Patents

Literature

58results about How to "Easy to adjust performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep water low temperature cementing cement system

InactiveCN101054513AImprove performanceRapid development of strengthDrilling compositionWell cementingCement slurry

The invention belongs to sea deep water complex well cementing which is suitable for low temperature, tending to superficial water-gassed-out. The mineral components and mass percent composition are: 23-45 wt.% of tricalcium silicate, 12-25 wt.% of calcium sulphoaluminate, 15-23 wt.% of dicalcium silicate, 3-10 wt.% of gypsum, 4-8 wt.% of calcium carbonate, and residual celite, calcium aluminate and other microelement. The using process of the deep water complex well cementing includes: adding 0-3 wt.% of coagulant, 0-1.2 wt.% of retarder, 15-45 wt.% of hollow microglobin and water to prepare a low density cement slurry system of 1.35-1.60g / cm3 which has a controllable gelled time and has a perfect right-angle gelling capacity, a set cement volume microdilatancy and develops fast at low temperature. The inventive deep water low temperature complex well cementing has a high early strength, a short curing time, a powerful channeling-preventing ability, and microdilatancy, which provides a powerful guarantee to improve the deep water complex well quality.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

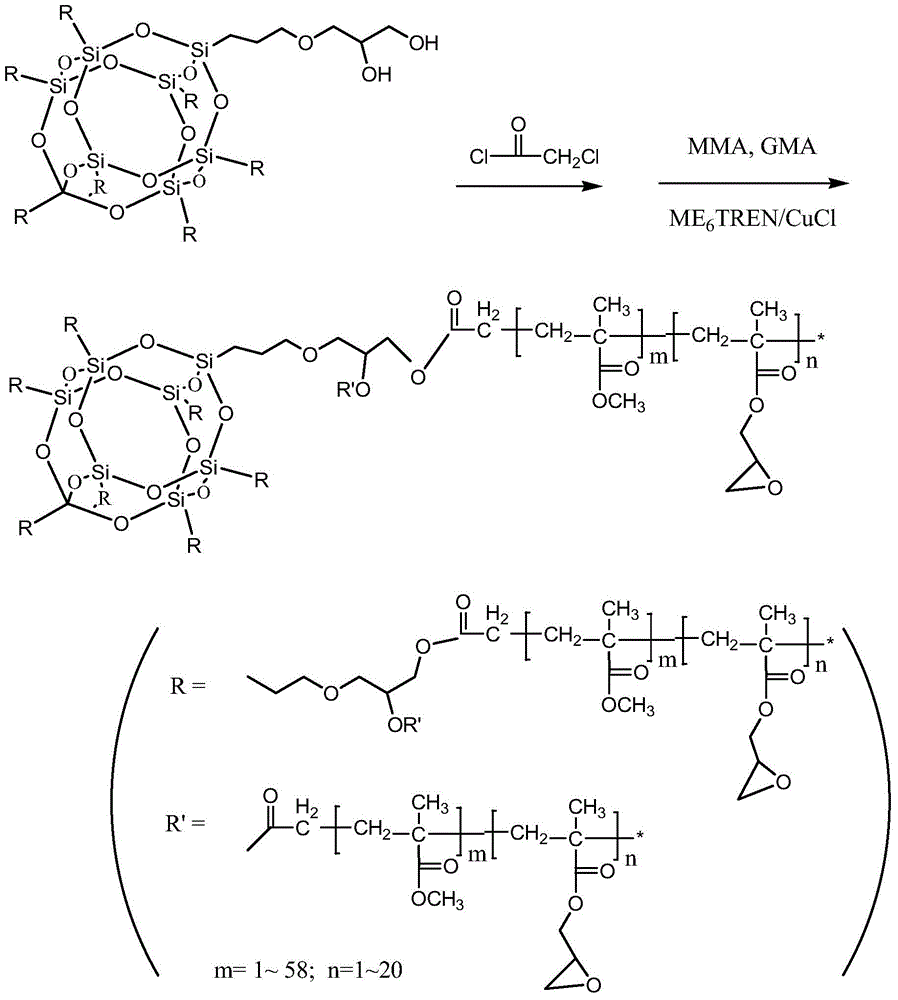

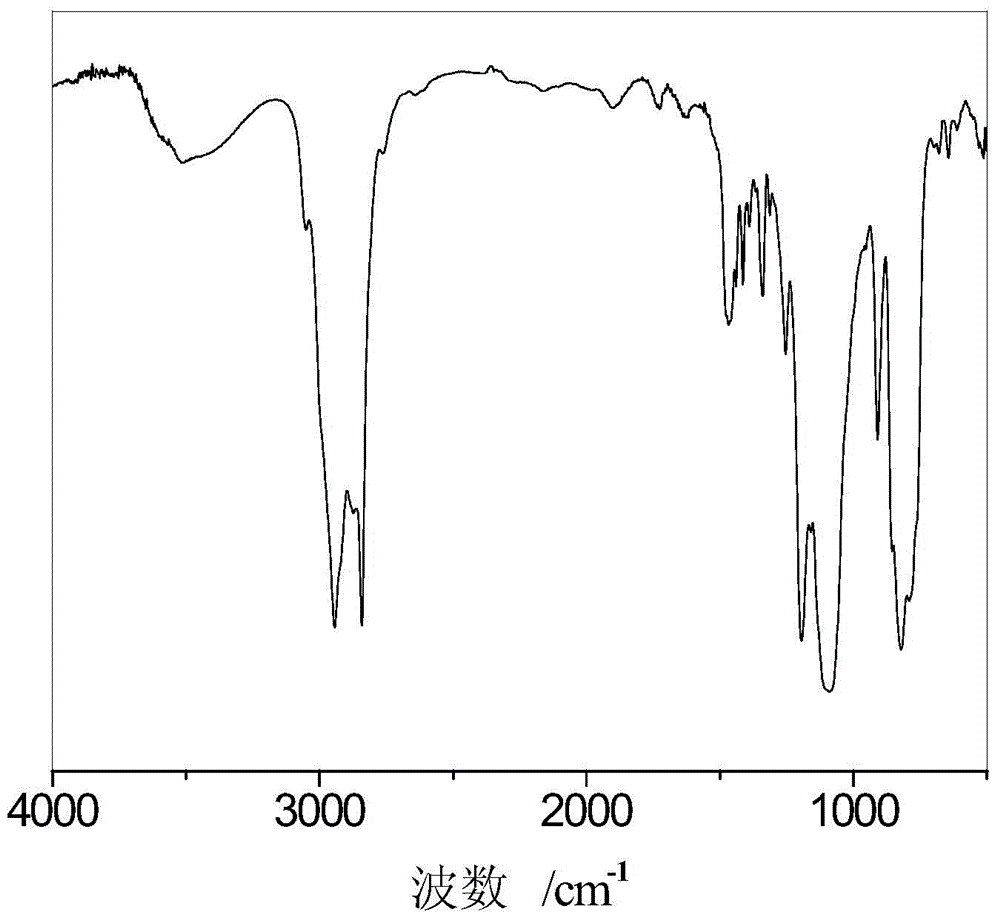

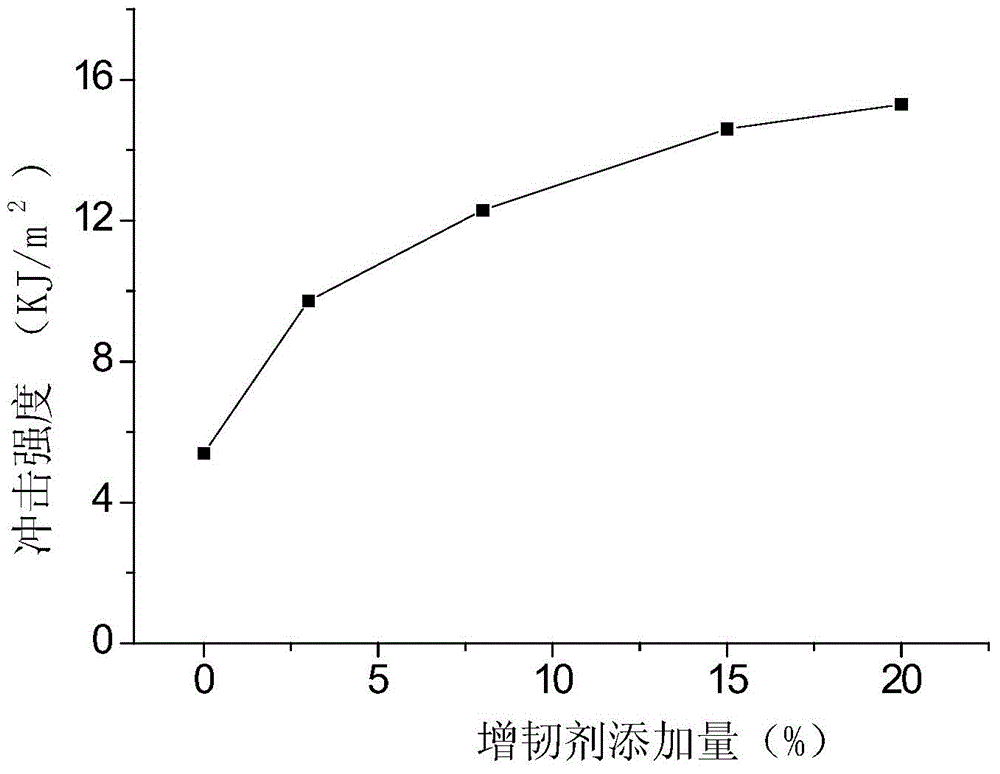

Epoxy functional group containing nano-reinforcer for hybrid polymer epoxy resin

The invention discloses an epoxy functional group containing nano-reinforcer for hybrid polymer epoxy resin. The preparation method of the epoxy functional group comprises the following steps: taking gamma-(2,3-epoxypropyoxy)propyltrimethoxysilane as a raw material, conducting condensation polymerization to prepare the raw material to hydroxyl octapolyhedral oligomeric silsesquioxane (POSS-OH), then transforming the substance to form a macroinitiator, taking methyl methacrylate and glycidyl methacrylate as monomers to conduct atom transfer radical polymerization (ATRP), under the control action of the ATRP polymerization to molecular weight, adjusting the ratio of an inorganic component to a high polymer component in the star hybrid polymer, so as to control the properties; synthesizing the nano-reinforcer containing the epoxy functional group for hybrid polymer epoxy resin, which regards the inorganic component POSS-OH as a core, and the copolymer chain segment as an arm. The polymer nano-reinforcer can be added to the powered epoxy resin to modify the resin; the impact strength of the modified and cross-linked epoxy resin is 1.8-2.9 times of that before modification, the glass transition temperature is increased by 21 DEG C, and the tensile strength is increased by 44%.

Owner:山东泰特尔新材料科技有限公司

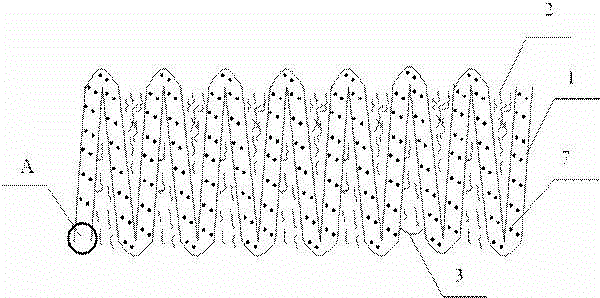

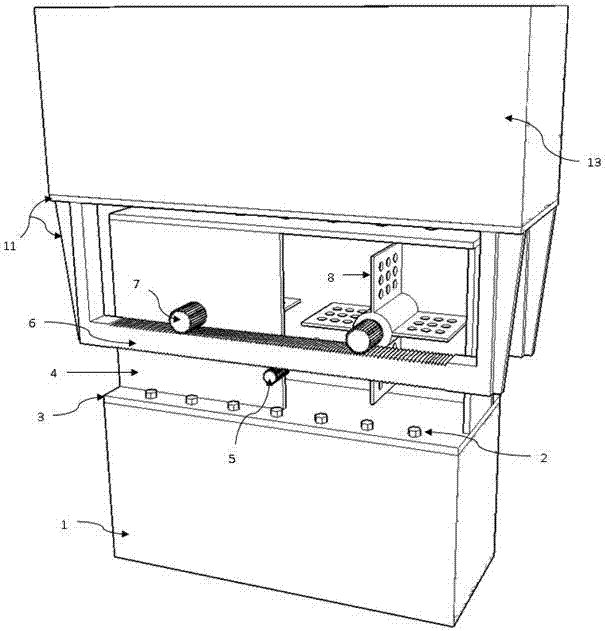

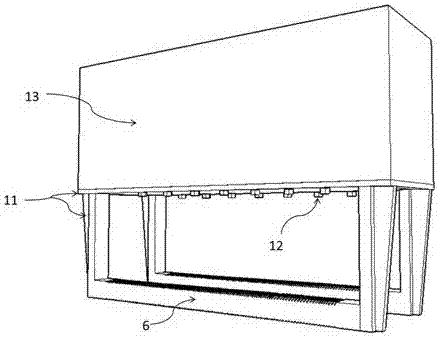

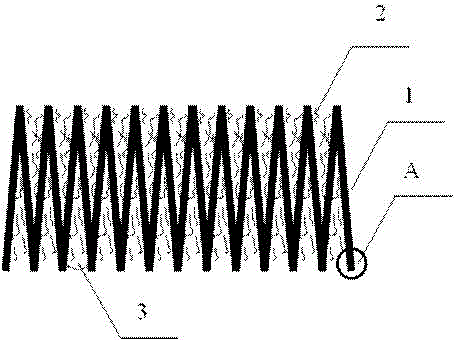

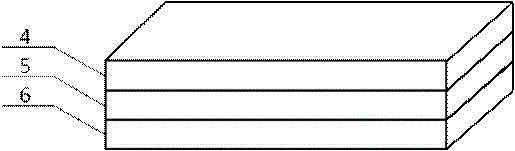

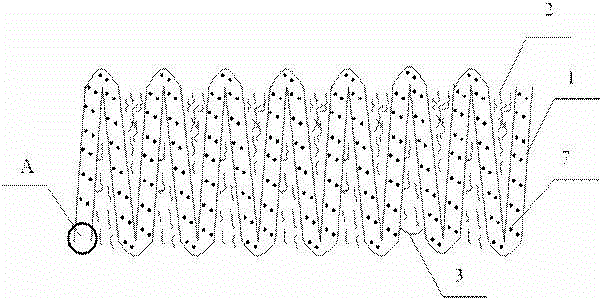

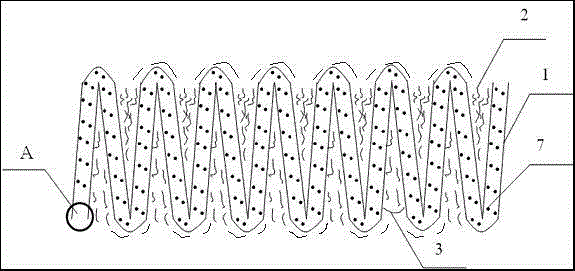

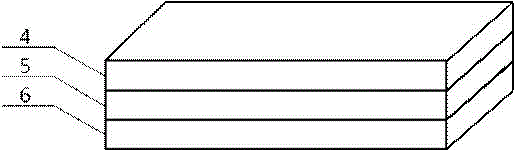

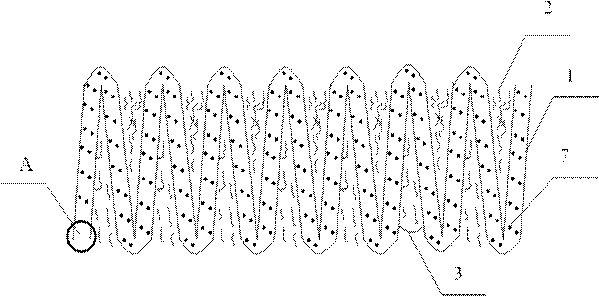

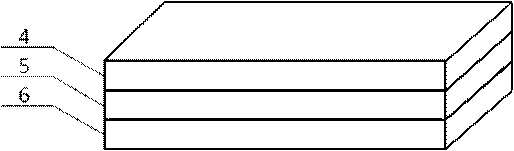

High-elastic flame-retardant non-woven cloth of honeycomb structure and preparation method thereof

The invention relates to a high-elastic flame-retardant non-woven cloth of a honeycomb structure. The high-elastic flame-retardant non-woven cloth of the honeycomb structure comprises a plurality of compound fiber webs which are stacked in a round-trip Z shape. The inner sides of the fiber webs are spread with mixed powders of hot-melting powders and flame-retardant powders. The compound fiber webs are connected from heads to ends in sequence. Hot-melting fibers are clamped between adjacent compound fiber webs. When the high-elastic flame-retardant non-woven cloth of honeycomb structure is manufactured, an upper layer fiber web, an elastic fiber web and a lower layer fiber web are prepared respectively through the processes of reparation before web forming and carding web by a machine. The hot-melting powders and flame-retardant powders are spread on the upper layer fiber web, the elastic fiber web and the lower layer fiber web. The upper layer fiber web, the elastic fiber web and the lower layer fiber web are overlapped into a compound fiber web. The upper layer fiber web and the lower layer fiber web are a mixture of low-melting-point dacron staple fibers and three-dimensional crimped hollow dacron staple fibers. The elastic fiber web is a mixture of low-melting-point dacron staple fibers and elastic polyester staple fiber. Vertical lapping is conducted through the process of vertical lapping, hot-melting fibers are spread between the compound fiber webs, and the high-elastic flame-retardant non-woven cloth of the honeycomb structure is manufactured through the processes of drying, trimming and winding.

