Ignition apparatus with improved sealing properties

An ignition device, ignition coil technology, applied in the direction of engine ignition, spark ignition controller, spark plug, etc., can solve the problems of time-consuming and cost, and achieve the effect of cost economy and simplicity, great cost saving potential, and simplified quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

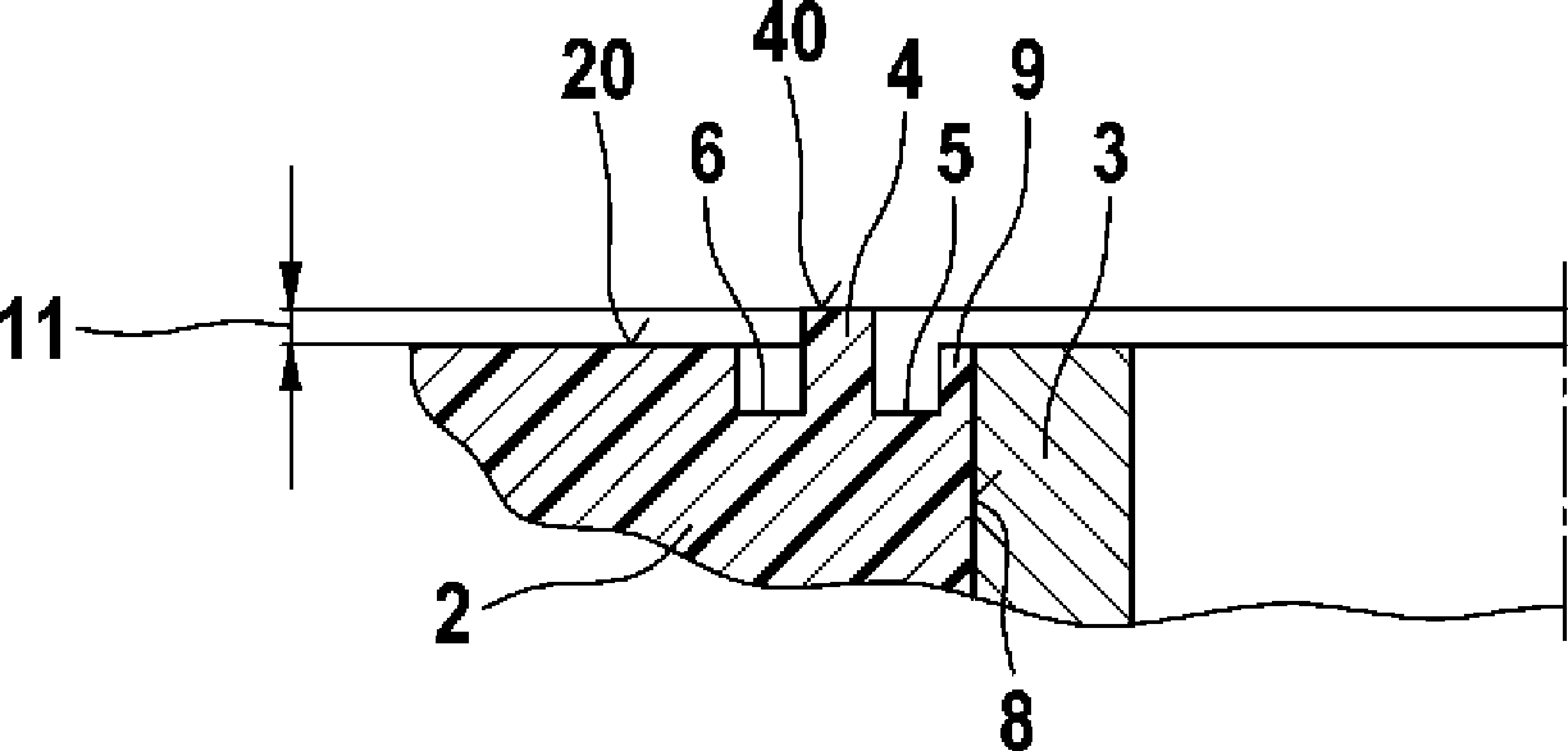

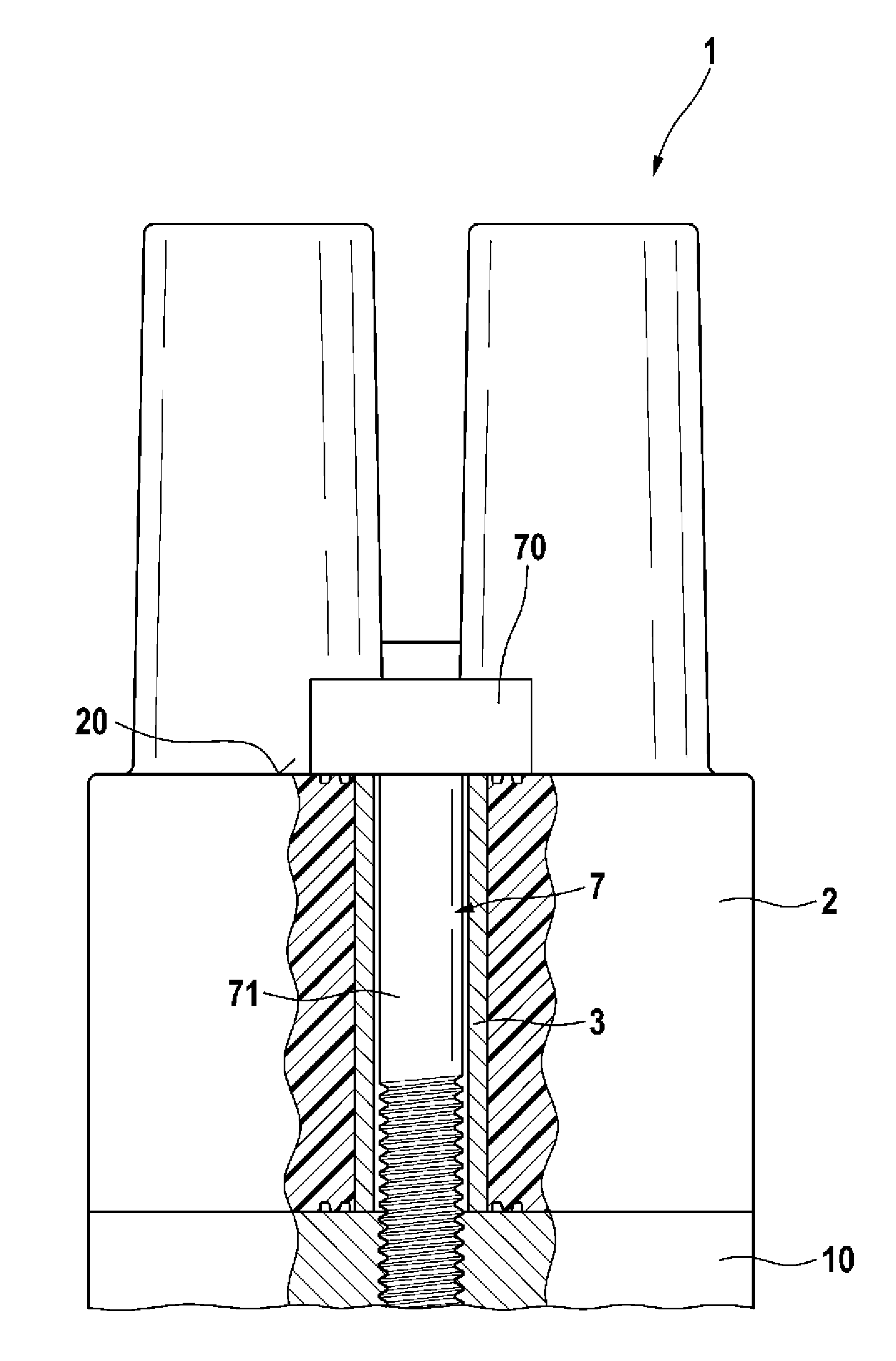

[0019] An ignition device 1 according to a preferred embodiment of the present invention will be described in detail below with reference to FIGS. 1 to 6 .

