Ignition device with improved sealing performance

A technology of ignition device and ignition coil, which is applied in the direction of engine ignition, spark ignition controller, spark plug, etc., can solve the problems of time-consuming and cost, and achieve the effects of cost economy and simplicity, simplified quality inspection, and great cost saving potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

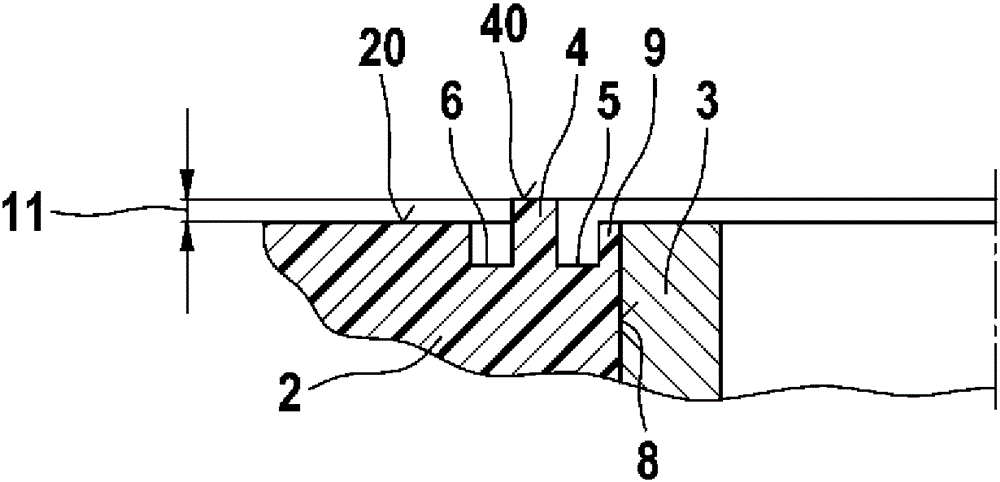

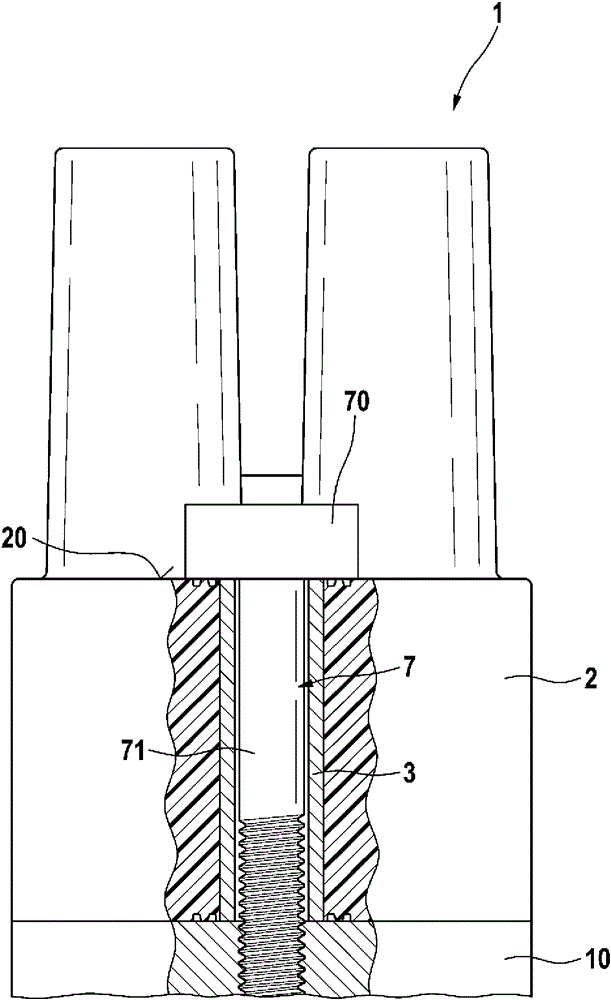

[0019] Refer below Figure 1 to Figure 6 An ignition device 1 according to a preferred exemplary embodiment of the invention will be described in detail.

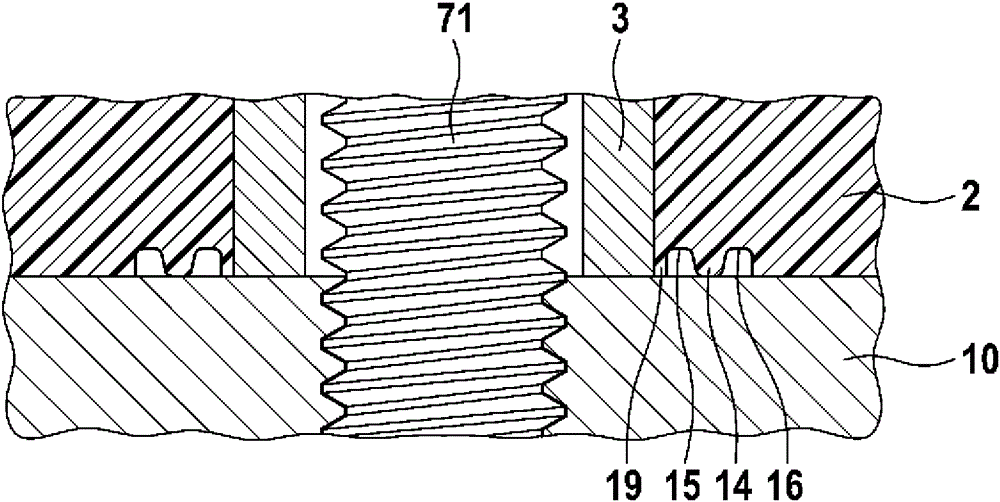

[0020] The ignition device 1 comprises a housing 2 for accommodating an ignition coil and other components, said housing being figure 1 Shown in perspective. For fastening the ignition device to the engine component 10 , one or more through-holes 8 are provided in the housing with inserted screw-on bushings 3 , through which screw-in screws 7 are threaded. This fixation of the housing 2 in the Figure 4 shown in . The screw-in bush 3 is a cylindrical bush which accommodates the threaded shaft 71 of the threaded screw 7 .

[0021] In the prior art, the pre-screw bushing 3 is always coated with an anti-corrosion coating, wherein problems can arise due to peeling or peeling and flakes. According to the invention, therefore, the screw-in bushing 3 is designed without an anti-corrosion coating. as from figure 2 with im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com