Owner:WUHAN TEXTILE UNIV

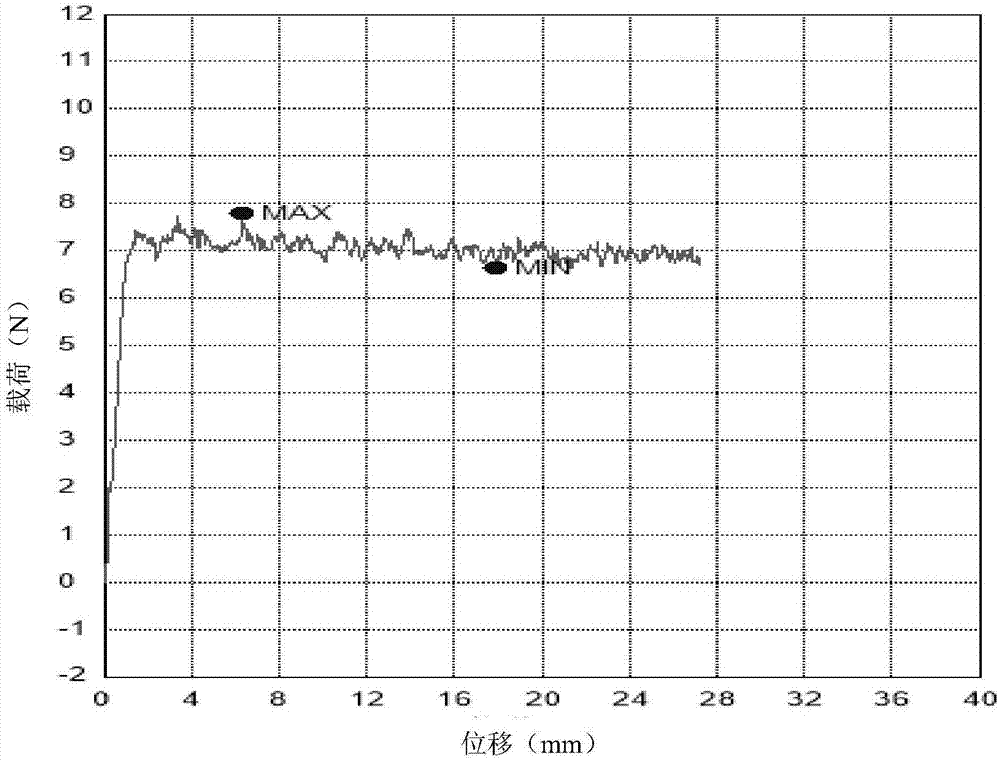

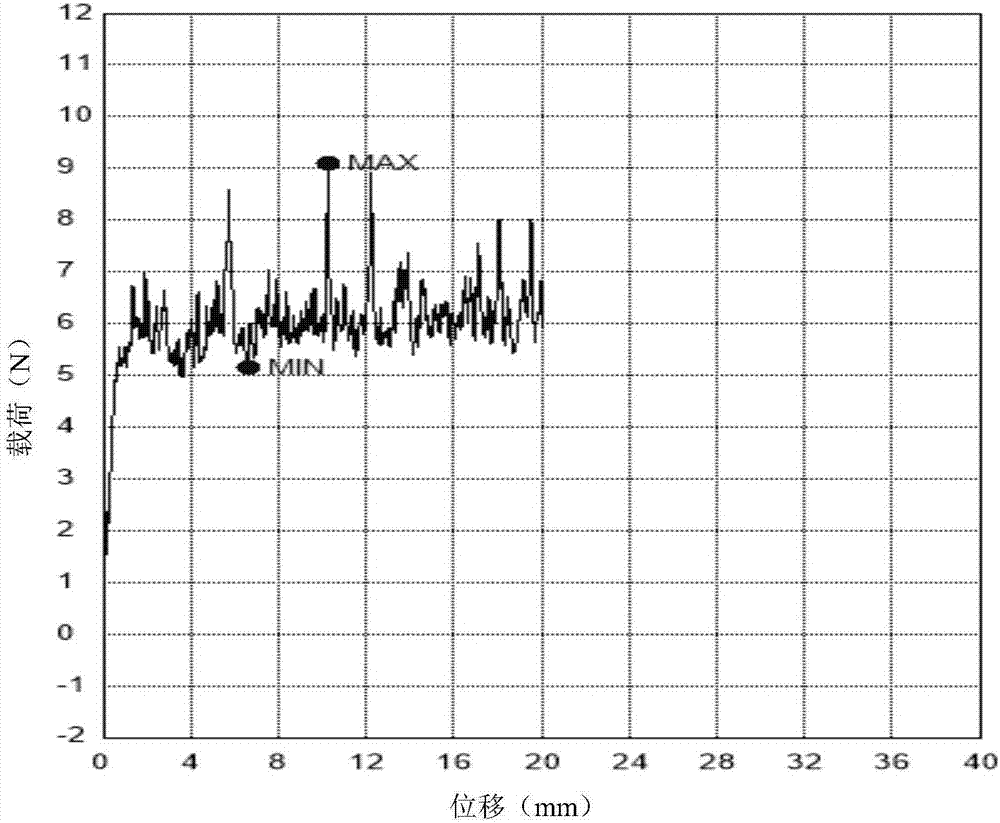

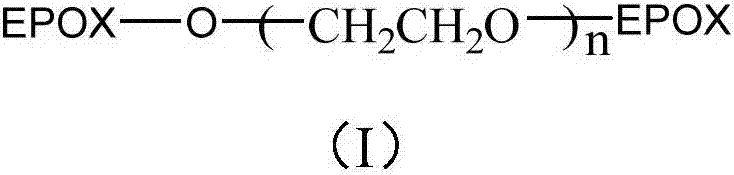

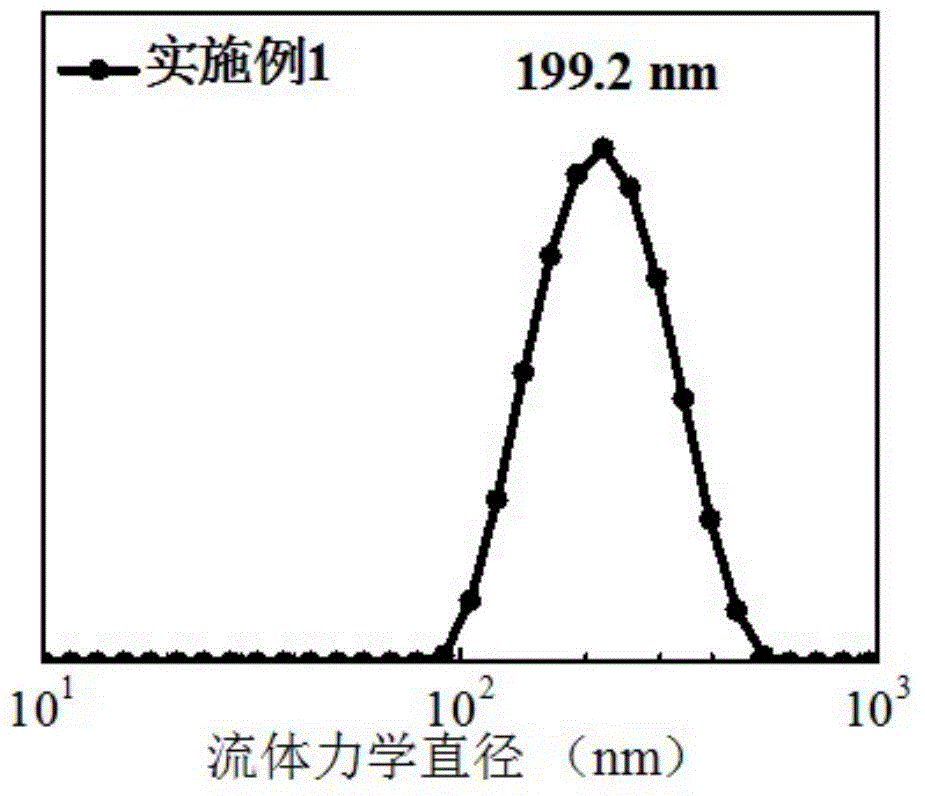

Multi-glycol epoxy derivative cross-linked sodium hyaluronate gel used for injection and preparation method thereof

ActiveCN107880282AGood flexibilityIncrease elasticityOrganic chemistryPharmaceutical delivery mechanismEpoxyCross-link

The invention discloses a multi-glycol epoxy derivative cross-linked sodium hyaluronate gel used for injection and a preparation method thereof. The multi-glycol epoxy derivative is preferably a compound with a single molecular weight, multiple ether bonds exist in the molecule, the compound is good in water solubility and can generate cross-linking reaction with polysaccharide more easily, and because the quantity of multi-glycol repeating units is easy to adjust and the length is relatively easy to control, the performance of sodium hyaluronate gel prepared as a cross-linking agent is relatively easy to regulate; and the cross-linked sodium hyaluronate gel is low in toxicity, less in residue, weak in extruding thrust, good in moulding property, good in enzyme resistance and long in retaining time in the body. The invention further discloses a mild cross-linking agent inactivation technology, unreacted epoxy group in the gel undergoes hydrolysis reaction in a carbonate buffer system with pH of 8-9, so as to effectively reduce the difficulty in impurity removal of cross-linked sodium hyaluronate gel and avoid the problem of toxicity of BDDE used in a cross-linking method of the prior art.

