Patents

Literature

110results about How to "Avoid collision hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

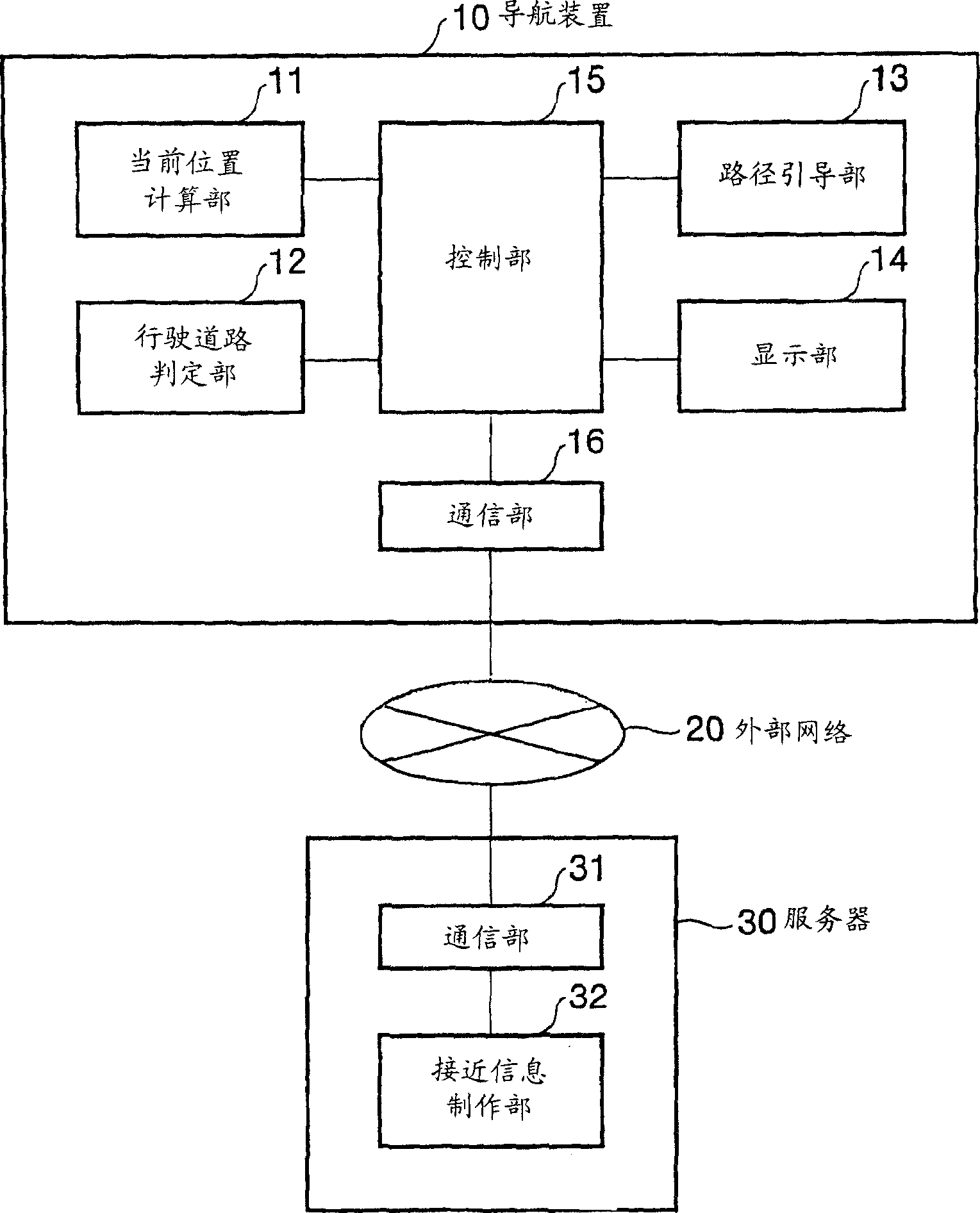

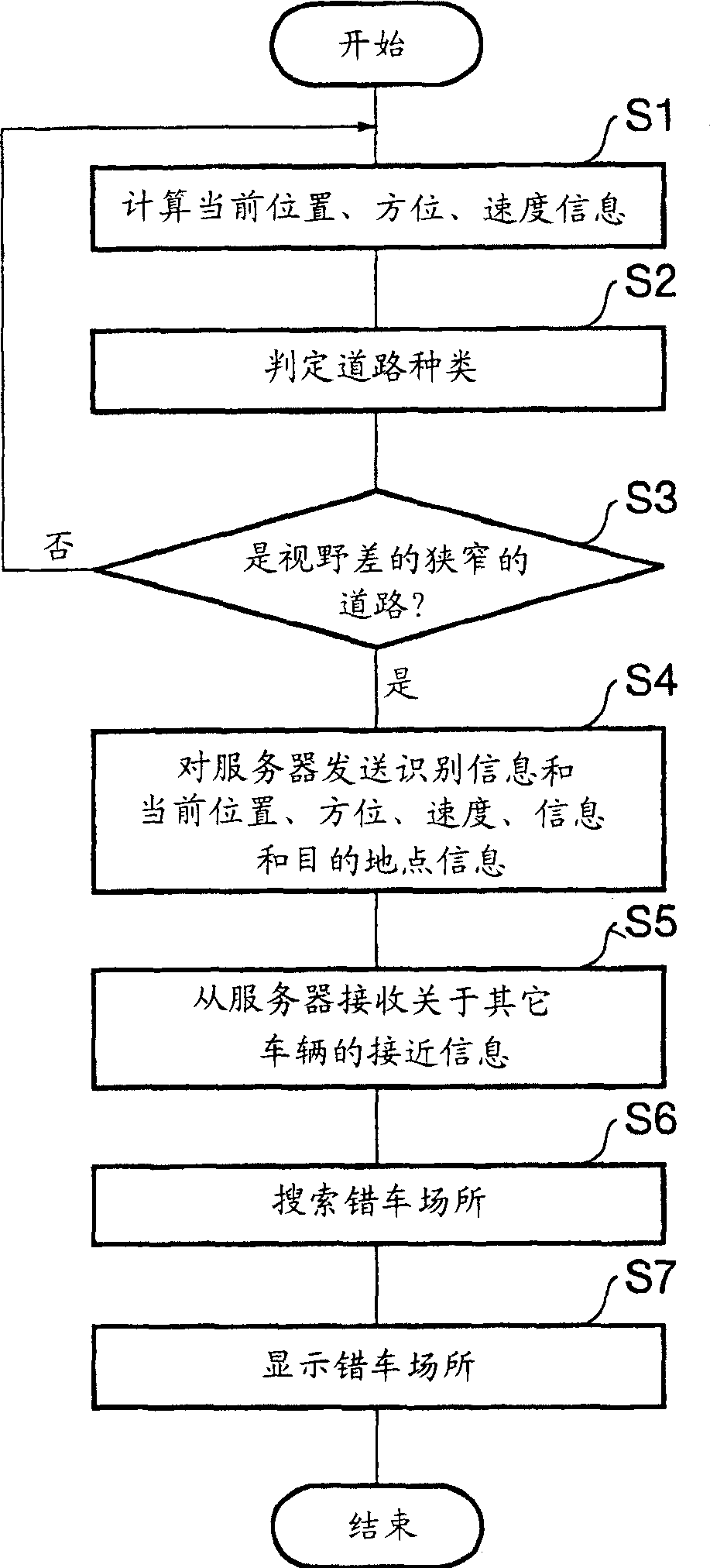

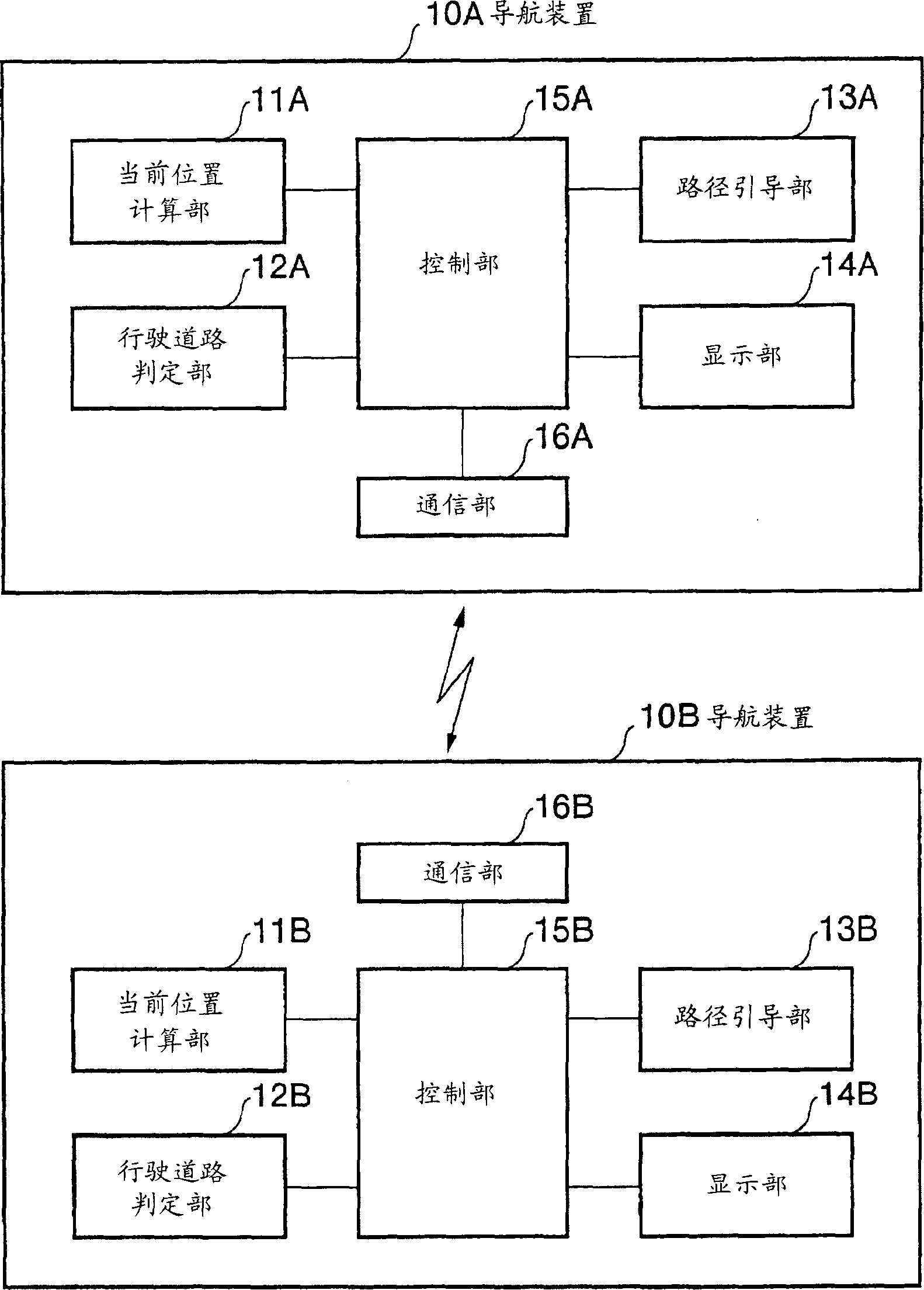

Navigation device and approach information display method

InactiveCN1723481AReduce the burden onAvoid collision hazardArrangements for variable traffic instructionsAnti-collision systemsIdentification deviceEngineering

Owner:PANASONIC CORP

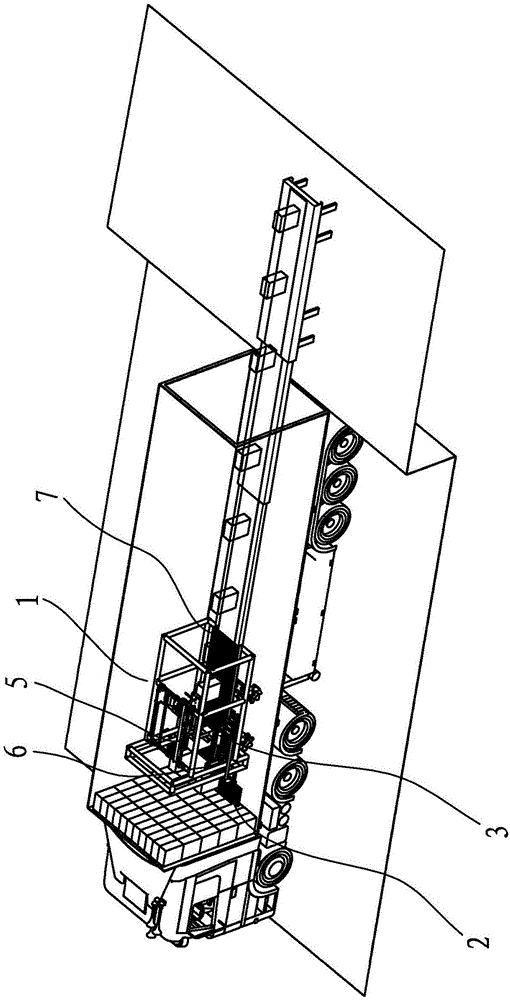

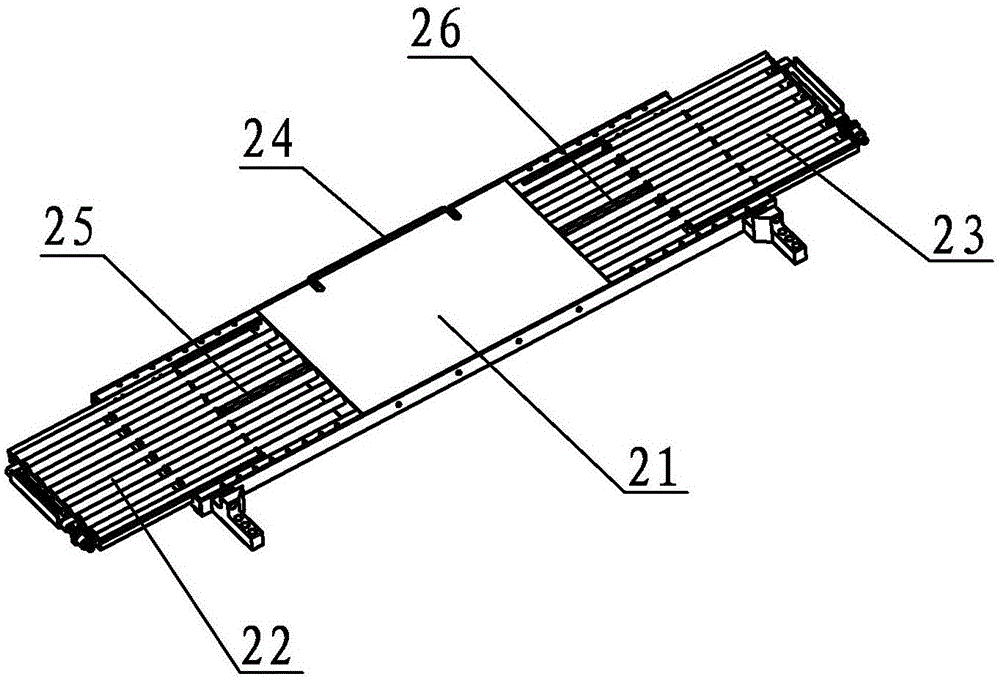

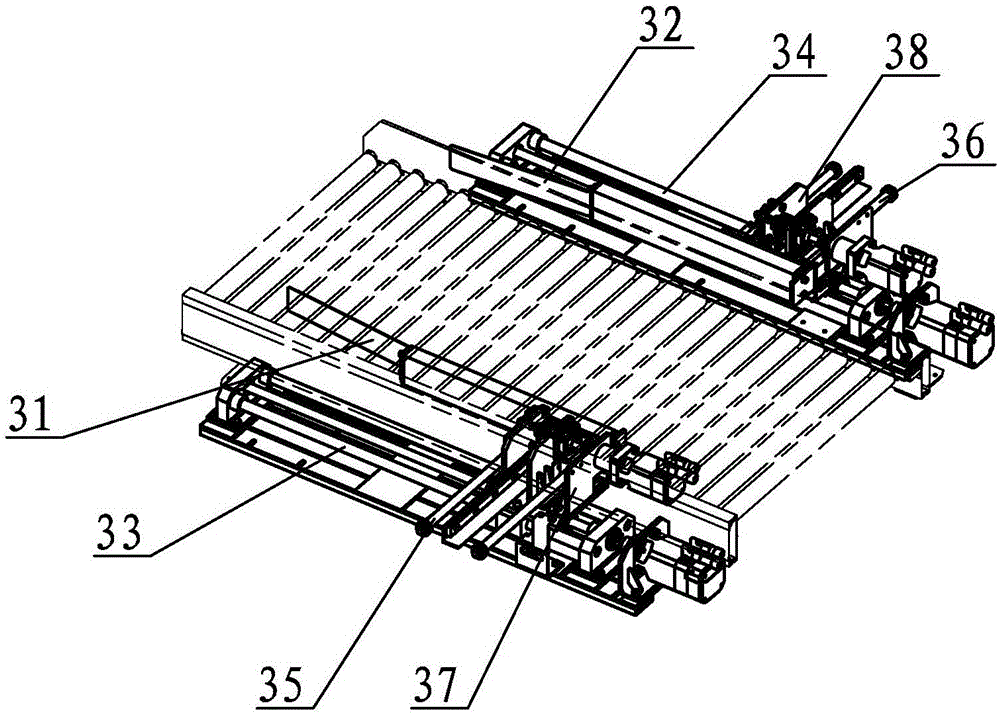

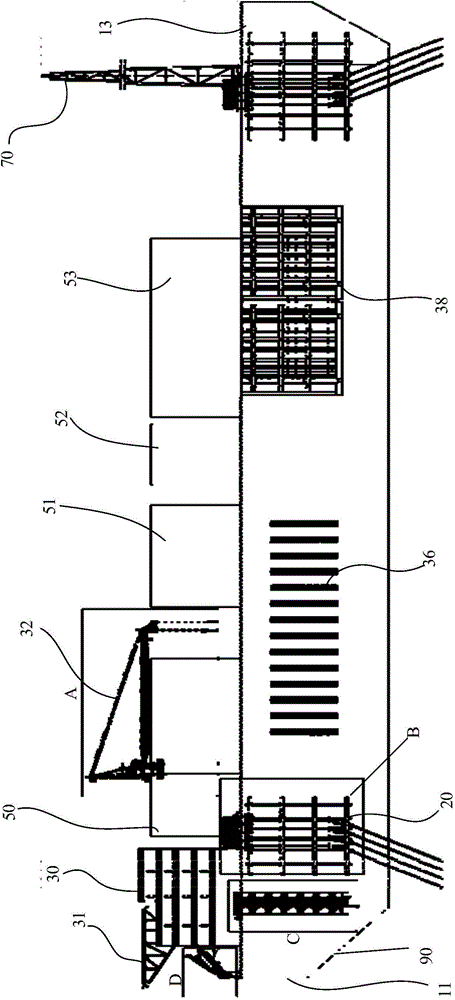

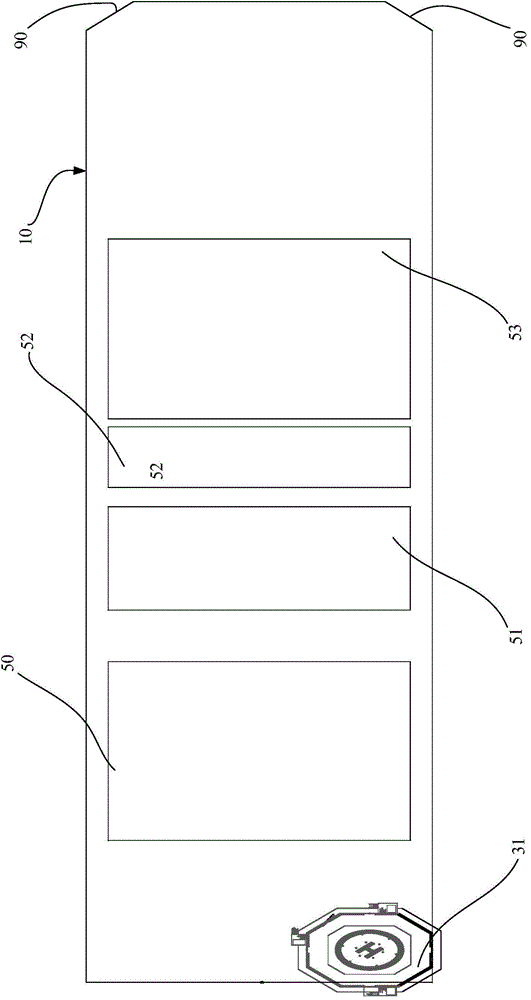

Full-automatic car loader

The invention relates to a full-automatic car loader. The full-automatic car loader comprises a wheel-type walking frame, a supporting board mechanism, a leading-in mechanism, a lifting mechanism, a case pushing mechanism, a case allocating mechanism, a conveying mechanism and a layer pushing mechanism; a distance detection unit is arranged on the wheel-type walking frame and can position the motion trail of the wheel-type walking frame; the supporting board mechanism, the lifting mechanism and the layer pushing mechanism share the same power source; the supporting board mechanism and the layer pushing mechanism are provided with telescoping devices and can be adjusted according to the width of a boxcar so as to adapt to the change of the width of the boxcar; the lifting mechanism adopts two lifting guide rails and can adjust the frame and the height of lifting according to the height of the boxcar so as to adapt to the change of the height of the boxcar; two pairs of horizontal guide rails and driving mechanisms are arranged on the leading-in mechanism, so that the leading-in mechanism moves back and forth and right and left so as to enable targeted materials to move into the supporting board mechanism accurately; and the movement of the lifting mechanism, the case pushing mechanism, the case allocating mechanism, and the layer pushing mechanism is all controlled by a PLC control unit.

Owner:HARBIN BOSHI AUTOMATION

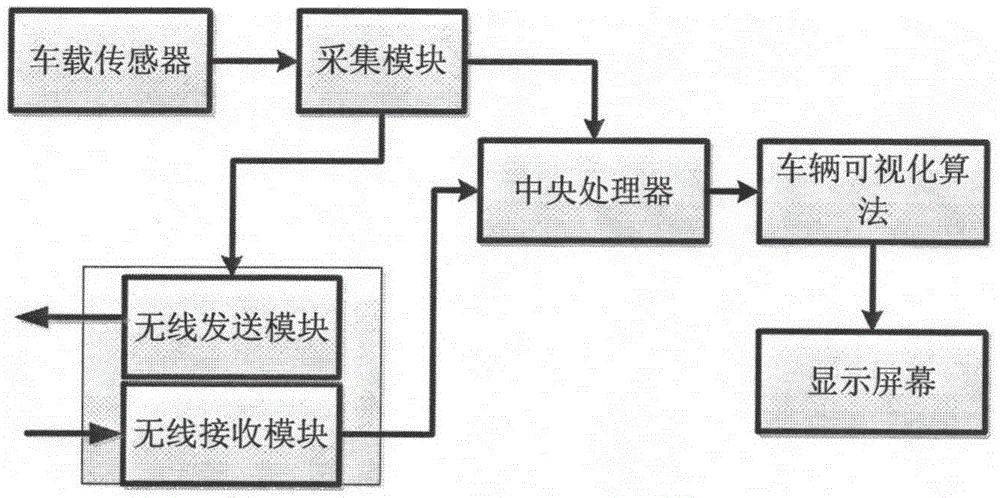

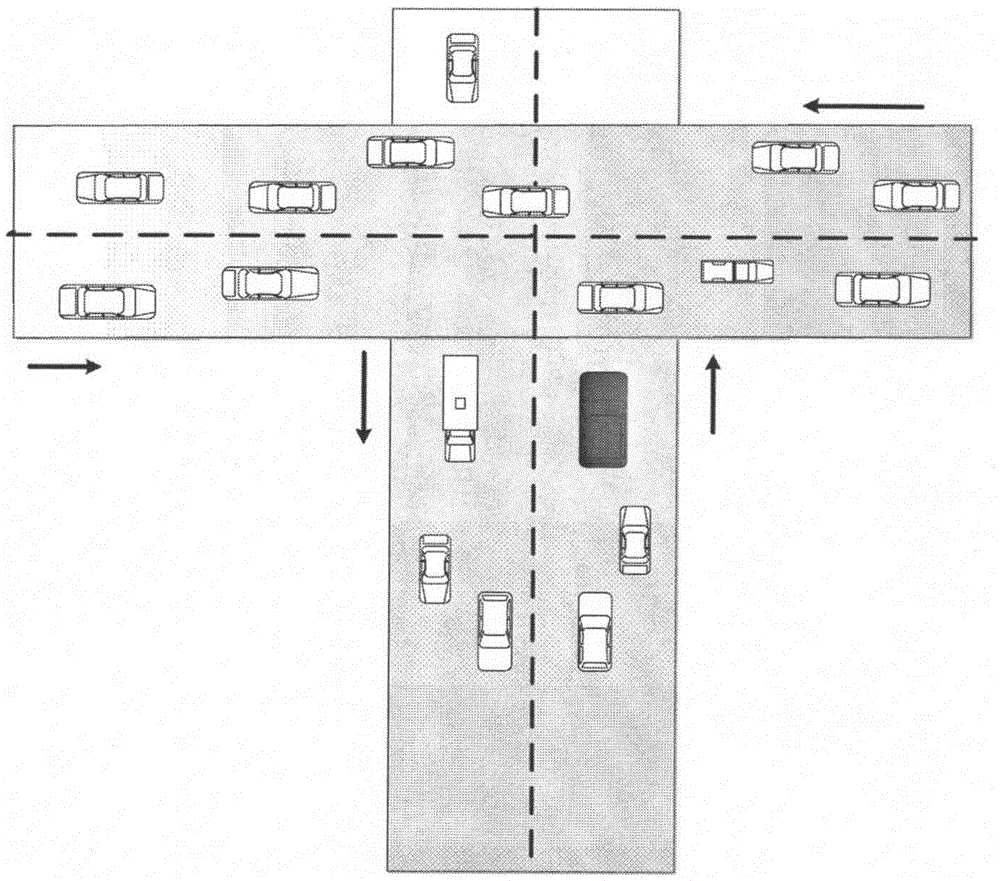

Visualized early warning method against collision based on Internet of Vehicles

The invention provides a visualized early warning method against collision based on the Internet of Vehicles. According to the method, vehicles exchange state messages by utilizing the vehicular Ad-hoc network technology to sense the driving states of vehicles in the surrounding, limit of the visibility is overcome, position information of vehicles that cannot be seen can be received, and after receiving the information, a vehicle can use a collision early-warning algorithm to determine whether the vehicle may collide with a neighbor vehicle. According to the invention, satellite positioning coordinates are converted into vehicle-mounted screen coordinates, and the driving positions and states of the vehicle and the neighbor vehicle are displayed in a vehicle-mounted screen in real time.

