Tool support for lathes

A tool holder and lathe technology, applied in lathes, turning equipment, turning equipment, etc., can solve the problems of high cost and complex structure, and achieve the effect of low additional time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

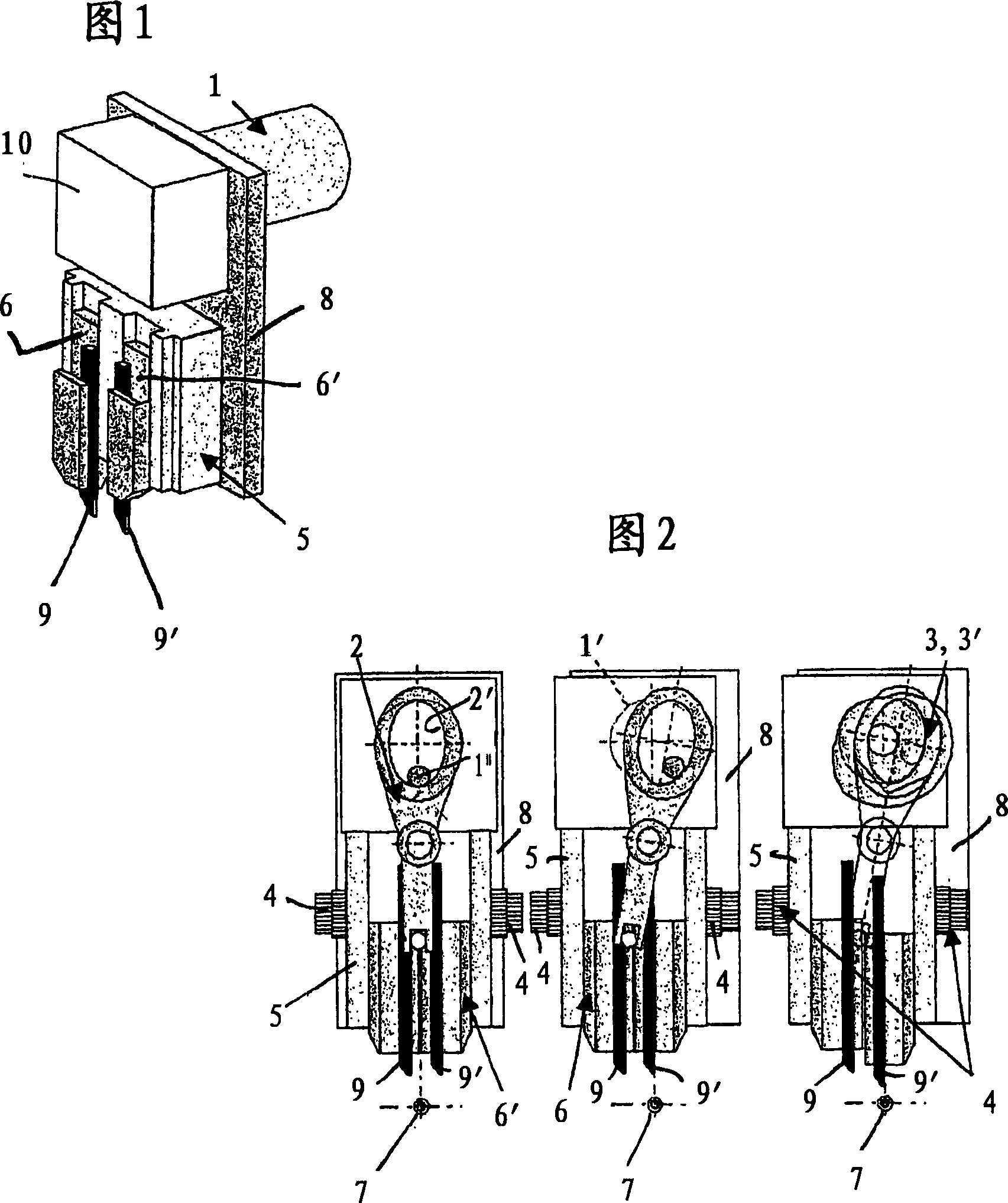

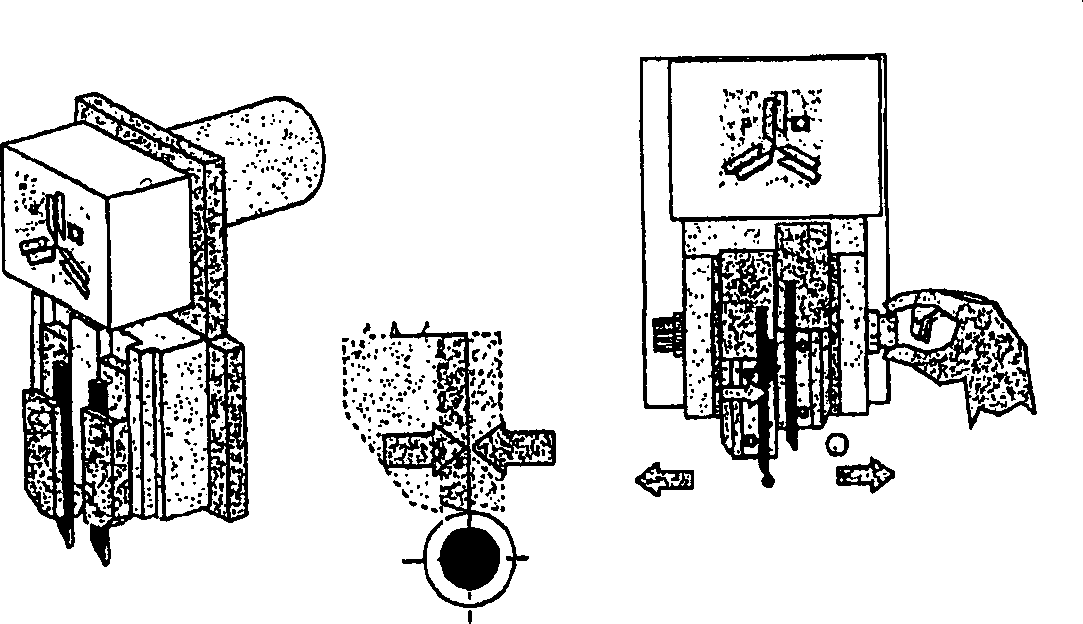

[0018] Figure 1 of the accompanying drawings shows a purely schematic representation of a tool holder according to the invention, which comprises a central drive motor 1 and a base frame 8 on which a transversely movable, with two The slide seat 5 of the knife holder 6, 6'. Different tools 9, 9' are fixed in the tool holders 6, 6'. Behind the movable cover 10 connected to the slide 5 there is the actual drive of the control elements 2 and 3, 3' (see FIG. 2 ).