Owner:JENKEM TECH

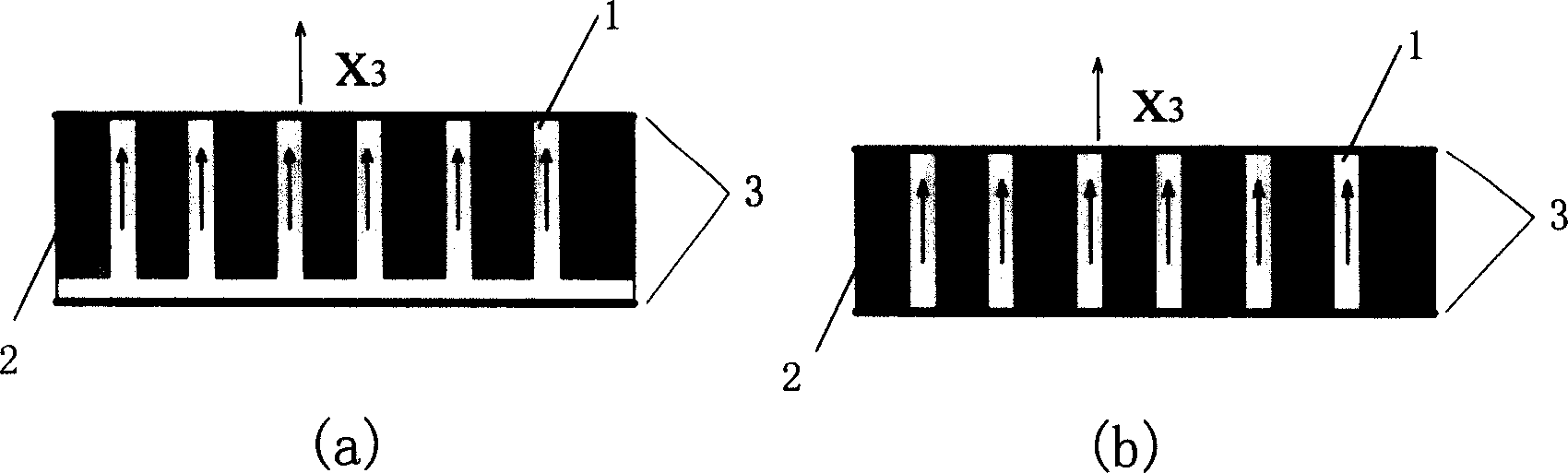

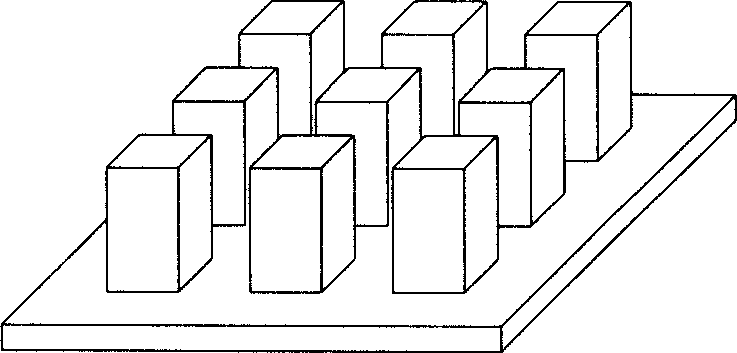

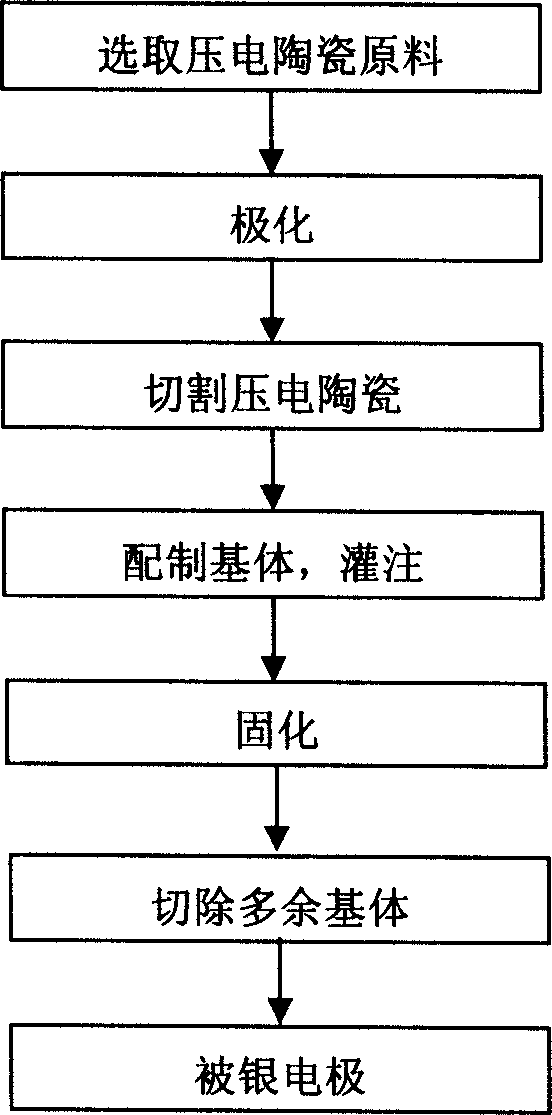

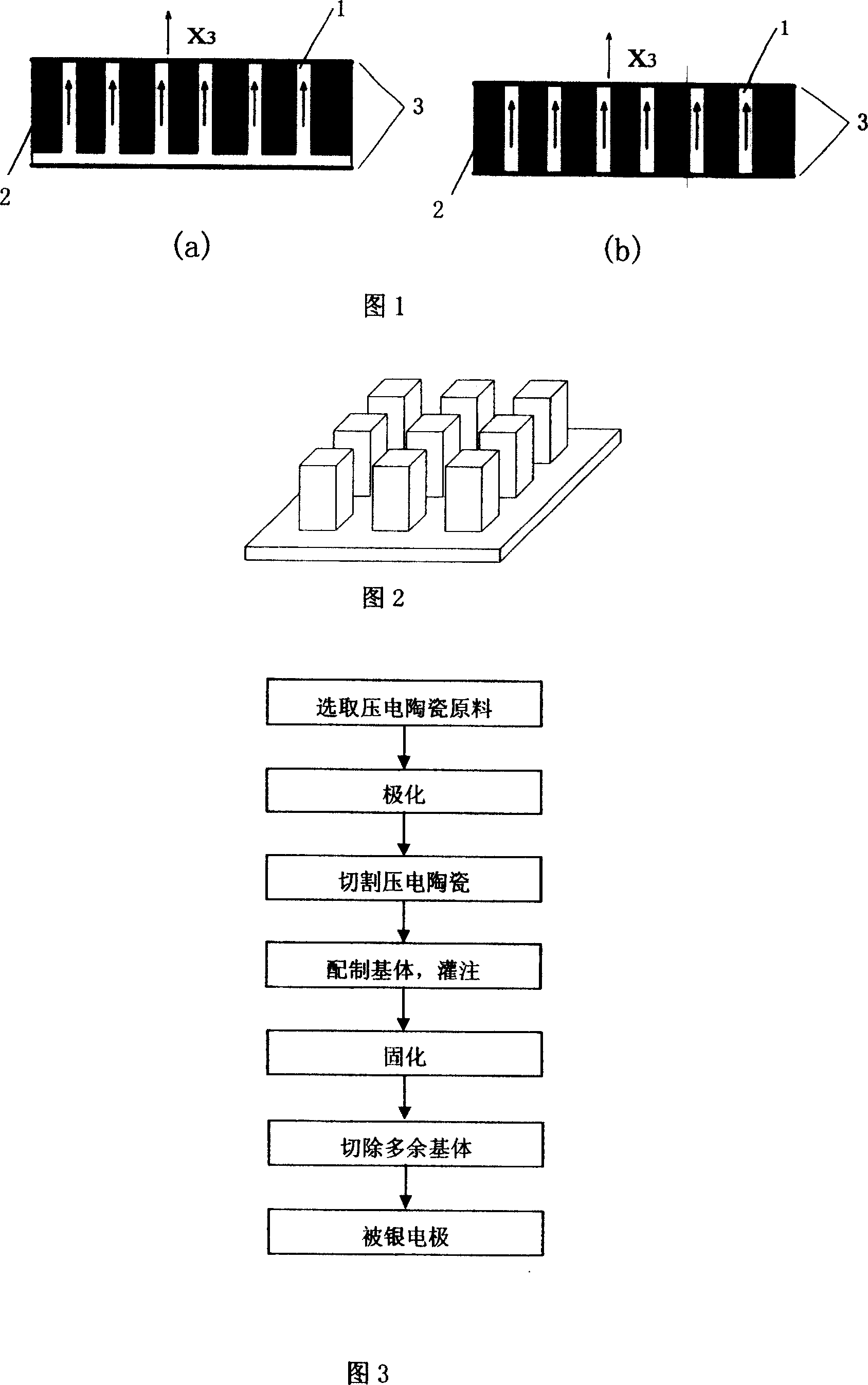

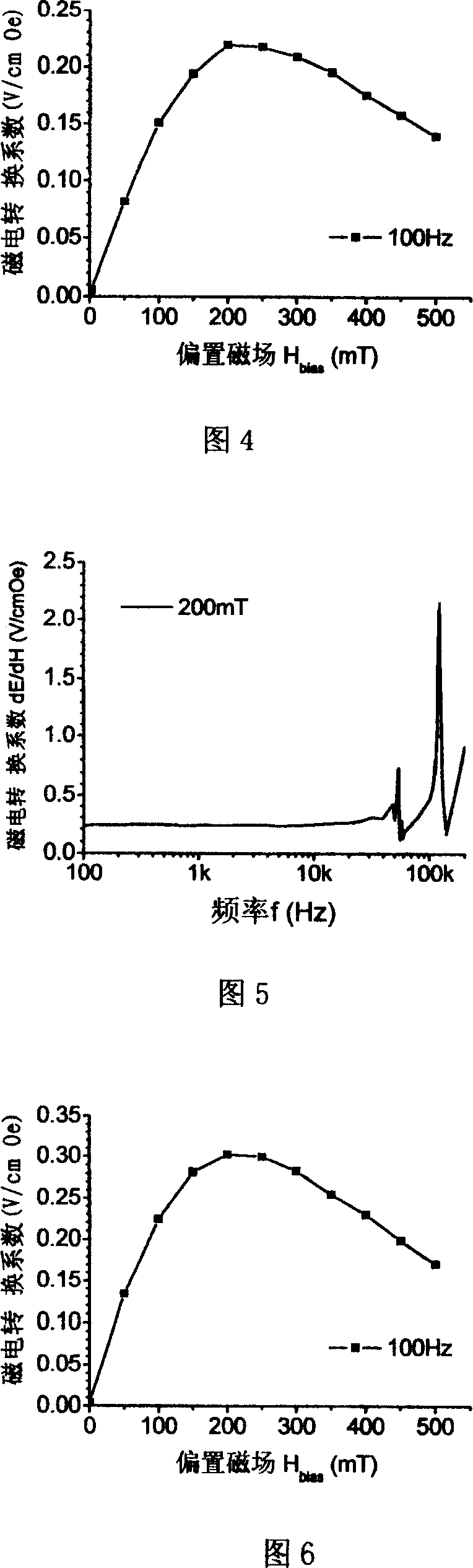

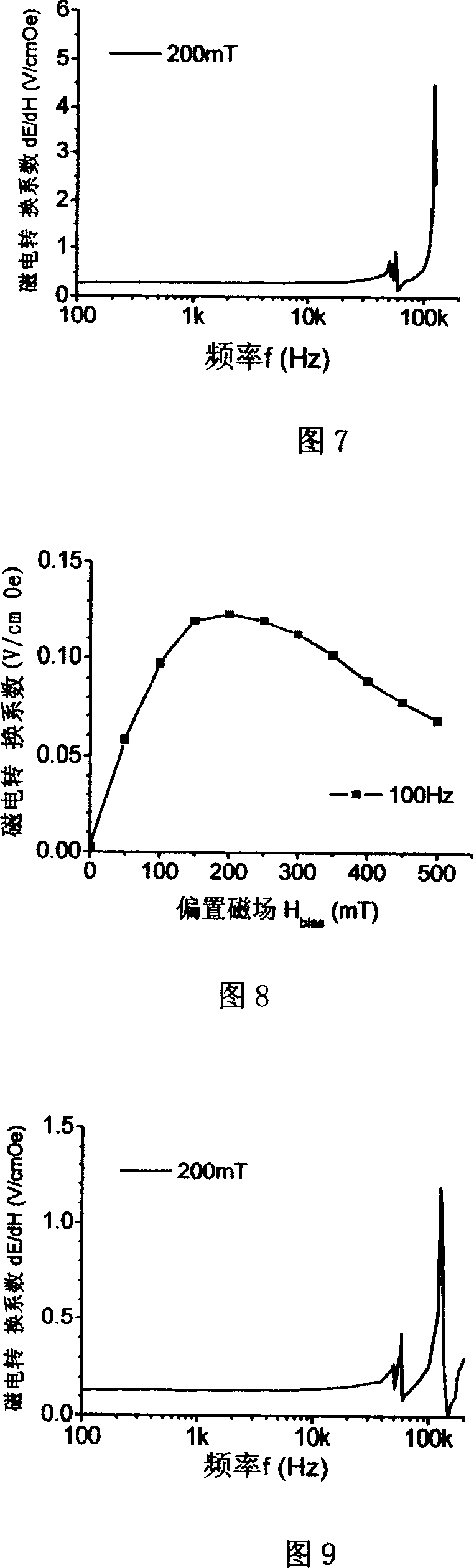

1-3 structure huge magnetoelectric material and preparing process thereof

InactiveCN1719635AImprove magnetoelectric propertiesEasy to makeDevice material selectionGalvano-magnetic material selectionElectricityConversion coefficients

This invention relates to a 1-3 structured huge magnet electric material and its preparation method. The material is composed of piezoelectric ceramics, magnetostriction materials and a high-molecular binding agent, among which, one of the dimension of the piezoelectric ceramics is greater than the other two shaped in a long column and distributed in a 3-D matrix composed of the magnetostriction materials powder and the high-molecular binding agent. This 1-3 structured material has high and stable magnetoelectric conversion coefficient, which can be regulated by altering contents of the piezoelectric ceramics.

Owner:TSINGHUA UNIV

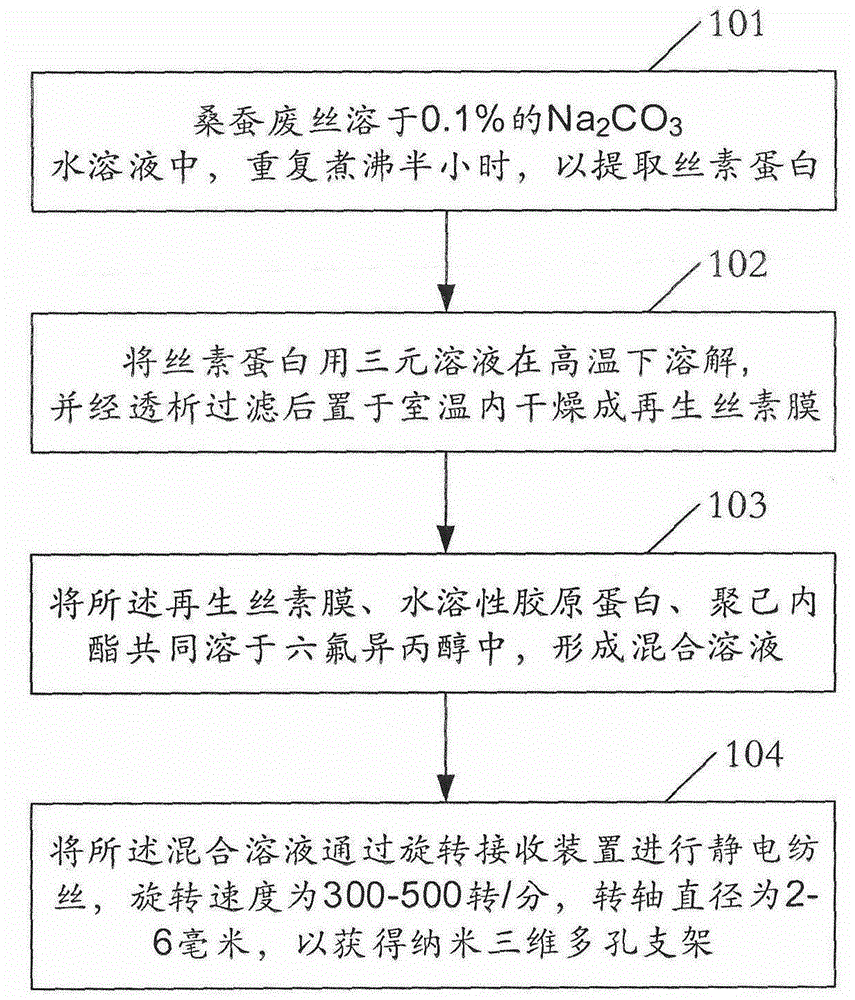

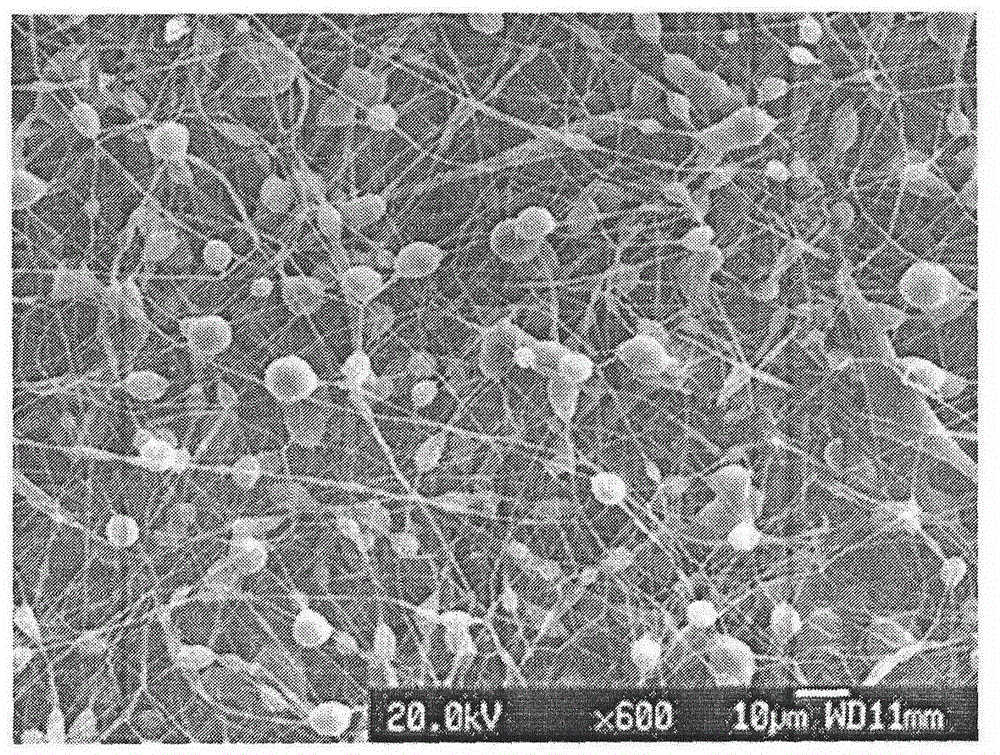

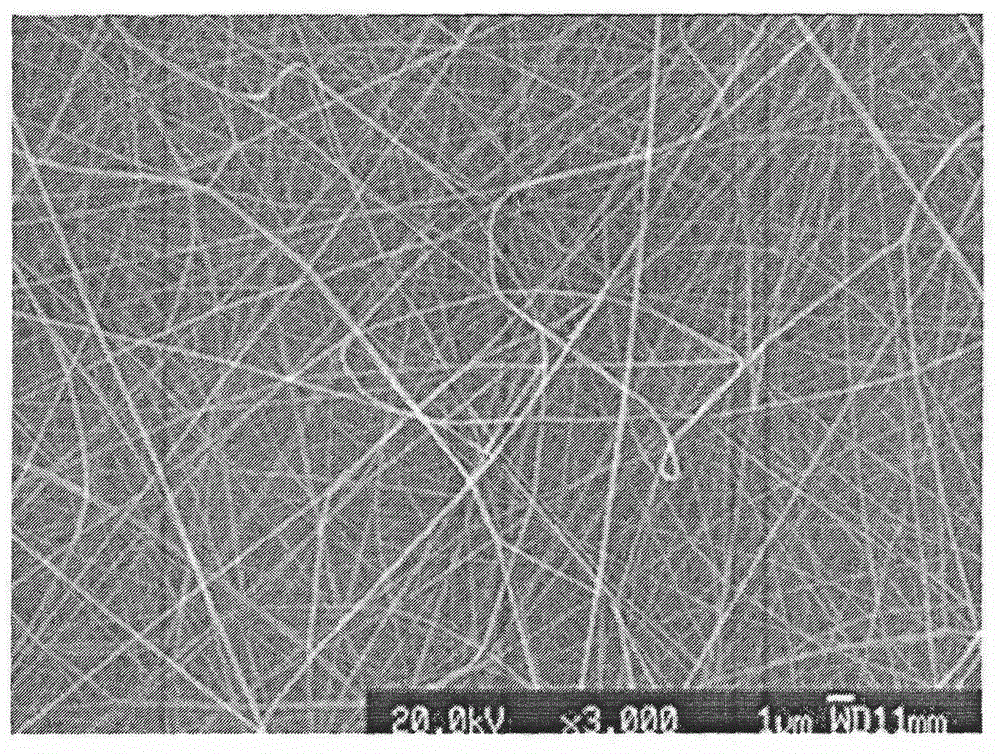

Polycaprolactone-collagen-fibroin nano three-dimensional porous stent and preparation method thereof

InactiveCN104874018AEasy to processEfficient manufacturing processFilament/thread formingConjugated cellulose/protein artificial filamentsUrethral stentsFresh Tissue

The invention relates to the field of the preparation of urethral stents, and discloses a polycaprolactone-collagen-fibroin nano three-dimensional porous stent and a preparation method thereof. The preparation method comprises the following steps of dissolving waste mulberry silk in a 0.1 percent of Na2CO3 aqueous solution, and repeatedly boiling for half an hour, so as to extract silk fibroin; dissolving the silk fibroin at a high temperature by using a ternary solution, dialyzing and filtering, and then putting at a room temperature for drying to form a regenerated silk fibroin membrane; dissolving the regenerated silk fibroin membrane, water-soluble collagen and polycaprolactone in hexafluoroisopropanol together, so as to form a mixed solution; carrying out electrostatic spinning on the mixed solution through a rotary receiving device, so as to obtain the nano three-dimensional porous stent, wherein a rotation speed is 300 to 500 revolutions per minute, and the diameter of a rotating shaft is 2 to 6 millimeters. The stent provided by the invention is convenient and efficient to process and manufacture, is convenient to apply, moreover, is convenient for adjusting various performances of a material, is stale in structure, and has certain mechanical strength to support the growth of a fresh tissue.