Owner:DONGHUA UNIV

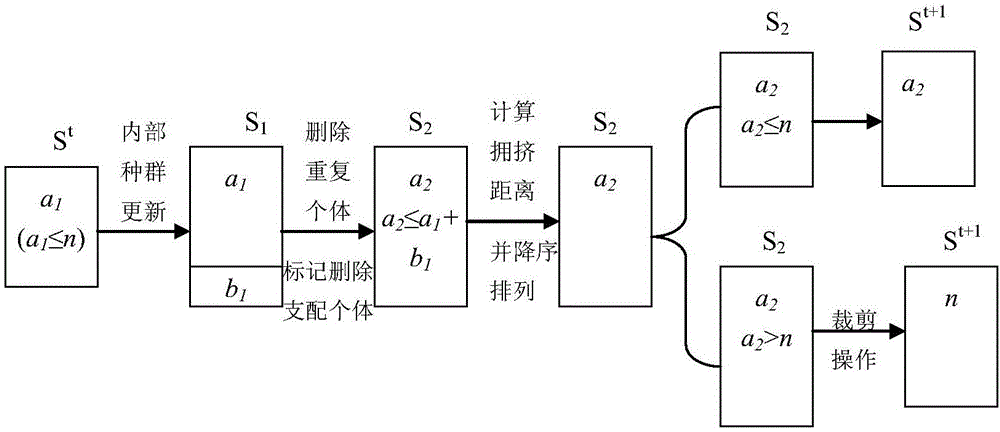

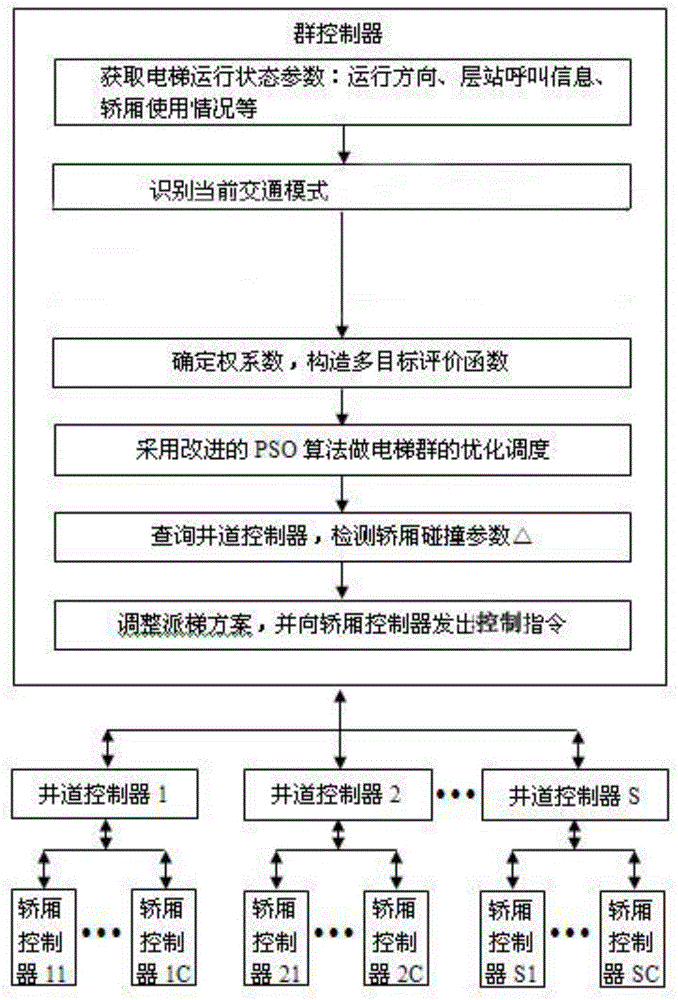

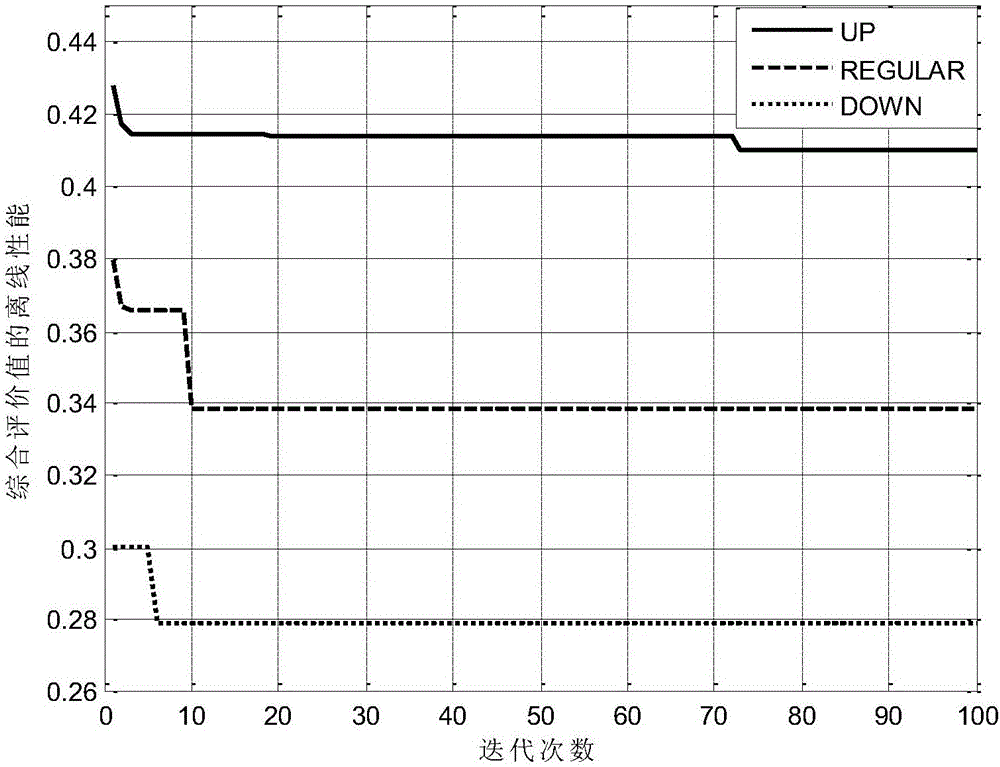

Optimized scheduling method for multi-lift-car elevator cluster

An optimized scheduling method based on a particle swarm optimization algorithm and used for a multi-lift-car elevator cluster includes the following steps that passenger flow information is generated through a passenger flow generator, wherein the passenger flow information is a hall layer elevator calling signal; parameter initialization is conducted, wherein parameters include the parameters including cluster size, the iteration number and the like of the adopted particle swarm optimization algorithm and the comprehensive evaluation function determined according to elevator running information; optimized calculation is conducted through the particle swarm optimization algorithm, the optimal solution is obtained through the limited times of iteration, and the optimal elevator dispatching scheme is determined; and the elevator dispatching scheme is converted into a control signal, elevator calling signals are reasonably distributed for all elevators, operation of all the elevators is coordinated, and therefore optimized scheduling of the elevator cluster is achieved. Because the update strategy of the global extremum is improved in the scheduling algorithm, optimal particles which are evenly distributed are obtained, the algorithm convergence and the scheduling performance are improved, meanwhile, it is avoided that the danger of collision may happen when lift cars run in the same shaft, and running safety of a whole elevator system and validity of the scheduling algorithm are ensured.

Owner:BOHAI UNIV

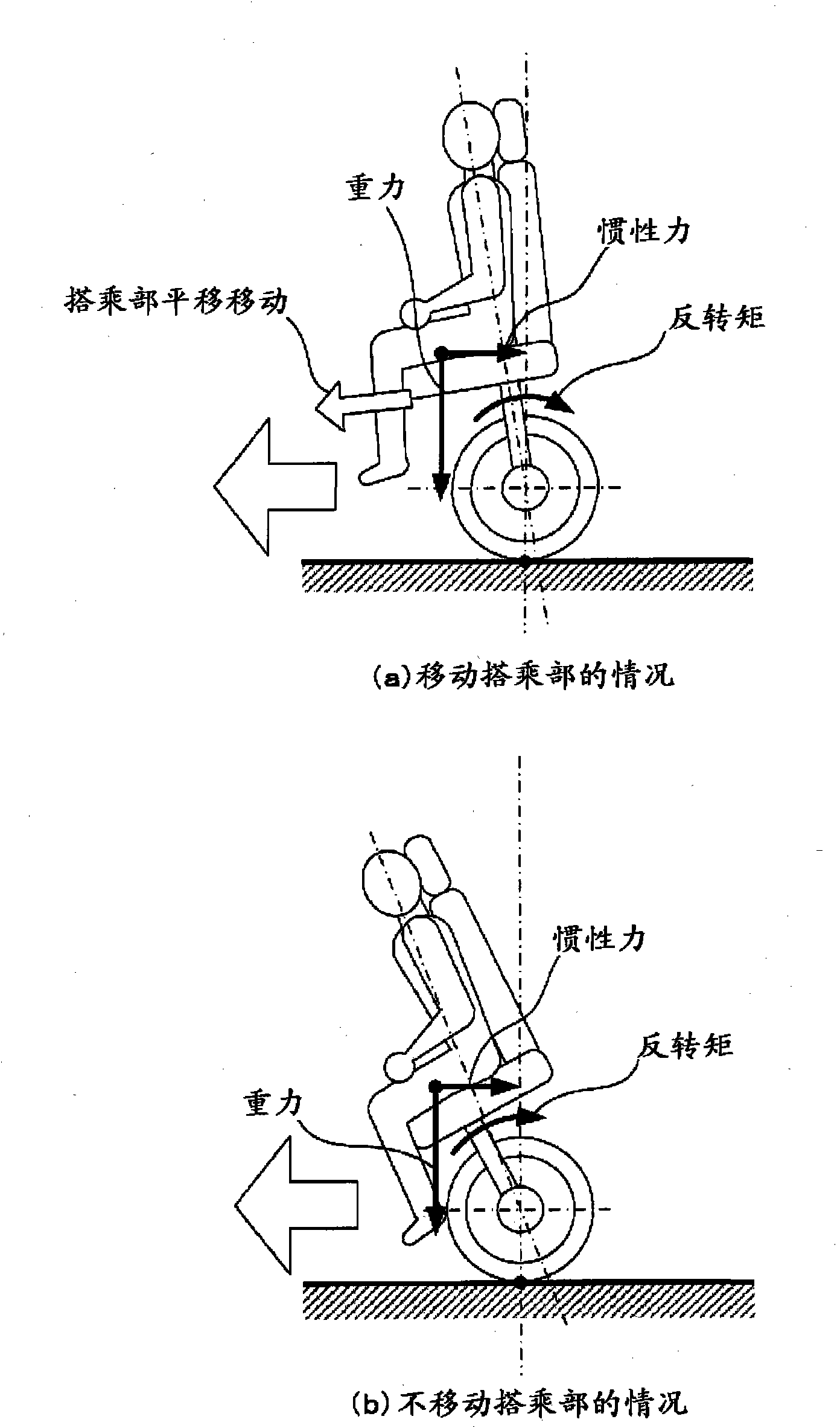

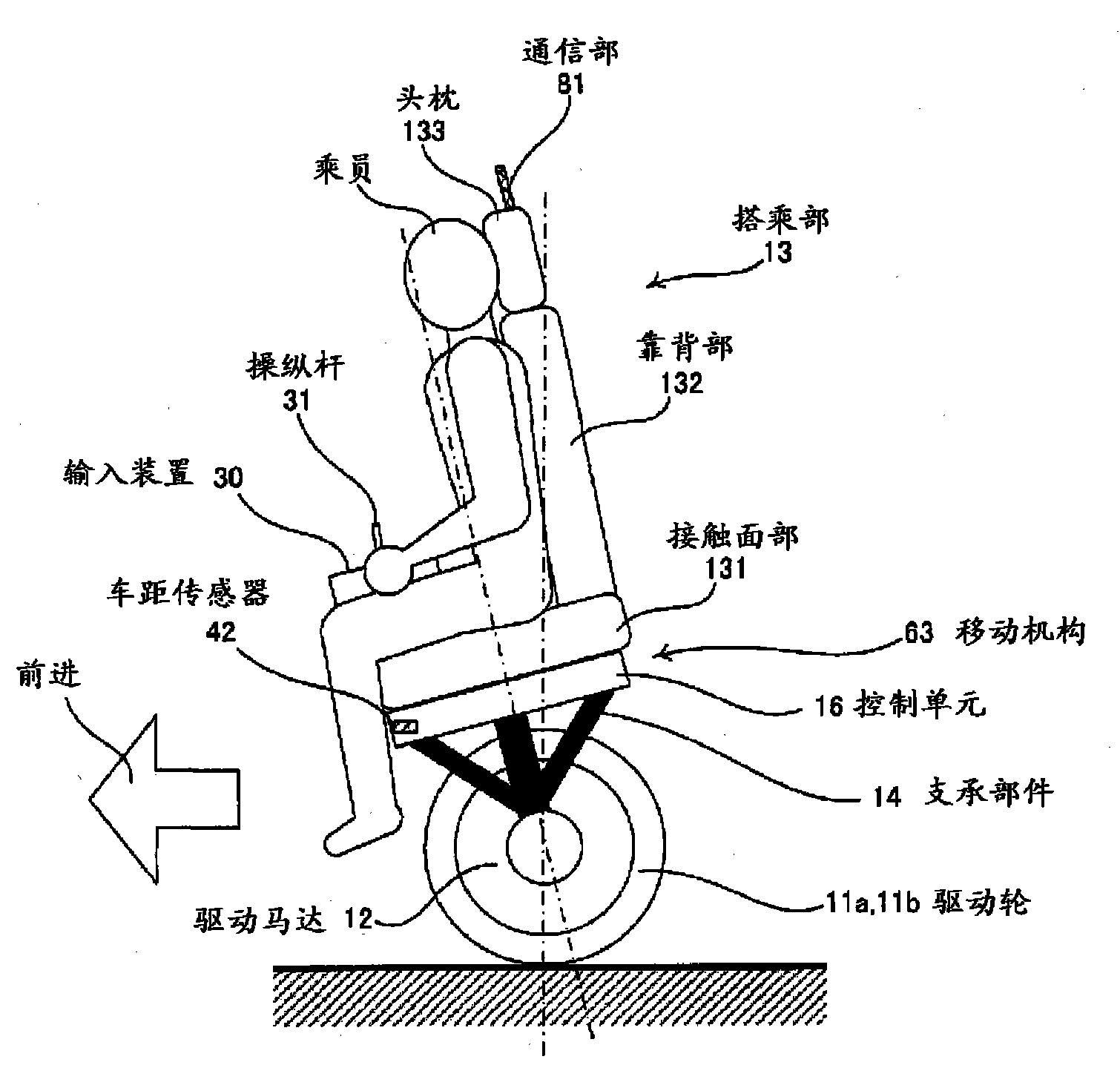

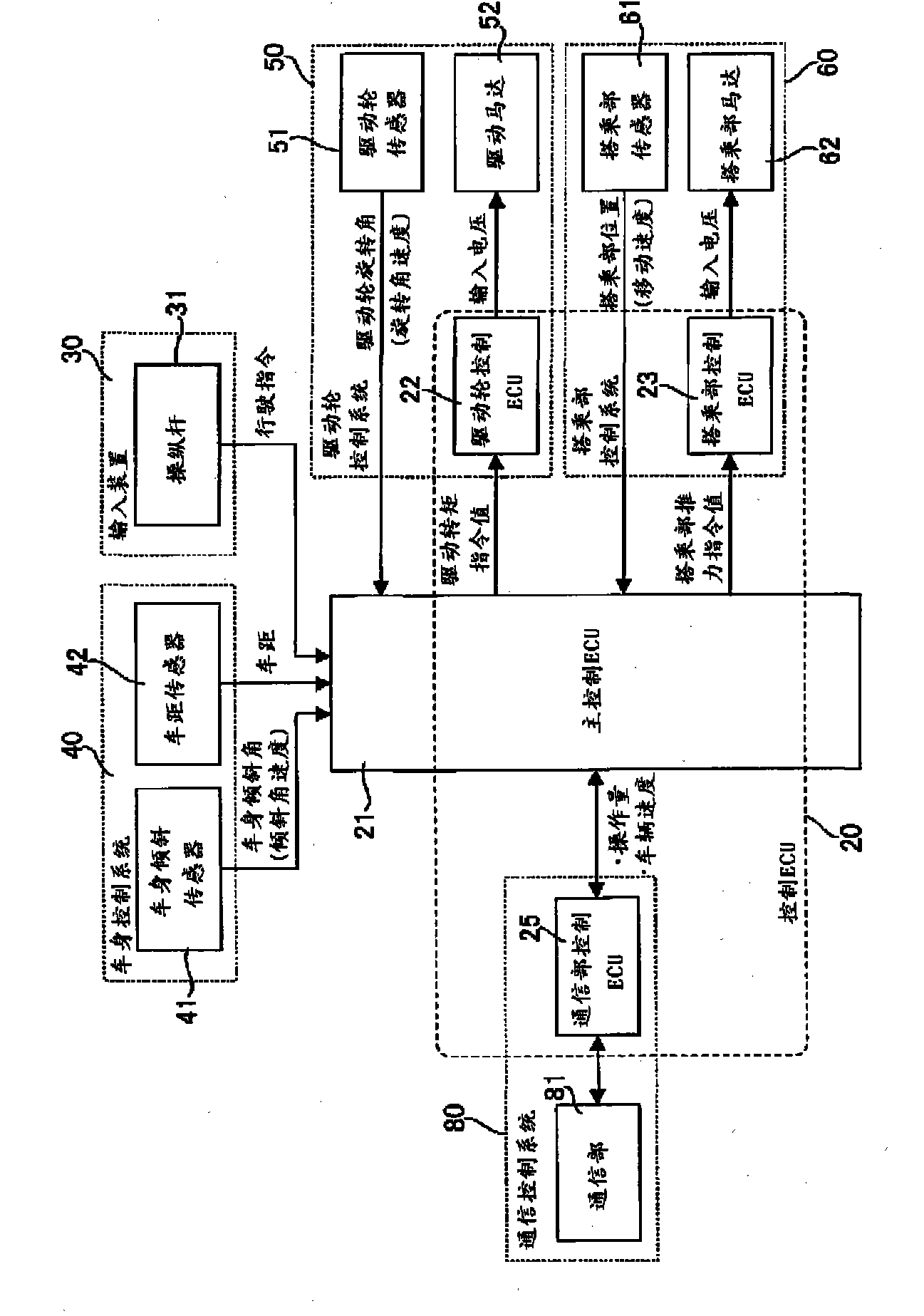

Vehicle control device

InactiveCN101868392AAvoid collision hazardAutomatic tracking driving control with high precisionArrangements for variable traffic instructionsAnti-collision systemsJoystickCommunication unit

In order to provide a vehicle control device configured to improve accuracy of an automatic follow-up control in an inverted control vehicle, the vehicle control device, which carries out automatic follow-up driving control for the control of the inverted control vehicle to automatically follow up a preceding vehicle, is provided with a communication unit (81) that receives a vehicle speed of the preceding vehicle and driving condition data in regard to a joystick operation amount from the preceding vehicle, a vehicle distance sensor (42) that measures a vehicle distance defined with the preceding vehicle, and a main control ECU (21) that calculates an acceleration command value to follow up the preceding vehicle, wherein the main control ECU (21) is characterized in making either a first acceleration command value calculated on the basis of the vehicle speed of the preceding vehicle measured by the communication unit (81) and the vehicle distance measured by the vehicle distance sensor (42) or a second acceleration command value calculated by the joystick operation amount acquired by the communication unit (81) into a target acceleration command value.

Owner:EQUOS RES

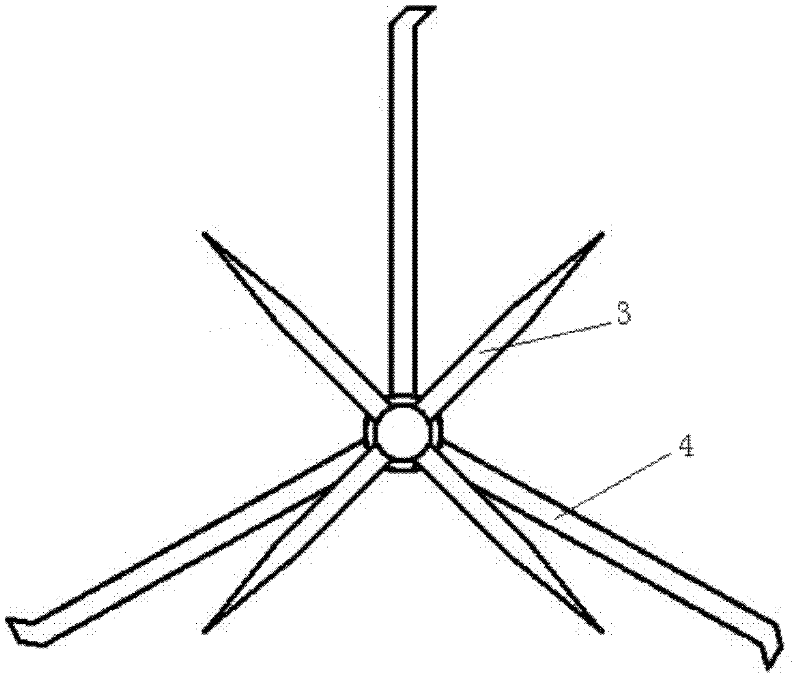

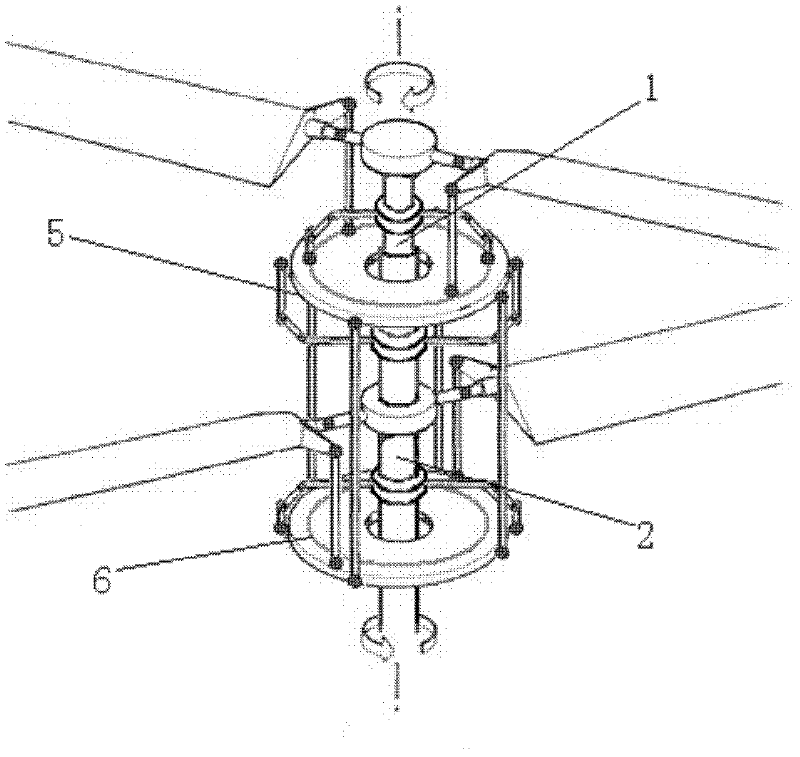

Coaxial dual-rotor helicopter

The invention discloses a coaxial dual-rotor helicopter, which includes a rotor shaft mounted at the upper part of a helicopter body and including an outer rotating shaft and an inner rotating shaft. An upper rotor and a lower rotor are arranged on the rotor shaft; the inner rotating shaft and the outer rotating shaft are connected mutually through a bearing; the upper rotor is mounted on the inner rotating shaft; the lower rotor is mounted on the outer rotating shaft; and the lengths of blades on the upper rotor are smaller than that of blades on the lower rotor. The upper rotor is provided with four blades; and the lower rotor is provided with three blades. Due to the adoption of the technical scheme, the structure is simple; the lengths, the number, the rotating speed and the material of the blades on the upper rotor are improved substantively, so that the structure is simple to operate, and the risk of blade collision caused by upper and lower rotor interference can be avoided; and meanwhile, two rotors have smaller parasite area, thereby improving the ascending power, the maximum level speed and the combination properties of the helicopter.

