Optical cable branch line protection structure

A technology for protecting structures and optical cables, applied in fiber mechanical structures, optics, light guides, etc., can solve problems such as difficult to achieve fixed length, affect optical fiber signal transmission effect, poor consistency of branch sub-cable lengths, etc., to ensure length consistency, ensure The effect of optical performance and signal transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

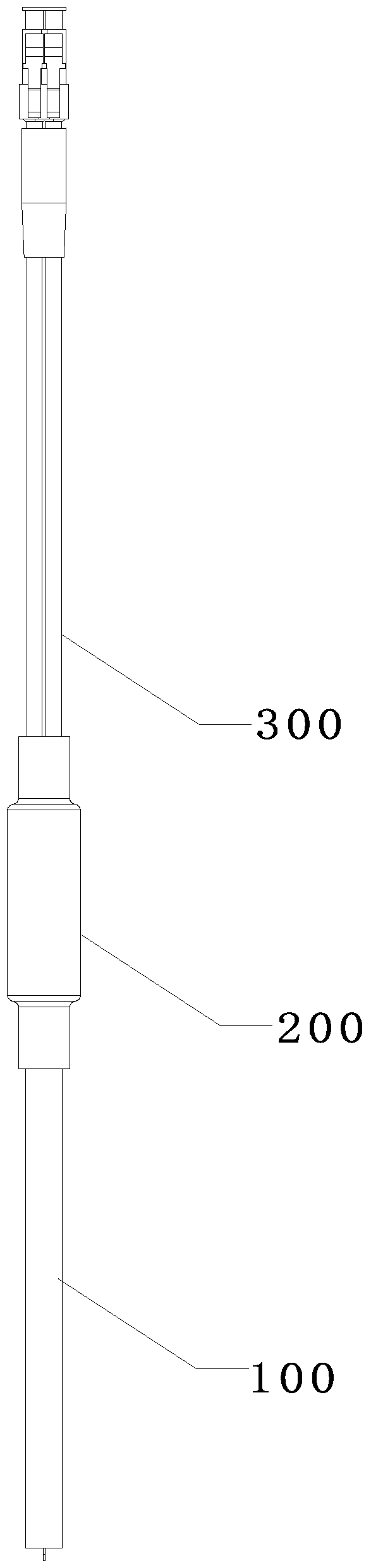

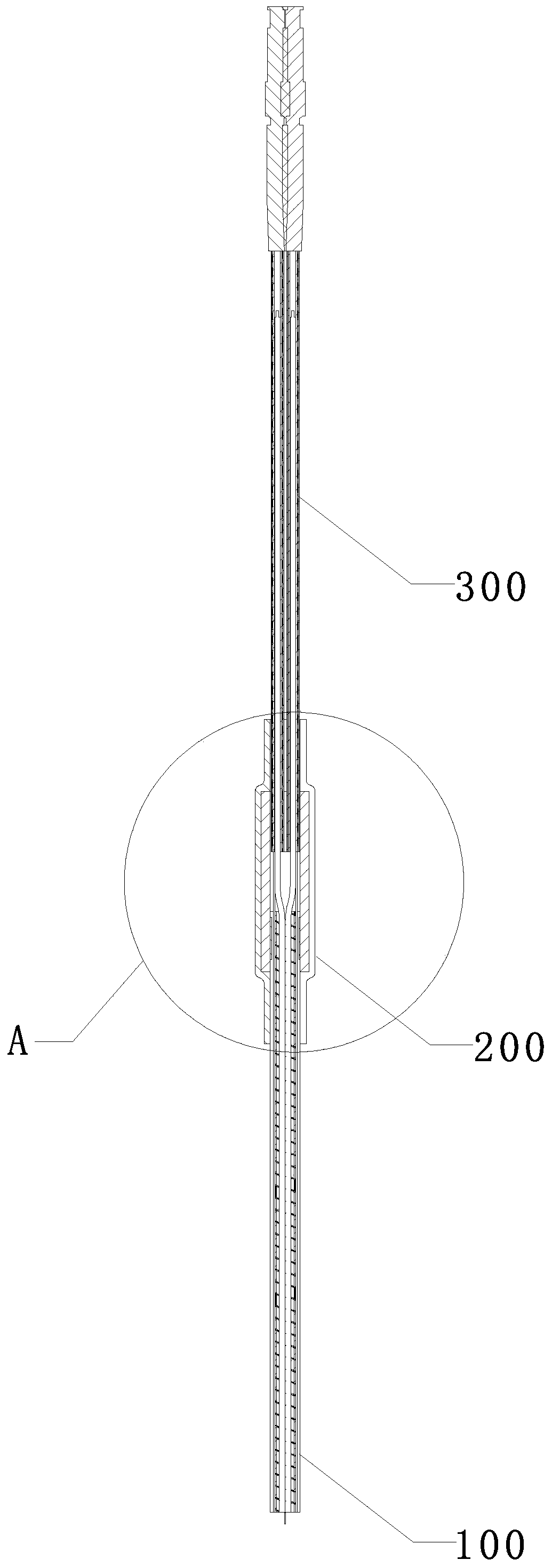

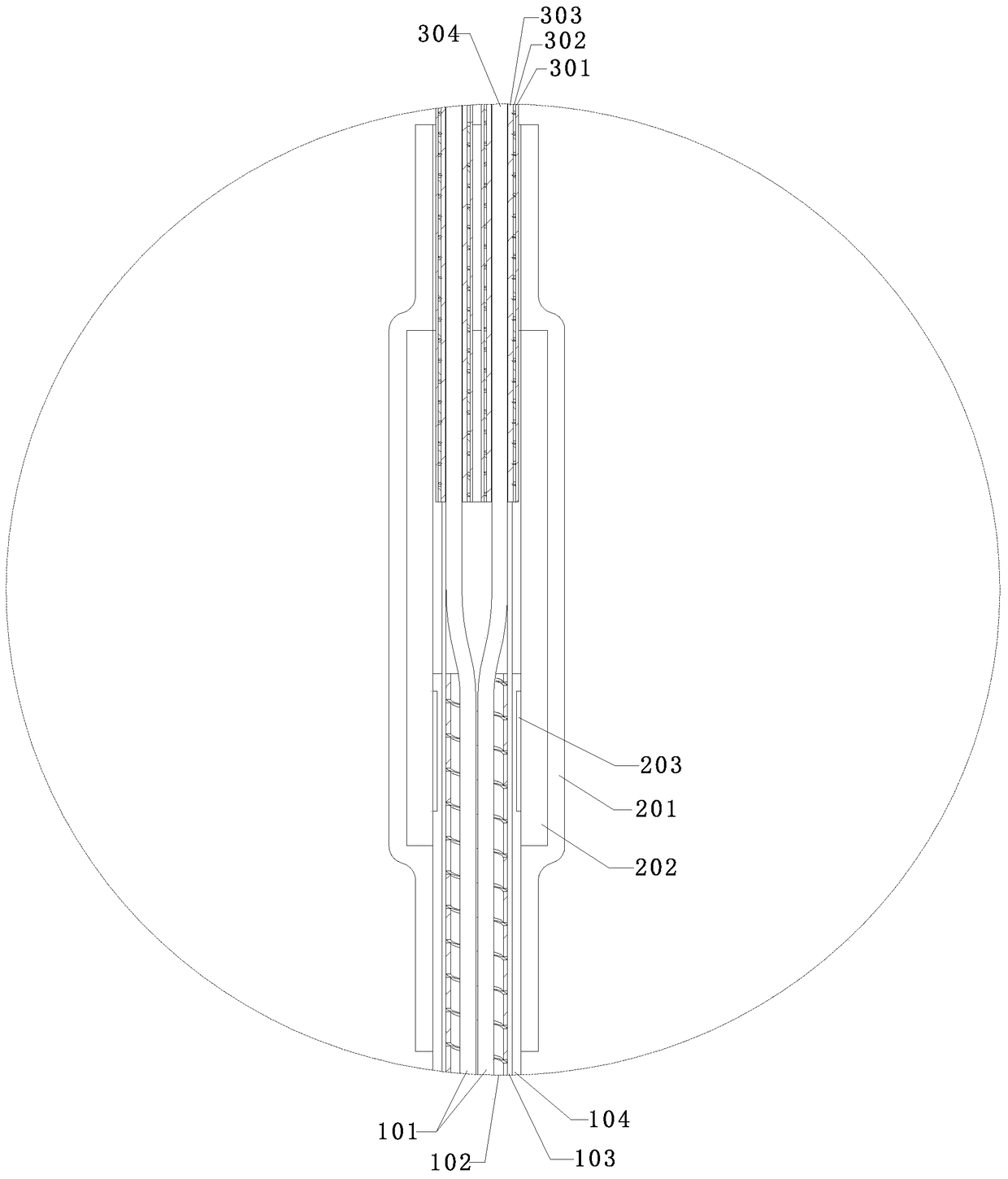

[0022] See figure 1 , figure 2 as shown, figure 1 It is a three-dimensional schematic diagram of the optical cable branching protection structure of the present invention; figure 2 for figure 1 cutaway view. This embodiment discloses an optical cable branching protection structure, which is mainly used for the problem of inconsistency in the lengths of the branch sub-cables caused by the movement of the tension-resisting elements in the optical cable when the optical cable is in the process of branching, as well as the separation between the main cable and the sub-cables. Glue encapsulation at the branch line will cause the optical fiber in the optical cable at the glue filling position to be fixed, which cannot guarantee the optical performance of the optical fiber and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com