Owner:SHANGHAI TONGJI HOSPITAL

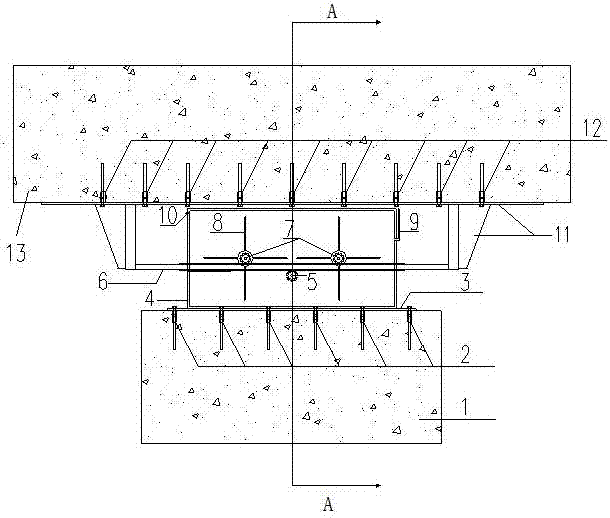

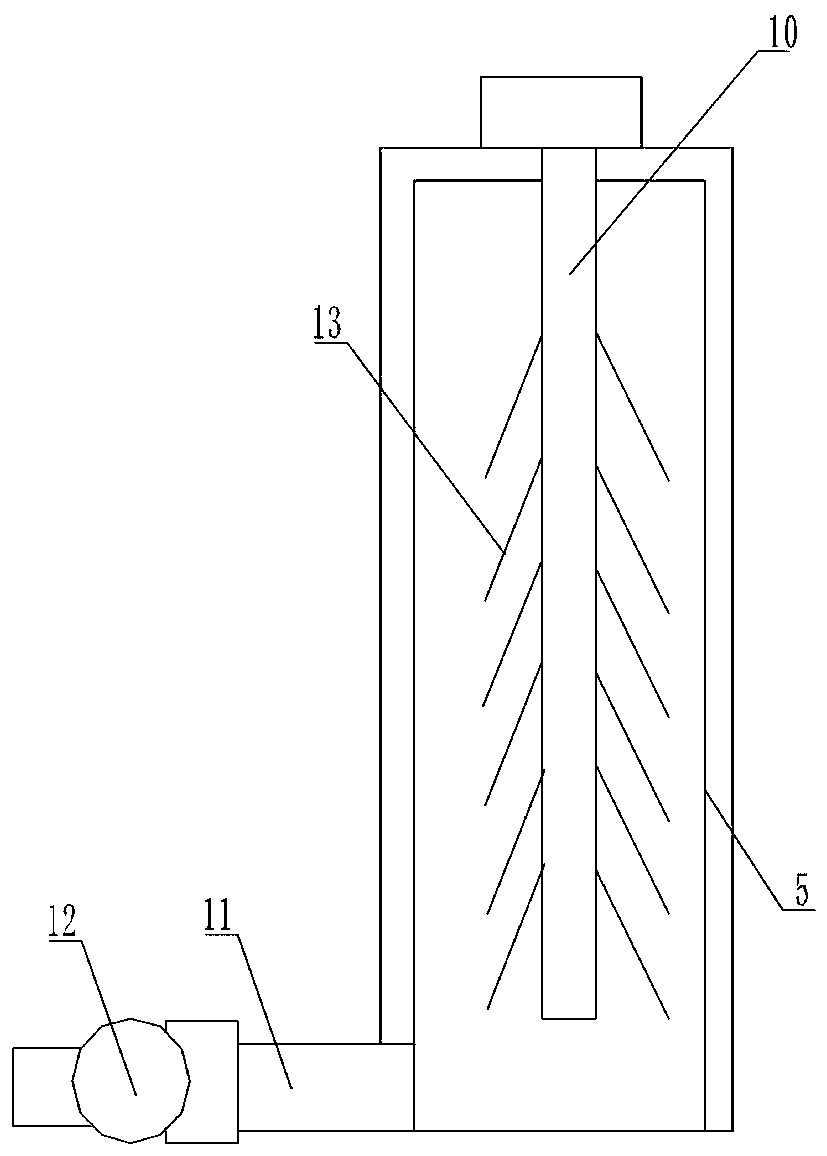

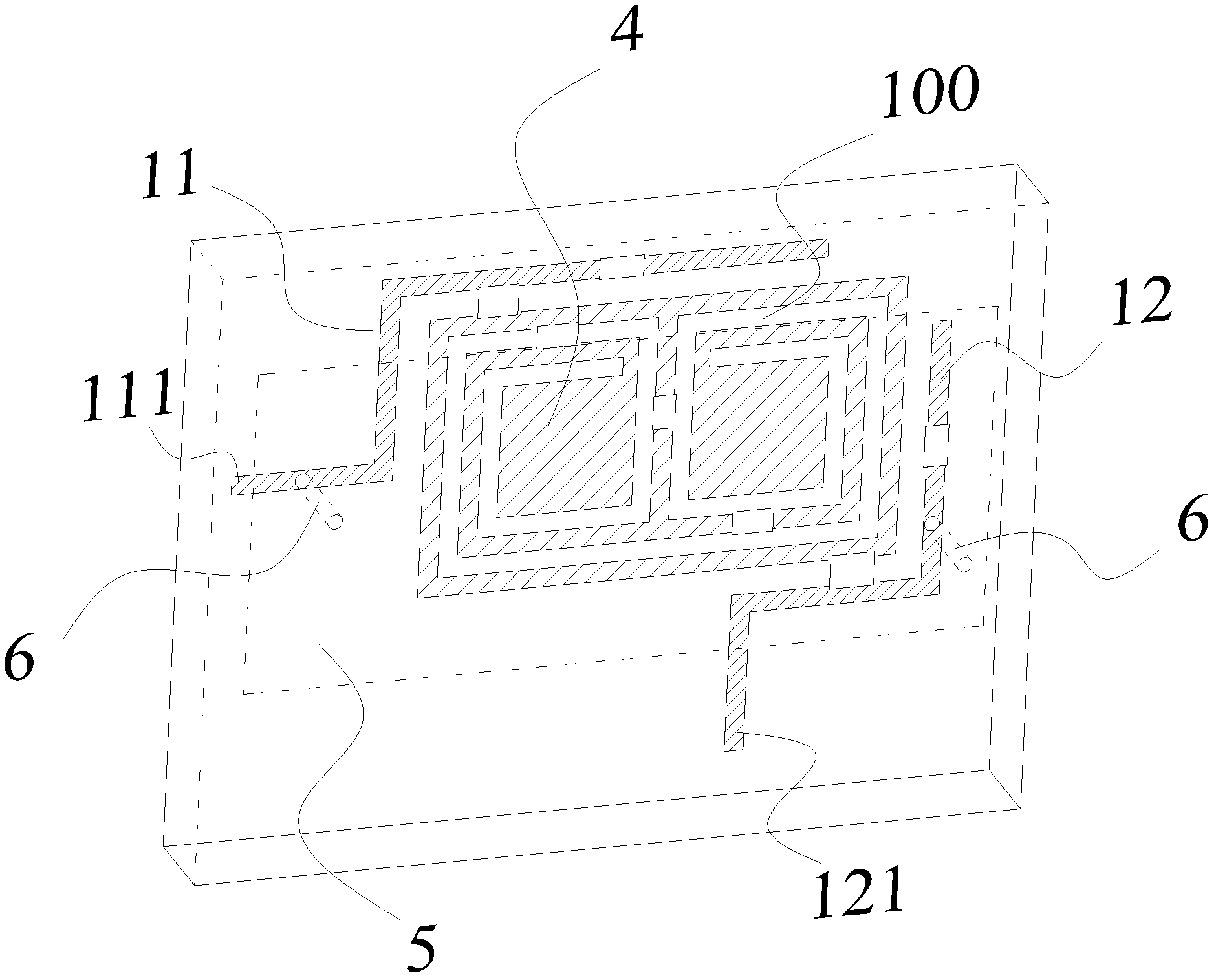

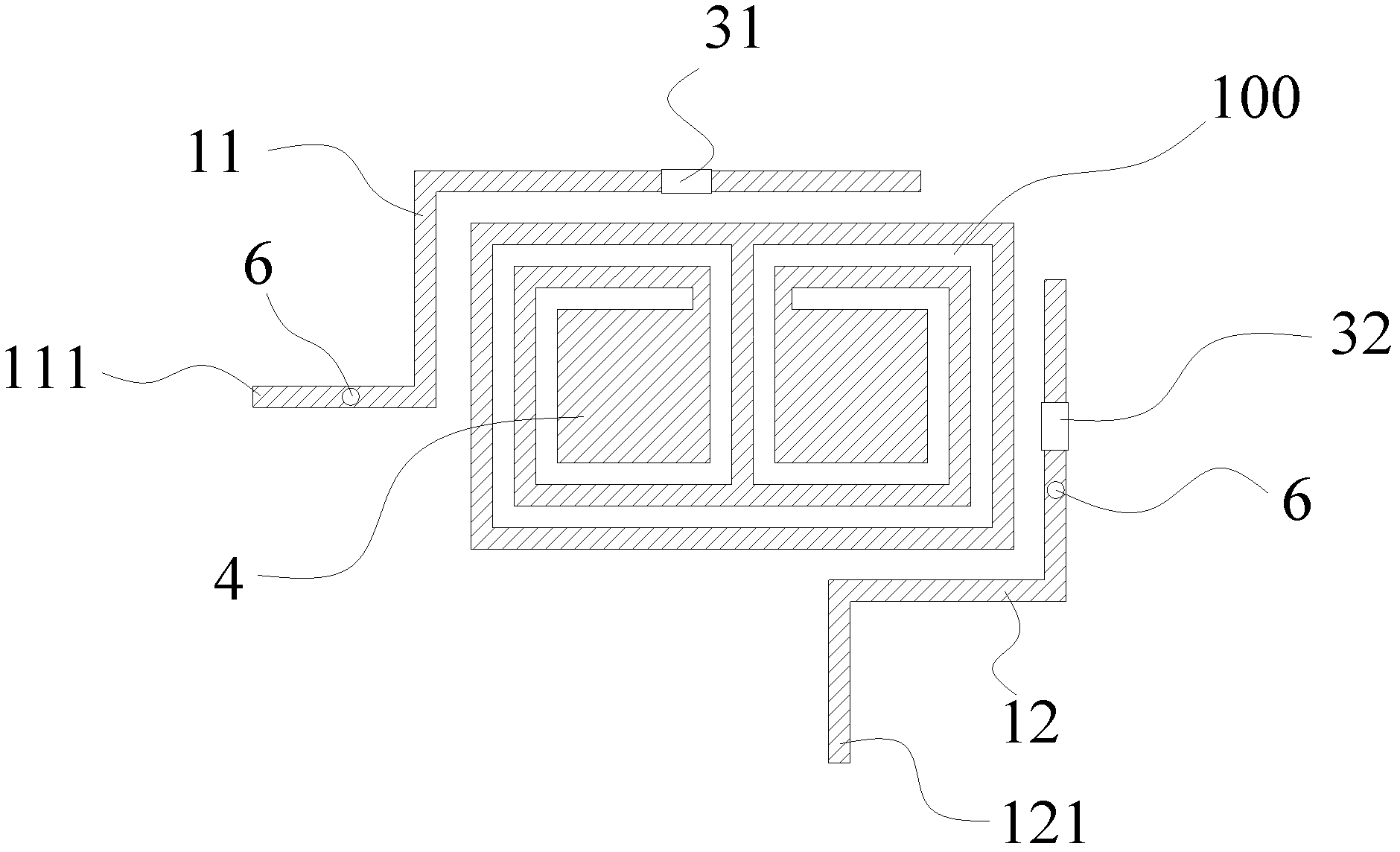

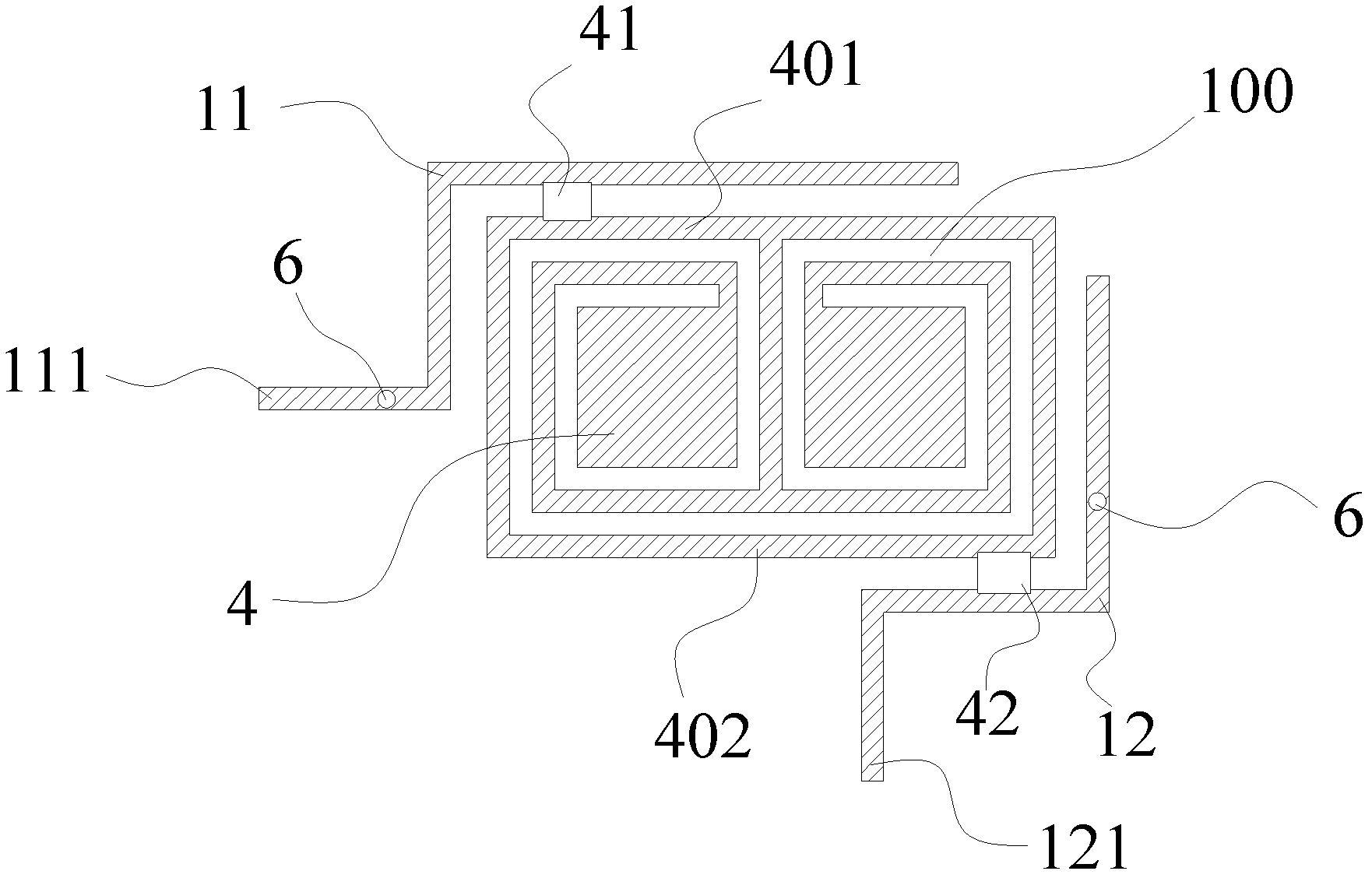

Gear double-spiral-type fluid viscous damper

ActiveCN107060127AStable performanceSimple structure design processProtective buildings/sheltersShock proofingGear transmissionSteel plates

The invention discloses a gear double-spiral-type fluid viscous damper. The bottom end of a lower connecting plate is connected with the top end of a lower concrete connecting wall through a lower telescope-feed connecting piece, the top end of the lower connecting plate of the damper is closely connected with the bottom end of a viscous liquid tank with a viscous liquid filler and a communicating vessel inspection window, wherein the viscous liquid tank is welded by steel plates and filled with viscous liquid, and a spiral gear shaft and a stable gear shaft are embedded into the viscous liquid tank; a plurality of energy-consuming blades perpendicular to the rotating direction are welded on the spiral gear shaft, and the top end of a double-faced gear transmission rod is in close contact with the spiral gear shaft through a gear; and the bottom end of the double-faced gear transmission rod is in close contact with the stable gear shaft through a gear, and the double-faced gear transmission rod is connected with an upper concrete connecting wall through an upper connecting piece by adopting an upper telescope-feed connecting piece. According to the gear double-spiral-type fluid viscous damper, the energy-consuming capacity does not depend on structural relative deformation, the performance is stable and efficient, and the gear double-spiral-type fluid viscous damper can be widely used in anti-seismic and wind resistant design of multiple and high-storey buildings.