Owner:李杏健

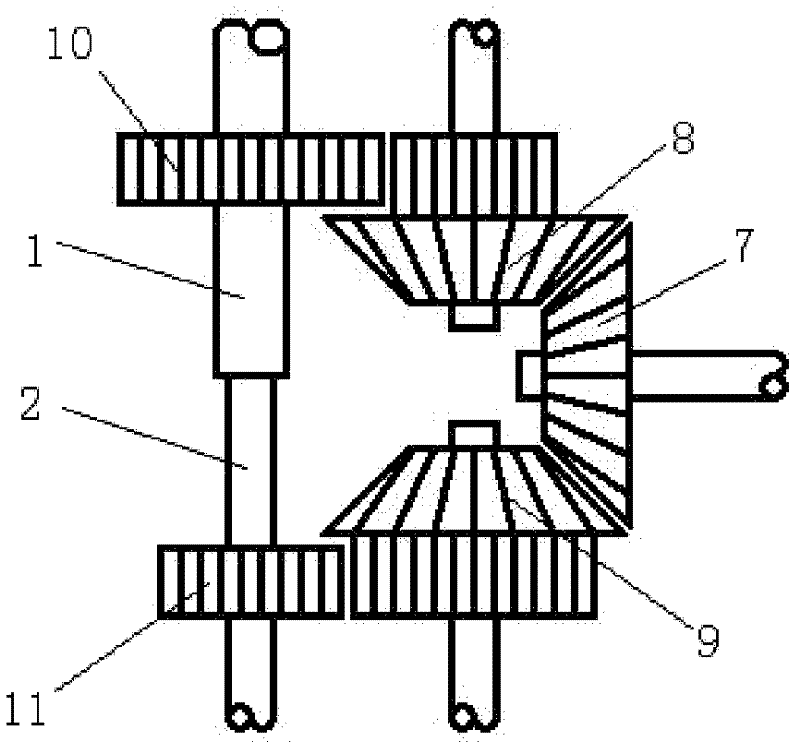

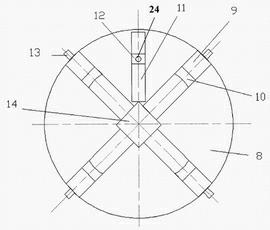

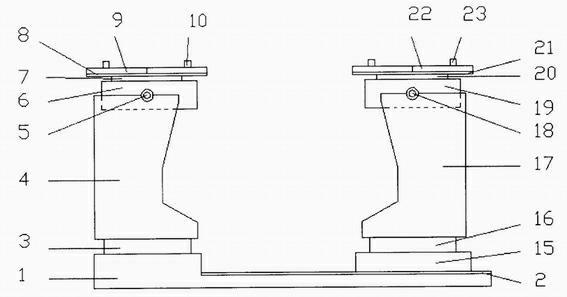

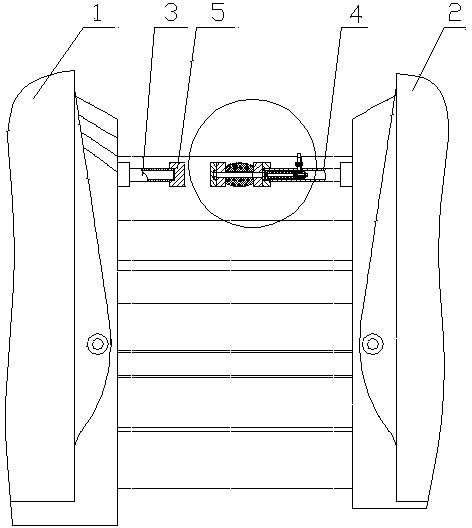

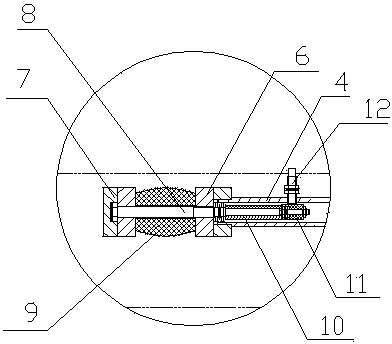

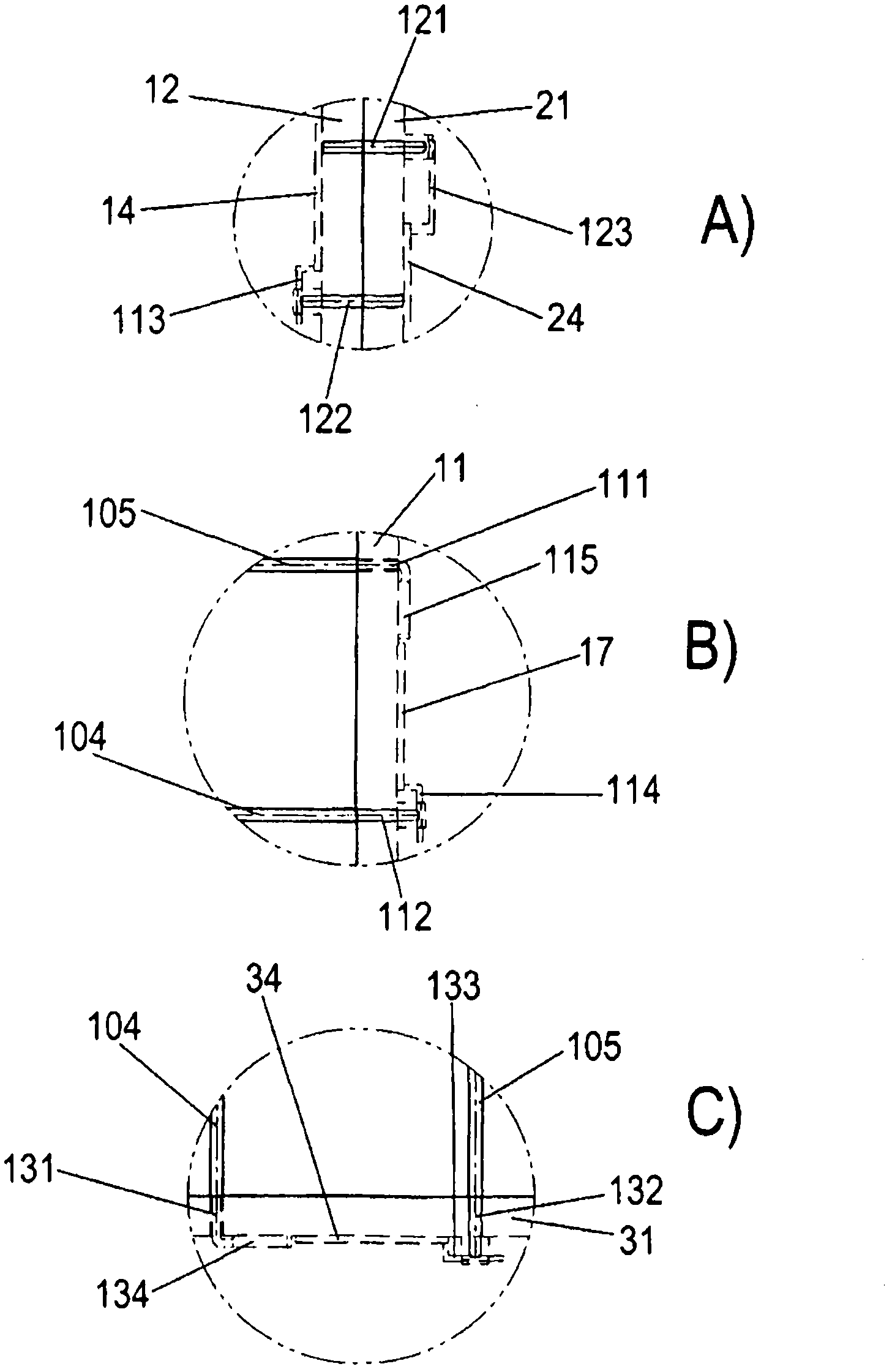

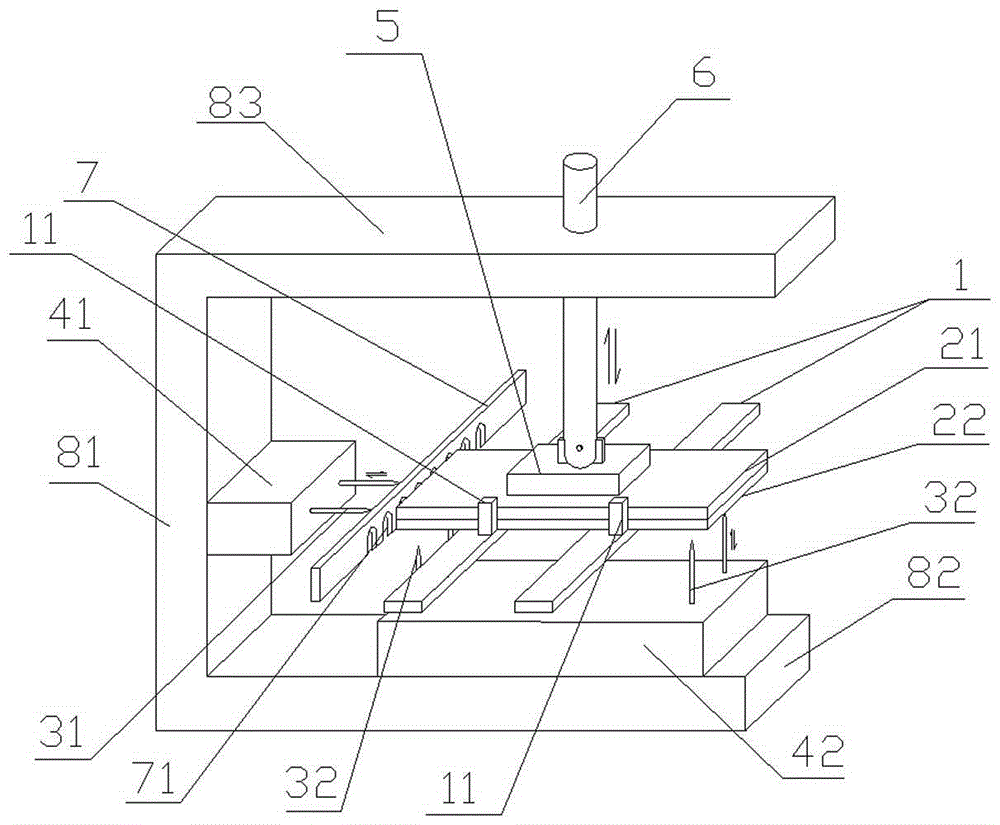

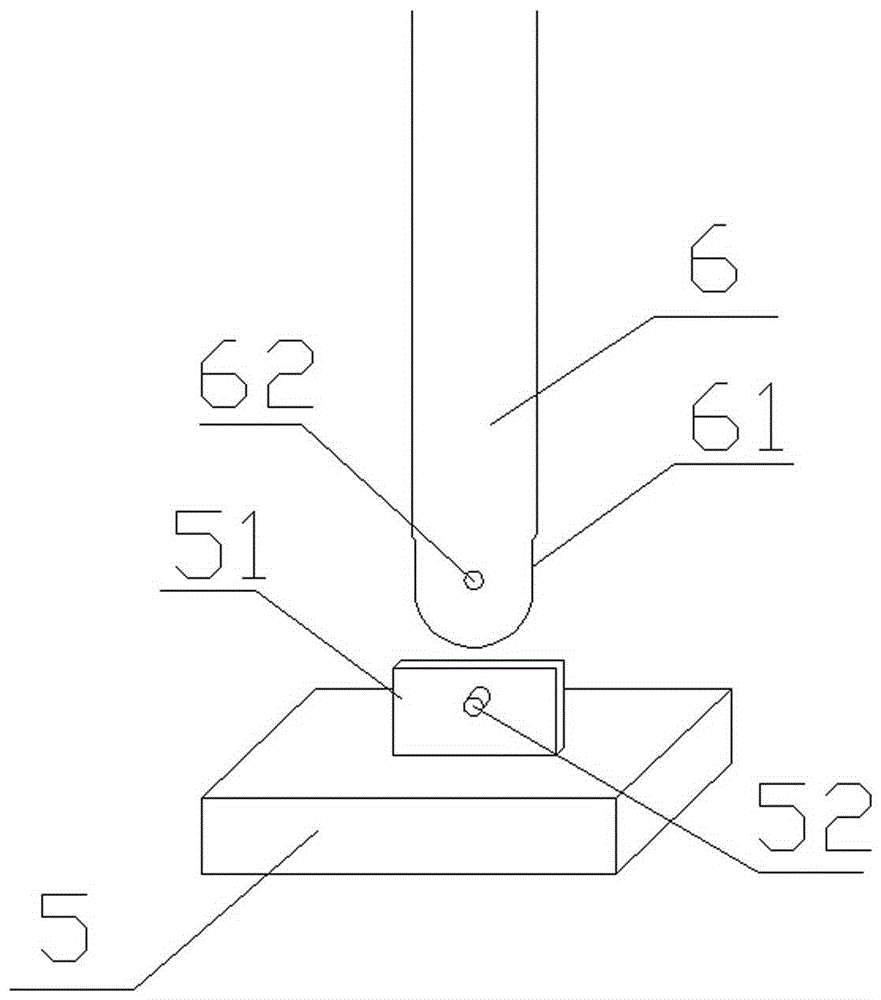

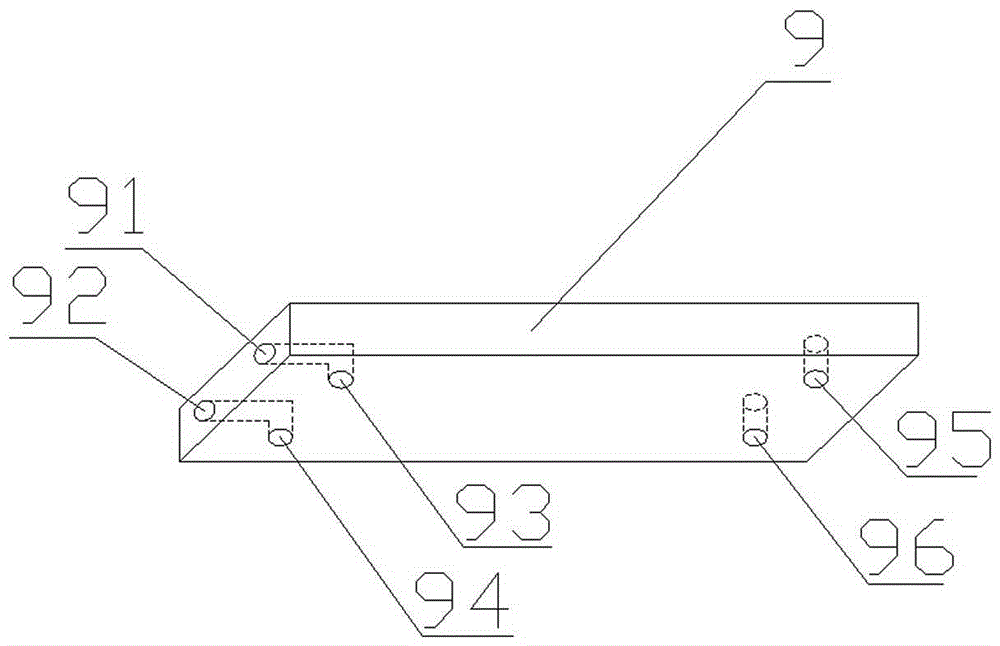

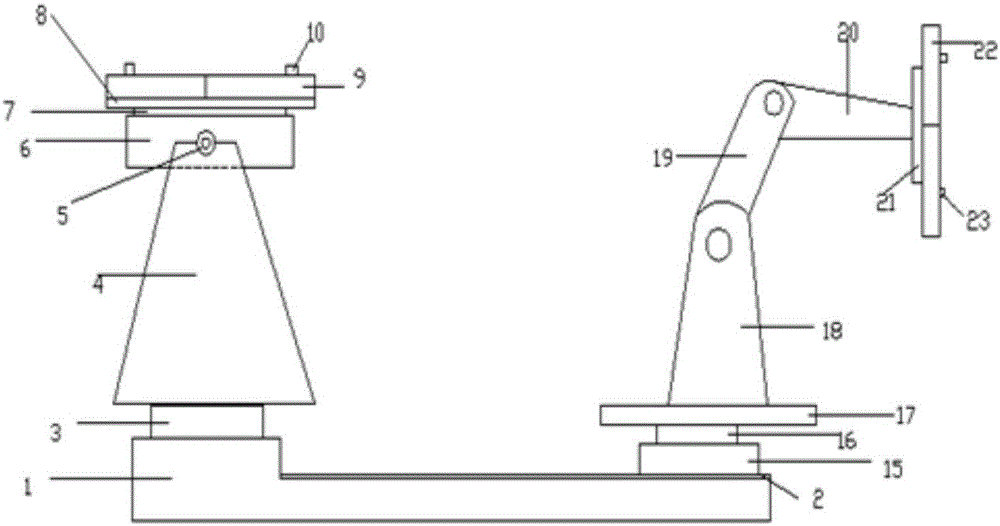

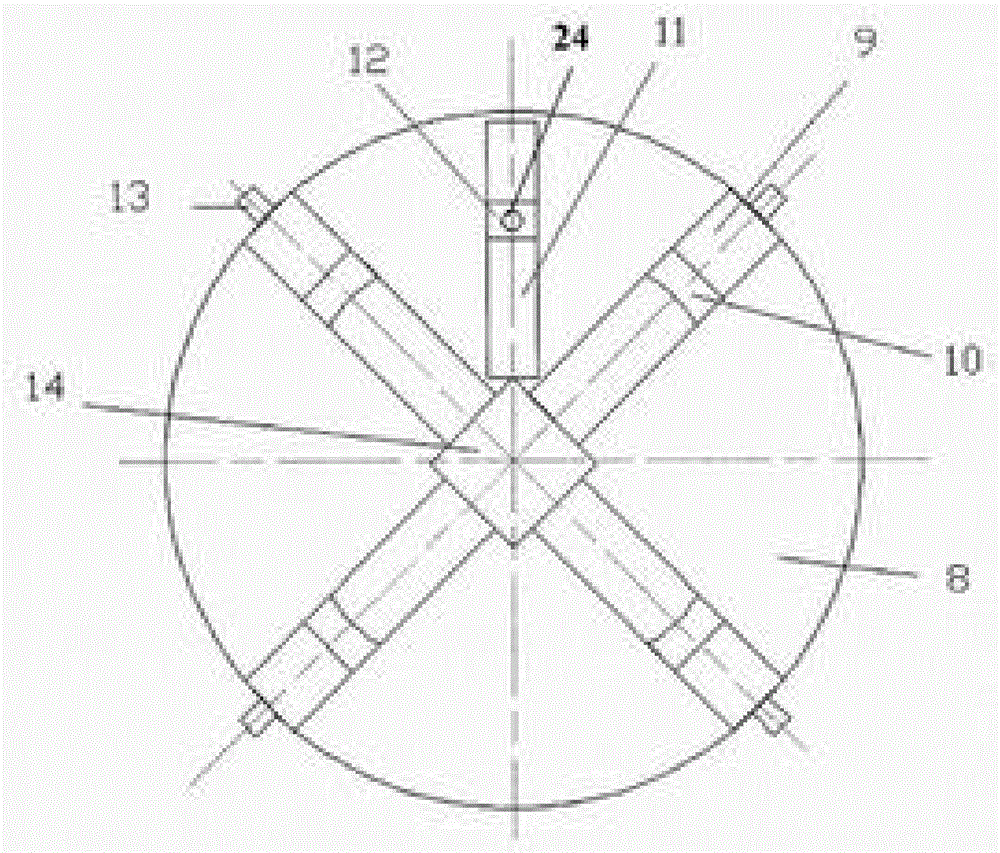

Position changing machine for measurement reproduction system of folding pipe

ActiveCN102350605AEasy to adjustPrecise processingWelding/cutting auxillary devicesAuxillary welding devicesRotational axisHeadframe

The invention discloses a position changing machine for a measurement reproduction system of a folding pipe, wherein a pedestal (1) of the position changing machine is stepped; a headstock (4) is connected with an upper step of the pedestal through a headstock rotating shaft (3); a headstock overturning platform (6) is connected with the headstock through a headstock overturning shaft (5); a headstock chuck (8) is fixed on the headstock overturning platform through a chuck rotating shaft (7); four headstock lead screw jaws (9) are installed on the headstock chuck, and four headstock locating blocks (10) are installed on the headstock lead screw jaws; a lead screw rotating handle (13) is connected with the headstock lead screw jaws through threads of the lead screw; the four headstock lead screw jaws are engaged together through a bevel gear box (14); a locating groove (11) is installed on the headstock chuck along a direction vertical to the headstock overturning shaft, and a zero point locating block (12) is installed on the locating groove; guide rails (2) are arranged on the lower step of the pedestal, a tailstock pedestal (15) is installed on the guide rails and is capable of moving along the guide rails; and the structural designs of other devices on the tailstock are same as the structural design of the headstock.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

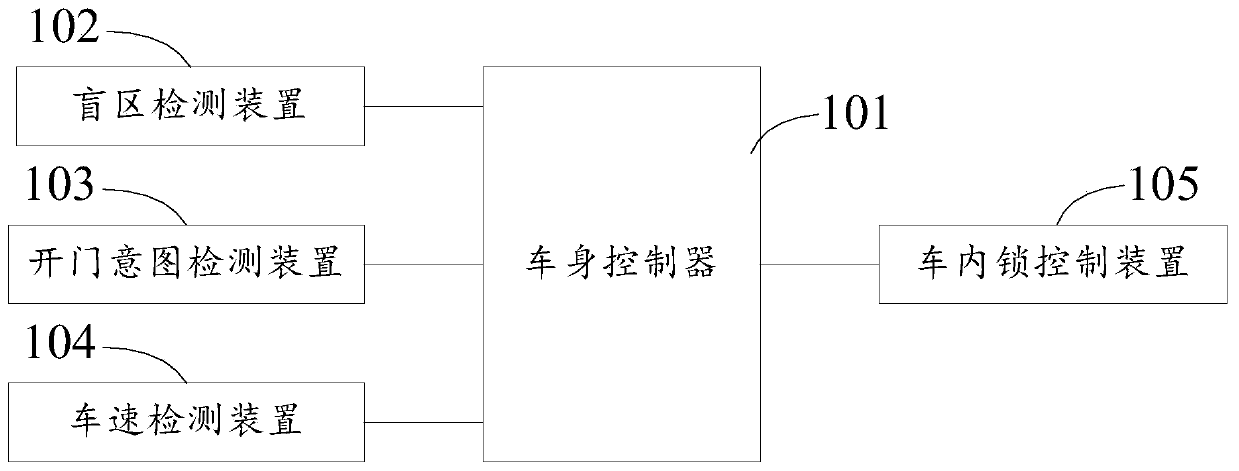

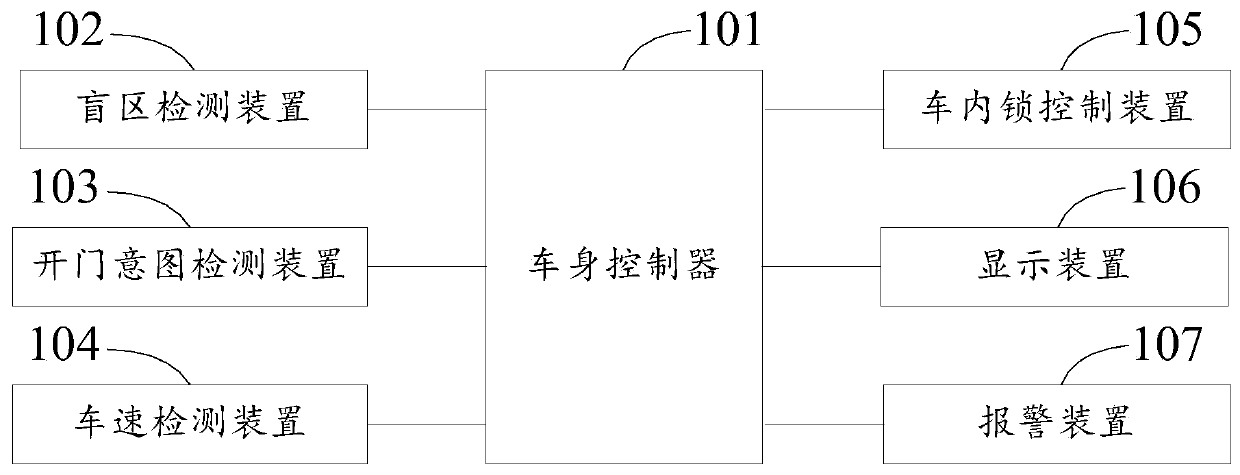

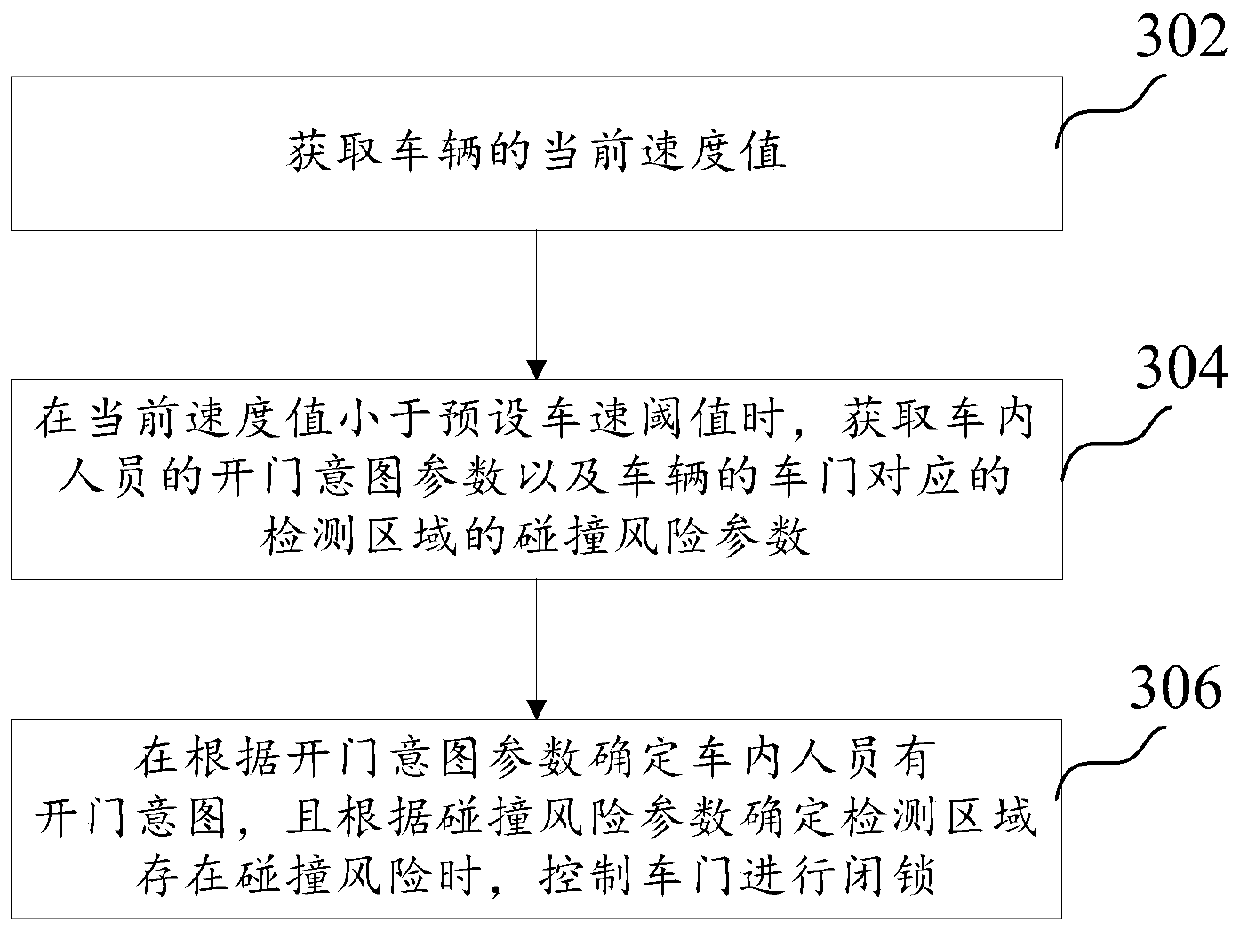

Vehicle door control system, method and device and vehicle body controller

InactiveCN110696719ARealize latchingAvoid collision hazardSignalling/lighting devicesCar doorReal-time computing

The invention relates to a vehicle door control system, method and device and a vehicle body controller. The vehicle door control system comprises the vehicle body controller, a blind area detection device, a door opening intention detection device, a vehicle speed detection device and an in-vehicle lock control device. The vehicle speed detection device is used for transmitting the detected current speed value of a vehicle to the vehicle body controller, the vehicle body controller is used for activating a safe door opening auxiliary function of the vehicle when the current speed value is smaller than a preset vehicle speed threshold value, wherein the preset vehicle speed threshold value is larger than zero, and the blind area detection device is used for detecting the collision risk ofa detection area corresponding to the door of the vehicle when the safety door opening auxiliary function is activated, and transmitting the detected collision risk parameter to the vehicle body controller. By adopting the vehicle door control system, the collision risk and the door opening intention can be detected in advance before the vehicle is parked, so that the waiting time for people in the vehicle to judge whether the door can be opened is shortened, and the efficiency is higher.

Owner:DFSK MOTOR LTD CHONGQING BRANCH CO

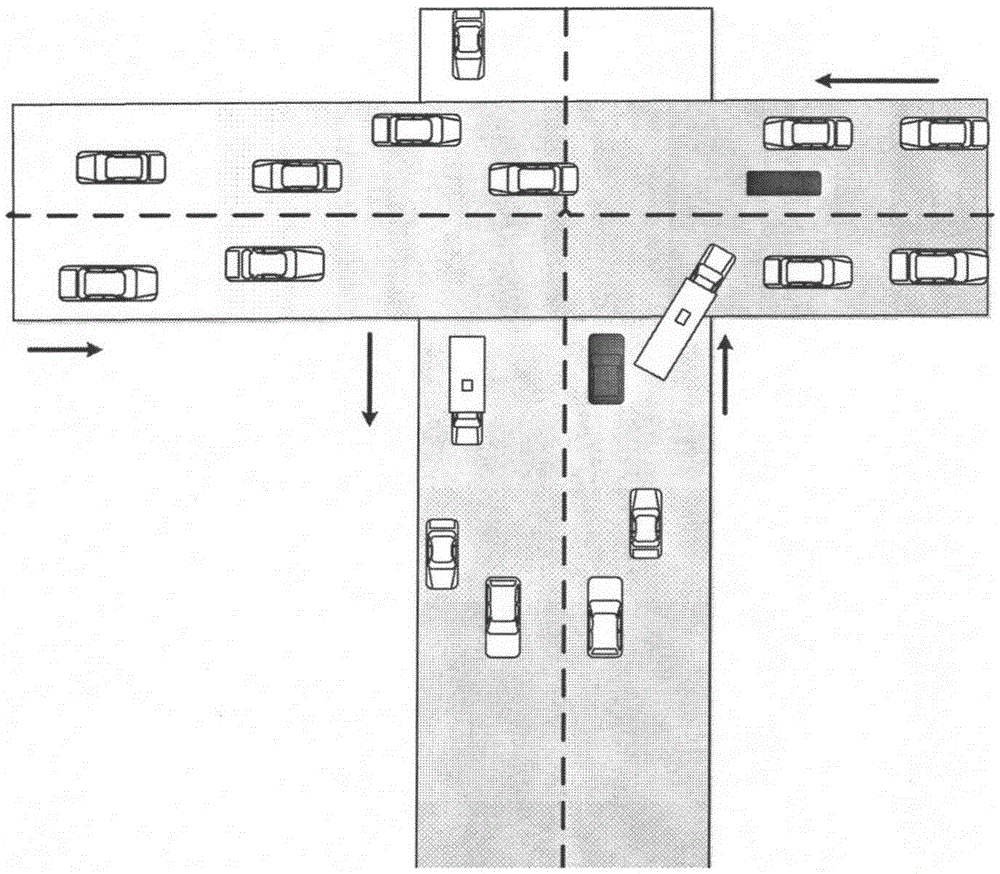

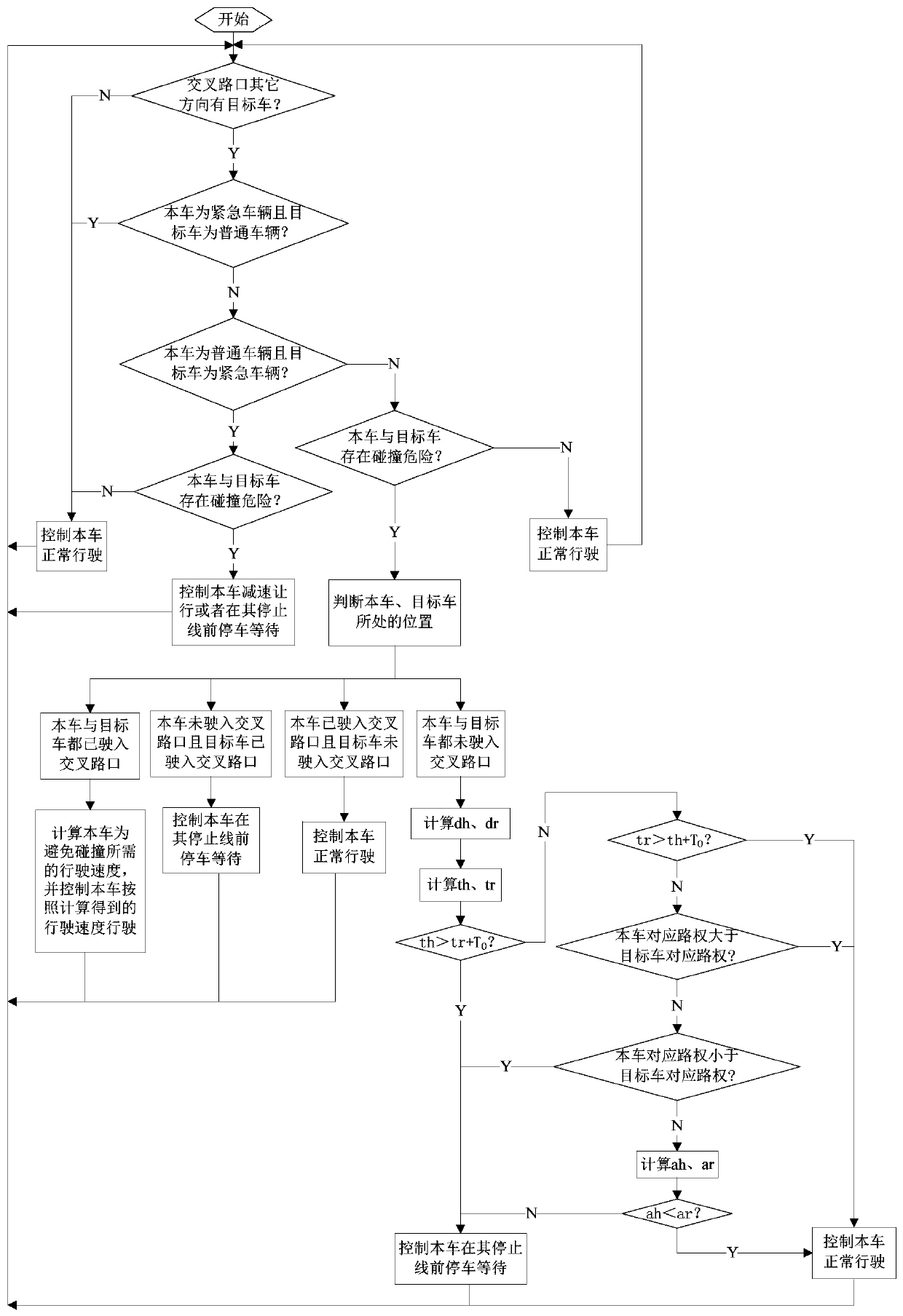

Passing method for self-driving vehicle at intersection without signal light

InactiveCN110473419ALow costAvoid collision hazardAnti-collision systemsReal-time computingSelf driving