[0019] The base frame 8 is usually built on a Z-slide (not shown), which allows additional controlled movement in the Z direction (along the main axis).

[0020] By means of the additional Z-movement, a simultaneous machining process can be realized which results in a considerable increase in productivity, especially for longitudinal cutting automatic lathes.

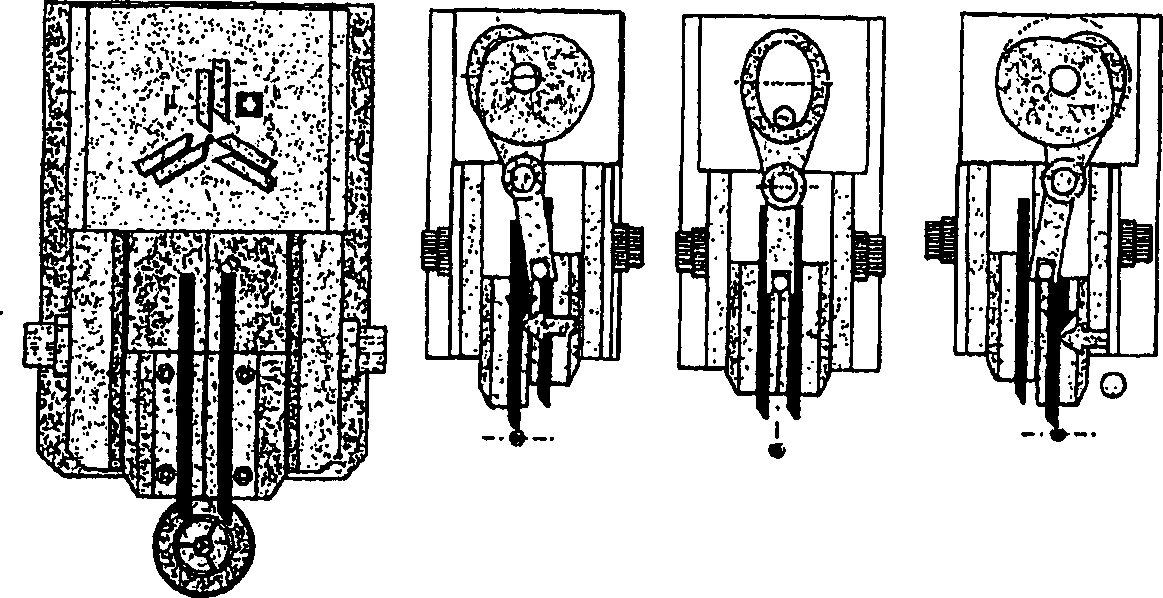

[0021] Figure 2 schematically shows the working principle of a double or twin tool holder:

[0022] The motor 1 drives the control part lever 2 and cam 3 via ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com