Owner:KUNMING UNIV OF SCI & TECH

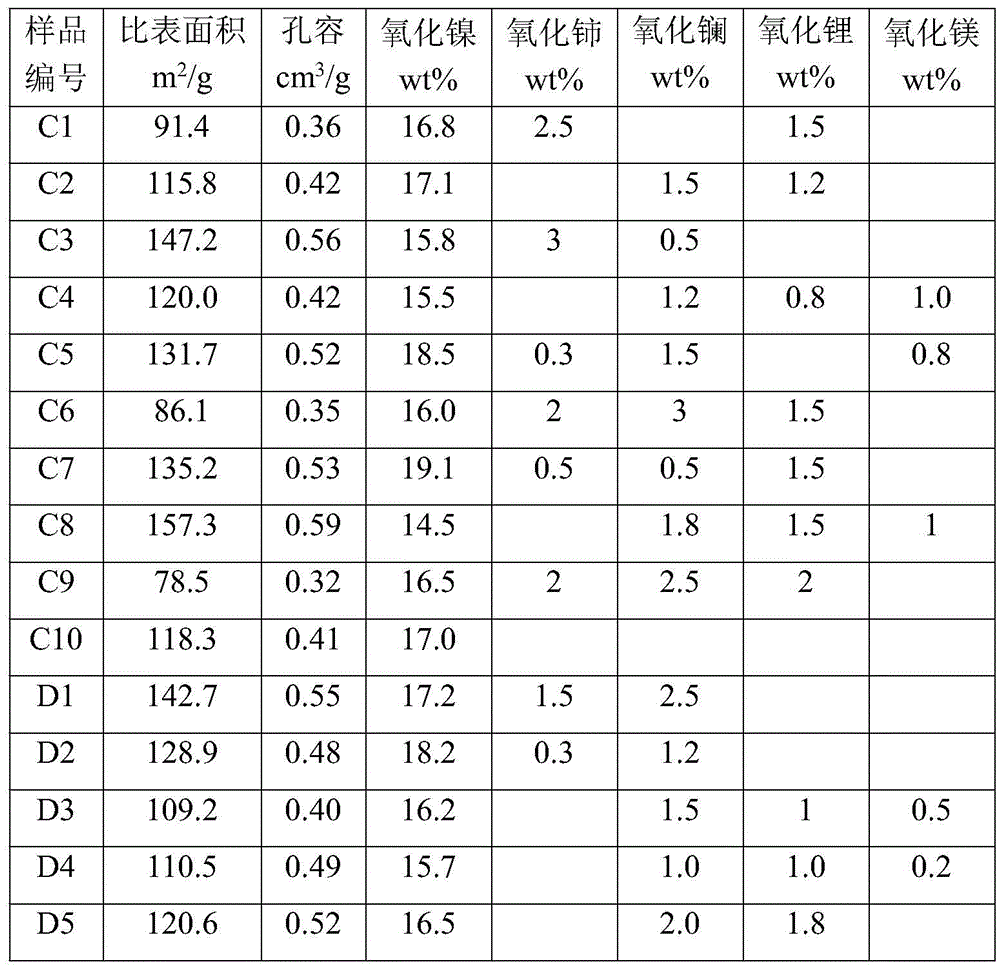

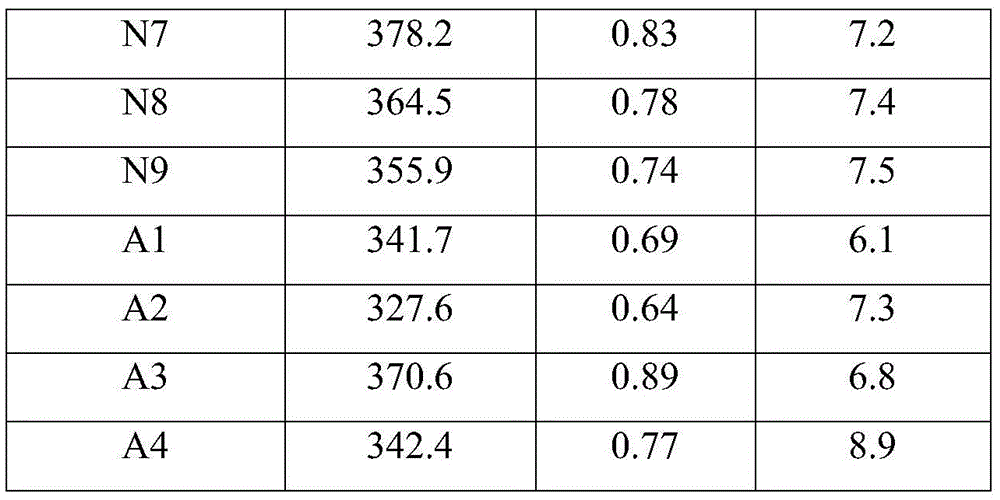

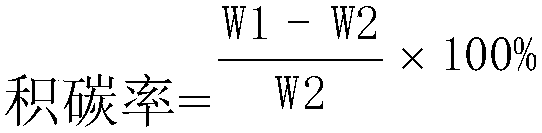

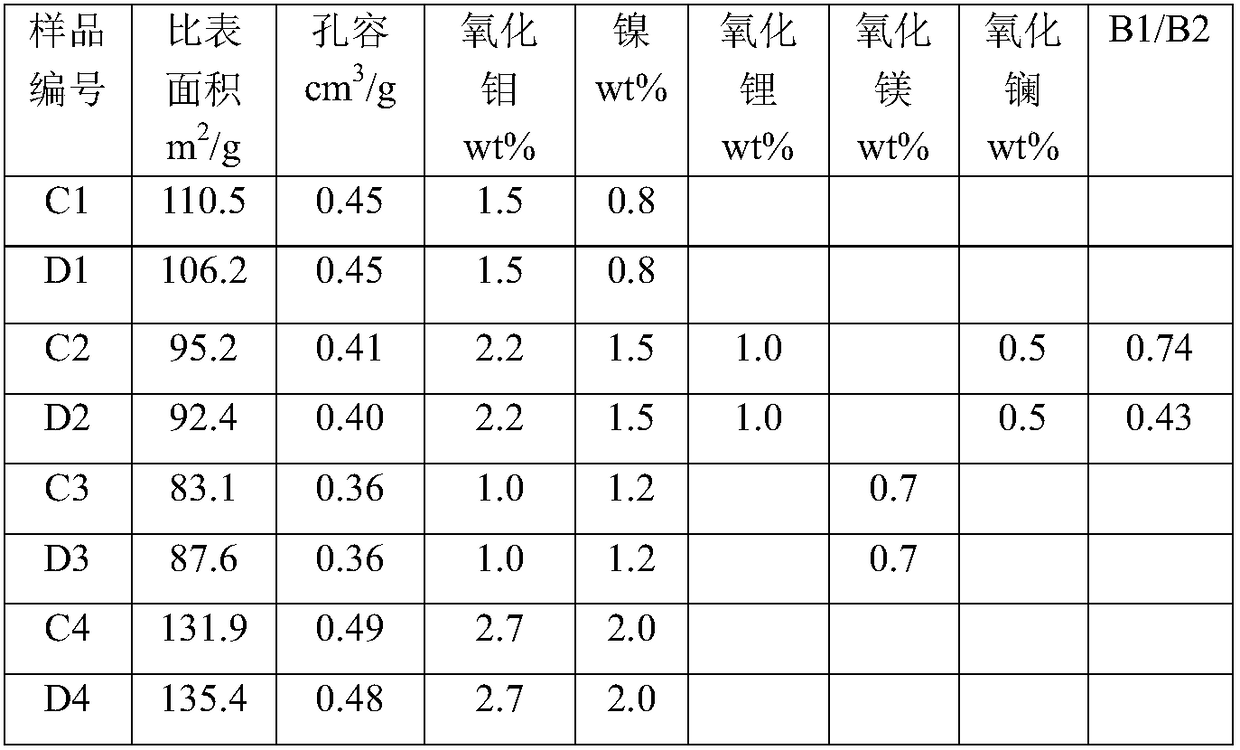

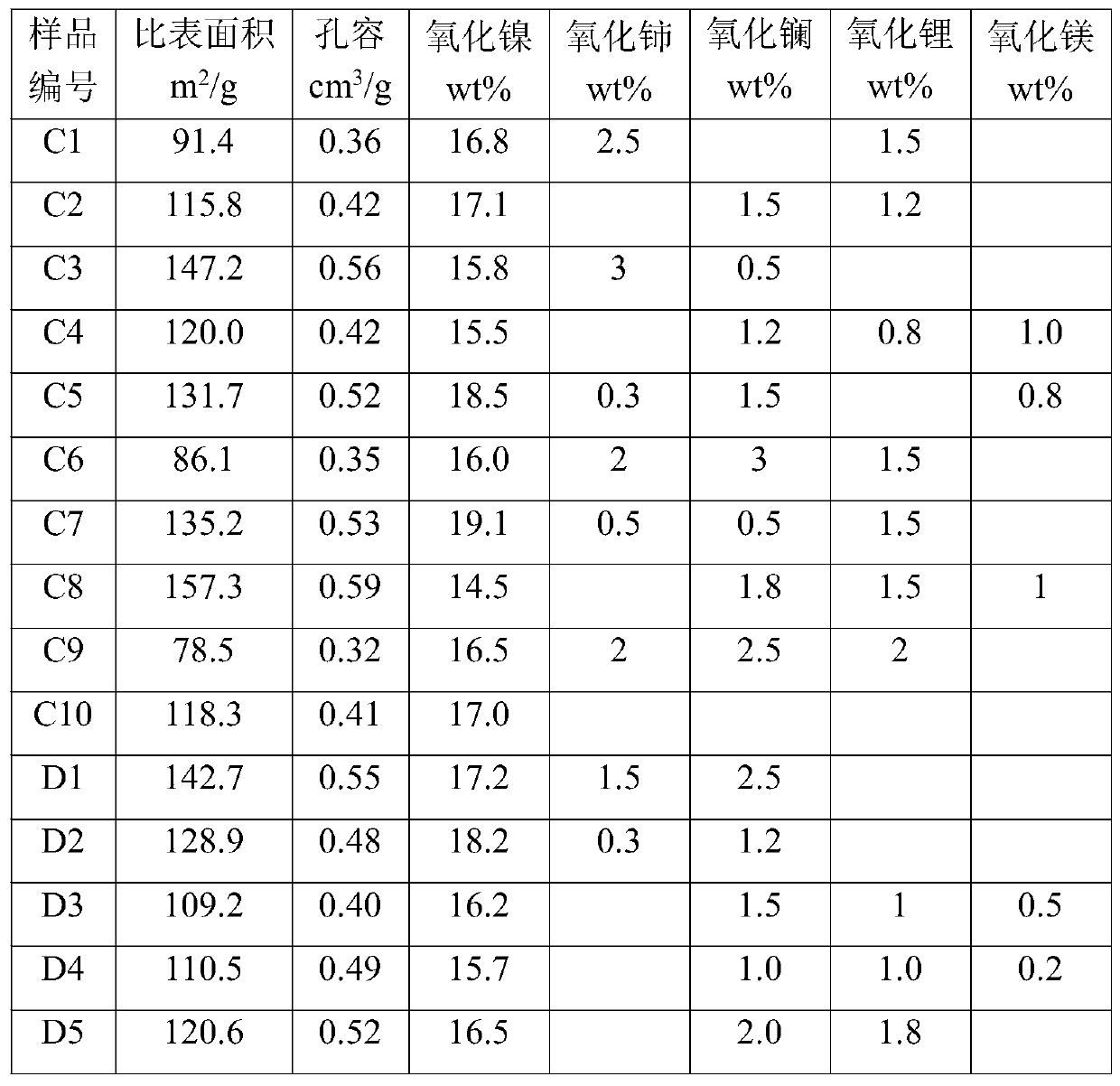

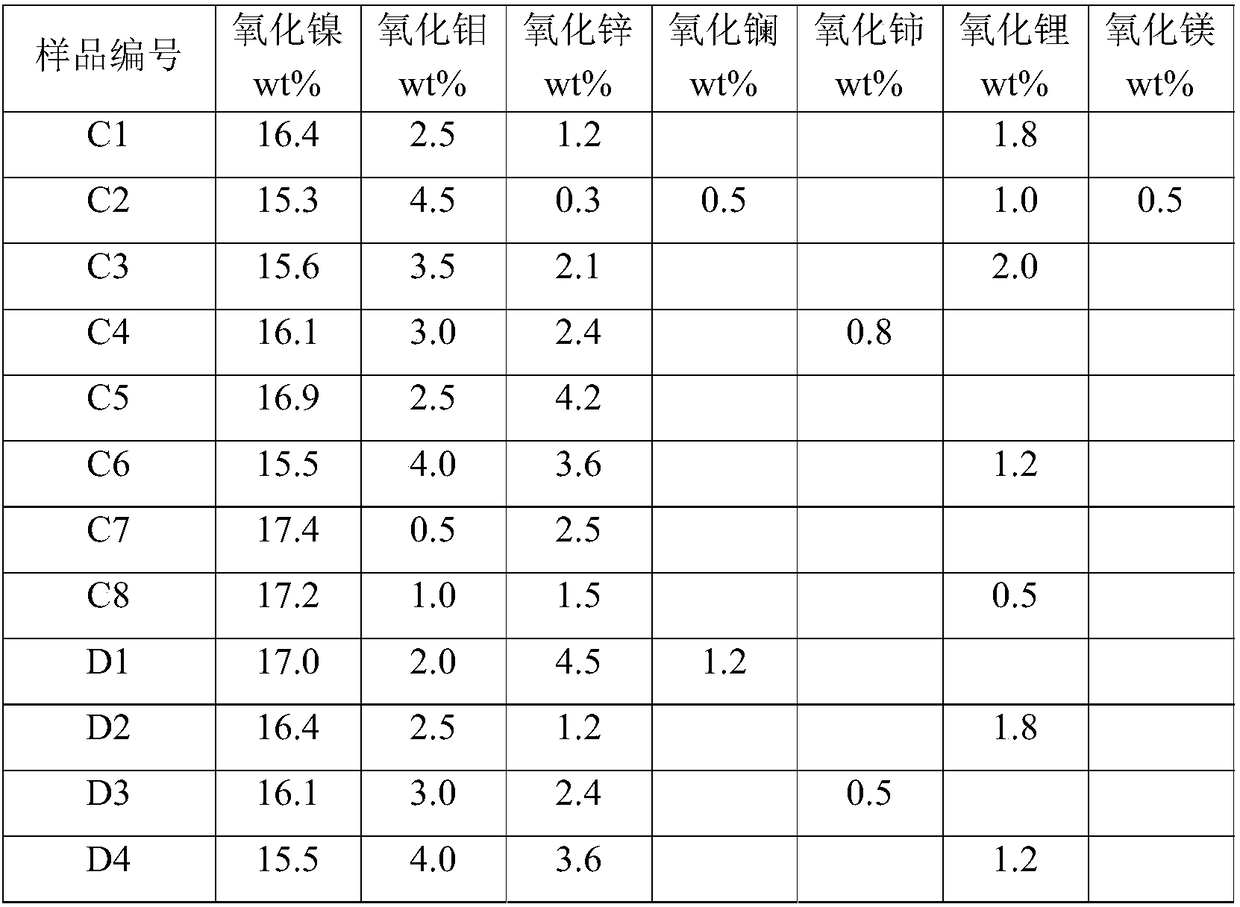

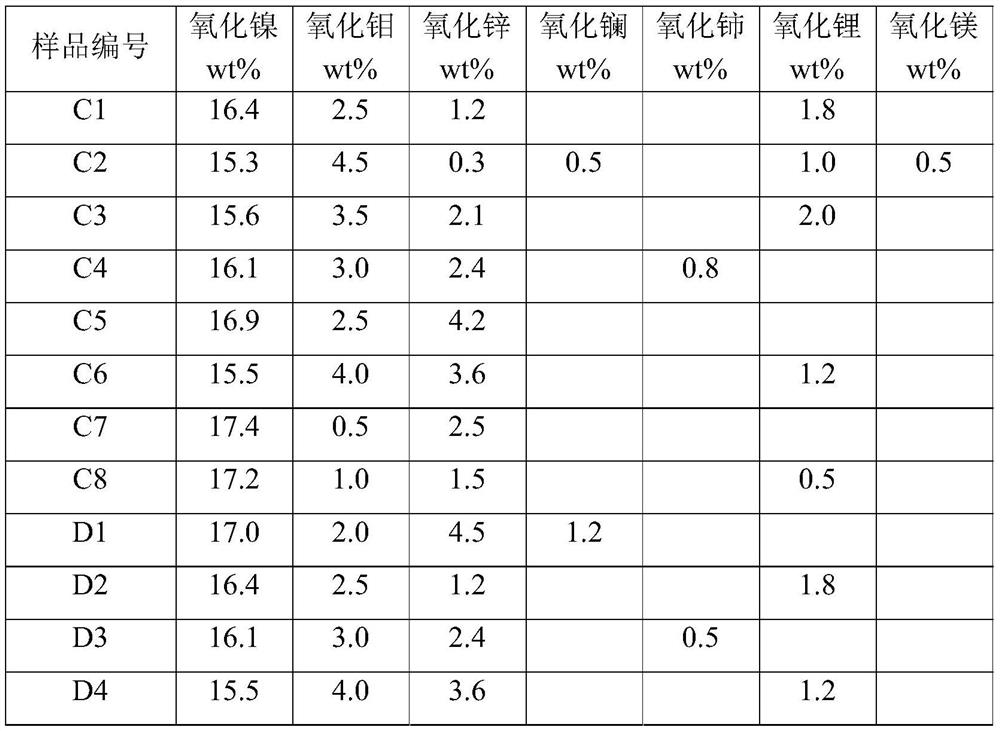

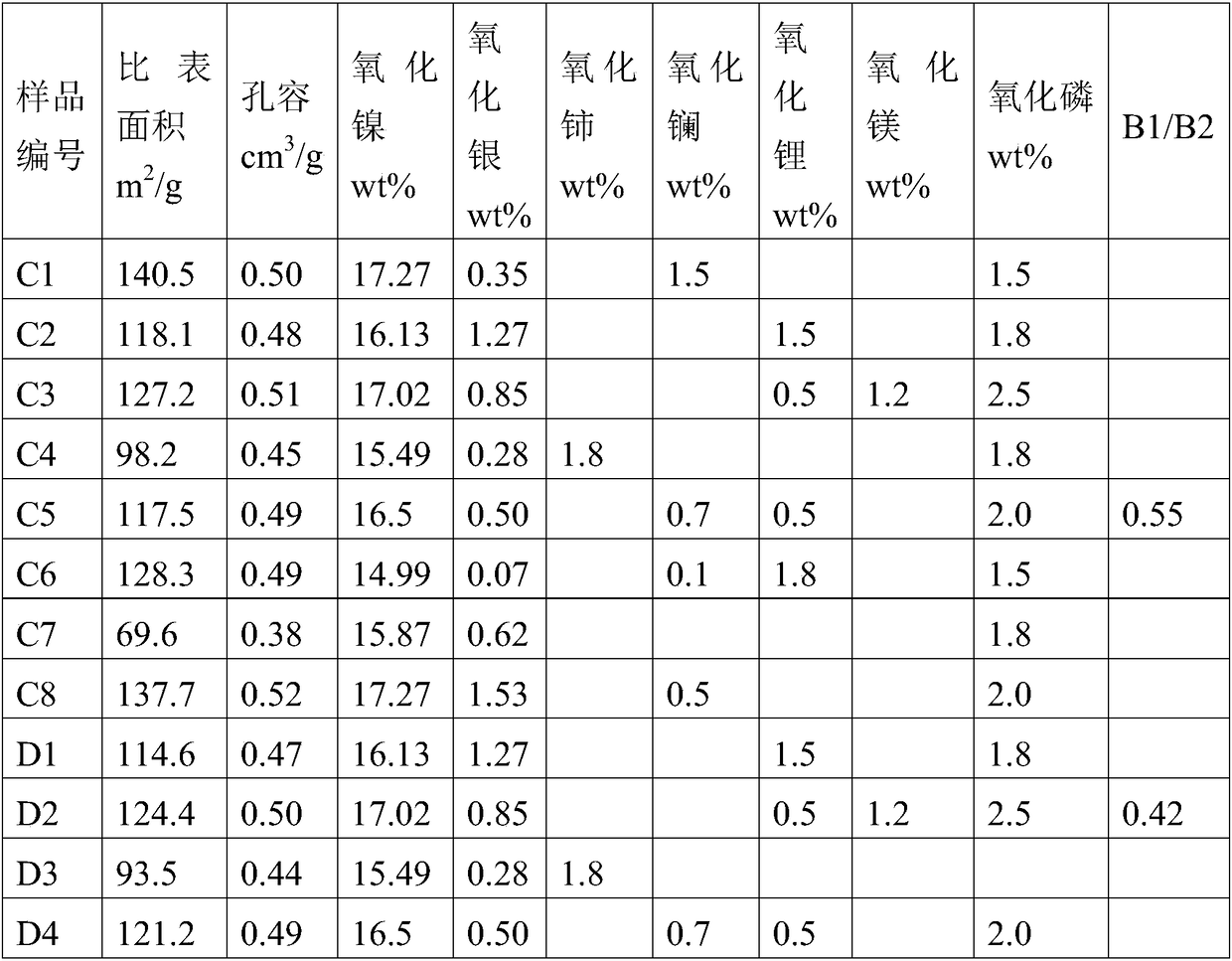

Nickel-based hydrogenation catalyst and preparation method thereof

ActiveCN106732620AGood chemical stabilityImprove thermal stabilityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActive componentThermal stability

The invention provides a nickel-based hydrogenation catalyst and a preparation method of the nickel-based hydrogenation catalyst. A nickel-containing alumina carrier is impregnated with a nickel-containing solution, dried and calcined to obtain a catalyst; the nickel-containing alumina carrier is obtained by forming and calcining nickel-containing pseudo-boehmite, wherein the preparation process of the nickel-containing pseudo-boehmite comprises an acid-alkali neutralization process and a gel forming process. According to the invention, nickel and the pseudo-boehmite are organically combined, so that the nickel taken as an active component is effectively dispersed in the pseudo-boehmite, and the nickel-containing alumina carrier in a specific crystal form is formed, furthermore, the pore structure and acidity of the carrier are better adjusted. The finally prepared catalyst has higher hydrogenation activity and selectivity, and good chemical stability and thermal stability.

Owner:PETROCHINA CO LTD

High-elastic non-woven fabric with honeycomb structure and preparation method thereof

A high-elastic non-woven fabric with a honeycomb structure comprises a plurality of compound fiber meshes sequentially stacked in a back-and-forth Z shape. The compound fiber meshes are sequentially in end-to-end connection, and a hot melting fiber is clamped between the adjacent compound fiber meshes. When the high-elastic non-woven fabric is manufactured, through preparation prior to mesh formation and a process of mesh formation through mechanical combing, an upper layer fiber mesh, an elastic fiber mesh and a lower layer fiber mesh are prepared respectively and then are overlaid into the compound fiber mesh through a fiber