The invention discloses a passing method for a self-driving vehicle at an intersection without a signal light. The method is executed by a vehicle-mounted actuator, and comprises steps: whether a target vehicle exists in other directions of the intersection is firstly judged; if yes, judgment is performed according to types of the vehicle and the target vehicle; and judgment is then performed according to whether the danger of collision exists to the vehicle and the target vehicle; and whether the vehicle can pass is thus determined. The danger of collision happening to the self-driving vehicle at the intersection without the signal light can be avoided, and safe passing of the vehicle can be ensured.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

FPSO (Float Production Storage and Offloading) ship

InactiveCN104590497AGood ability to resist wind and wavesIncrease oil storageVessel superstructuresVessel mastsProcess systemsFlare

The invention discloses an FPSO ship. The total length of a ship body is 310m to 330m; the molded breadth is 60m to 65m; the moulded depth is 30m to 35m and the maximum draft is 20m to 25m; from a stern to the other stem of the ship body, the ship body sequentially comprises a living building, a main power station, a power distribution module, a heat station module, a process system module, an oil gas processing and metering module and a flare tower, wherein four mooring sites are symmetrically arranged at the left and right boards of the stern and the other stem of the FPSO ship in total; the left and right boards of the stern are respectively and symmetrically provided with a set of external oil transportation device. According to the FPSO ship, the principle dimension of the ship body meets the oil storage capacity of an oil hold of the FPSO ship and the demands of an upper part module, as well as that the functions implemented are adaptive to the ship type; furthermore, the layout of the stem, the middle part of the ship and the other stem meets the living and operating demands of personnel; in addition, by adopting the multi-site mooring, the maximum tension of a mooring line of the mooring system and the maximum operating response of the ship body can be controlled better; and the external oil transportation device can be set to prevent the danger of being impacted with the FPSO ship.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD +1

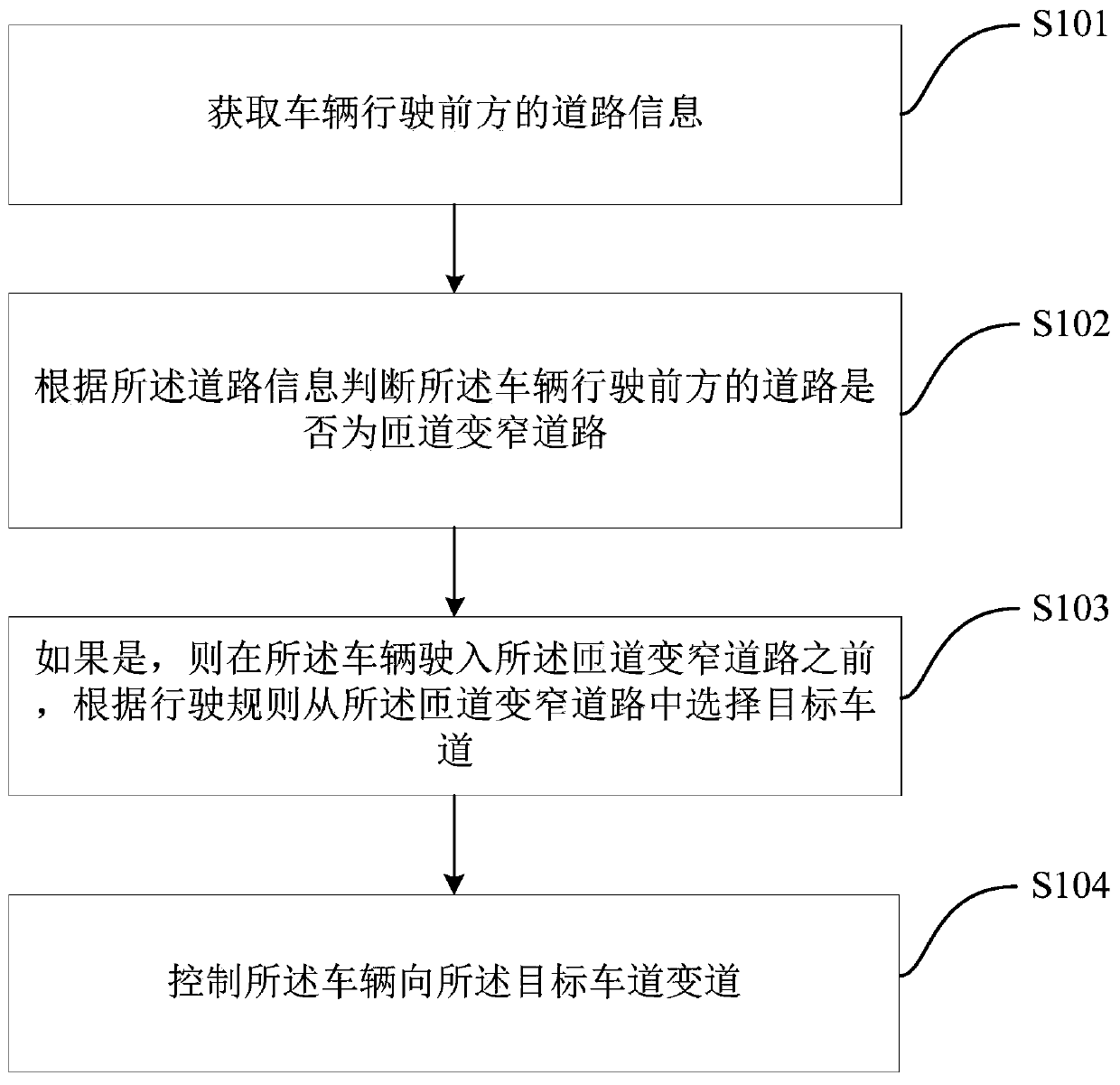

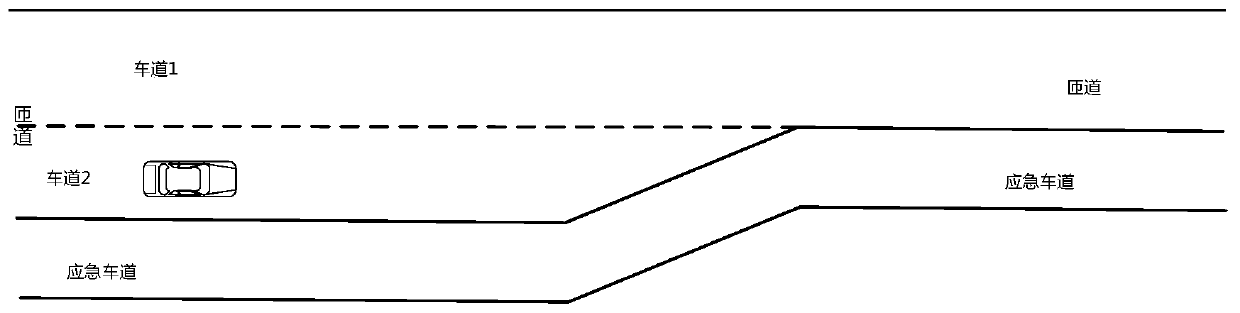

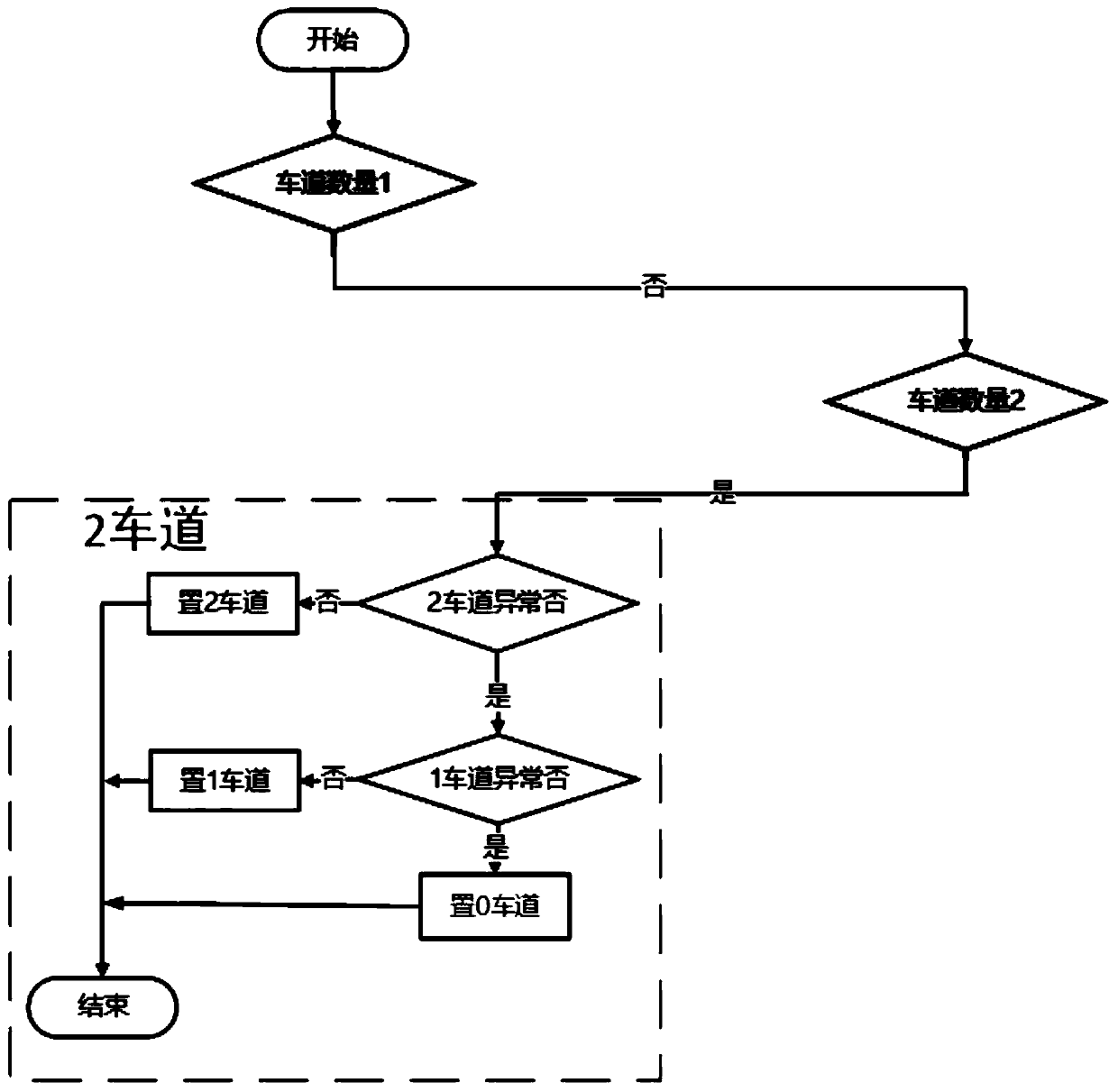

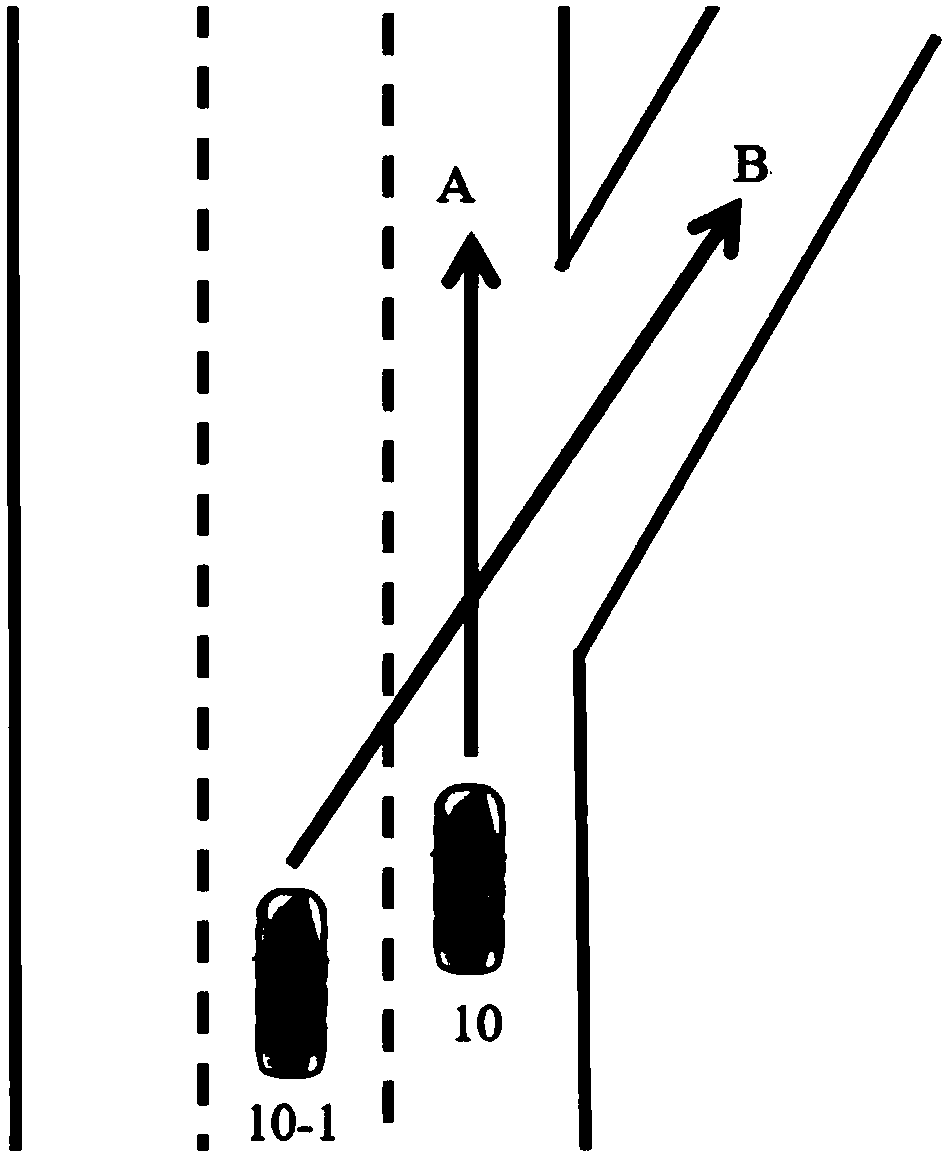

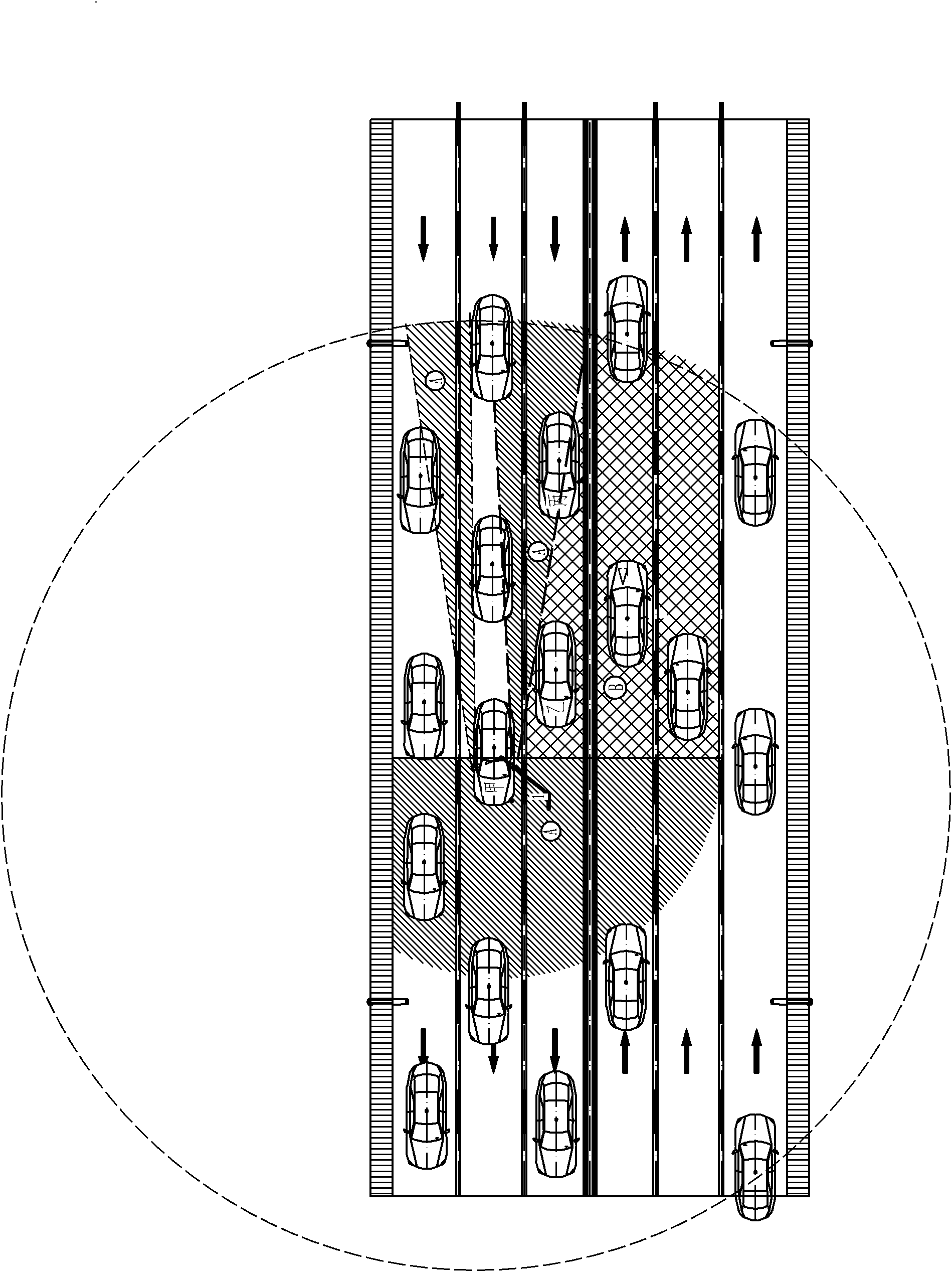

Autonomous driving vehicle lane selection method and system, and vehicle

ActiveCN110619758AIn line with driving habitsAvoid collision hazardRoad vehicles traffic controlPosition/course control in two dimensionsEngineeringVehicle driving

The invention provides an autonomous driving vehicle lane selection method and system and a vehicle. The autonomous driving vehicle lane selection method comprises the steps of obtaining road information ahead of the vehicle; judging whether the road ahead of the vehicle is a ramp narrowing road according to the road information; if so, before the vehicle drives into the ramp narrowing road, selecting a target lane from the ramp narrowing road according to a driving rule; and controlling the vehicle to change lanes to the target lane. According to the autonomous driving vehicle lane selectionmethod provided by the invention, the priority driving target lane of the autonomous driving vehicle can be planned when the autonomous driving vehicle drives on the expressway ramp, thereby avoidingthe danger of collision with other vehicles caused by a large lateral deviation of the autonomous driving vehicle driving on the ramp due to inaccurate positioning of a map; and the target lane selection planning mode conforms to the driving habit of people.

Owner:毫末智行科技有限公司

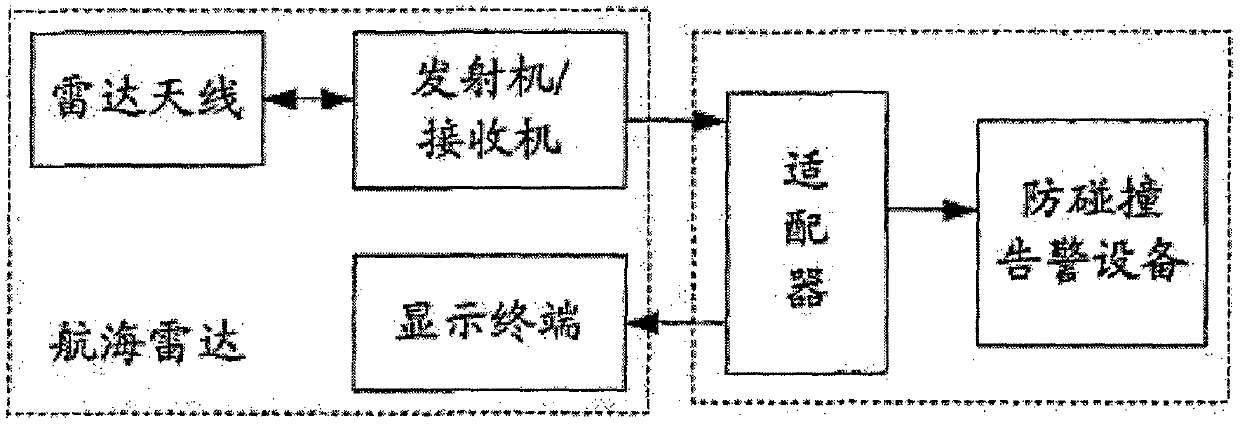

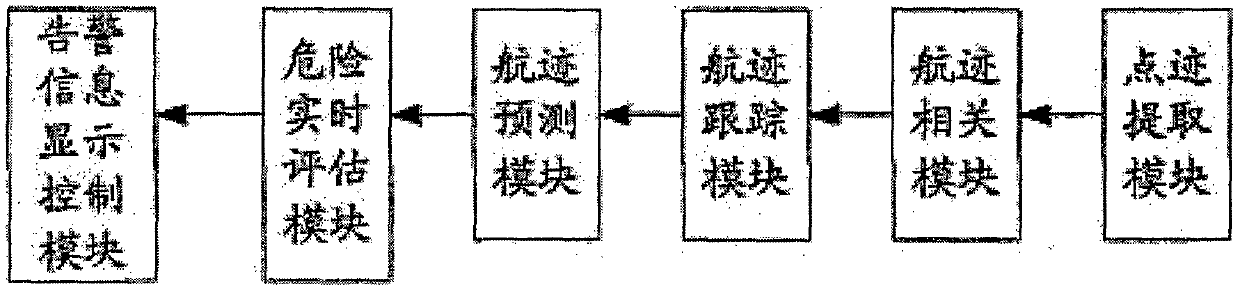

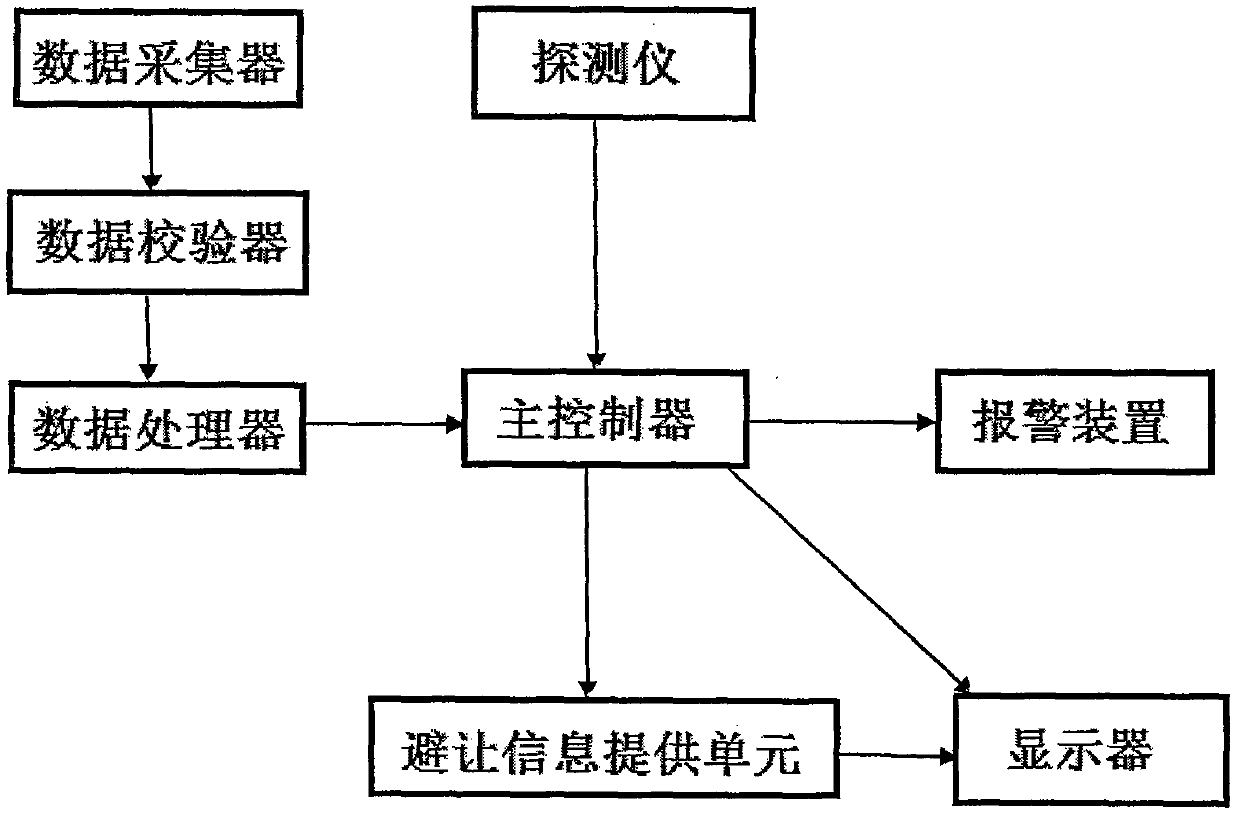

Anti-collision radar alarm system

PendingCN109683163AImprove readabilityImprove securitySatellite radio beaconingRadio wave reradiation/reflectionData collectorMarine navigation

The invention discloses an anti-collision radar alarm system. The system comprises a marine radar and an anti-collision warning device, and a transmitter / receiver and a display terminal of the marineradar are connected with the anti-collision warning device through a port adapter; the anti-collision warning device comprises a display, an alarm device, a depth sounder, a data collector, a data checker, a data processor and a main controller for receiving data information processed by the data processor, predicting future trends of target motion, conducting real-time evaluation judgement on a target risk, controlling the target information to be displayed on the display in graphic and character ways, and controlling the alarm device to emit an audible and optical alarm signal. The system can obtain the current navigation data of an area so that a ship can avoid the collision of other ships, island blocks or floating objects, and effectively improve the safety of navigation.

