Multi-glycol epoxy derivative cross-linked sodium hyaluronate gel used for injection and preparation method thereof

A technology of sodium hyaluronate and alcohol epoxy, which is applied in the fields of pharmaceutical formulation, tissue regeneration, and drug delivery, and can solve problems such as good injectability, small extrusion force, and strong degradation resistance of the gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

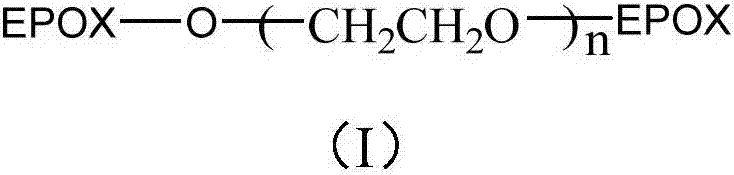

[0098] Embodiment 1: synthetic tetraethylene glycol diglycidyl ether (Ia)

[0099] Synthesize tetraethylene glycol diglycidyl ether of following structure:

[0100]

[0101] Add tetraethylene glycol (0.1mol), tetrahydrofuran (100mL) and potassium hydroxide (0.4mol) into the three-necked flask, stir in a water bath, then add epichlorohydrin (0.6mol) dropwise to the reaction system, and control the reaction temperature not to exceed React overnight at room temperature at 35°C. After the reaction, the reaction solution was filtered, and the filter residue was washed with dichloromethane, then the filtrate was collected, and the dichloromethane was removed by rotary evaporation to obtain a crude product. The crude product was molecularly distilled to obtain pure tetraethylene glycol diglycidyl ether.

[0102] 1 H-NMR (DMSO-d6): 2.52-2.55 (m, 2H), 2.70-2.73 (m, 2H), 3.07-3.11 (m, 2H), 3.22-3.28 (m, 2H), 3.52-3.56 (m , 16H), 3.68-3.73(m, 2H);

[0103] HPLC detection: the pro...

Embodiment 2

[0105] Embodiment 2: Synthesis of dodecaethylene glycol diglycidyl ether (Ib)

[0106] Synthesize dodecaethylene glycol diglycidyl ether of following structure:

[0107]

[0108] Add dodecaethylene glycol (0.1mol), tetrahydrofuran (100mL) and potassium hydroxide (0.4 mol) in the there-necked flask, stir in a water bath, then drop epichlorohydrin (0.6mol) in the reaction system, control the reaction temperature Over 35°C, react overnight at room temperature. After the reaction, the reaction solution was filtered, and the filter residue was washed with dichloromethane, then the filtrate was collected, and the dichloromethane was removed by rotary evaporation to obtain a crude product. The crude product was molecularly distilled to obtain pure dodecaethylene glycol diglycidyl ether.

[0109] 1 H-NMR (DMSO-d6): 2.51-2.55 (m, 2H), 2.70-2.73 (m, 2H), 3.07-3.11 (m, 2H), 3.22-3.29 (m, 2H), 3.51-3.57 (m , 48H), 3.68-3.73(m, 2H);

[0110] HPLC detection: the product purity is 99...

Embodiment 3

[0112] Embodiment 3: synthesizing Tetracethylene glycol diglycidyl ether (Ic)

[0113] Synthesize four tetraethylene glycol diglycidyl ethers of the following structure:

[0114]

[0115] Add tetracosanethylene glycol (0.1mol), tetrahydrofuran (100mL) and potassium hydroxide (0.4mol) into the three-necked flask, stir in a water bath, then add epichlorohydrin (0.6mol) dropwise to the reaction system, and control the reaction temperature Do not exceed 35°C, and react overnight at room temperature. After the reaction, the reaction solution was filtered, and the filter residue was washed with dichloromethane, then the filtrate was collected, and the dichloromethane was removed by rotary evaporation to obtain a crude product. The crude product was separated by a column to obtain pure tetracosanthyl glycol diglycidyl ether.

[0116] 1 H-NMR (DMSO-d6): 2.51-2.55 (m, 2H), 2.70-2.73 (m, 2H), 3.07-3.11 (m, 2H), 3.22-3.28 (m, 2H), 3.51-3.56 (m , 96H), 3.68-3.73(m, 2H);

[0117] H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com