mesh compounding process; each of the upper layer fiber mesh and the lower layer fiber mesh is the mixture of a low melting point polyester short fiber and a three-dimensional curly hollow polyester short fiber, and the elastic fiber mesh is the mixture of a low melting point polyester short fiber and an elastic polyester short fiber. The prepared compound fiber meshes are vertically laid through a vertical mesh laying process, the hot melting fiber is scattered between the compound fiber meshes, and then the high-elastic non-woven fabric with the honeycomb structure is obtained through a drying, trimming and winding process. The high-elastic non-woven fabric not only is high in elasticity and simple in structure, but also is low in cost and environmentally friendly.

Owner:WUHAN TEXTILE UNIV

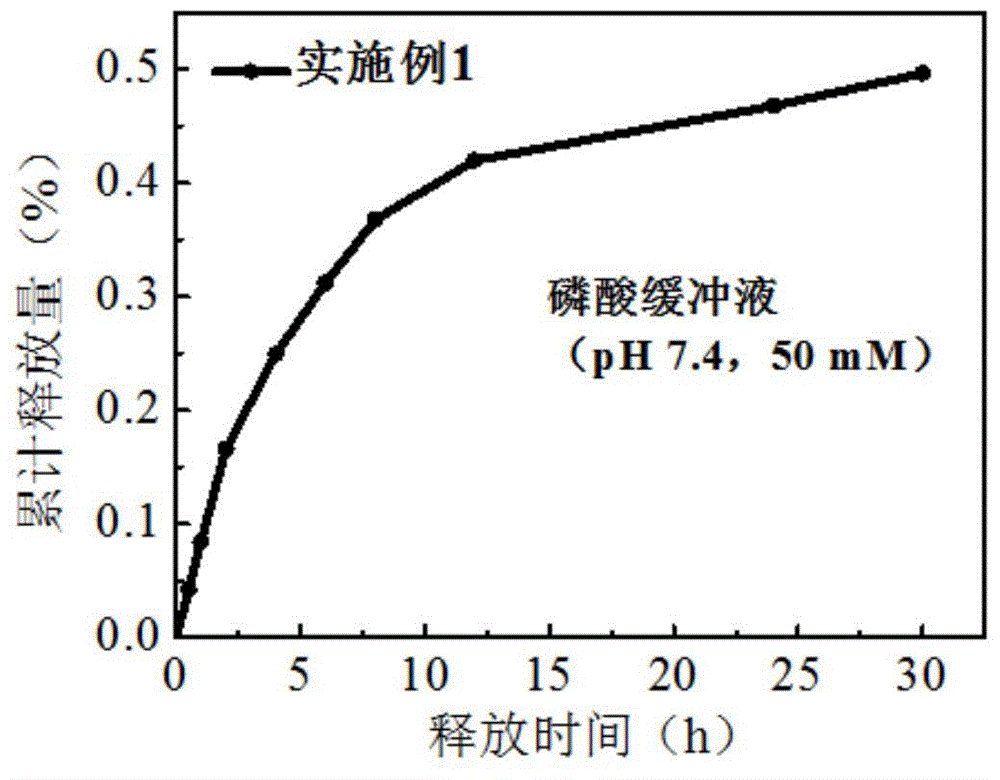

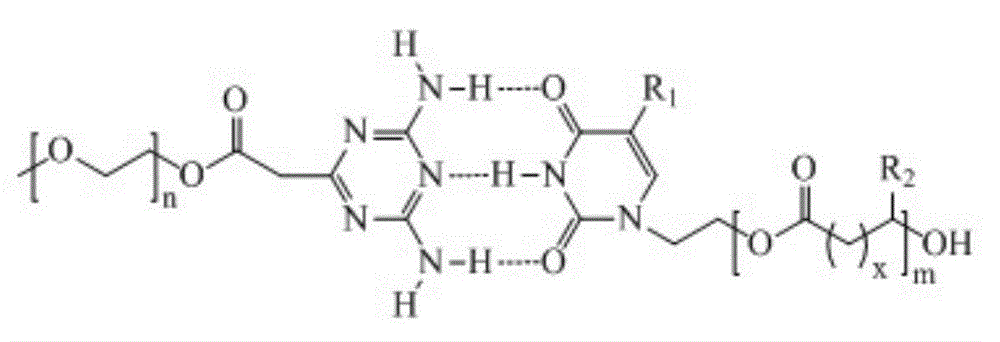

Preparation method of biodegradable supermolecule segmented copolymer and copolymer micelle

InactiveCN104945630AStrong triple hydrogen bondImprove stabilityPharmaceutical non-active ingredientsEmulsion deliveryTritiumUracil formation

The invention relates to the field of wrapping and target releasing of hydrophobic drugs and aims at providing a preparation method of a biodegradable supermolecule segmented copolymer and a copolymer micelle. The biodegradable supermolecule segmented copolymer is composed of a component A and a component B, wherein the component A is single-ended diamino-triazine functionalized polyglycol with the molecular weight of 1-10kDa; the component B is single-ended thymine or uracil polylactone with the molecular weight of 0.7-8kDa; and inserted segments of the component A and the component B are connected by virtue of a tritium bond between diamino-triazine and thymine or a uracil group. The prepared supermolecule segmented copolymer has high stability, is sensitive to external environment such as temperature, saline ions and pH value, adjustable in structure and performance and hopeful to being used in the field of controlled release. The preparation method of the biodegradable supermolecule segmented copolymer has good generality, can be used for preparing pyrimidine-end-functionalized polylactone and also can be used for preparing pyrimidine-end-functionalized polycyclic carbonate.