Owner:杭州网为通信有限公司 +1

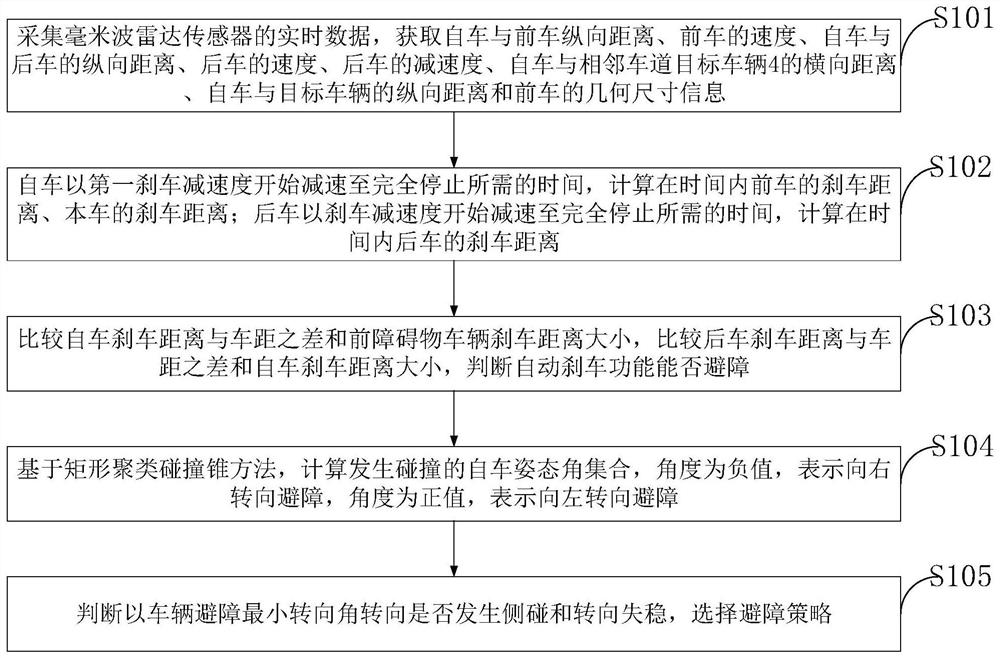

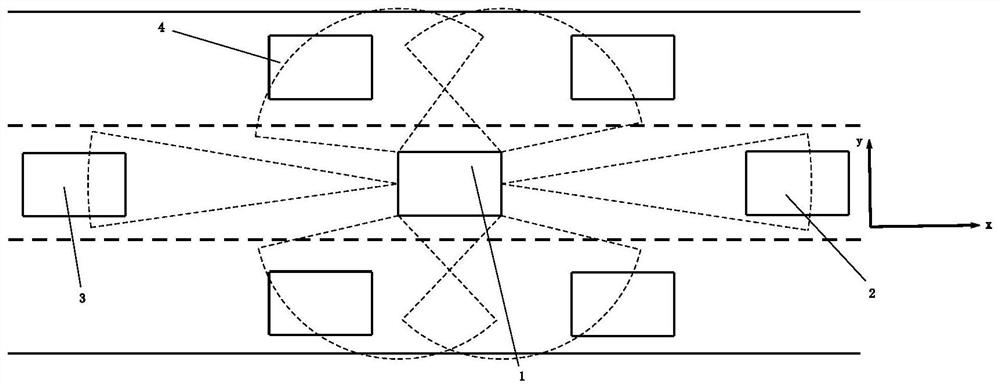

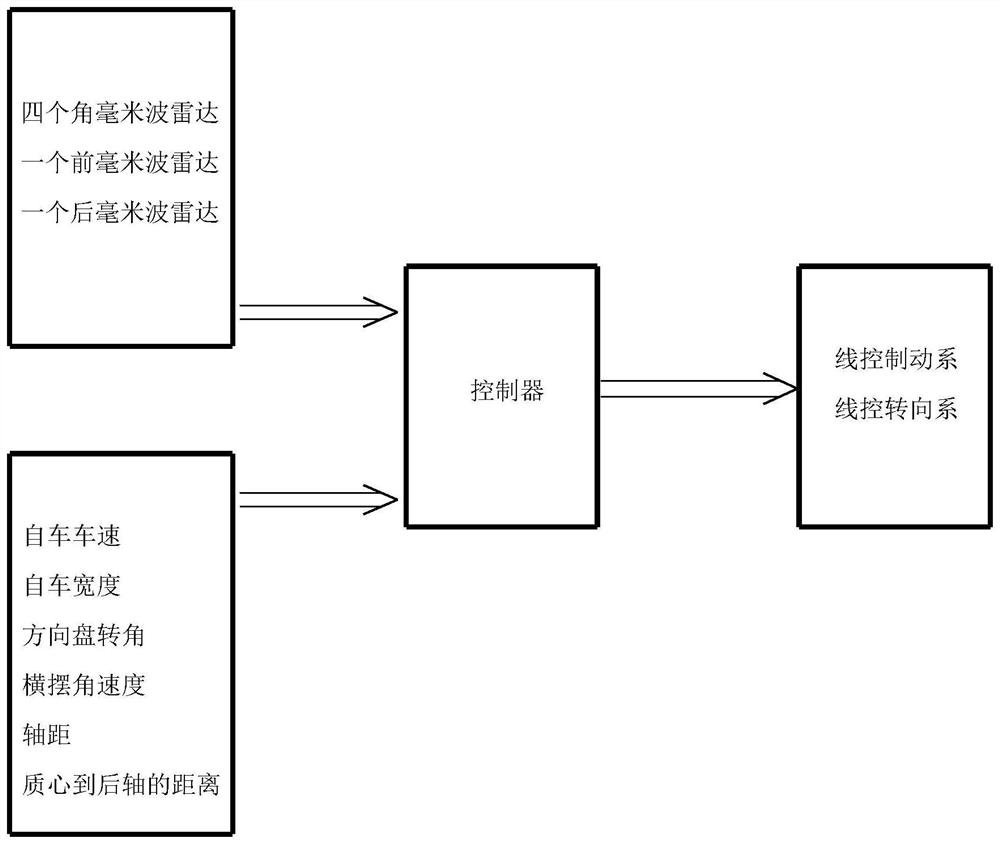

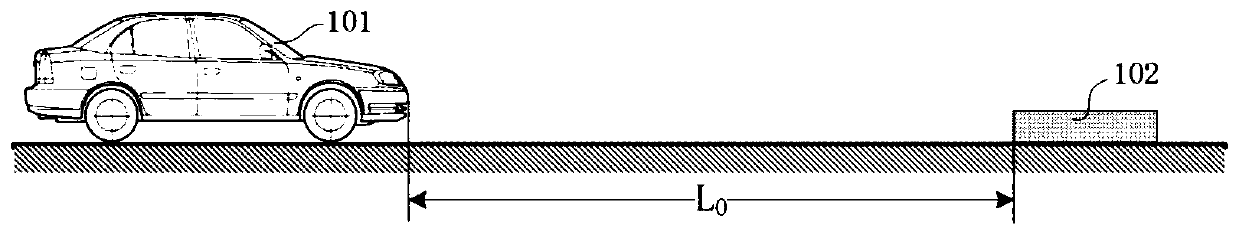

Active obstacle avoidance control method based on rectangular clustering collision cone model

ActiveCN111976721ANo rear-end riskSolve operational problemsControl devicesAutomatic steeringSteering angle

The invention belongs to the technical field of automobile safety, and discloses an active obstacle avoidance control method based on a rectangular clustering collision cone model. The method comprises the steps that whether collision can be avoided through automatic braking in a lane or not is judged, and if that collision can be avoided through automatic braking and meanwhile a rear vehicle andan own vehicle have no rear-end collision risk is judged, automatic braking is adopted; if that collision cannot be avoided through automatic braking is judged, rectangular clustering is conducted onthe own vehicle and a front obstacle vehicle, the minimum steering angle during automatic steering collision avoidance is calculated by means of the collision cone principle; and if that the own vehicle and a target vehicle on an adjacent lane have no collision risk under the input of the steering angle and meanwhile the own vehicle can keep steering stability is met, automatic steering collisionavoidance is conducted. According to the active obstacle avoidance control method based on the rectangular clustering collision cone model, the minimum steering angle during automatic steering is calculated by means of the collision cone principle, the problem caused by steering amplitude misoperation of a driver under the emergency condition is solved, and the purpose of reducing more serious accidents caused by side collision of the own vehicle and the front vehicle or vehicle instability is achieved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

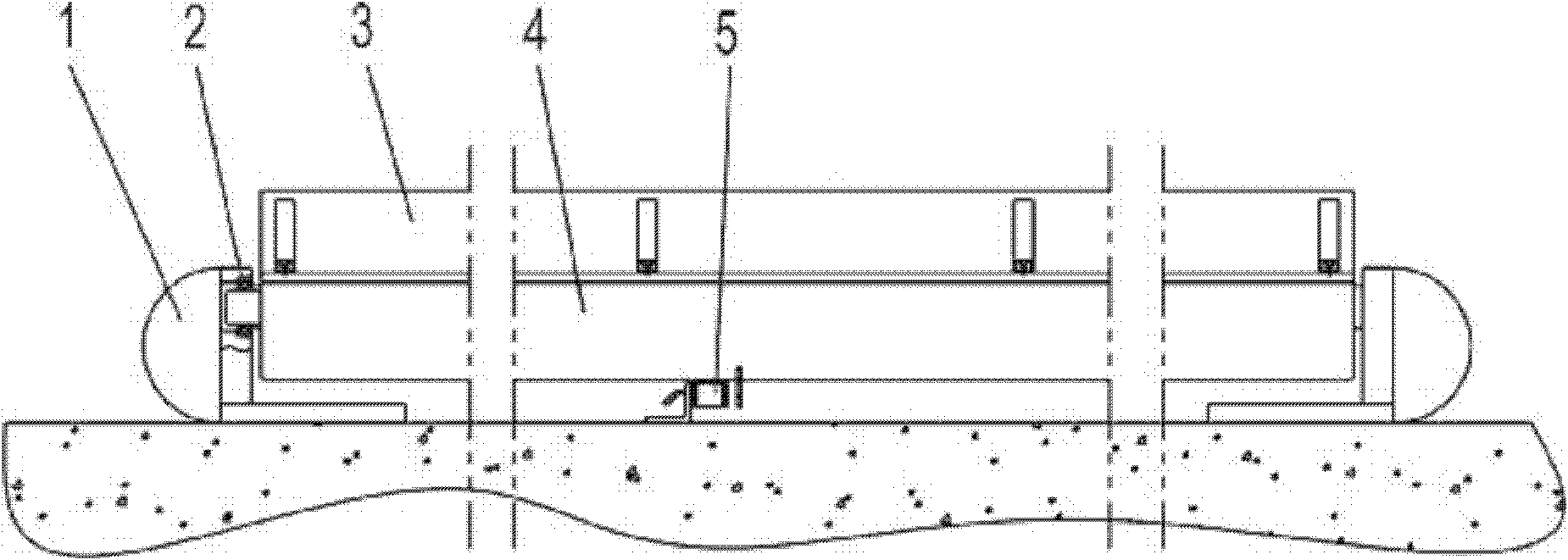

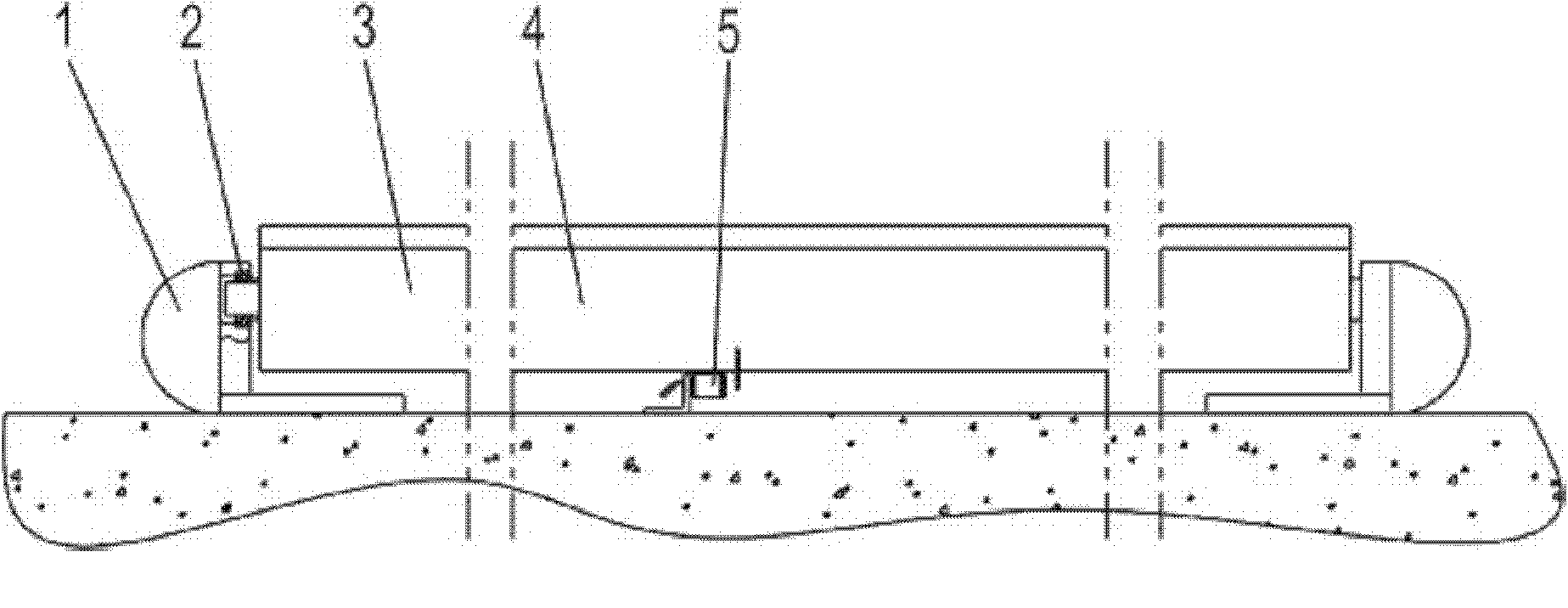

Vehicle chassis height detecting device

The invention provides a vehicle chassis height detecting device, which comprises a fixing seat, a supporting bearing, a rubber strip, an eccentric shaft and a position switch. The rubber strip is fixed on the eccentric shaft, the eccentric shaft is connected with the fixing seat via the supporting bearing, the position switch is disposed on the eccentric shaft, the rubber strip is in a perpendicular detecting work state under the gravity action of the eccentric shaft, and simultaneously, the position switch is located at a detection position. Compared with the prior art, the vehicle chassis height detecting device is low in cost and simple in structure, is safe and reliable, realizes that the heights of chassis of vehicles permitted to enter stereoscopic parking equipment are compulsorily limited by a mechanical means before the vehicles enter the stereoscopic parking equipment, and prevents vehicles with over-low chassis from entering the stereoscopic parking equipment to cause collision dangers.

Owner:HANGZHOU XIZI IUK PARKING SYST CO LTD

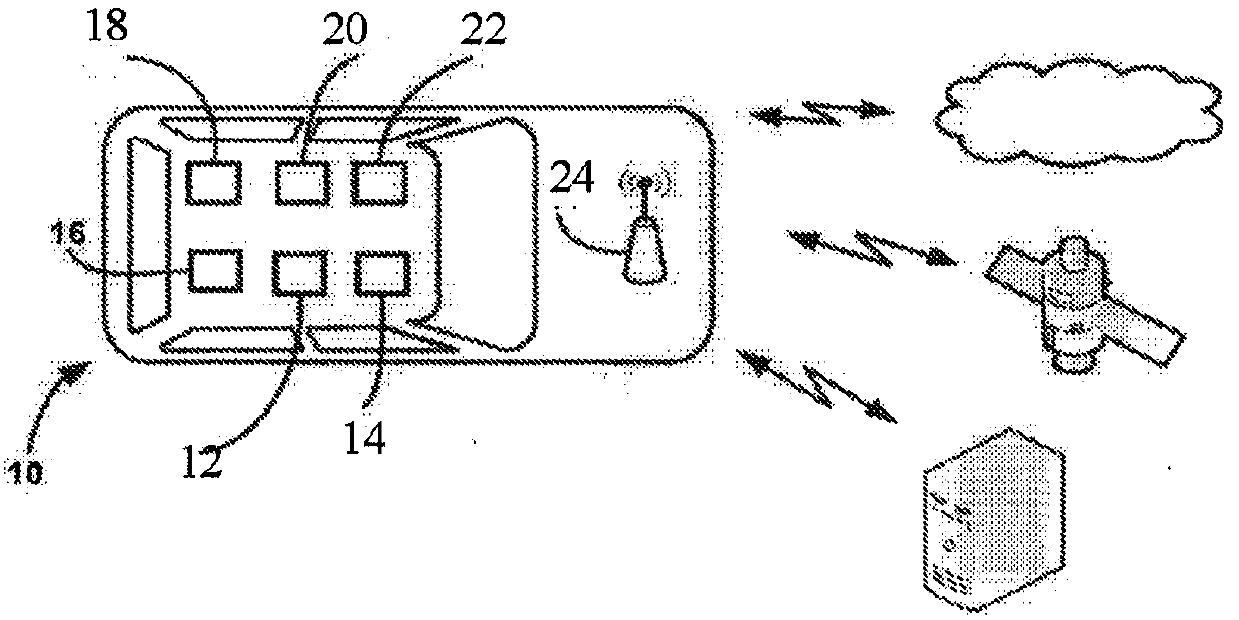

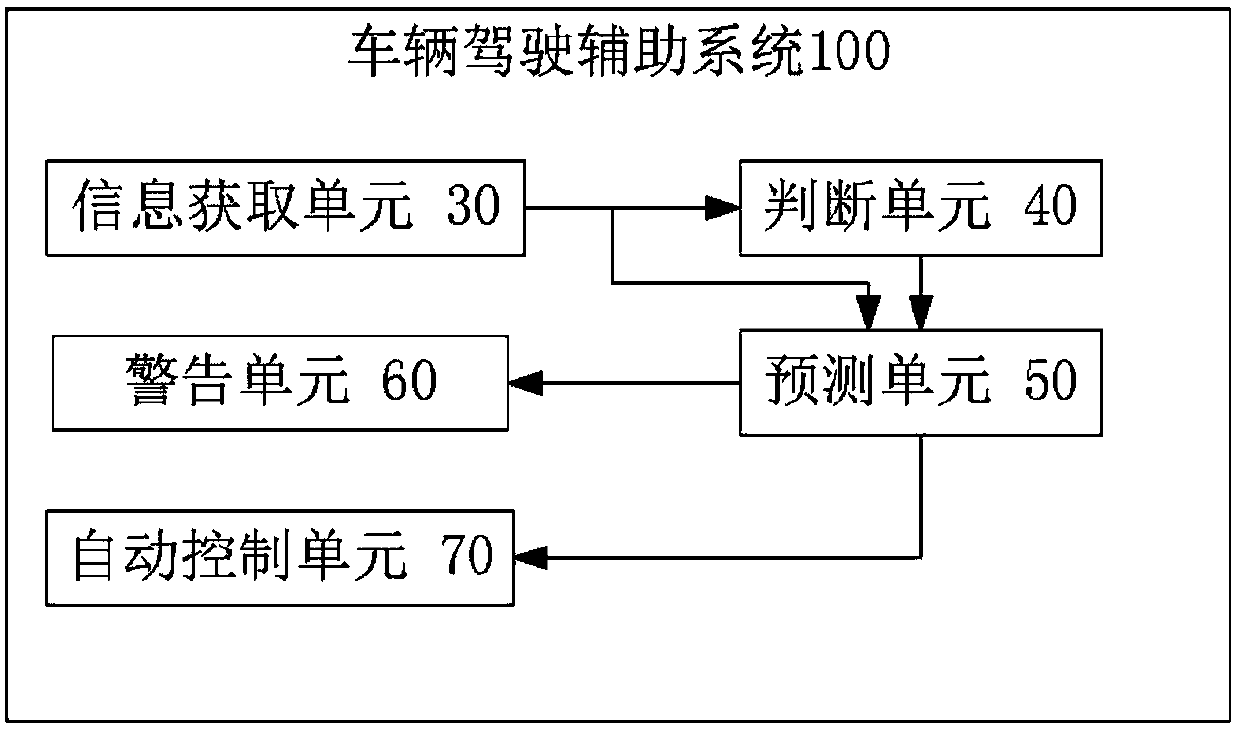

Vehicle driving assistance system and method

ActiveCN109841088AAccurate predictionAvoid collision hazardAnti-collision systemsLocation dataEngineering

The invention discloses a vehicle driving assistance system and a vehicle driving assistance method. The vehicle driving assistance system comprises an information acquisition unit, a determination unit and a prediction unit, wherein the information acquisition unit is configured to detect other traffic participants on a co-directional driving lane of a surrounding region of a present vehicle, andacquire position data, motion data and predetermined navigation routes of one or more detected other traffic participants, and the information acquisition unit is further configured to position location data, motion data and a predetermined navigation route of the present vehicle; the determination unit is configured to determine whether the one or more other traffic participants and the presentvehicle are about to turn at or near a front intersection based on the respective current positions and predetermined navigation routes of the one or more other traffic participants and the present vehicle; and the prediction unit is configured to predict whether the present vehicle is going to collide with the one or more other traffic participants under the condition that any one of the one or more other traffic participants and the present vehicle is about to turn at or near the front intersection.

Owner:AUDI AG

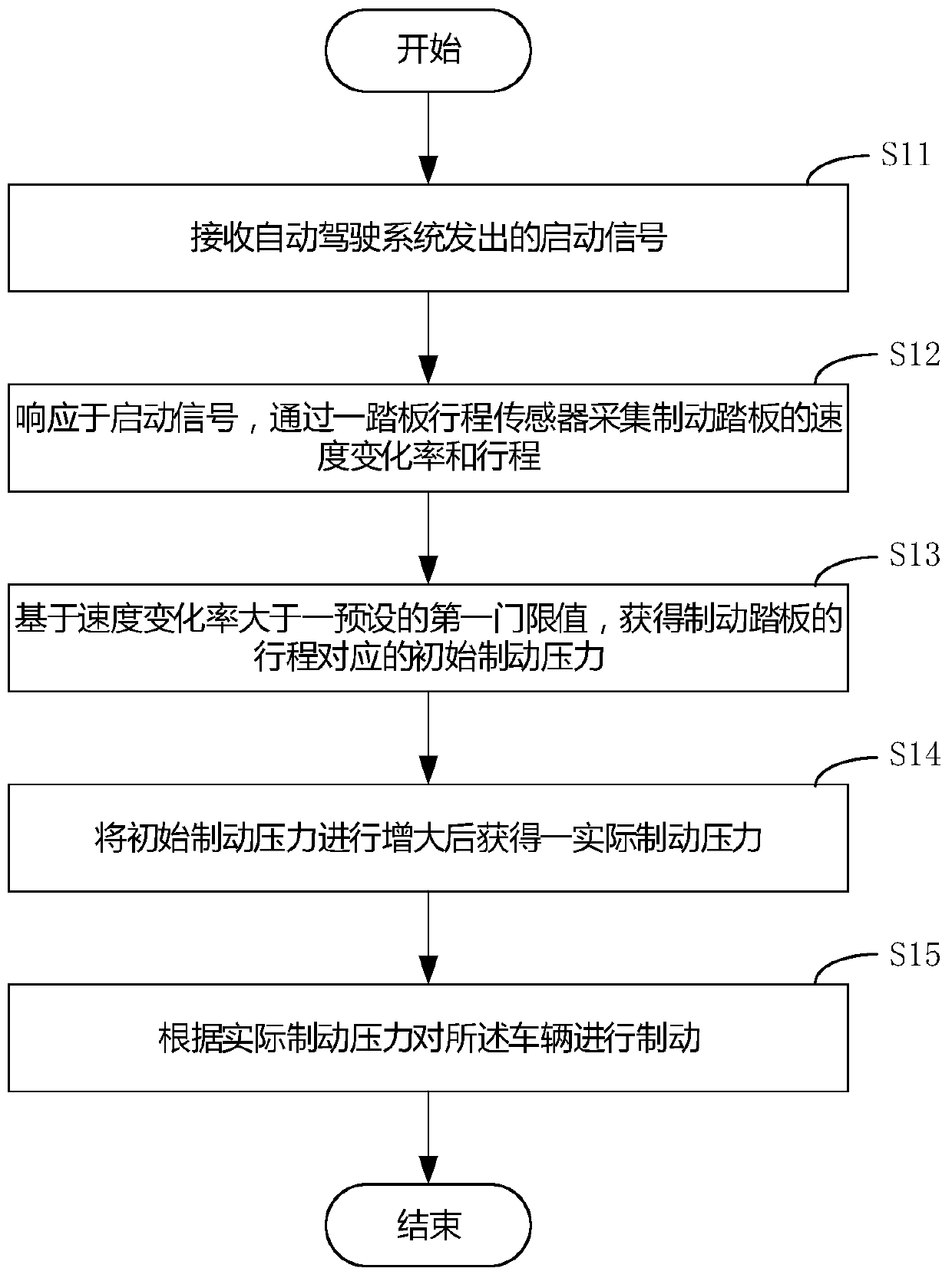

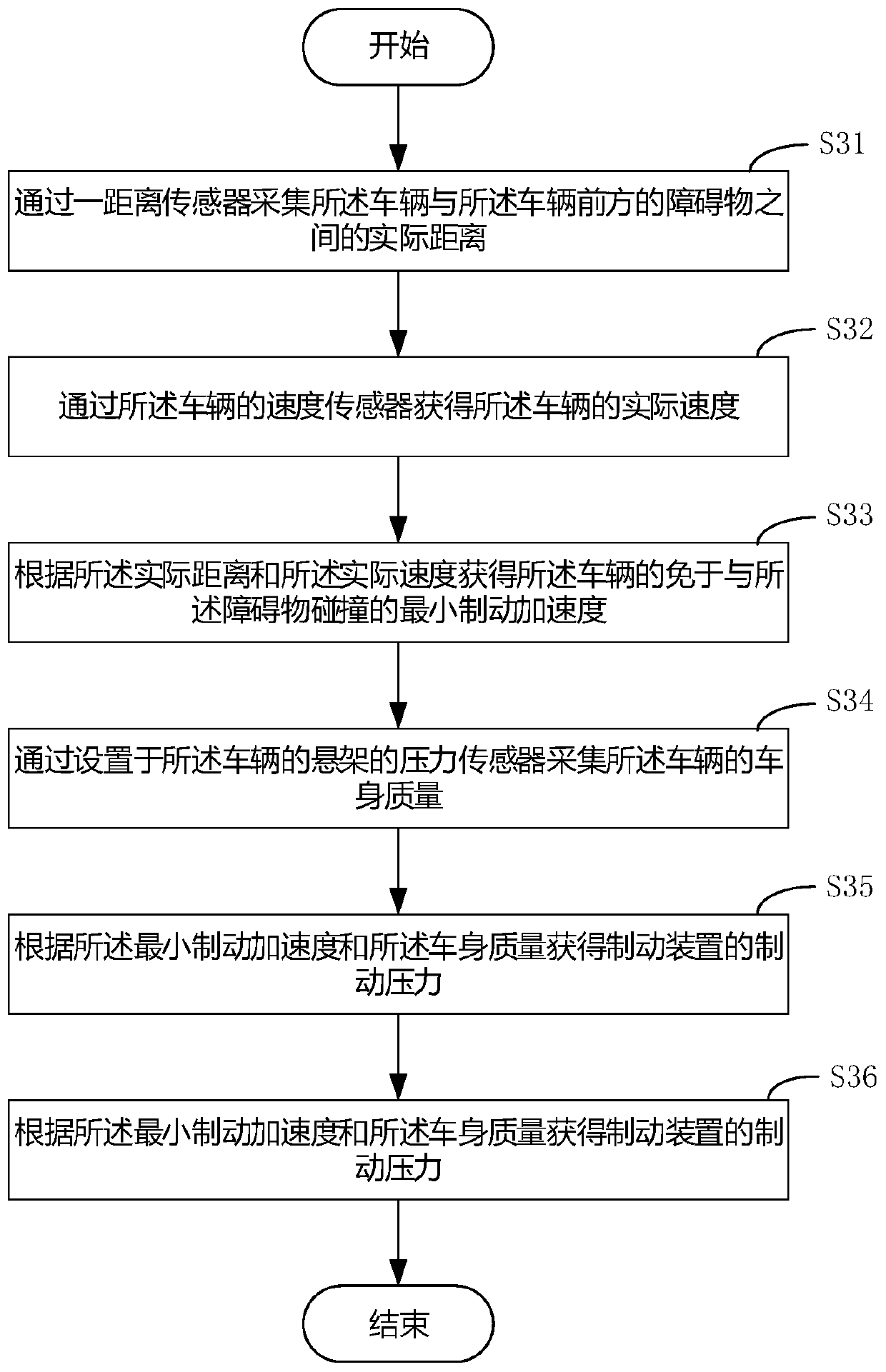

Vehicle braking method, system and equipment and medium

InactiveCN110217216AReal-time detection of speed change rateDetection rate of change of speedAutomatic initiationsAutopilotRoad condition

The invention discloses a vehicle braking method, system and equipment and a medium. The vehicle braking method comprises the following steps: receiving a starting signal sent by an automatic drivingsystem; responding to the starting signal, and collecting a speed change rate and a stroke of a brake pedal through a pedal stroke sensor; obtaining an initial brake pressure corresponding to the stroke of the brake pedal based on the fact that the speed change rate is greater than a preset first threshold value; increasing the initial brake pressure to obtain an actual brake pressure; braking thevehicle according to the actual brake pressure. According to the method, the speed change rate of the brake pedal can be detected in real time, and when the speed change rate is larger than the threshold value, the brake pressure is increased, so that rapid braking is achieved; three brake pressure curves are adopted to obtain different initial brake pressures, that is, different brake pressure curves are obtained before and after the automatic driving system is started, so that the actual brake pressure can be changed along with different road conditions and vehicle conditions, and a drivercan brake the vehicle in time.