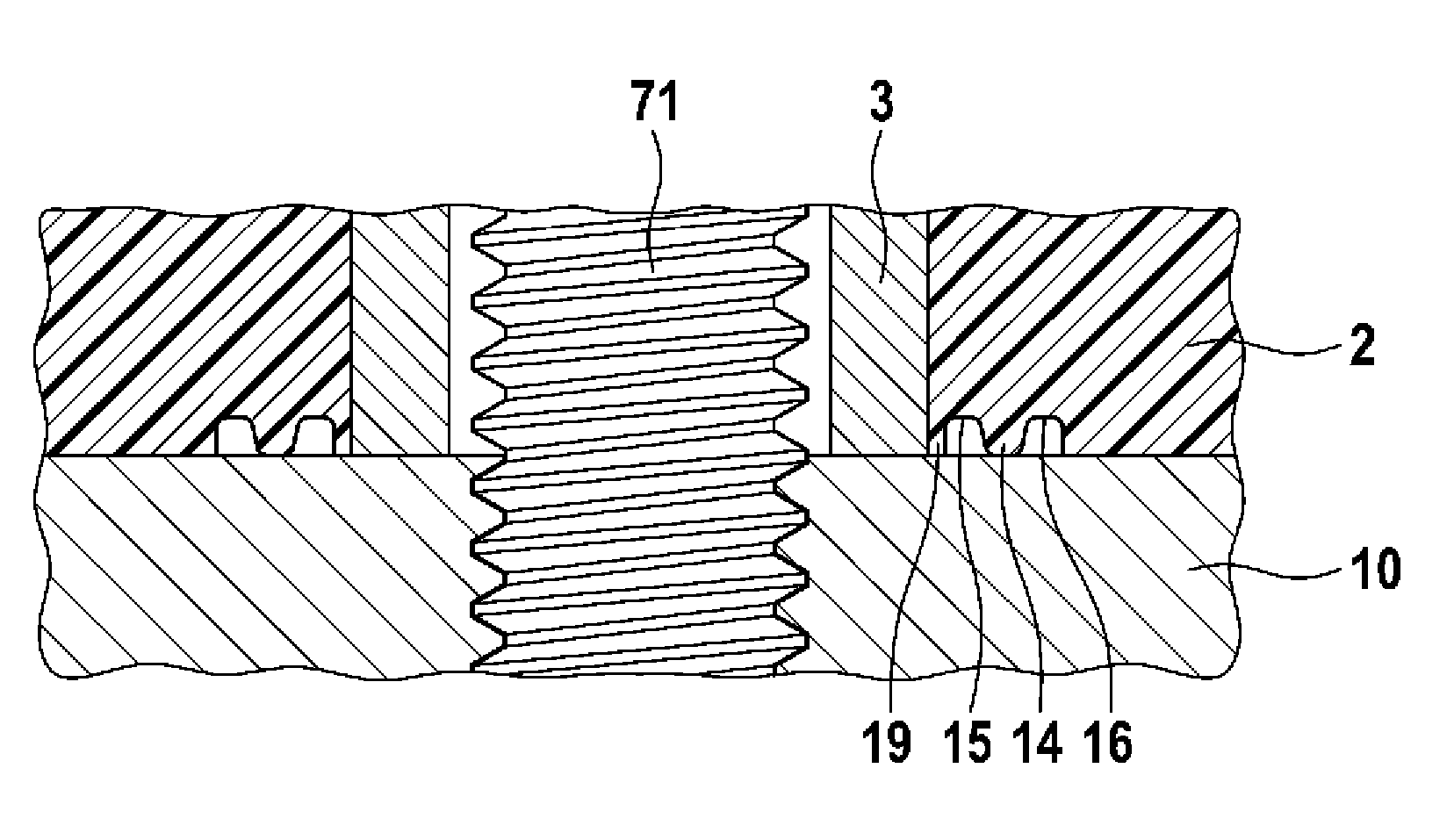

[0020] The ignition device 1 comprises a housing 2 for accommodating an ignition coil and other components, which is shown perspectively in FIG. 1 . For fastening the ignition device to the engine component 10 , one or more through-holes 8 are provided in the housing with inserted screw-on bushings 3 , through which screw-in screws 7 are threaded. This fastening of the housing 2 is shown in FIG. 4 . The screw-in bush 3 is a cylindrical bush which accommodates the threaded shaft 71 of the threaded screw 7 .

[0021] In the prior art, the pre-screw bushing 3 is always coated with an anti-corrosion coating, wherein problems can arise due to peeling or peeling and flakes. According to the invention, therefore, the screw-in bushing 3 is designed without an anti-corrosion coating. As can be seen from FIGS. 2 and 3 , the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com