Owner:ZHEJIANG UNIV

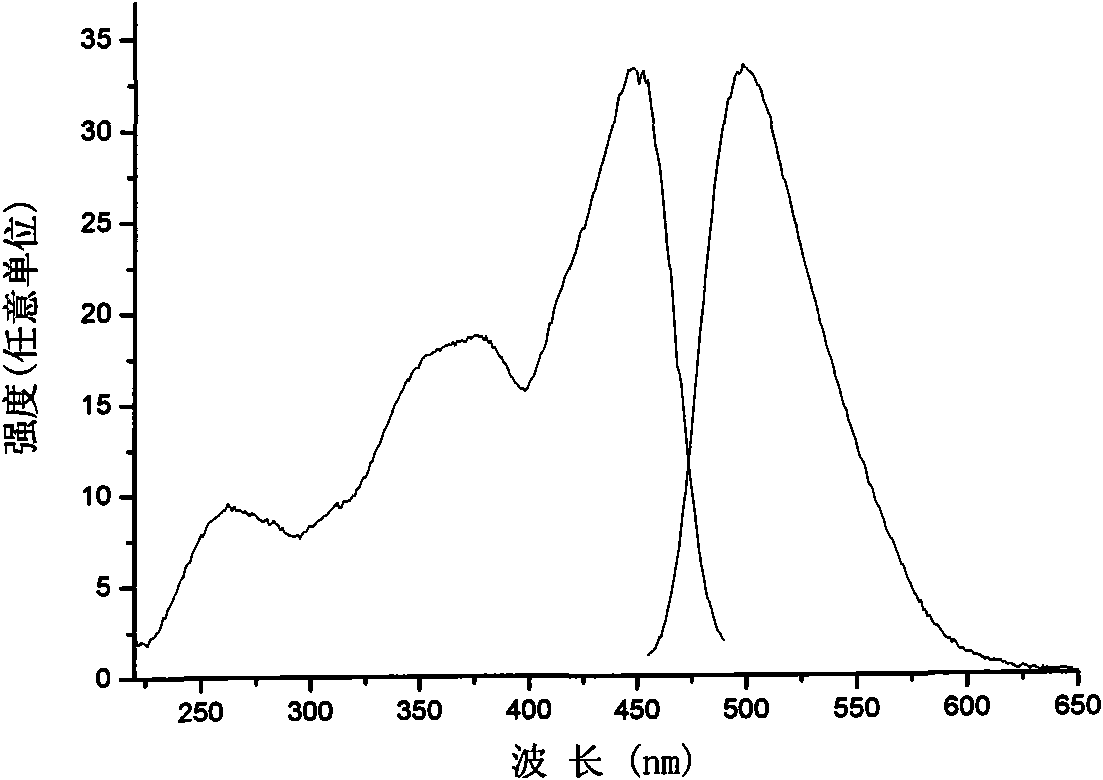

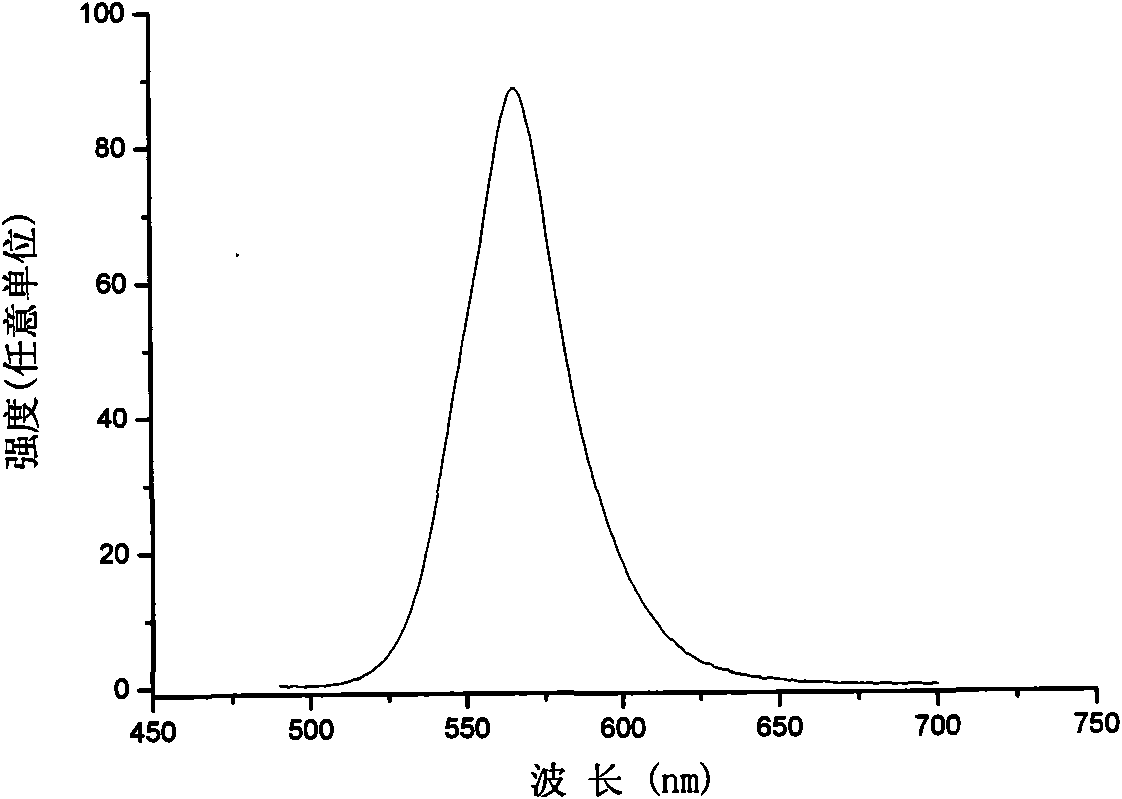

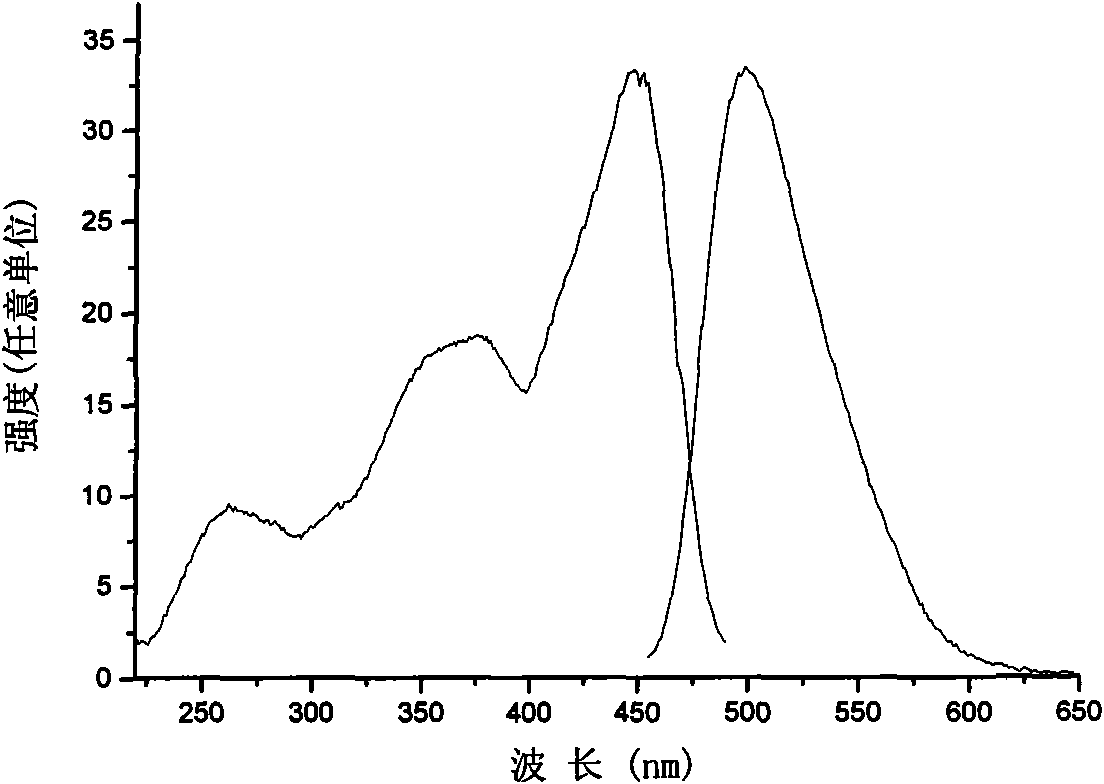

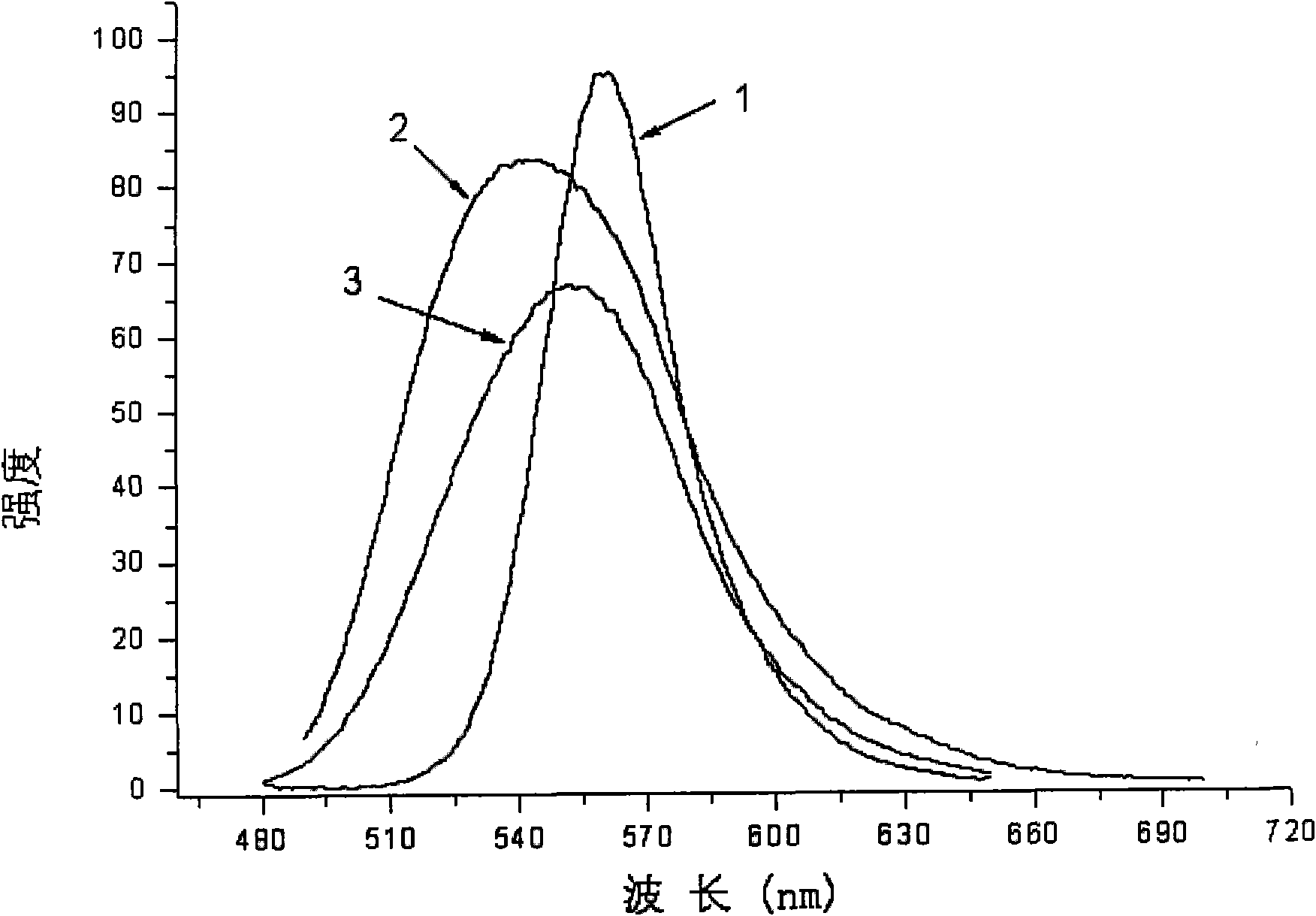

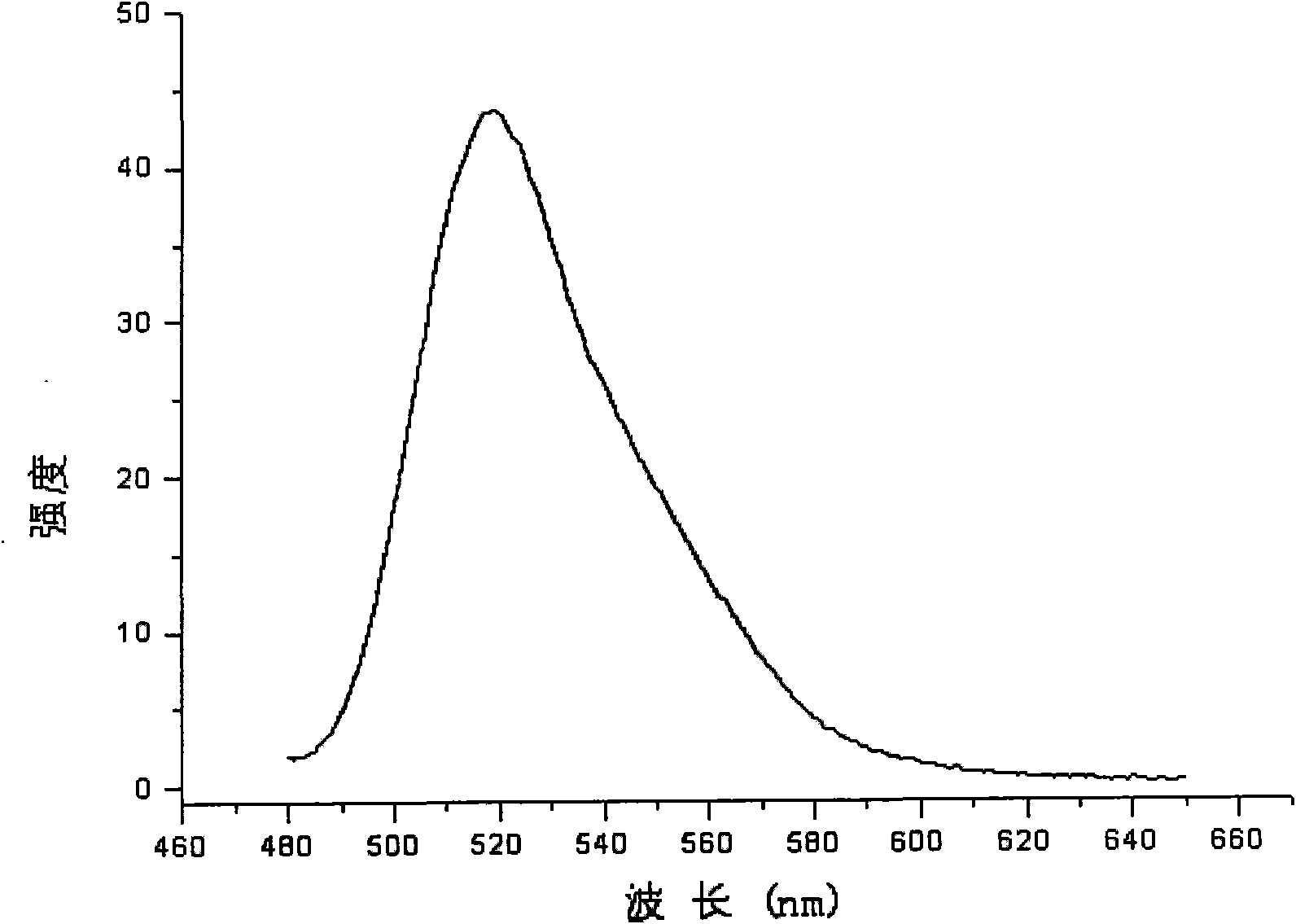

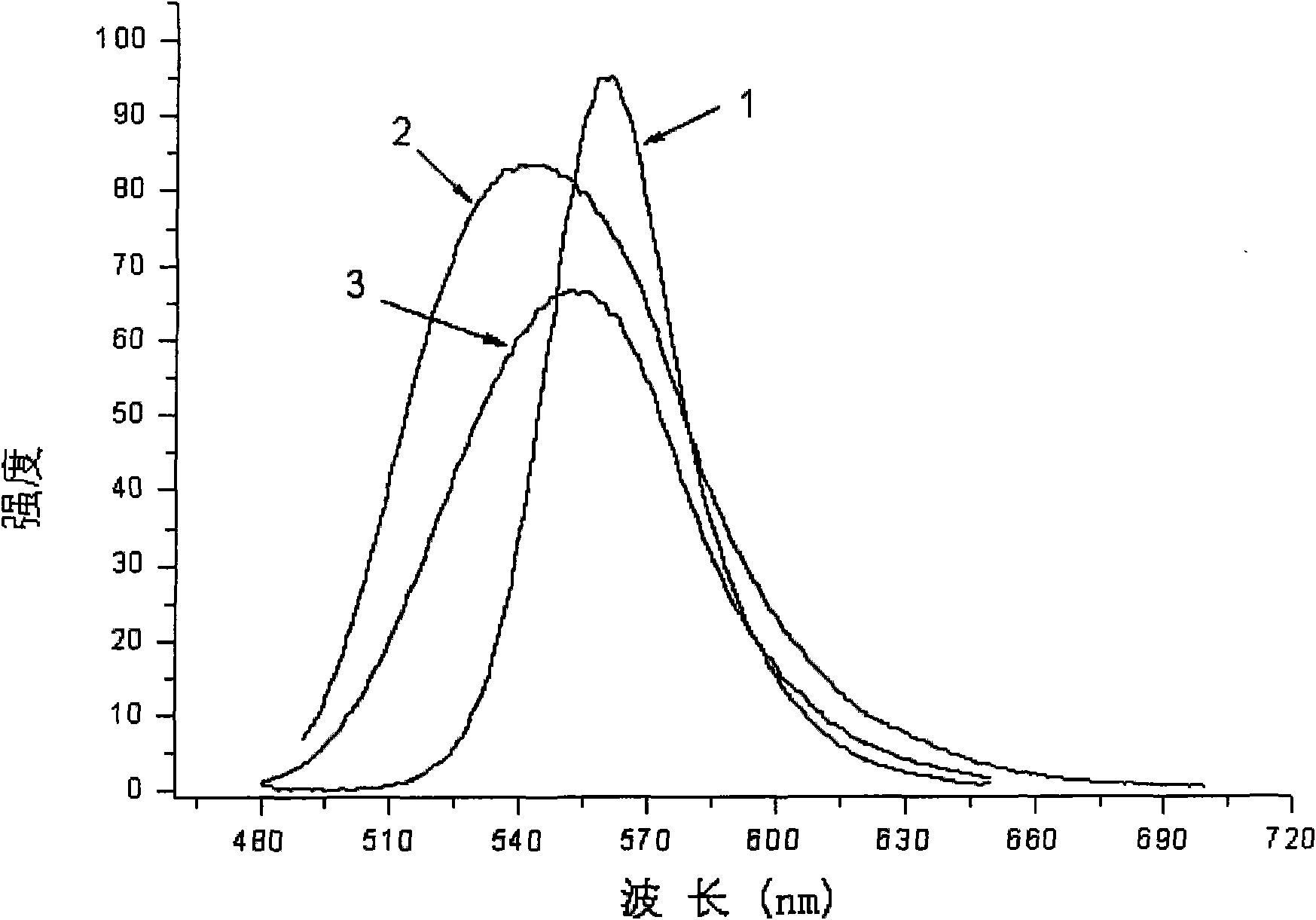

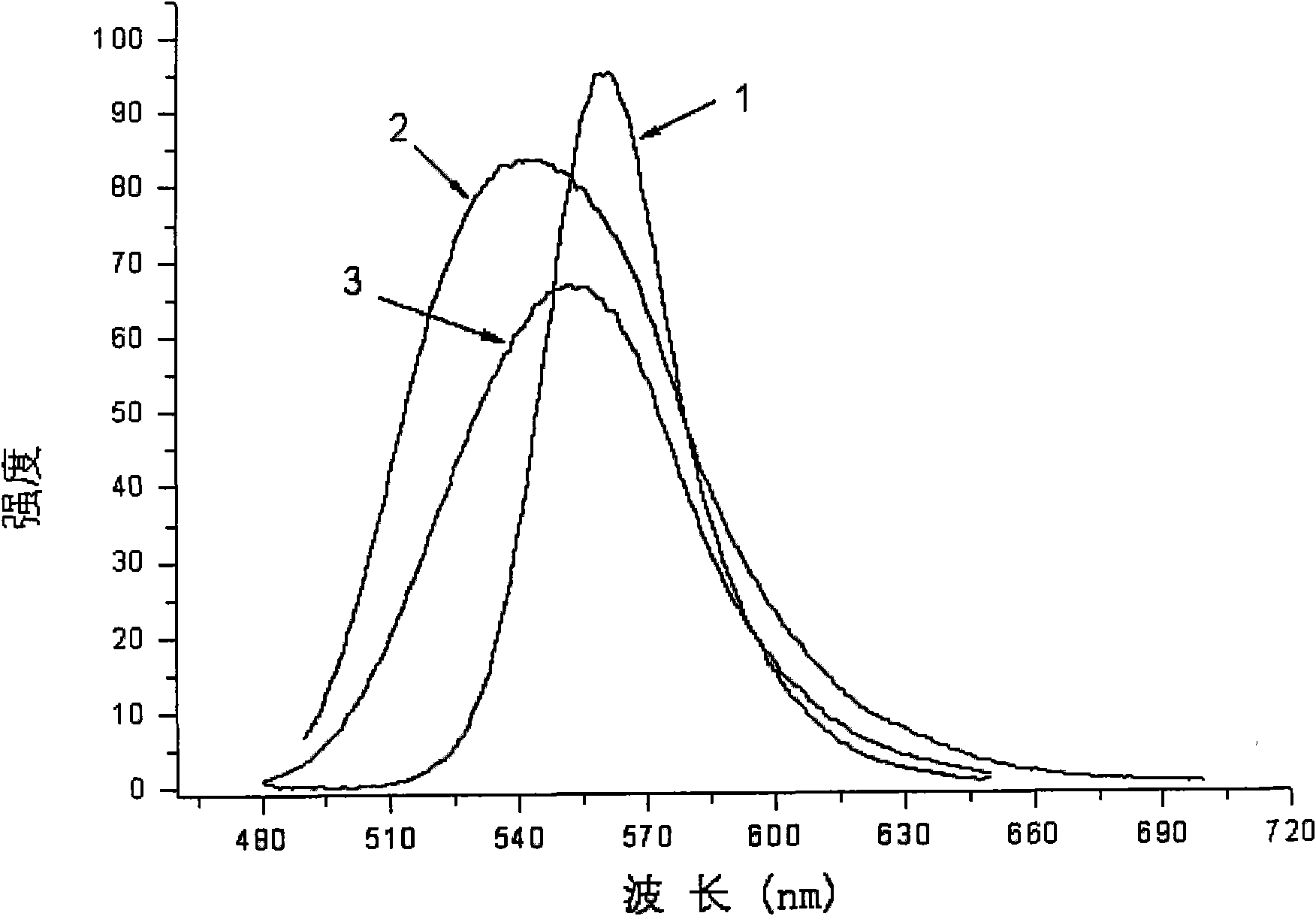

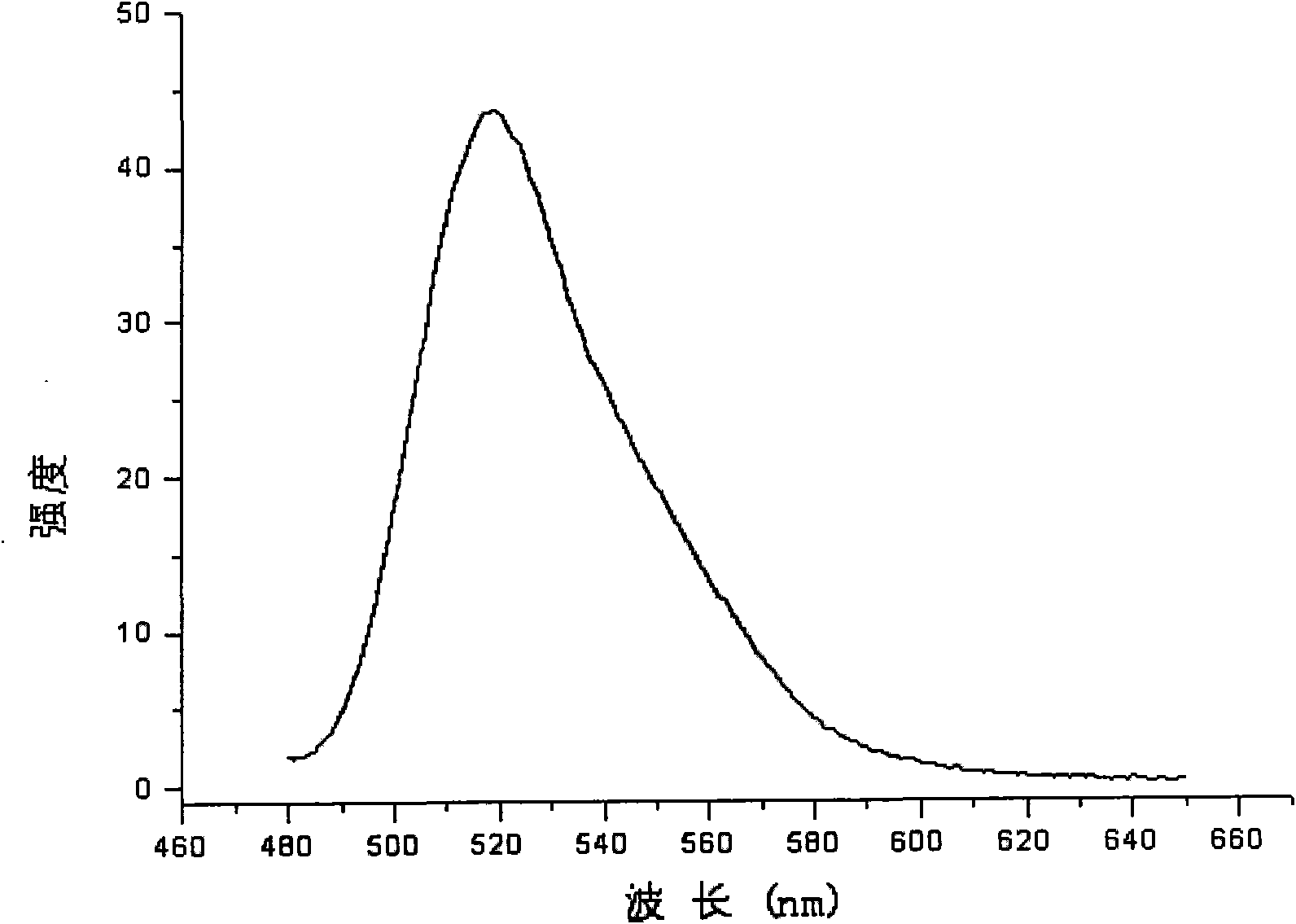

Luminescent glass, making method and application thereof

ActiveCN101928111AImprove quantum efficiencyImprove stabilityLuminescent compositionsSemiconductor devicesFluorescenceSolvent

The invention provides luminescent glass, a making method and application thereof. The making method comprises the following steps of, firstly, dissolving organic fluorescence materials in a solvent to form an organic fluorescence material solution; secondly, immersing porous glass into the organic fluorescence material solution, and absorbing the organic fluorescence material solution; and thirdly, taking out the porous glass immersed with the organic fluorescence material solution, and drying to prepare the luminescent glass. The luminescent glass is prepared by the method and can be matched with a semiconductor light emitting diode within a range of 200-550 nm to make a light emitting device. The making method of the luminescent glass has simple making technology, and the luminescent glass prepared by the method can be directly applied to the light emitting device of the semiconductor light emitting diode as fluorescence conversion substances and packaging materials, thereby solving the problem of photochemical reaction between the organic fluorescence materials and the organic packaging materials.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Anti-cracking stainless steel welding wire and preparation method thereof

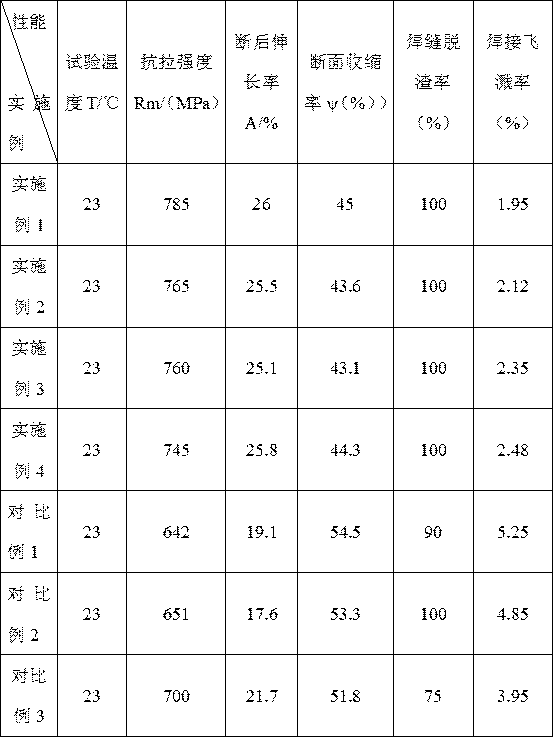

InactiveCN108465976AEasy to adjust performanceGood synergyWelding/cutting media/materialsSoldering mediaRare earthAlloy

The invention belongs to the field of welding materials, and relates to a stainless steel welding wire material, in particular to an anti-cracking stainless steel welding wire and a preparation methodof the anti-cracking stainless steel welding wire. The welding wire is composed of a sheath and a flux core. The flux core is prepared from, by mass, 5-10% of SiO2, 3-8 parts of rare earth fluoride,1-5% of attapulgite clay, 3-8% of calcium oxalate, 10-15% of alloy powder, 5-8% of chromium metal, 5-10% of ferromanganese iron, 1-3% of molybdenum powder, 3-5% of potassium carbonate, 5-12% of alkalimetal oxide, 2-9% of titanate and the balance iron, wherein the sum of the mass percents of the components is 100%. According to the anti-cracking stainless steel welding wire and the preparation method of the anti-cracking stainless steel welding wire, the welding wire has the excellent mechanical properties such as excellent welding technological performance, good toughness and high strength, and is remarkable in anti-cracking effect; electric arc is stable, splashing is small, deslagging is easy, forming is meticulous and attractive, and full-position welding can be achieved; and the preparation method is simple, low in cost, high in efficiency, environmentally friendly, free of pollution and capable of achieving large-scale production.