Owner:AIWAYS AUTOMOBILE CO LTD

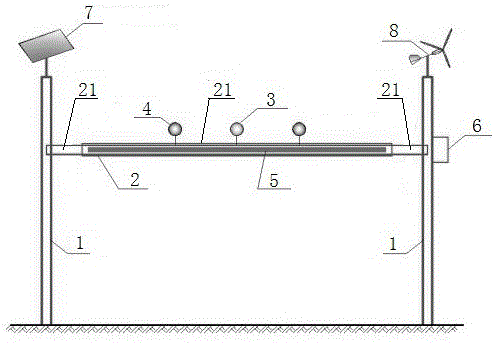

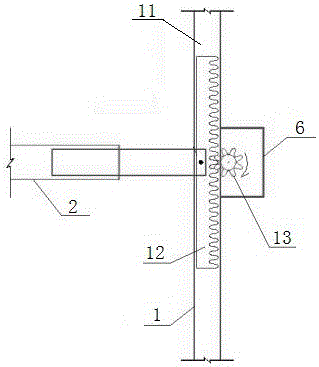

Intelligent safety height-restriction frame

The invention provides an intelligent safety height-restriction frame. The intelligent safety height-restriction frame comprises two stand columns and a cross beam. A slide groove is formed in each stand column. The two ends of the cross beam are arranged in the two slide grooves correspondingly and can move up and down in the slide grooves. A vehicle height inducting device and an alerting device are arranged on the cross beam. A roller shutter and a roller shutter motor used for driving the roller shutter are further arranged in the cross beam. The intelligent safety height-restriction frame further comprises a controller in communication connection with the vehicle height inducting device, the alerting device and the roller shutter motor. According to the intelligent safety height-restriction frame, the height of a vehicle is measured through the vehicle height inducting device, and the alerting device can be started automatically to remind a driver to stop advancing when the vehicle is overhigh; the roller shutter can drop down to block the advancing sight of the driver if the driver continues to advance, and the driver is forced to stop driving, so that danger caused by impacting between the overhigh vehicle and the height-restriction frame is avoided; and the height of the cross beam can be adjusted electrically according to height-restriction values of specific roads or different time periods.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

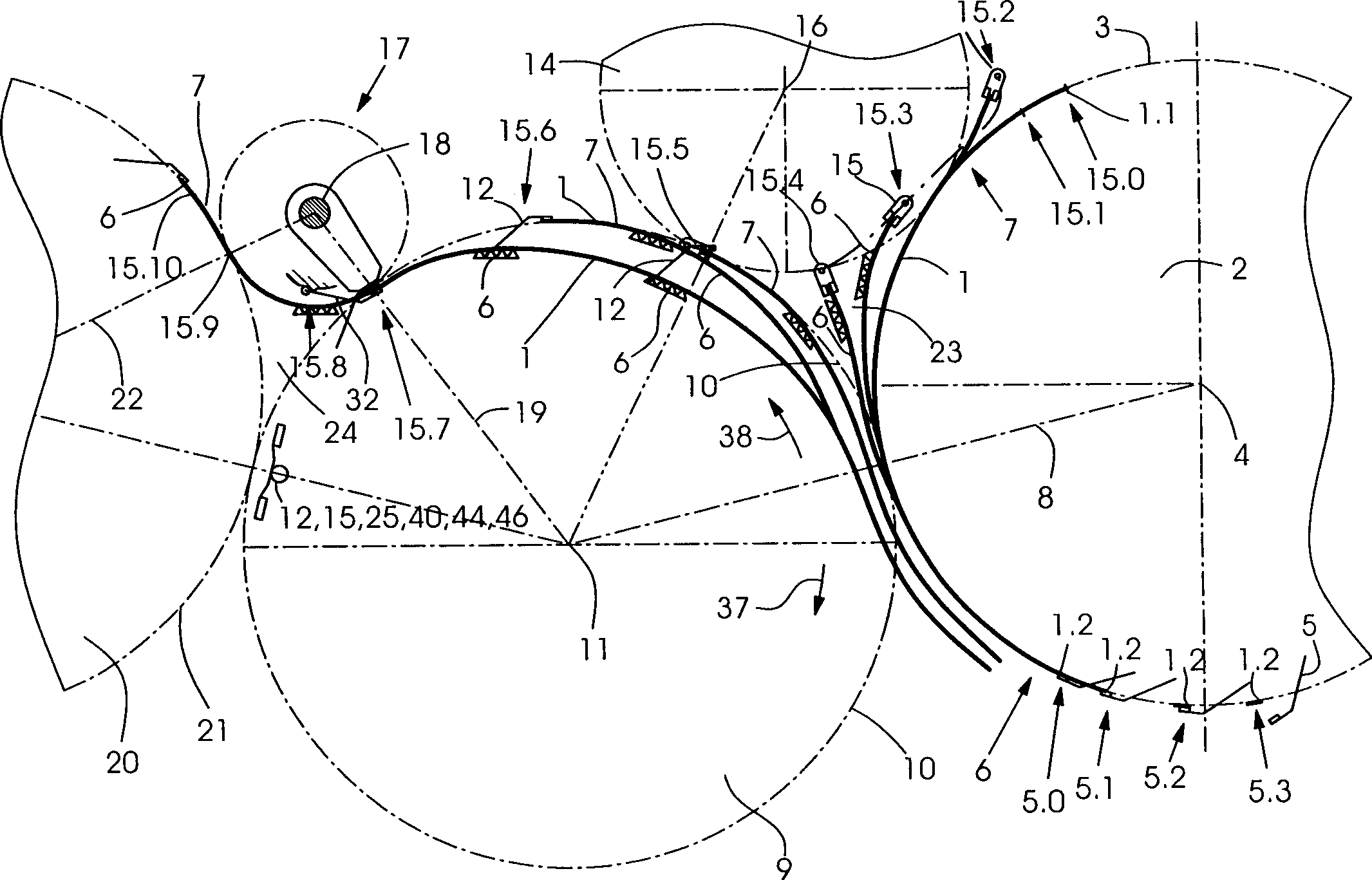

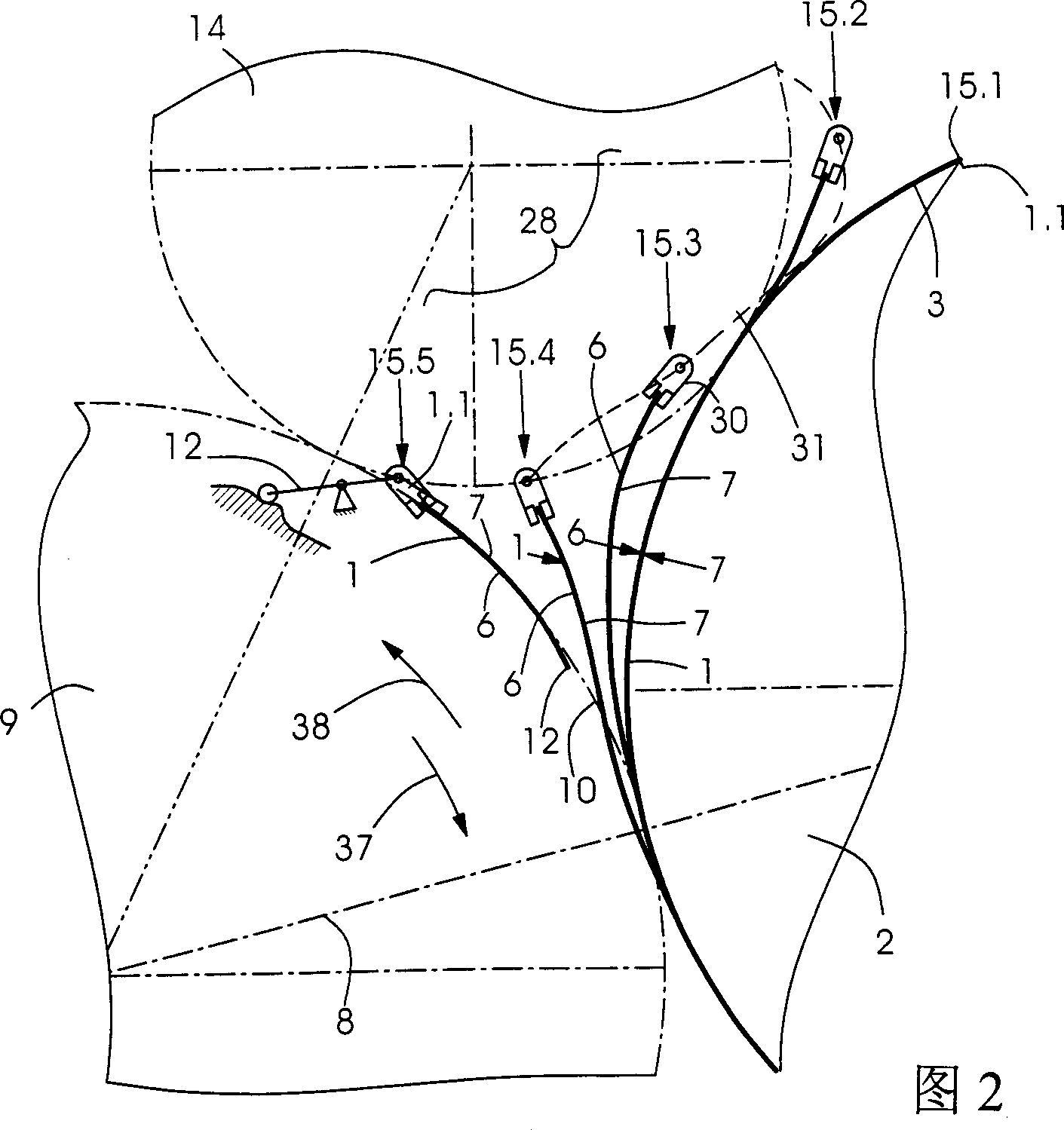

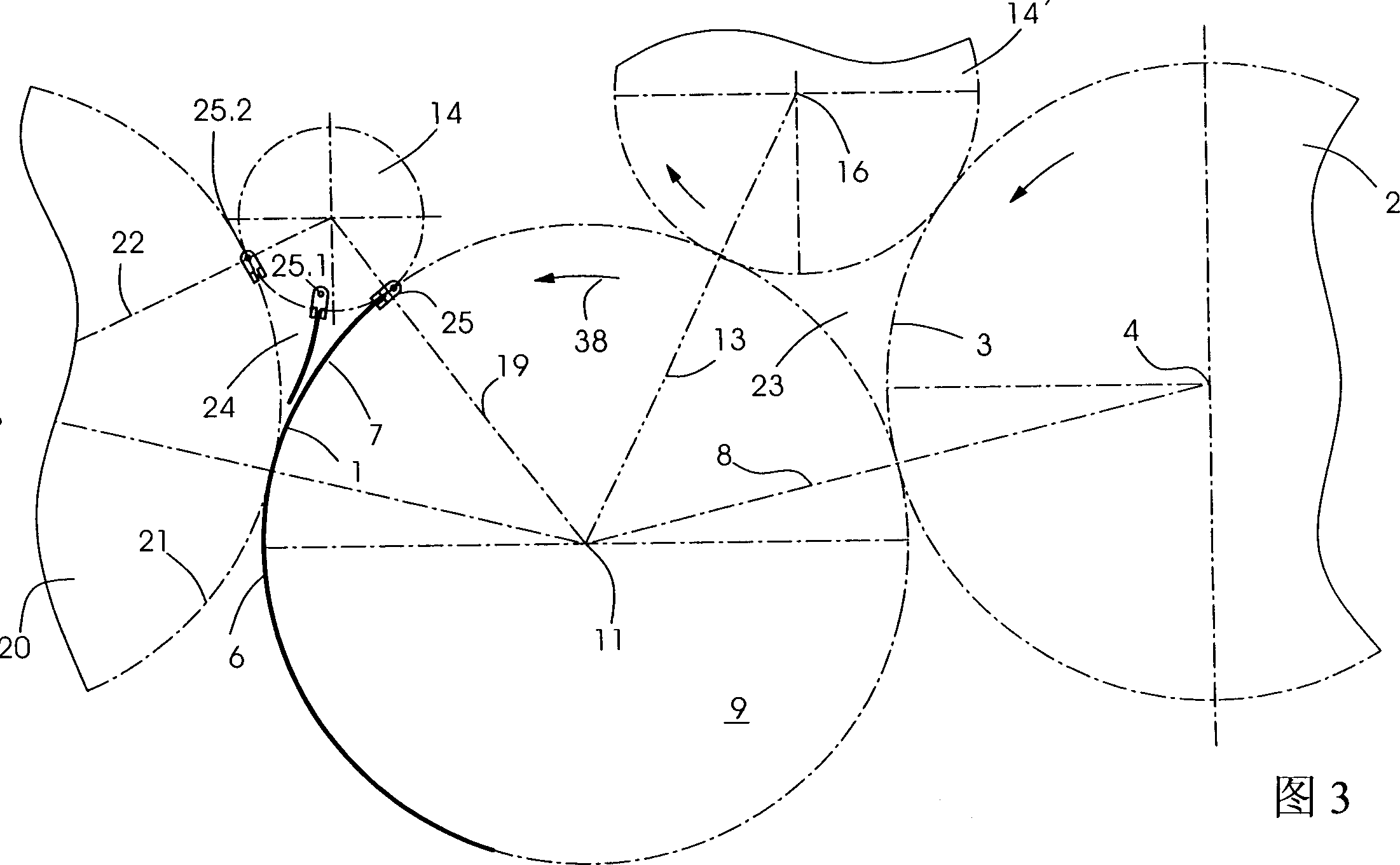

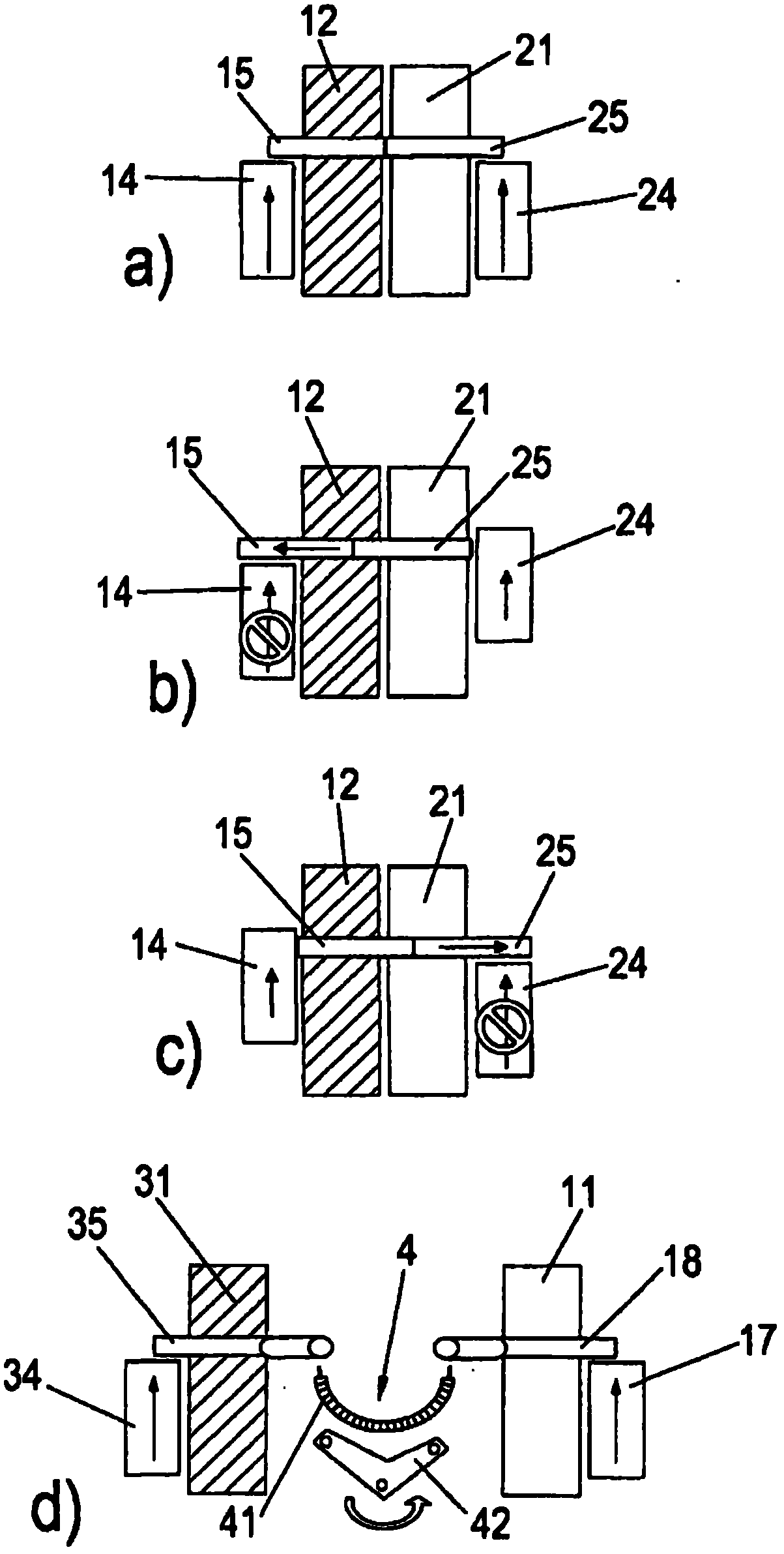

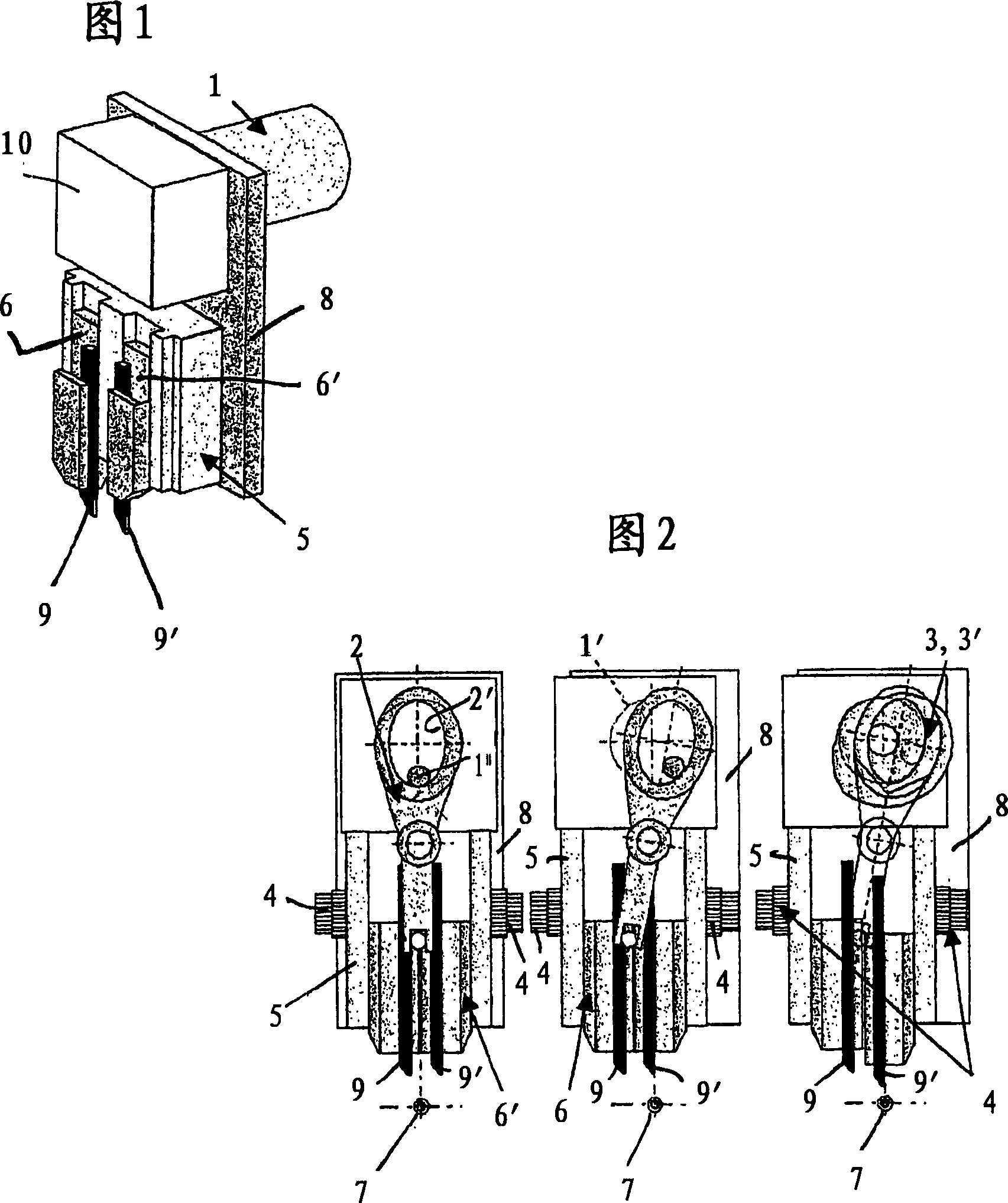

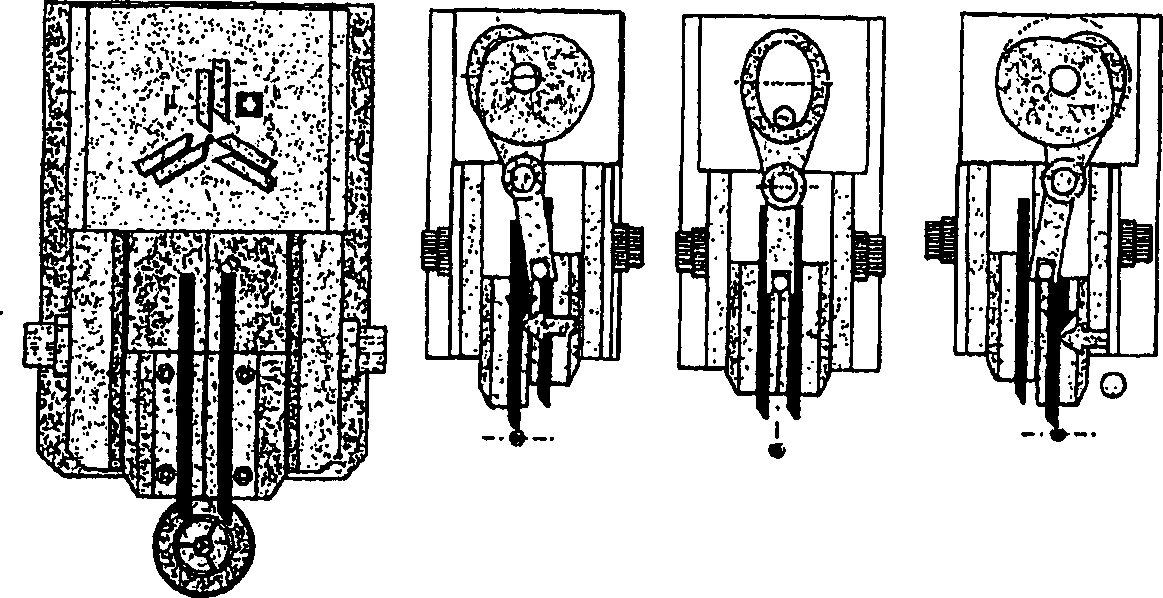

Apparatus for turning plane printed matter in half turning paper treating machine

InactiveCN1365889ASave drive energySave installation spaceArticle feedersSheet deliveryEngineeringPrinting press

The invention relates to a device for turning over paper (1, 65) using a paper delivery roller (9), which is adjacent to two paper guide rollers (1, 20), and is equipped with a turning / turning / With storage rollers (14, 26) and an additional transport element (17), the rotary printing press for handling paper can operate in single-sided printing mode and double-sided printing mode (59, 60). When using single-sided printing mode and double-sided printing mode (59, 60), the transfer cylinder (9) can be driven in opposite directions of rotation (37, 38). A gripper system (12; 15, 25, 40, 44) that works in two rotation directions (37, 38) of the transfer roller (9) is installed on the outer shell surface (10) of the transfer roller (9). ,46).

Owner:HEIDELBERGER DRUCKMASCHINEN AG

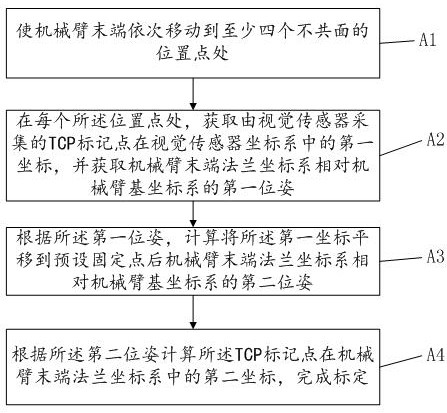

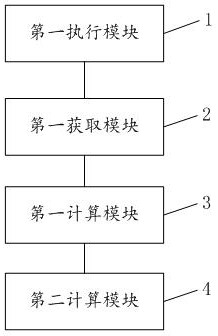

Mechanical arm tool coordinate system original point calibration method and device and electronic equipment

ActiveCN113021358AFully automatedImprove work efficiencyProgramme-controlled manipulatorControl engineeringProcess engineering

The invention provides a mechanical arm tool coordinate system original point calibration method and device and electronic equipment. The method comprises the steps that the tail end of a mechanical arm is made to move to at least four non-coplanar position points in sequence; at each position point, a first coordinate of a TCP mark point collected by a visual sensor in a visual sensor coordinate system is obtained, and a first pose of a mechanical arm tail end flange coordinate system relative to a mechanical arm base coordinate system is obtained; according to the first pose, a second pose of the mechanical arm tail end flange coordinate system relative to the mechanical arm base coordinate system after the first coordinate is translated to a preset fixed point is calculated; and a second coordinate of the TCP mark point in the mechanical arm tail end flange coordinate system is calculated according to the second pose. Therefore, the automation of the calibration process can be realized, the working efficiency is improved, the manpower consumption is reduced, and the collision danger in the manual teaching calibration process is avoided.

