Apparatus for manufacturing compacted irons of reduced materials comprising fine direct reduced irons and apparatus for manufacturing molten irons provided with the same

A technology for reducing iron powder and equipment, applied in the direction of manufacturing tools, presses, etc., can solve the problems of scattered reducing materials, difficult to discharge gas, and easy deformation of the discharge port, and achieve the effect of improving durability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Exemplary embodiments of the present invention will be explained in detail below with reference to the accompanying drawings so that those skilled in the art to which the present invention pertains can easily implement the present invention. However, the present invention can be implemented in various forms and is not limited to the embodiments explained below. In addition, in this specification and drawings, the same code|symbol represents the same element.

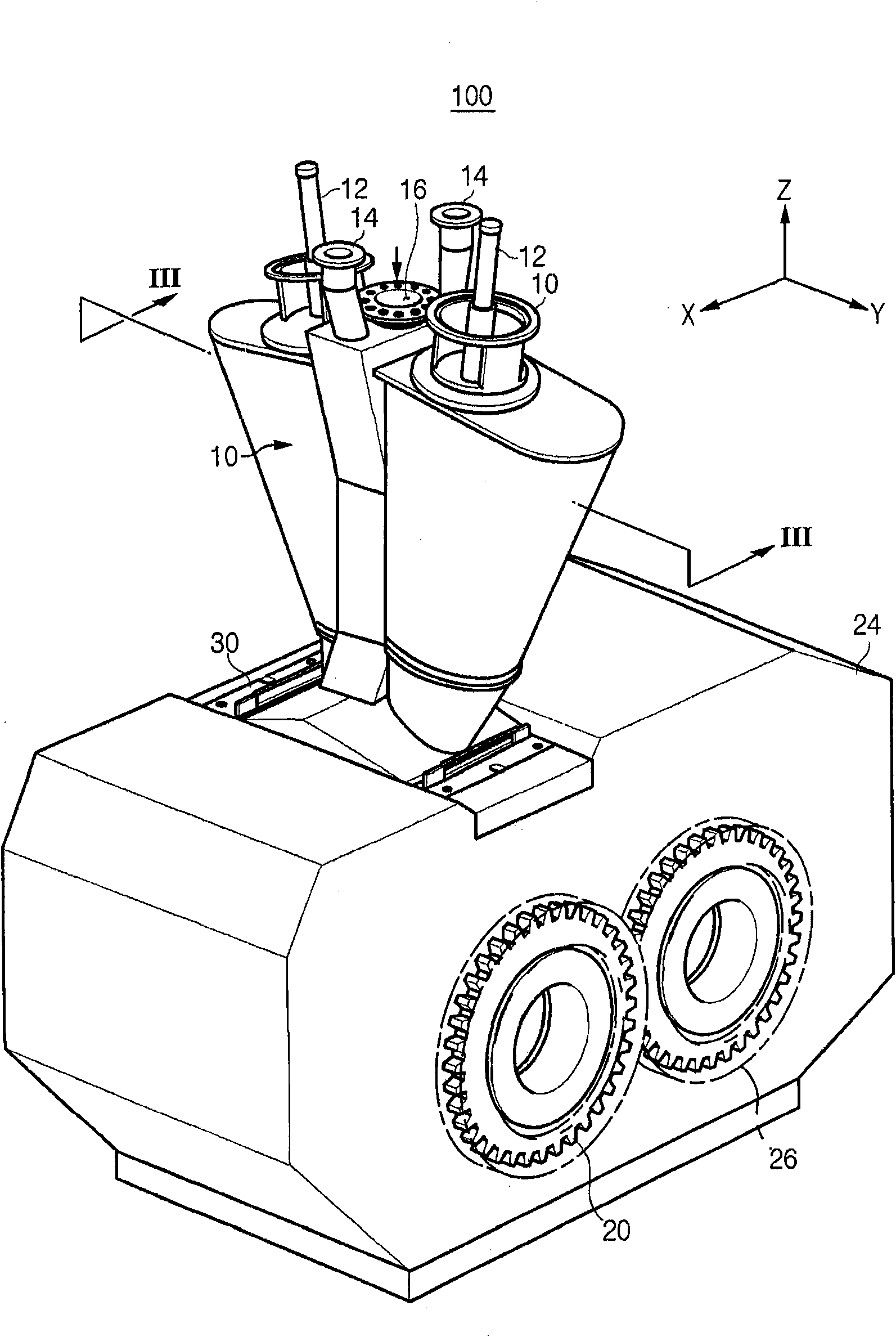

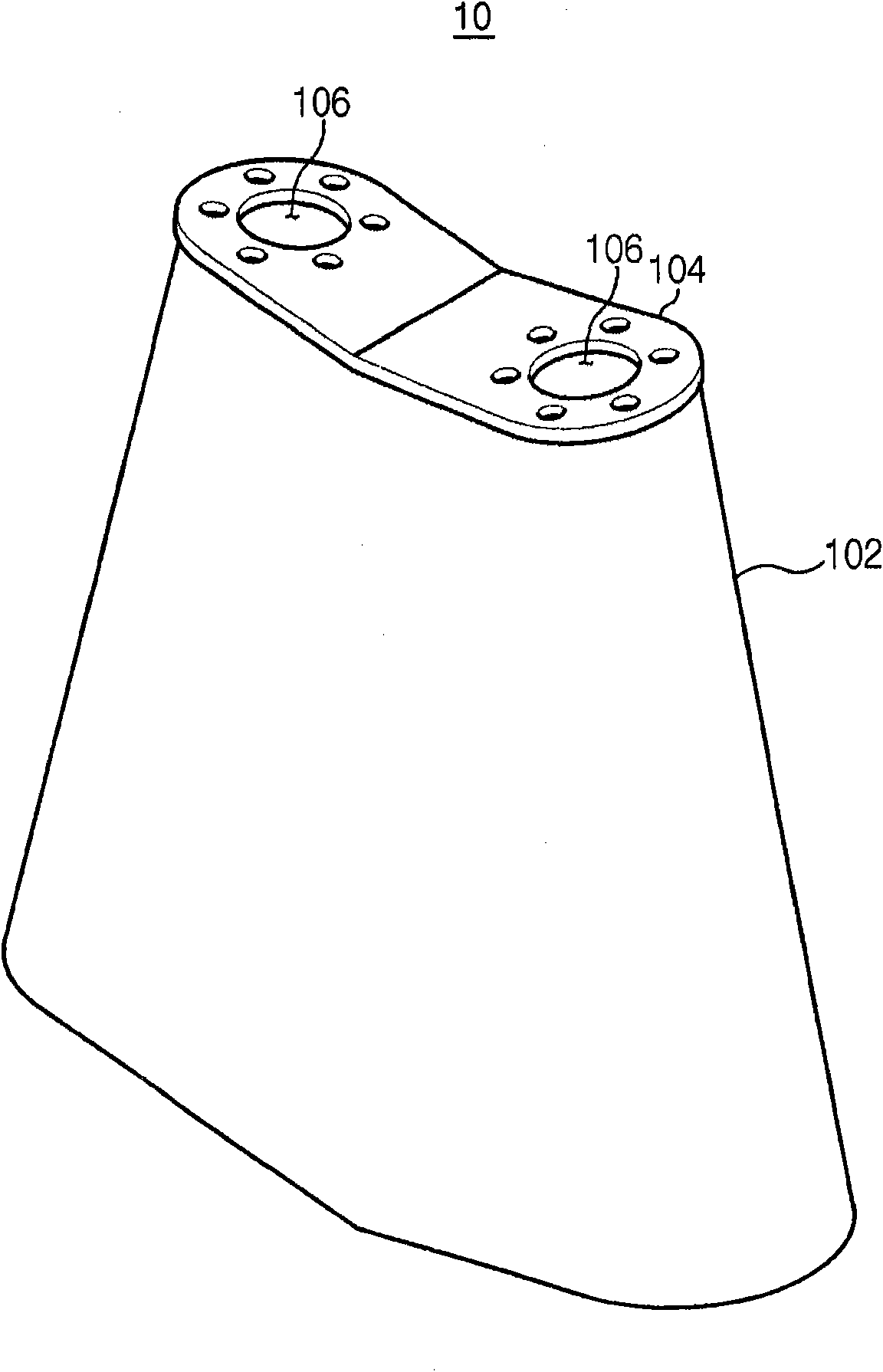

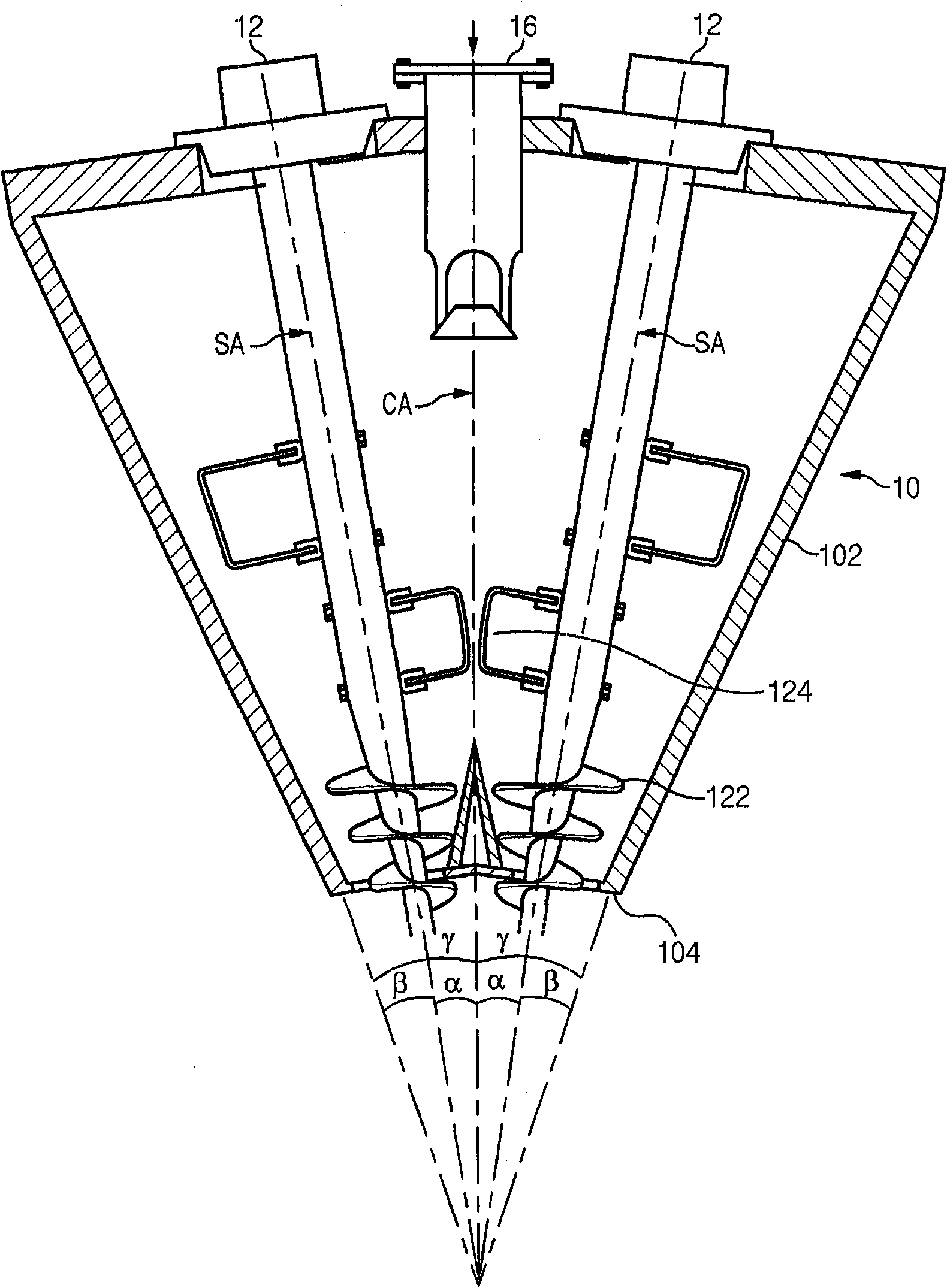

[0032] figure 1 An apparatus 100 for manufacturing compressed iron according to an embodiment of the present invention is schematically shown. The apparatus 100 for manufacturing compressed iron includes a charging hopper 10 and a pair of rollers 20 .

[0033] exist figure 1 In the apparatus 100 for manufacturing compacted iron shown in , the roll mantle 24 is placed at the lower portion of the apparatus 100 for manufacturing compacted iron, and the feed box 30 is installed on the upper side of the roll mantle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com