Apparatus and method for processing plastic melts

A melt and plastic technology, applied in the direction of chemical instruments and methods, chemical/physical processes, mixers with rotating stirring devices, etc., can solve problems such as inability to control the quantity or quality of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] At the outset, it should be pointed out that the same components have the same reference signs or the same component designations in different embodiments, and that the disclosure contained in the entire description can reasonably be transferred to the same components with the same reference signs or the same component designations superior. Likewise, positional expressions such as top, bottom, side, etc. selected in the description relate to the current description and the illustrated figure and can be transferred to the new position if the position changes.

[0084] The expression "in particular" is to be understood below as meaning that this expression can be a possible special configuration or a more specific specification of a subject matter or a method step, but not necessarily its mandatory, preferred embodiment or treatment .

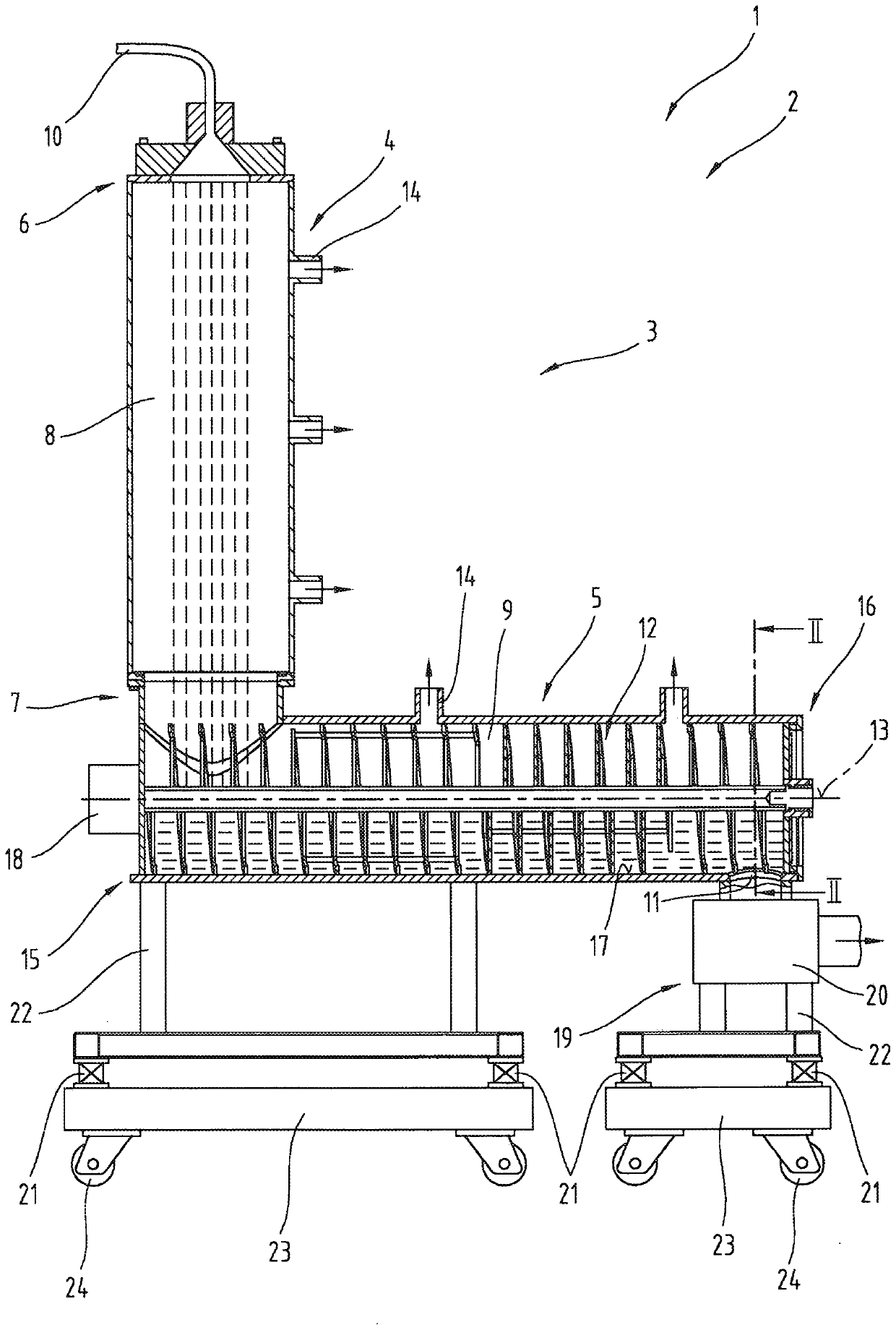

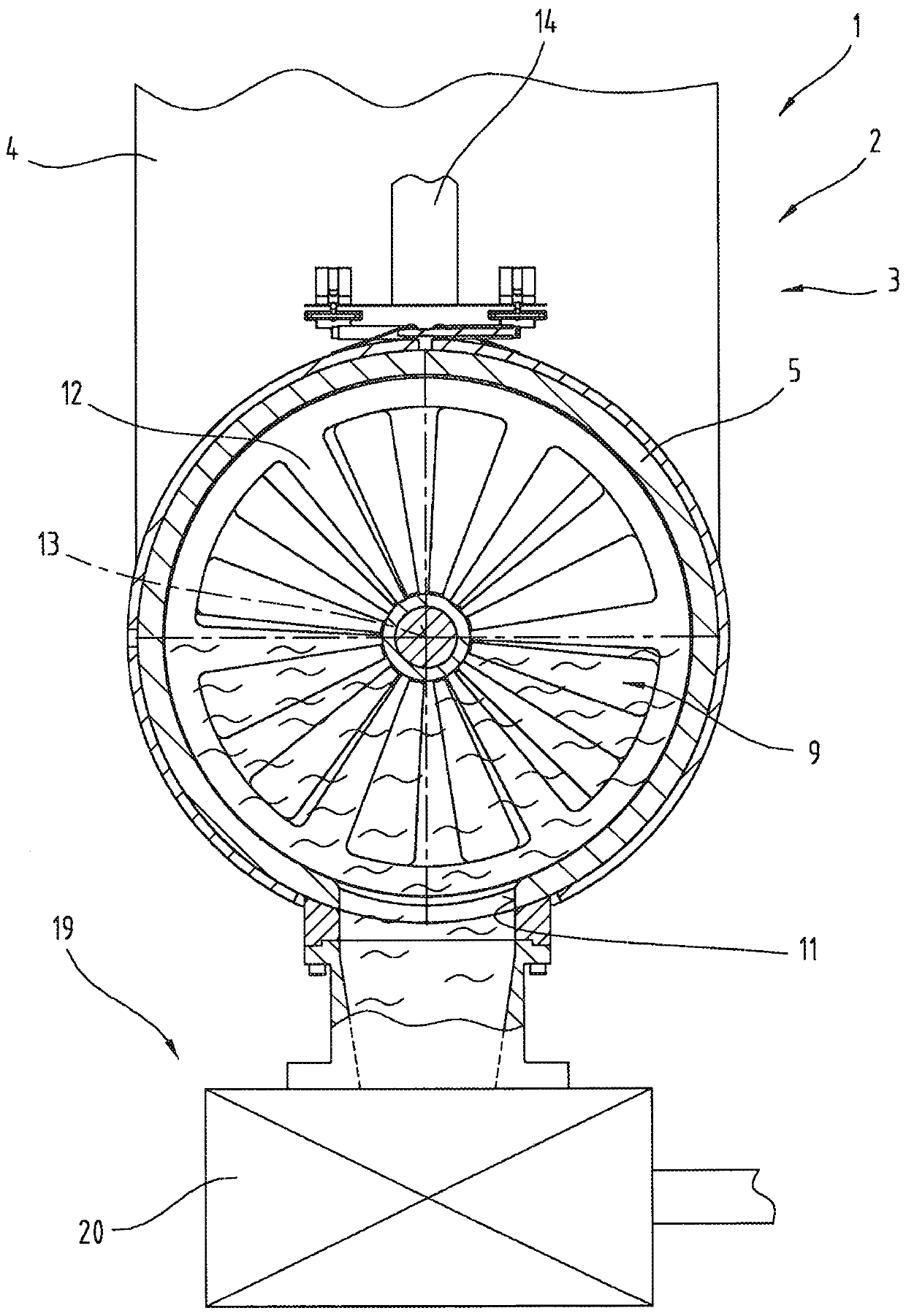

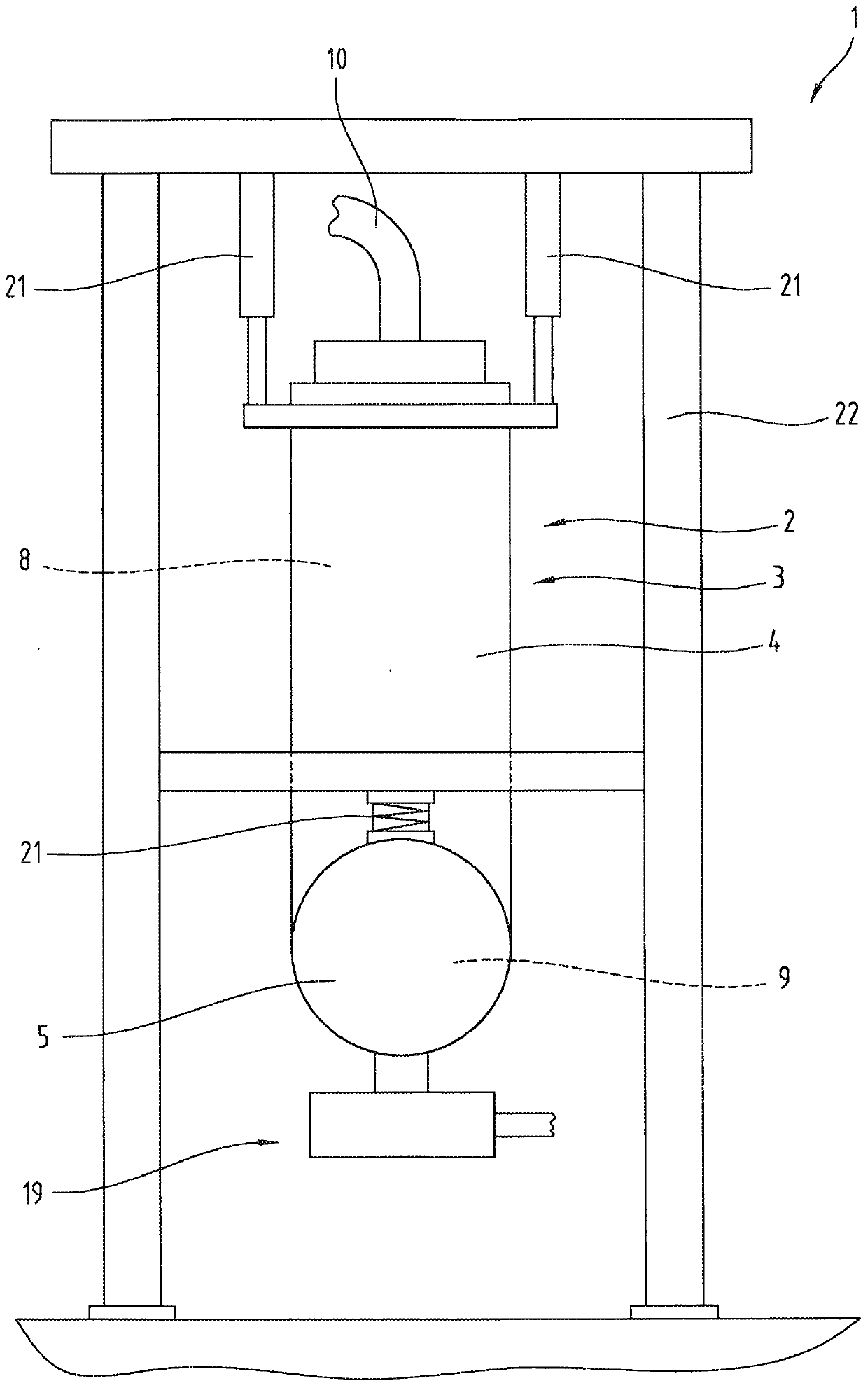

[0085] exist Figures 1 to 3 A part of a plant 1 for processing plastic melts, in particular polycondensate melts, is shown in simplif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com