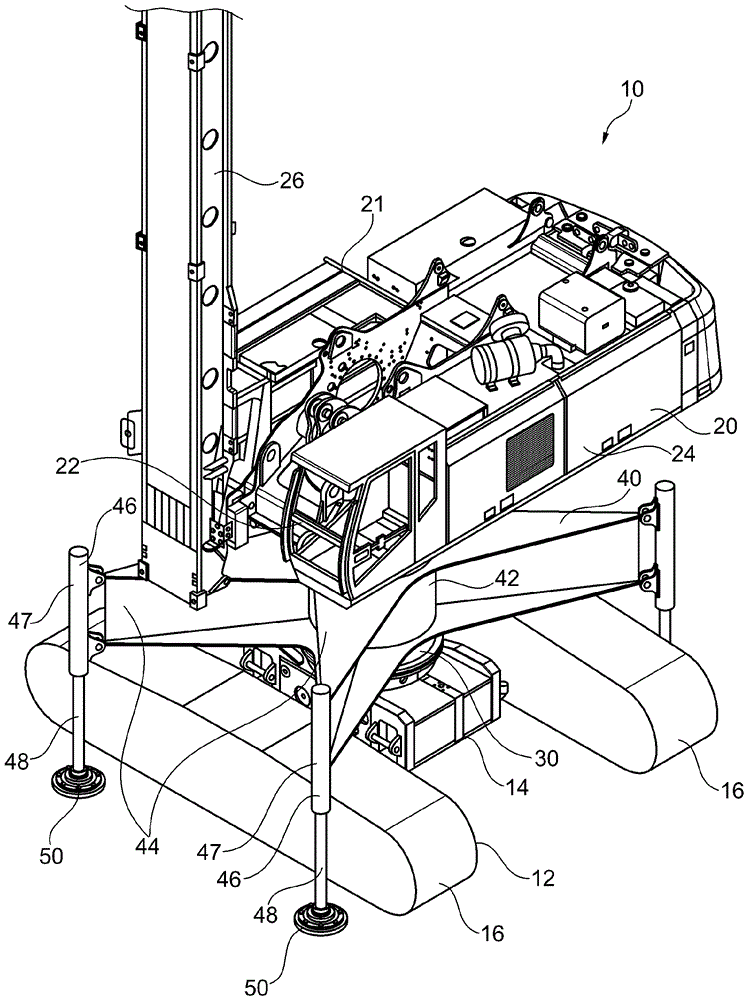

[0030] according to figure 1 , according to the earth working equipment 10 of the present invention has an underframe 12, and the underframe 12 is designed as a crawler running gear. On the central carrier frame 14 of the undercarriage 12 , track units 16 are arranged transversely in each case in a known manner. Above the bottom frame 12, an upper frame 20 is supported in the horizontal direction in a rotatable manner.

[0031] The upper frame 20 has a base frame 21 to the front side of which a vertical pole 26 is pivotably linked. Furthermore, on the front side of the upper frame 20 , a cab 22 is provided for operating the earth working equipment 10 . Furthermore, on the base frame 21 of the upper frame 20, a drive unit (in particular a drive motor for the underframe 12), a winch and hydraulic components are arranged. These units are housed within a housing 24 of the upper shelf 20 . in accordance with figure 1 In the illustration, the winches and hydraulic positioning c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com