Owner:JIHUA LAB

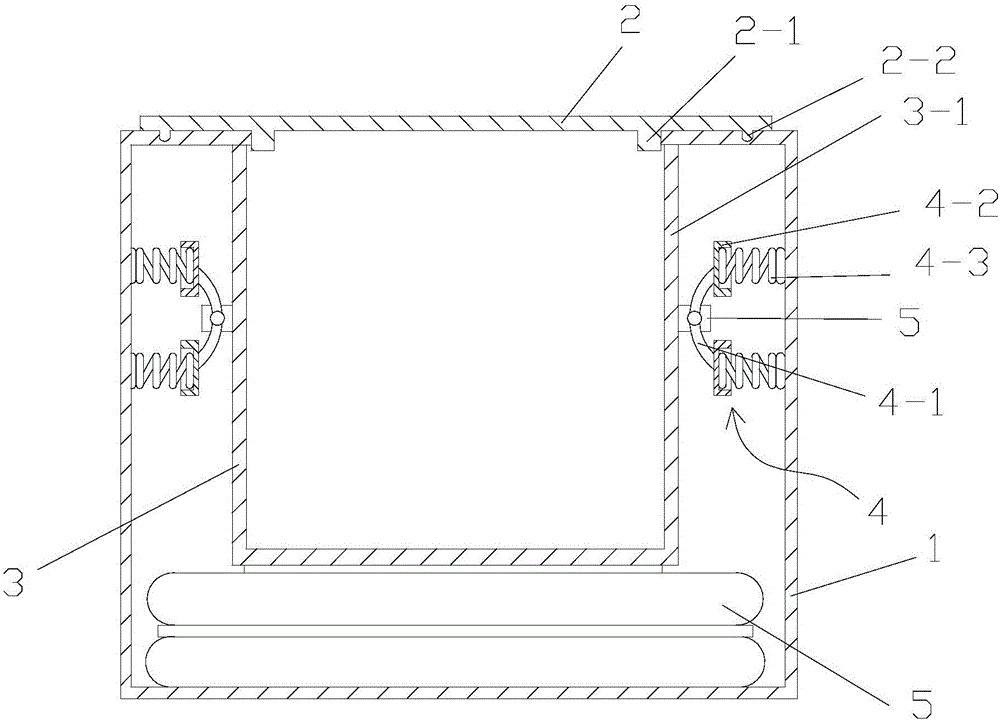

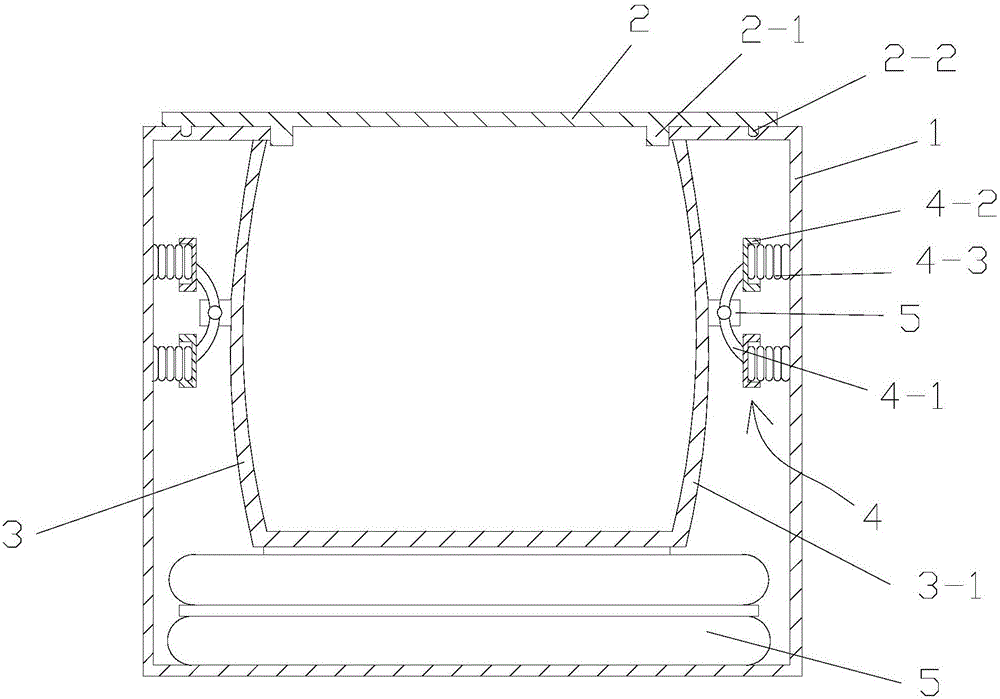

Novel package box

InactiveCN105129208AAvoid damageAvoid collision hazardContainers to prevent mechanical damageInternal fittingsAir springLongitudinal vibration

The invention discloses a novel package box. The novel package box comprises a box body and a box cover, wherein the box body comprises an inner box body and an outer box body; a gap is formed between the side wall of the inner box body and the side wall of the outer box body; the side wall of at least one side of the inner box body is an arcuately-deformed and outwardly-expanded elastic plate; the package box also comprises a pressing device used for generating pre-tightening extrusion force when the elastic plate recovers; the package box further comprises an air spring; the spring is arranged between the bottom wall of the inner box body and the bottom wall of the outer box body and is used for reducing vibration. According to the novel package box, a filling space formed after deformation of the elastic plate is filled with articles, the box cover is closed, the elastic plate recovers, the certain pushing force towards the interior of the box body is also applied to the elastic plate by the pressing device at the same time, the relative gaps among the filled articles is extruded under the combined action of the elastic plate and the pressing device, the articles are closely clung to one another, the relative movement among the articles is avoided, and the danger of collision caused by the relative movement is avoided; in addition, the air spring is arranged, so that the longitudinal vibration of the inner box body can be reduced.

Owner:重庆市合川区华丰包装有限公司

Tool rest anti-collision device of double-tool-rest vertical turning machine

The invention relates to a protection device of a vertical turning machine, and provides a tool rest anti-collision device of a double-tool-rest vertical turning machine in order to solve the technical problem that collision occurs in a left tool rest of the double-tool-rest vertical turning machine and a right tool rest of the double-tool-rest vertical turning machine. The tool rest anti-collision device of the double-tool-rest vertical turning machine comprises a left support fixed to the inner side of the left tool rest and a right support fixed to the inner side of the right tool rest and the left support and the right support are located on the same horizontal line. The tool rest anti-collision device is characterized in that a collision head is arranged at the front end of the left tool rest, a flange abutting disk is fixed to the front end of the right support, a screw parallel to the right support penetrates through the flange abutting disk, the front end of the screw is fixed with a collision flange, the part, located between the collision flange and the flange abutting disk, of a screw body is sleeved with an elastic sleeve, the part, located at the rear end of the flange abutting disk, of the screw body is sleeved with an insulation sleeve, a rubber sleeve is arranged at the tail end of the screw body and an insulation switch is arranged at the position, corresponding to the rubber sleeve, of the right support and the induction switch is connected with a turning machine servo system. The protection device is simple and reasonable in structure and convenient to install.

Owner:RONGCHENG METAL FORMING MACHINE GROUP

Device for synchronization of locking devices

ActiveCN102068127APull out automaticPull out to lock automaticallyBuilding locksDrawersEngineeringMechanical engineering

Owner:PAUL HETTICH

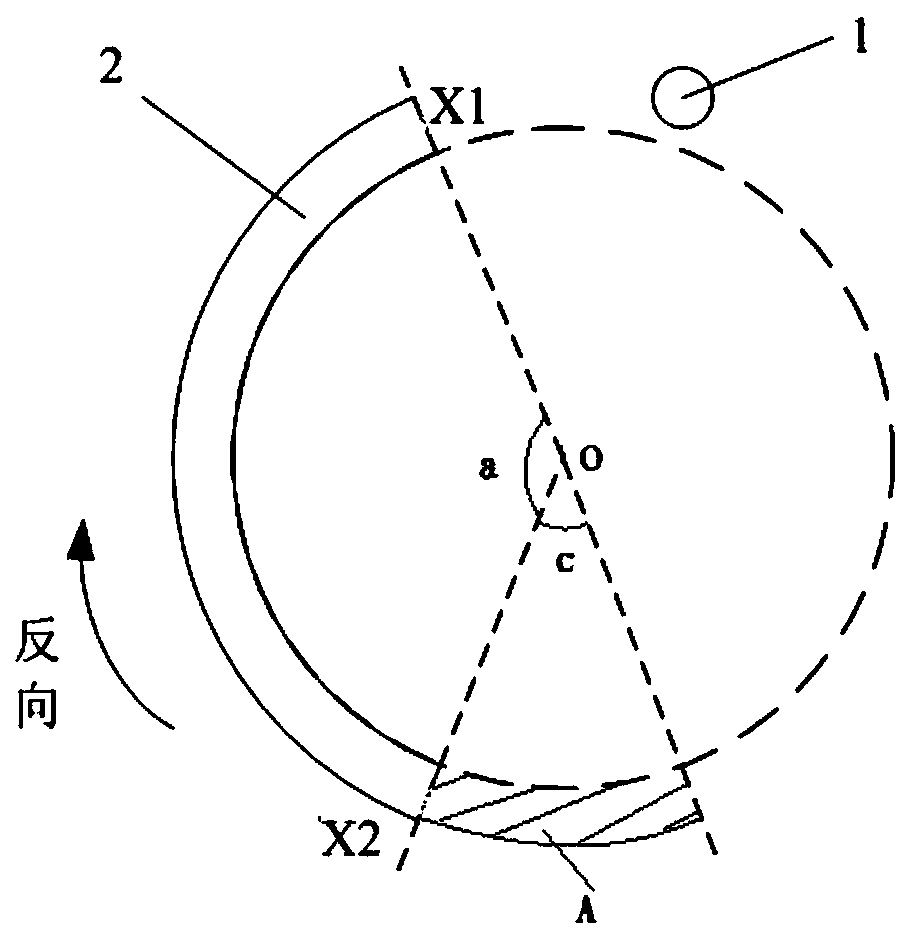

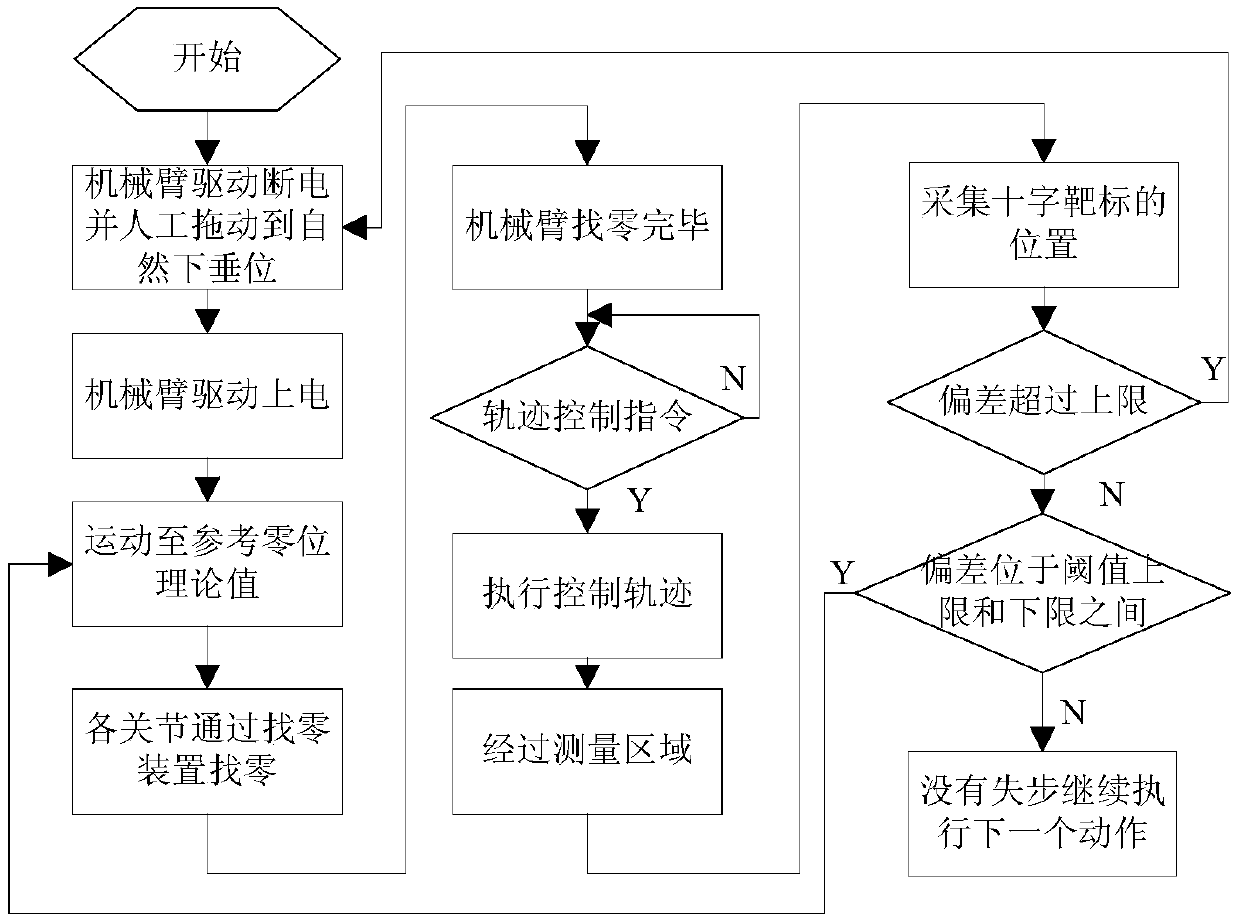

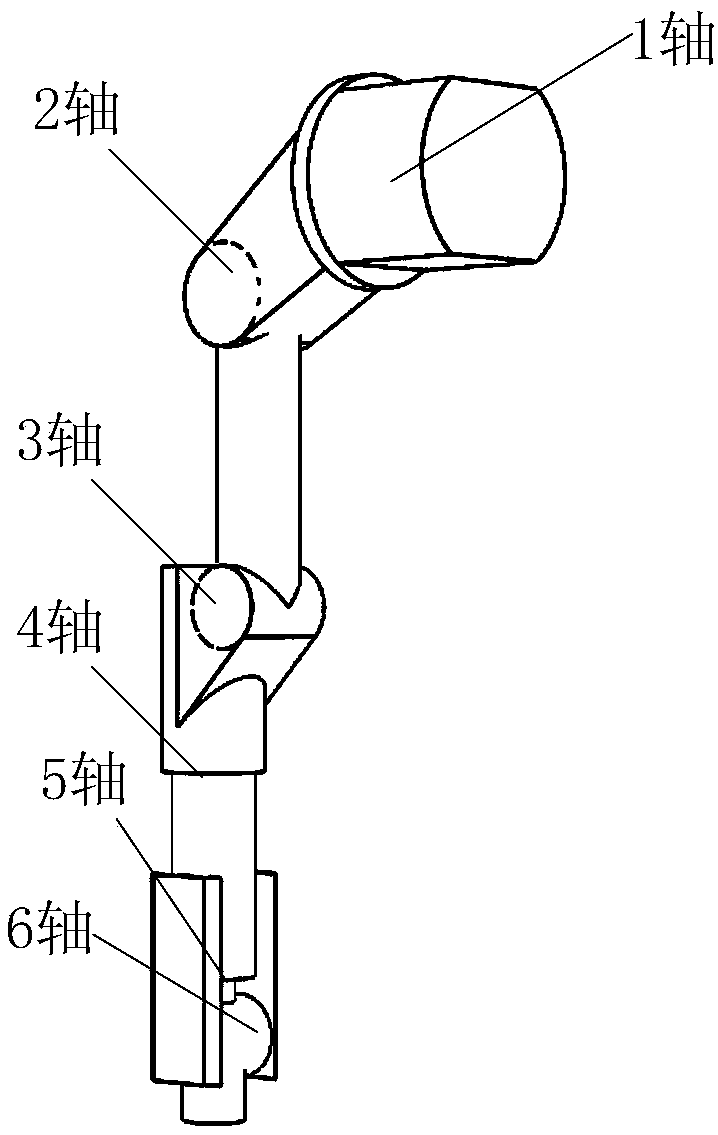

Multi-freedom-degree open loop stepping series mechanical arm and control method thereof

ActiveCN109605344ATroubleshoot Servo Positioning IssuesLow costProgramme-controlled manipulatorElectricityMulti degree of freedom

The invention discloses a multi-freedom-degree open loop stepping series mechanical arm and a control method thereof. Under the power failure condition of the mechanical arm, the mechanical arm can naturally hang down; zero position finding devices are arranged on joints of the mechanical arm and are used for detecting mechanical zero positions of the joints of the mechanical arm; a camera with depth information is arranged in a mechanical arm motion space, and a cross target is arranged at the tail end of the mechanical arm; and the control method of the mechanical arm is further provided, after the mechanical arm is powered on, the mechanical arm is controlled to rotate to the posture approaching to the zero position, the zero finding action is executed, the joints are controlled to return to the zero position according to a certain sequence, the current joint positions are recorded as reference zero position accuracy, at the moment, the control position of the mechanical arm is notmatched with the actual position, and the control precision is ensured. According to the multi-freedom-degree open loop stepping series mechanical arm and the control method thereof, a position sensordoes not need to be added, zero finding is achieved during step out, and control precision of the multi-freedom-degree open loop stepping series mechanical arm is ensured.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

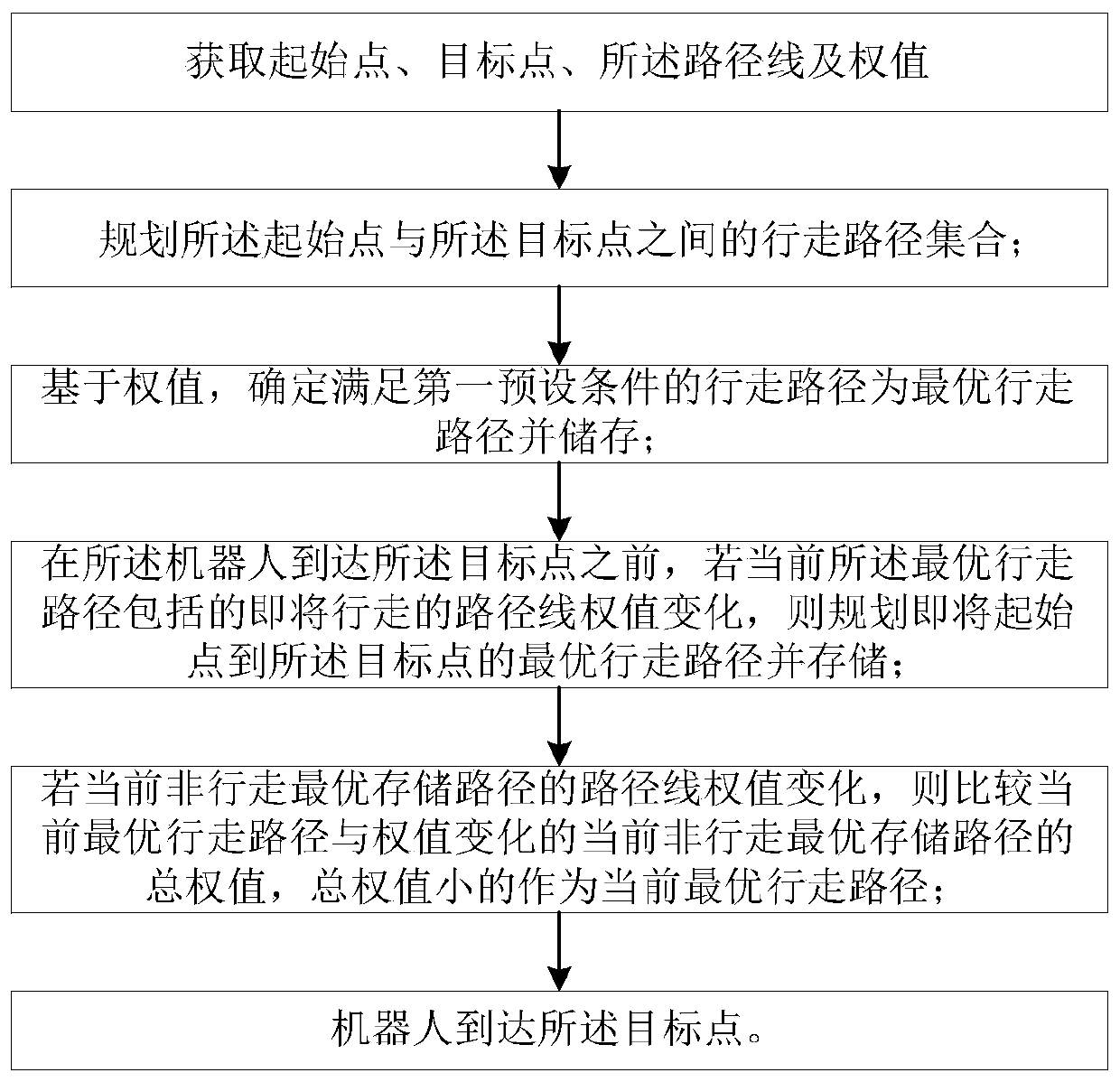

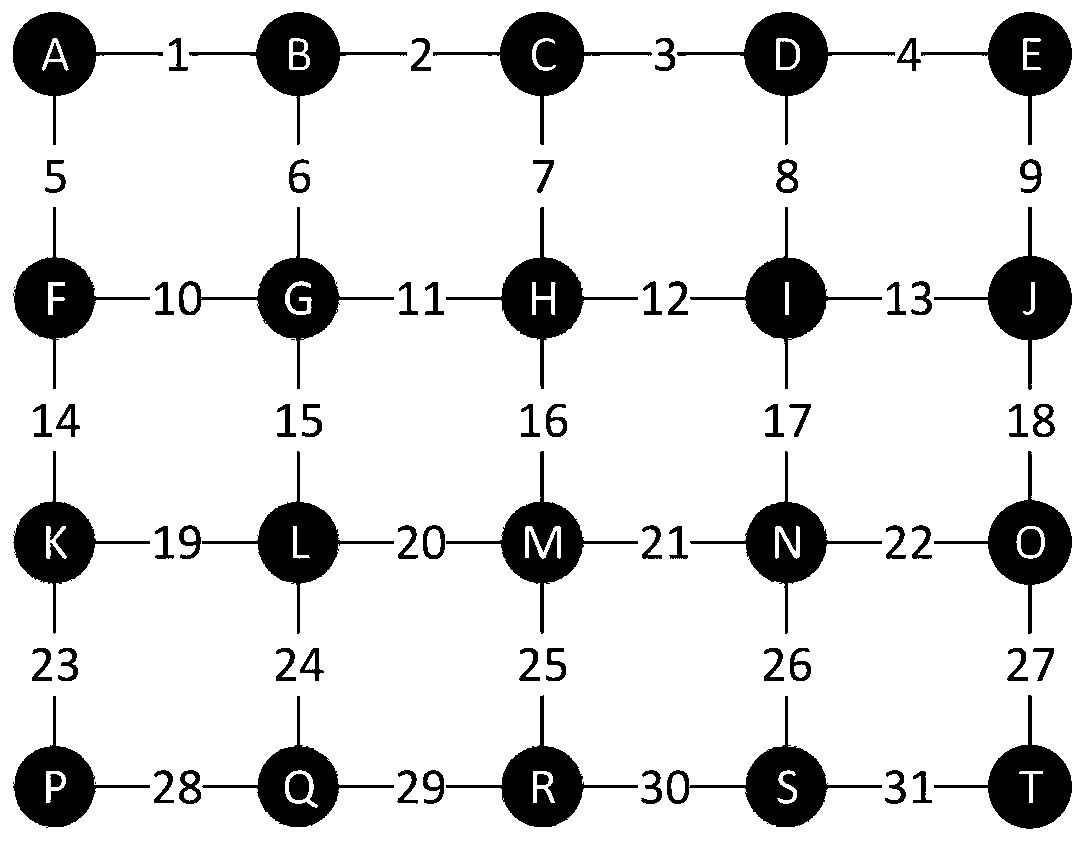

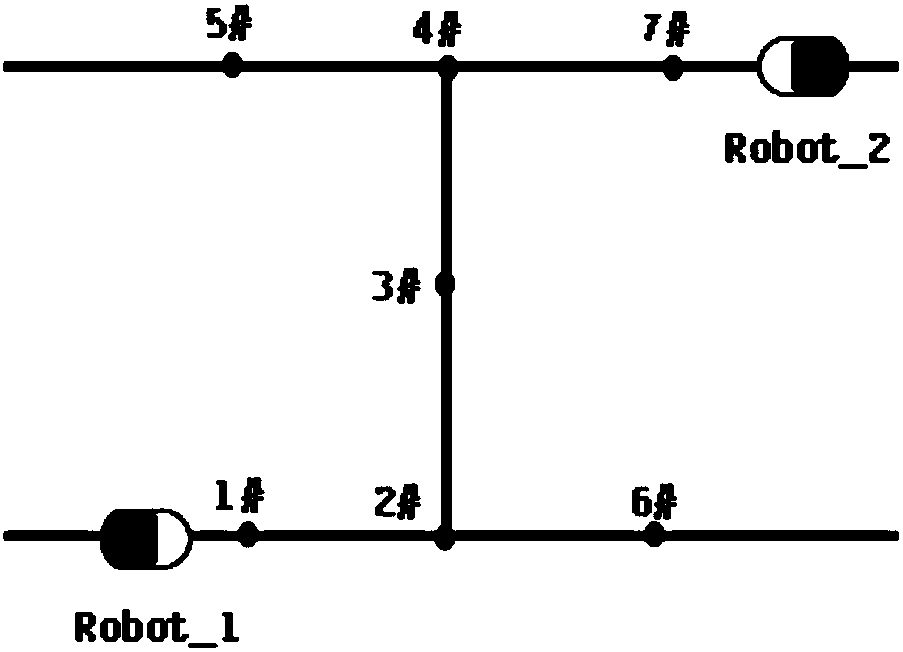

Robot path planning system and method, computer readable storage medium and device

InactiveCN110244711AImprove work efficiencyAvoid collision hazardPosition/course control in two dimensionsVehiclesPlanning approachSimulation

The invention relates to the technical field of intelligent trolley control, in particular to a robot path planning system and method, a computer readable storage medium and a device. The planning system comprises a map module, a weight value setting module, a path planning module and a vehicle-mounted receiving module. The planning method specifically comprises the steps of giving a weight value to each path line according to the workload, and judging an optimal walking path according to the sum of the weight values of the path lines between a starting point and an end point; and compared with the prior art, the robot path planning system and method has the advantages that dynamic weight values are given to the path lines, and the shortest path is changed according to actual traffic conditions, so that the robot always selects the most efficient path, the working efficiency is improved, and the collision danger is effectively avoided.

Owner:芜湖智久机器人有限公司

Multi-directional drilling equipment for artificial boards and method for processing same

InactiveCN105196361ASave manpower and material resourcesEven by forceStationary drilling machinesDrill holeEngineering

The invention relates to multi-directional drilling equipment for artificial boards. The multi-directional drilling equipment comprises support boards. The support boards are used for accommodating the two overlapped artificial boards, the two overlapped artificial boards include an upper first artificial board and a lower second artificial board, a first drill bit group is arranged on a side of the support boards, the first artificial board can be horizontally drilled by the first drill bit group, a second drill bit group is arranged below the support boards, the second artificial board can be vertically drilled by the second drill bit group, the first drill bit group and the second drill bit group are respectively connected with a first drill bit feeding device and a second drill bit feeding device so that first drill bits and second drill bits can advance, retreat and rotate, a pressure board is arranged above the support boards and is connected with a liftable vertical rod, and the two overlapped artificial boards can be fixedly compressed when the vertical rod descends. The multi-directional drilling equipment has the advantages that different hole locations on the two artificial boards can be processed by the multi-directional drilling equipment at the same time, accordingly, labor and materials can be saved to a great extent, and accidents due to collision of the drill bits can be prevented.

