Position changing machine for measurement reproduction system of folding pipe

A technology of closing tubes and positioners, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of long manufacturing time, low manufacturing precision of closing tubes, cumbersome process, etc., and achieve convenient operation, Friendly operation interface and good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

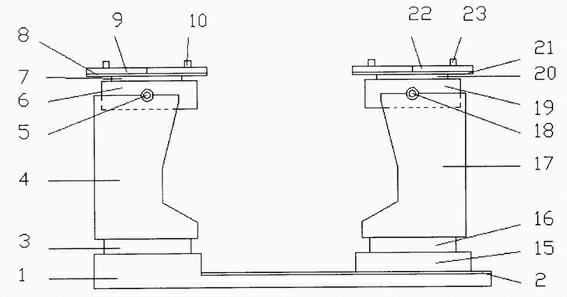

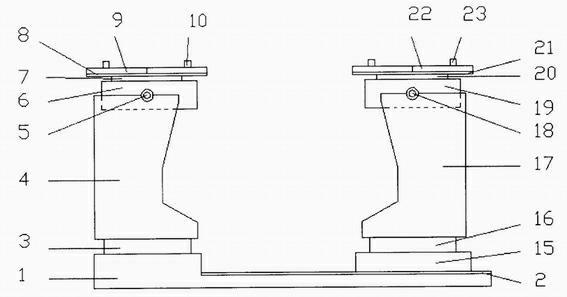

[0034] Such as figure 1 As shown, 1 is the base, 2 is the guide rail, 3 is the rotating shaft of the head frame, 4 is the head frame, 5 is the turning axis of the head frame, 6 is the turning table of the head frame, 7 is the rotation axis of the head frame chuck, and 8 is the head frame Chuck, 9 is the claw of the headstock screw rod, 10 is the positioning block of the headstock, 15 is the base of the tailstock, 16 is the rotary shaft of the tailstock, 17 is the tailstock, 18 is the turning axis of the tailstock, and 19 is the turning table of the tailstock , 20 is the rotating shaft of the tailstock chuck, 21 is the tailstock chuck, 22 is the claw of the tailstock screw rod, and 23 is the positioning block of the tailstock;

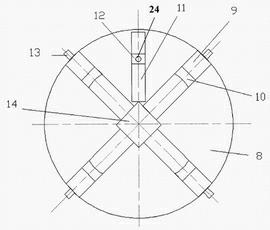

[0035] Such as figure 2 As shown, wherein 11 is a positioning groove, 12 is a zero point positioning block, 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com