Full-automatic car loader

A loader, fully automatic technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of small number of goods loaded, low work efficiency, collision with the inner wall of the loader compartment, etc., and achieves strong versatility and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

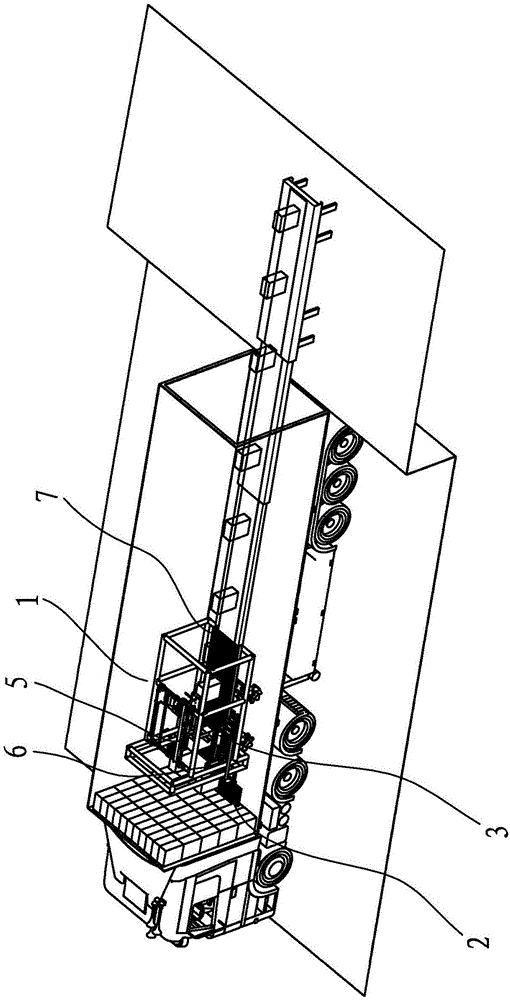

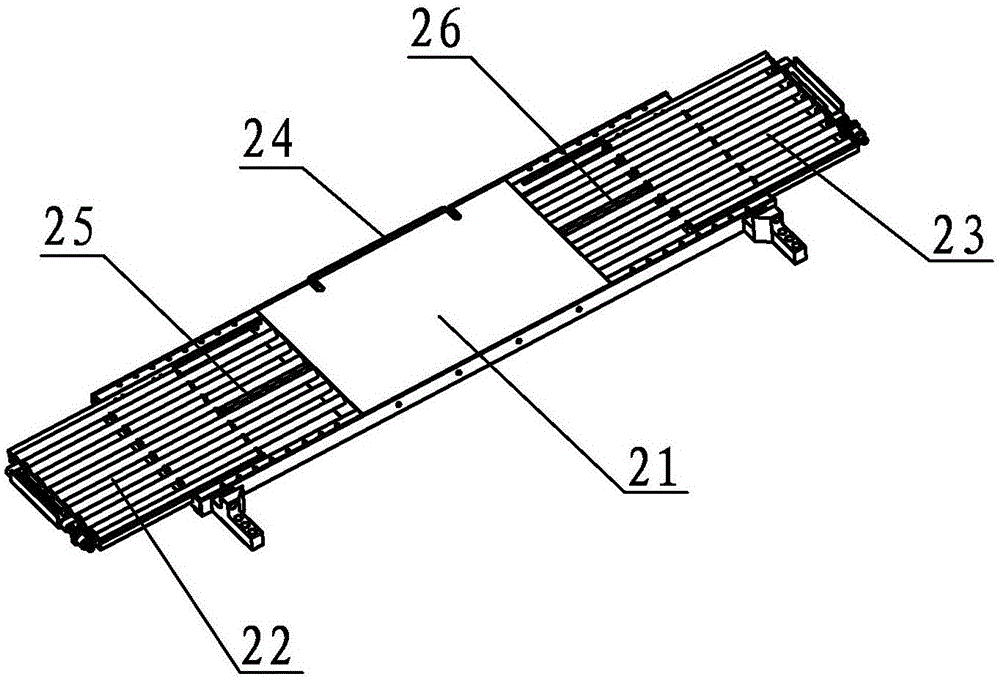

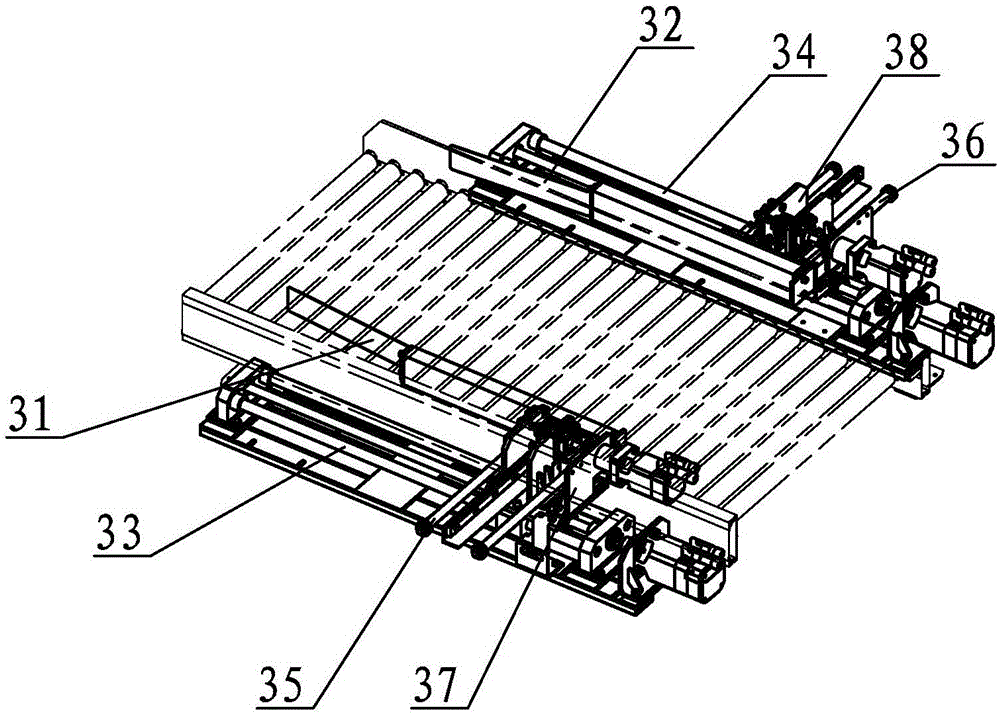

[0032] combine Figure 1 to Figure 8 As shown, the fully automatic car loading machine disclosed in this embodiment includes a wheeled walking frame 1, a pallet mechanism 2, an introduction mechanism 3, a lifting mechanism 4, a box pushing mechanism 5, a case dividing mechanism 6, a conveying mechanism 7, a pushing layer Mechanism 8; the conveying mechanism 7 and the introduction mechanism 3 are installed at the bottom of the wheeled walking frame 1; Mechanisms 8 are respectively installed on the front part of the wheeled walking frame 1; the action execution of the lifting mechanism 4, the box pushing mechanism 5, the box dividing mechanism 6, and the layer pushing mechanism 8 are all controlled by the PLC control unit.

[0033]The wheeled walking frame 1 is made of aluminum alloy profiles, which can meet the requirements of better rigidity and light weight. A dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com