Owner:FUTIAN FUZHOU ARTS & CRAFTS

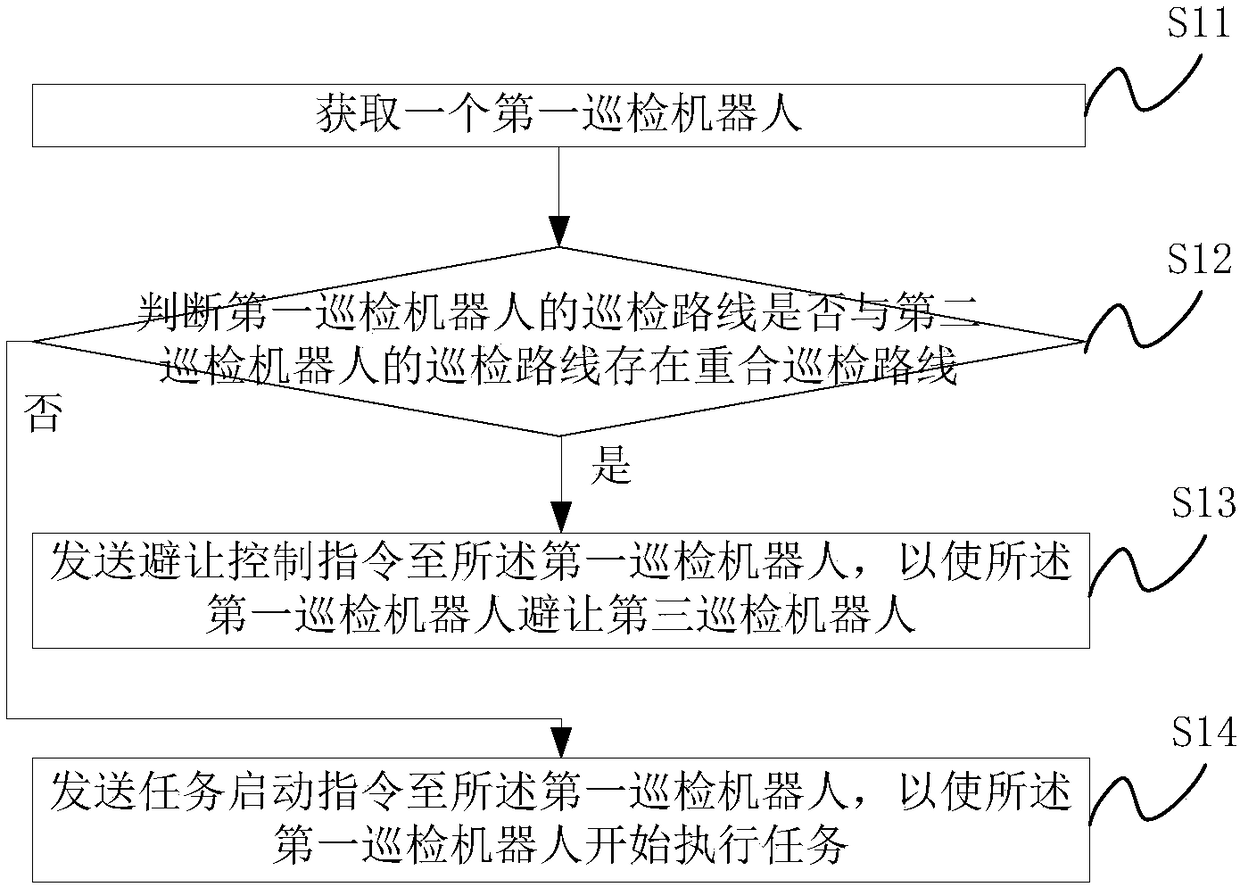

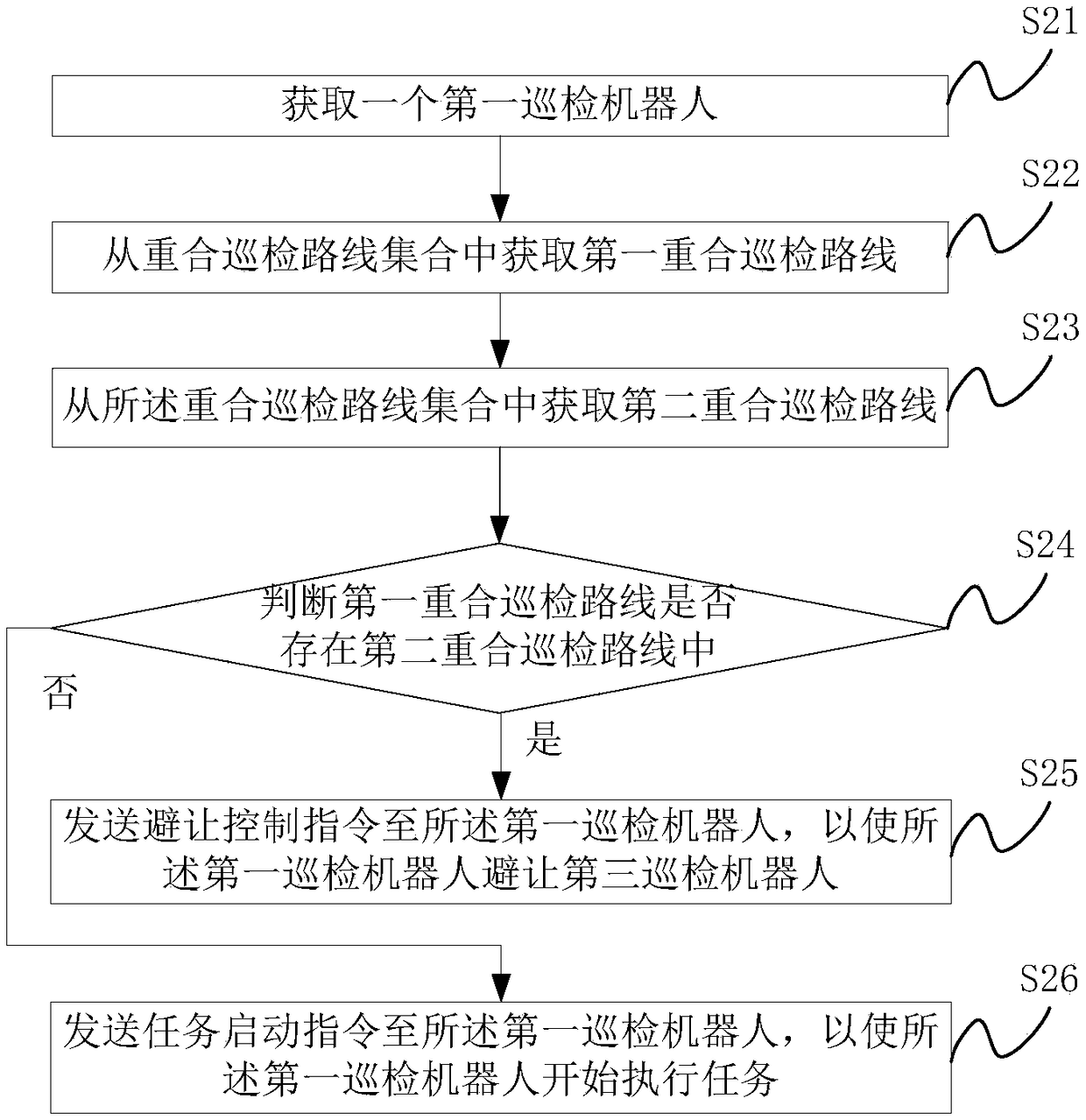

Safe operation method and device for inspection robot

InactiveCN108268043AAvoid collision hazardPosition/course control in two dimensionsEngineeringCollision risk

The invention discloses a safe operation method and device for an inspection robot. Before an inspection robot to be operated performs a task, it is first determined whether the inspection robot to beoperated has a coincident inspection route with an inspection robot that is operating, and in the presence of a coincident inspection route, the inspection robot to be operated avoids the inspectionrobot that is operating by the avoidance control. Furthermore, it is possible to avoid the collision risk of multiple inspection robots.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

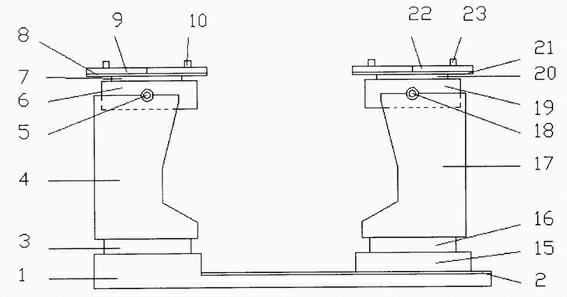

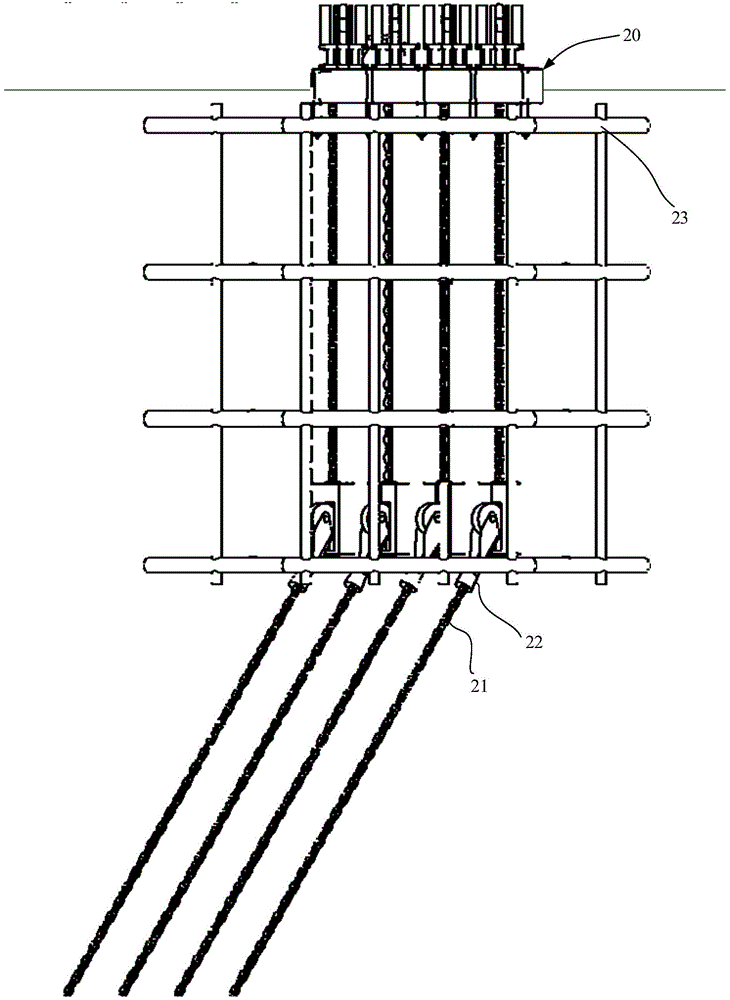

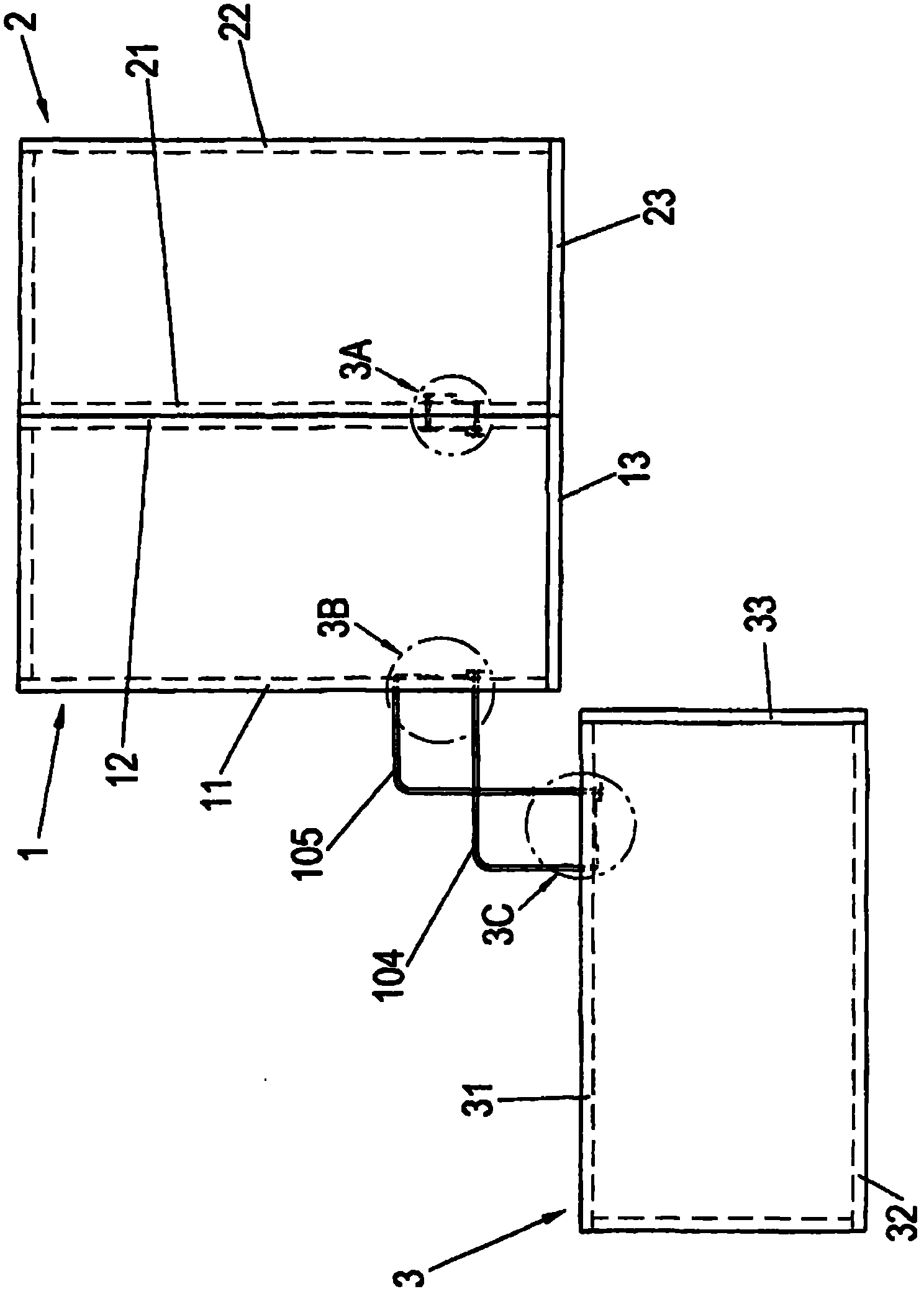

Recovering machine for installing marine assembling pipes and recovering method

ActiveCN106624583AGuaranteed not to deformHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesRobotic armAgricultural engineering

The invention discloses a recovering machine for installing marine assembling pipes. The recovering machine for installing the marine assembling pipes comprises a base, a guiding rail is installed on the base, a head frame rotating shaft is arranged at one end of the base, a head frame is installed on the head frame rotating shaft, a head frame overturning table is hinged to the head frame, a head frame chuck rotating shaft is arranged on the head frame overturning table, a head frame chuck is installed on the head frame chuck rotating shaft, and a clamping mechanism is arranged on the head frame chuck; a robot arm base moving along the guiding rail is arranged on the guiding rail, a chuck rotating shaft is installed on the robot arm base, a robot arm bottom frame is installed on the chuck rotating shaft, a mechanical arm is installed on the robot arm bottom frame, the overturning table is installed at the top end of the mechanical arm, and a robot-arm screw rod clamping jaw is installed on the overturning table. According to the recovering machine for the assembling pipes, flanges are shifted through the recovering machine for the assembling pipes, the flanges and the pipes are accurately assembled, and the aim that the assembling pipes are efficiently and accurately processed with low cost is achieved.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

Tool support for lathes

InactiveCN1842395ALow costLow attach timeLathesTool holdersStructural engineeringIndustrial engineering

Owner:MICROSWISS TECH

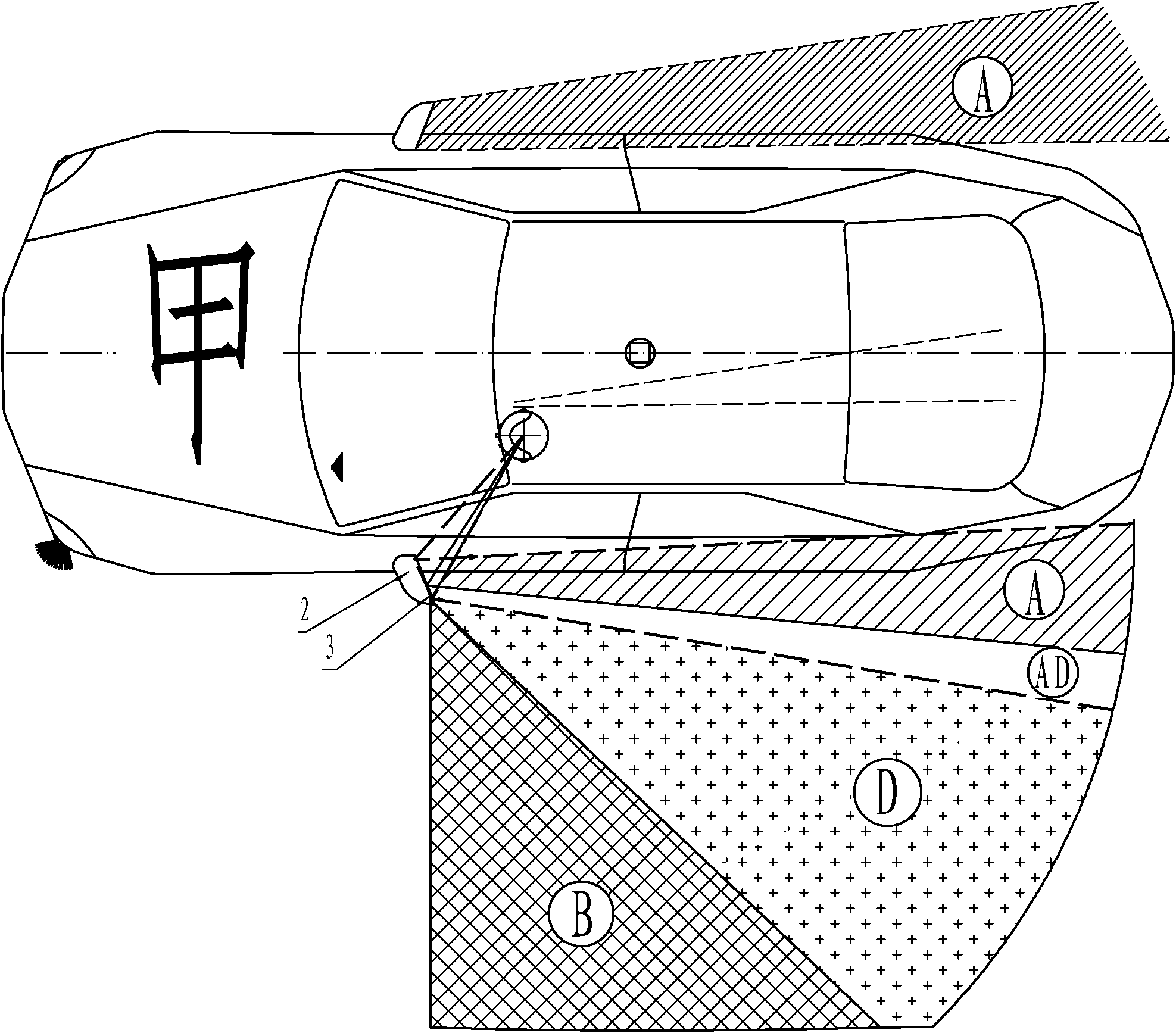

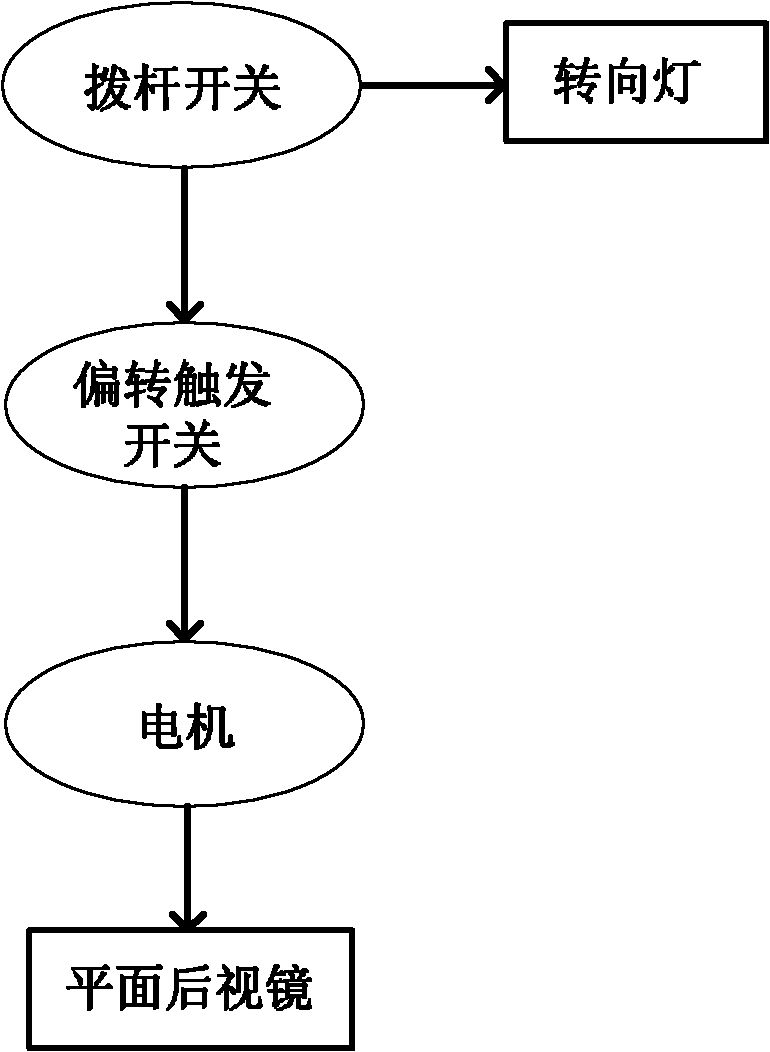

Automobile rearview mirror following-up method and automobile follow-up rearview mirror

InactiveCN102180127AComprehensive and accurate observationReduce blind spotsOptical viewingEngineeringWing mirror

The invention provides an automobile rearview mirror following-up method and an automobile follow-up rearview mirror realizing the method. According to the method, a deflection trigger switch is connected between an automobile shift lever switch and a power device of the rearview mirror, when an automobile performs overtaking or doubling, the shift lever switch gives a signal to the power device of the rearview mirror through the deflection trigger switch when automobile turns a steering lamp, so that the rearview mirror deflects by an angle under the driving of the power device, the deflection direction is that the outer end of the rearview mirror deflects towards the direction of a headstock and the inner end deflects towards the direction of a tailstock, and the rearview mirror can automatically reset to the position of normally driving after deflection. Due to adoption of the method, when the automobile performs overtaking or doubling, a driver can accurately observe the ambient vehicle and other objects, so that blind areas can be greatly reduced, and the safety is guaranteed.

Owner:高玉宗

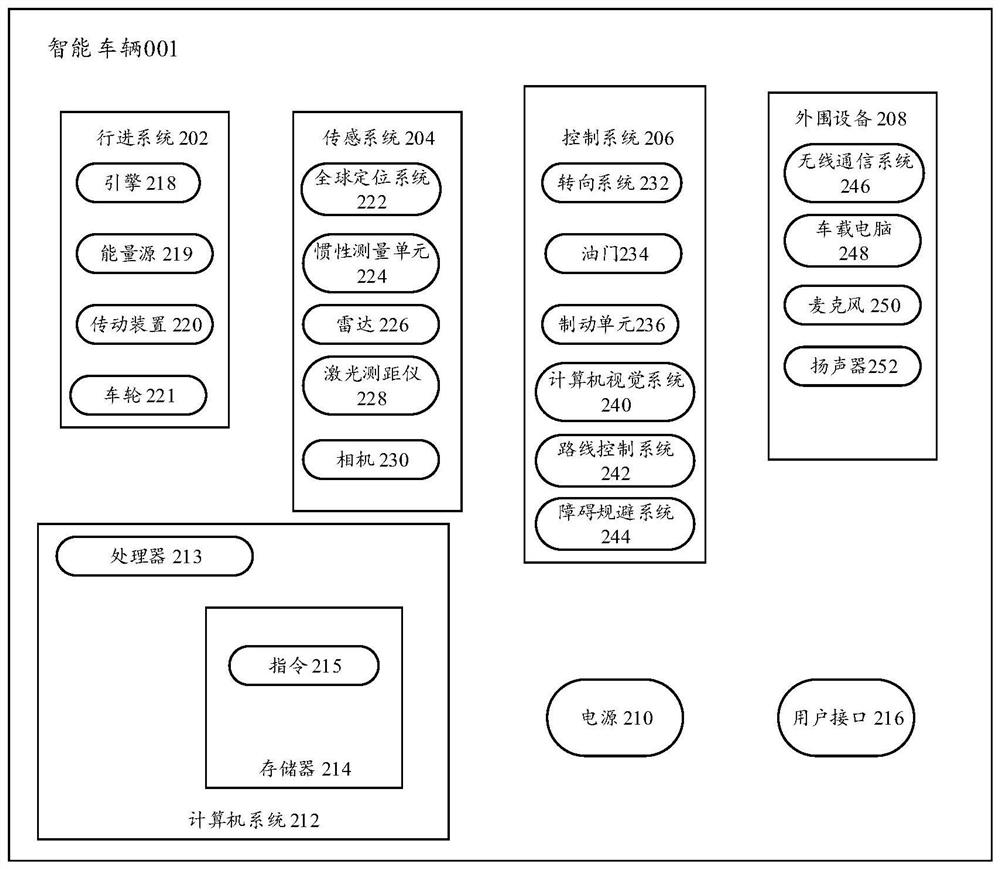

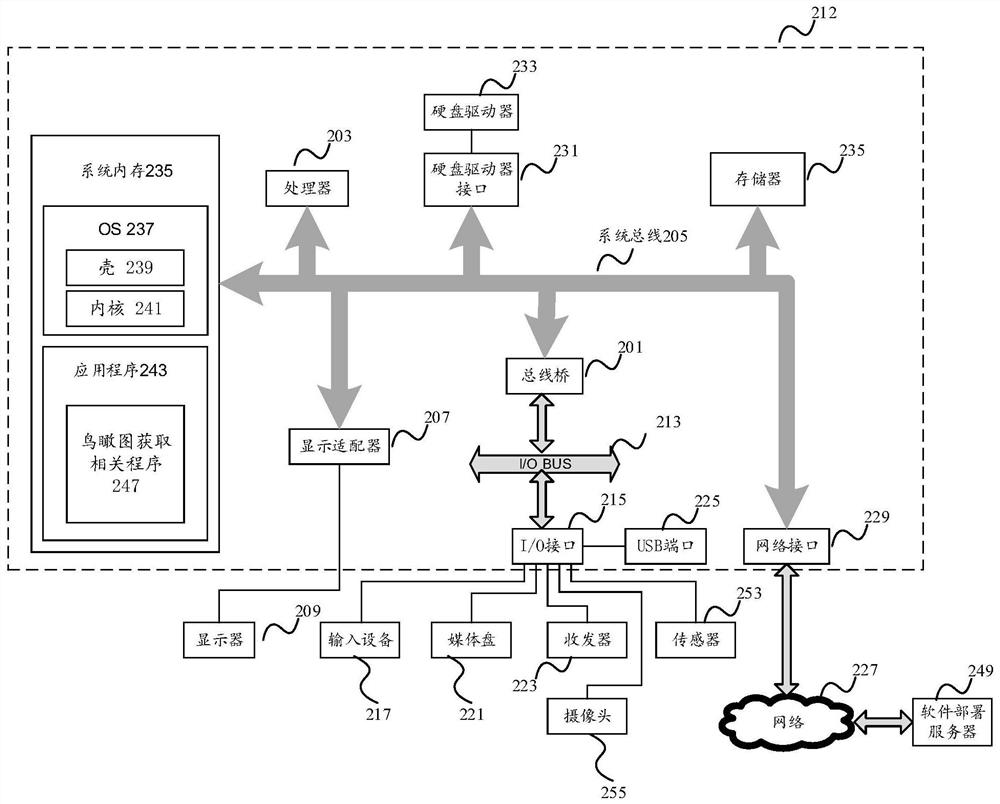

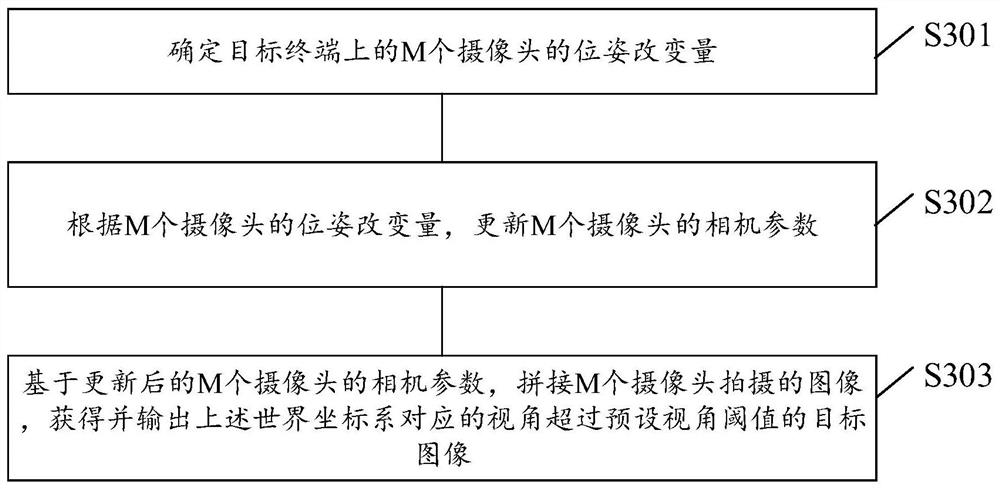

Image processing method and related terminal device

ActiveCN113261274AAvoid uneven and bumpy situationsImprove driving experienceTelevision system detailsColor television detailsImaging processingComputer graphics (images)

The embodiment of the invention discloses an image processing method and a related terminal device, wherein the method may comprise the steps: determining the pose change amount of M cameras on a target terminal, M being an integer greater than 1; according to the pose change amount of the M cameras, updating the camera parameters of the M cameras, each camera parameter comprising a mapping relation between a coordinate system of an image shot by the corresponding camera and a world coordinate system; and on the basis of the updated camera parameters of the M cameras, splicing images shot by the M cameras to obtain a target image of which the visual angle corresponding to the world coordinate system exceeds a preset visual angle threshold. By implementing the embodiment of the invention, the environment image around a terminal can be accurately spliced, and the driving safety of the terminal is ensured.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com