Self-supporting bimetal-based electrode material and preparation method and application thereof

A bimetallic and base electrode technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of restricting the development of supercapacitors, short cycle life, low energy density, etc., to alleviate Faraday reaction, long cycle The effect of life and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

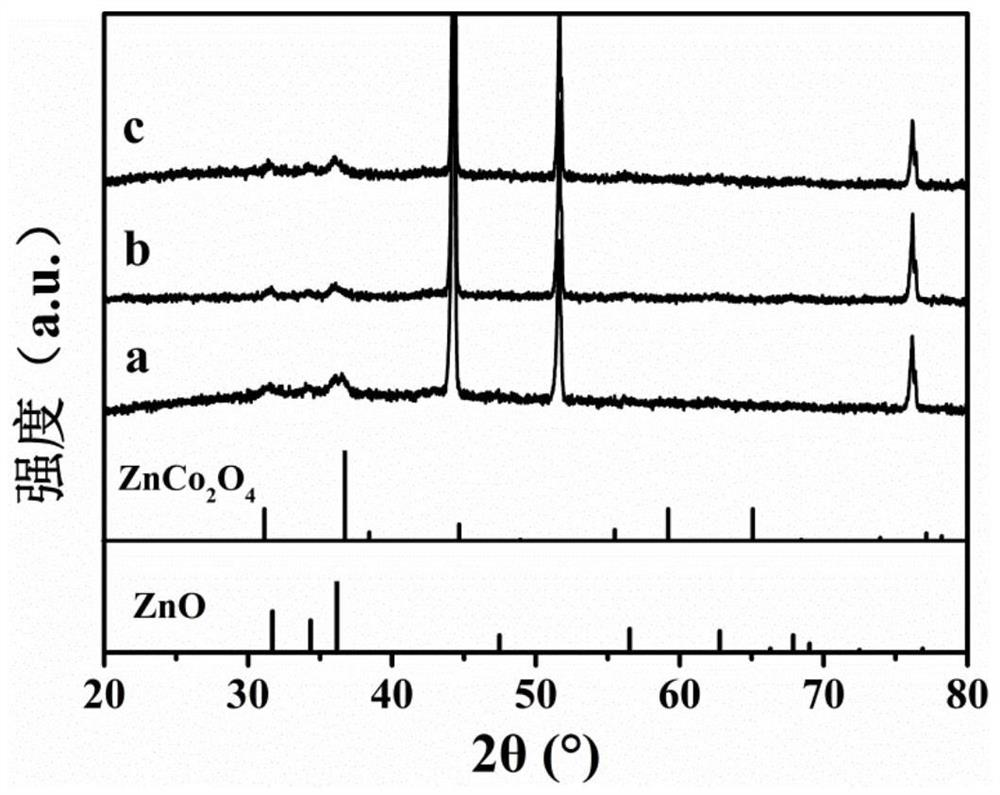

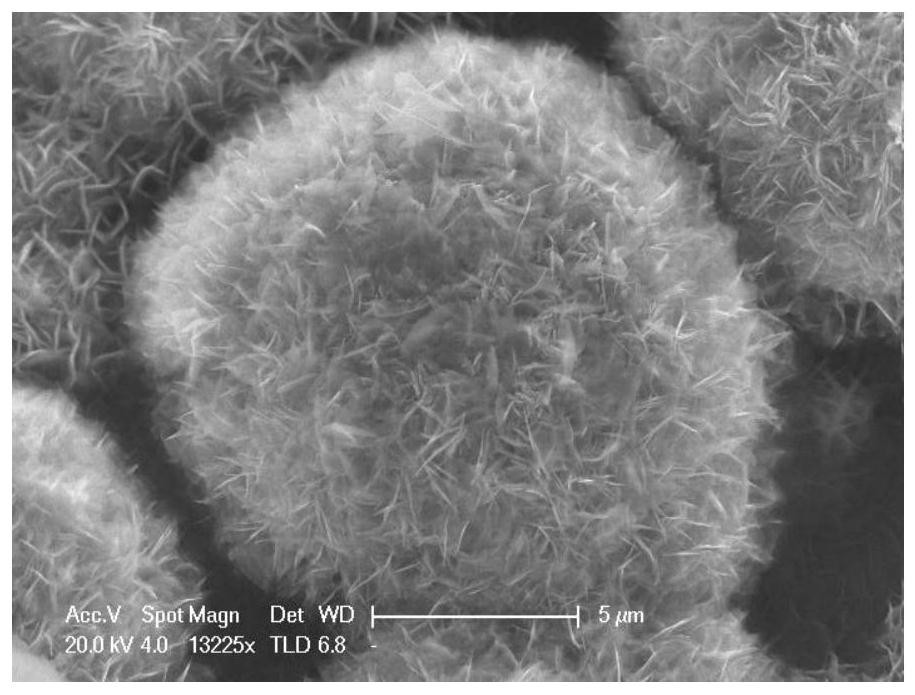

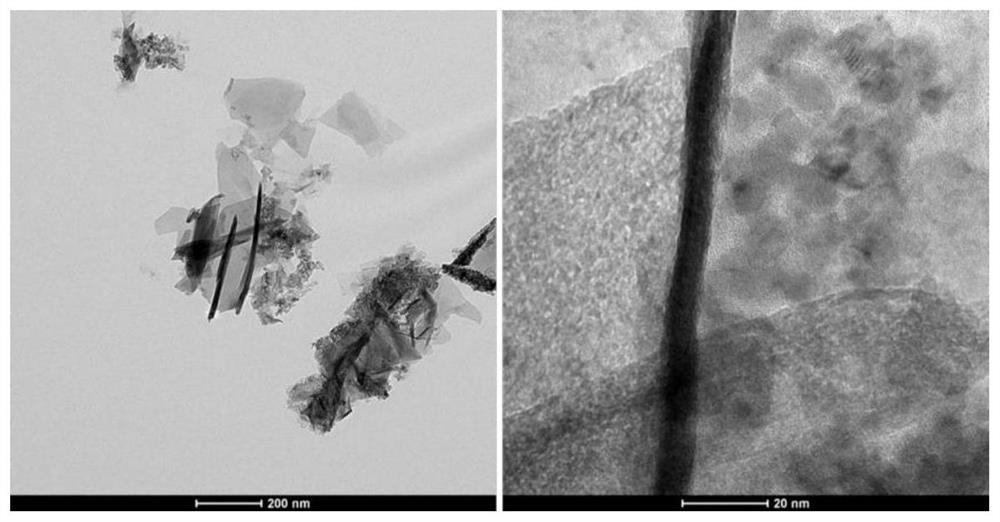

[0032] A self-supporting ZnCo 2 o 4 -The preparation method of ZnO@CoS composite material, comprises the following steps:

[0033] (1) Pretreatment of nickel foam:

[0034] Followed by 3mol L -1 Dilute hydrochloric acid, deionized water and absolute ethanol were used as cleaning agents to ultrasonically clean the nickel foam, and finally vacuum-dried at 60°C for 12 hours to obtain the pretreated nickel foam;

[0035](2) Dissolve 1.5mmol cobalt nitrate hexahydrate and 1.5mmol zinc nitrate hexahydrate in 20mL deionized water and 5mL absolute ethanol by solvothermal method, then add 4mmol urea, stir to obtain a pink uniform solution, transfer to Put the pretreated nickel foam obtained in step (1) into a stainless steel reaction kettle lined with polytetrafluoroethylene, seal the reaction kettle and place it in an oven, react at 130°C for 5h, cool naturally to room temperature, and then use it sequentially Rinse the nickel foam with deionized water and absolute ethanol, and dr...

Embodiment 2

[0039] On the basis of embodiment 1, different from embodiment 1 is:

[0040] In step (3), in the high-temperature-resistant glass bottle, Zn is grown on the surface x co 1-x (OH) 2 The concentration of nickel foam in the precursor is 0.05mol L -1 Glucose aqueous solution, sealed and placed in an oven, reacted at 85°C for 8h, cooled to room temperature; put the wet nickel foam into a tube furnace, calcined at 400°C for 2h, and completed the carbonization step to obtain ZnCo 2 o 4 - ZnO@C composite material;

[0041] In step (4), to grow ZnCo 2 o 4 -Ni foam of ZnO@C as working electrode to get ZnCo 2 o 4 - ZnO@C@CoS-6 composites.

Embodiment 3

[0043] On the basis of Example 2, the difference from Example 2 is that in step (3), the reaction temperature in the oven is 100° C., and the reaction time is 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com