Integrated gas injection micro-exhaust valve

An integrated, gas injection technology, applied in the field of water supply and drainage, to achieve the effect of safe and convenient use, reliable operation, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

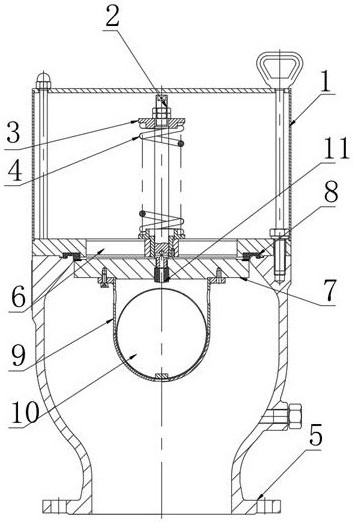

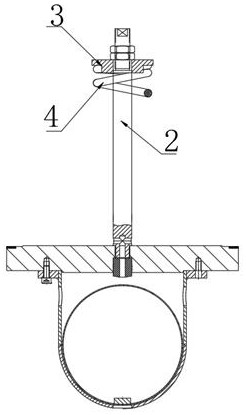

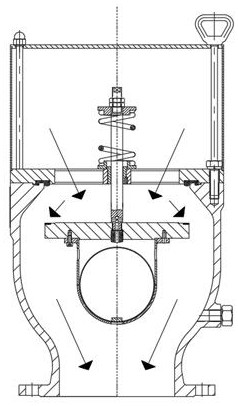

[0032]Example: such asFigure 1-5As shown, the present invention provides a technical solution, an integrated gas injection micro-exhaust valve, including a protective cover 1, two ring nuts are connected to the top of the protective cover 1 to facilitate normal installation and later traction, and the bottom end of the protective cover 1 passes The bolt is connected with the gas injection valve body 5. The gas injection valve body 5 has a full-diameter structure, and each part of the internal passage is not less than the nominal diameter. In order to further improve the sealing effect, the protective cover 1 and the gas injection valve body 5 are embedded and installed With valve seat sealing ring 8;

[0033]A guide shaft 2 is installed inside the protective cover 1, the top of the guide shaft 2 is connected with a limit block 3 through bolts, and the bottom end of the limit block 3 is connected with a spring 4;

[0034]A gas injection valve cover 6 is connected to the top of the gas inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com