Owner:DANYANG HUALONG SUPERIOR STEEL

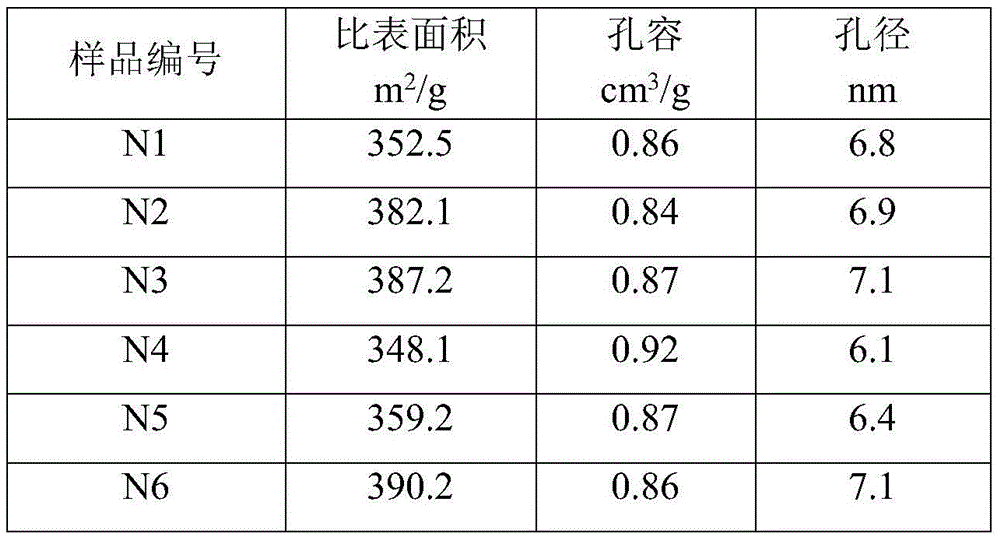

Nickel-containing pseudoboehmite and carrier prepared from nickel-containing pseudoboehmite

ActiveCN106732607AImprove hydrogenation activityEasy to adjust performanceCatalyst carriersHeterogenous catalyst chemical elementsPseudoboehmiteActive component

The present invention provides nickel-containing pseudoboehmite and a carrier prepared from the nickel-containing pseudoboehmite. According to the present invention, in the nickel-containing pseudoboehmite prepared through the method, nickel and pseudoboehmite are organically combined, the active component nickel is effectively dispersed in the pseudoboehmite, the nickel-containing alumina carrier having the specific crystal form is formed, the good regulation effects are provided on the pore structure and the acidity of the carrier, and the finally-prepared catalyst has high hydrogenation activity; and compared to the catalyst prepared through the single use of the impregnation method, the catalyst of the present invention has the following advantages that the process is simple, the performance of the carrier material is easy to modulate, and the like.

Owner:PETROCHINA CO LTD

Nickel-molybdenum hydrogenation catalyst and method for preparing same

ActiveCN108262047AImprove hydrogenation activityEasy to adjust performanceHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsActive componentThermal stability

The invention relates to a nickel-molybdenum catalyst and a method for preparing the same, in particular to a method for preparing a nickel-molybdenum hydrogenation catalyst. Nickel-containing aluminum oxide is used as a carrier for the nickel-molybdenum hydrogenation catalyst. The nickel-molybdenum hydrogenation catalyst contains nickel and molybdenum which are active components, the nickel-containing aluminum oxide is used as the carrier, nickel-containing pseudo-boehmite is used as a precursor for the nickel-containing aluminum oxide carrier, and procedures for preparing the nickel-containing pseudo-boehmite include acid-base neutralization and gelatinizing procedures. The method has the advantages that the specific carrier is used in the nickel-molybdenum hydrogenation catalyst, accordingly, the nickel and pseudo-boehmite can be organically bound with each other, the active component nickel can be effectively dispersed in the pseudo-boehmite, and the nickel-containing aluminum oxide carrier in specific crystal forms can be formed; good effects of regulating pore structures and the acidity of the carrier can be realized, procedures are simple as compared with catalysts simply prepared by the aid of impregnation processes, and the performance of carrier materials is easy to modulate; the nickel-molybdenum hydrogenation catalyst prepared by the aid of the method is high in hydrogenation activity and selectivity and good in chemical stability and thermal stability, and the like.

Owner:PETROCHINA CO LTD

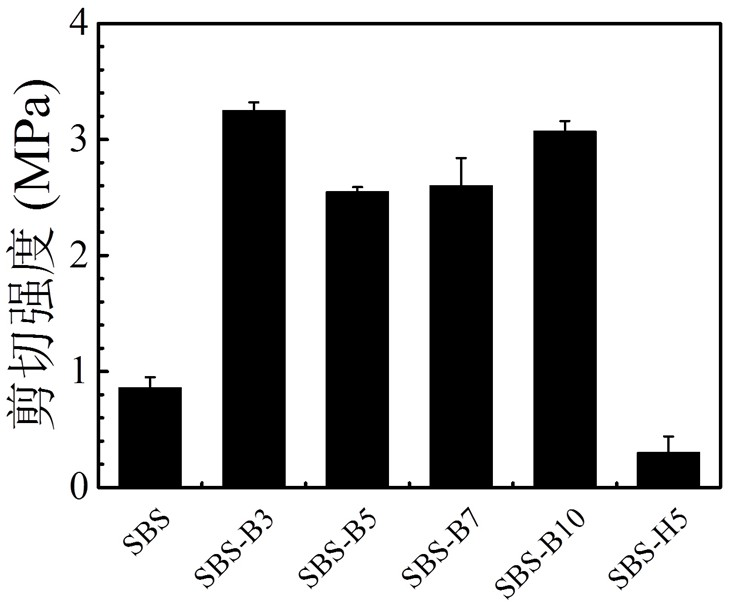

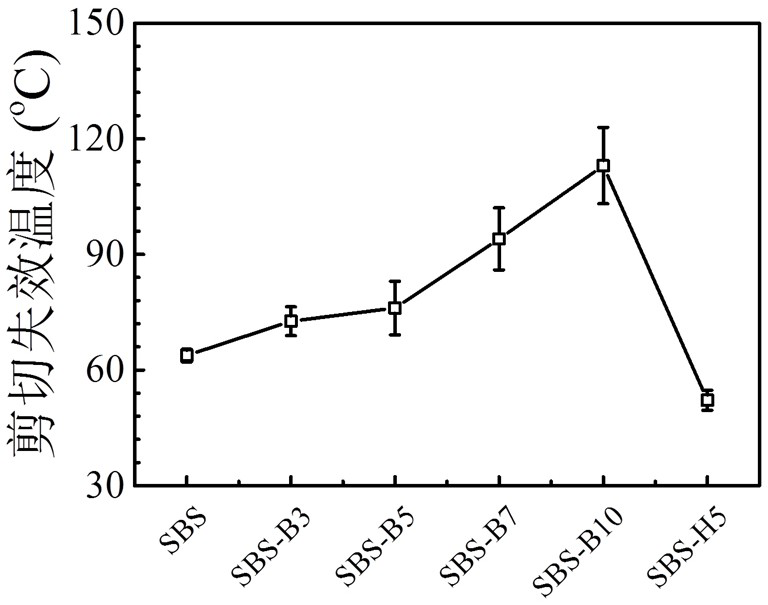

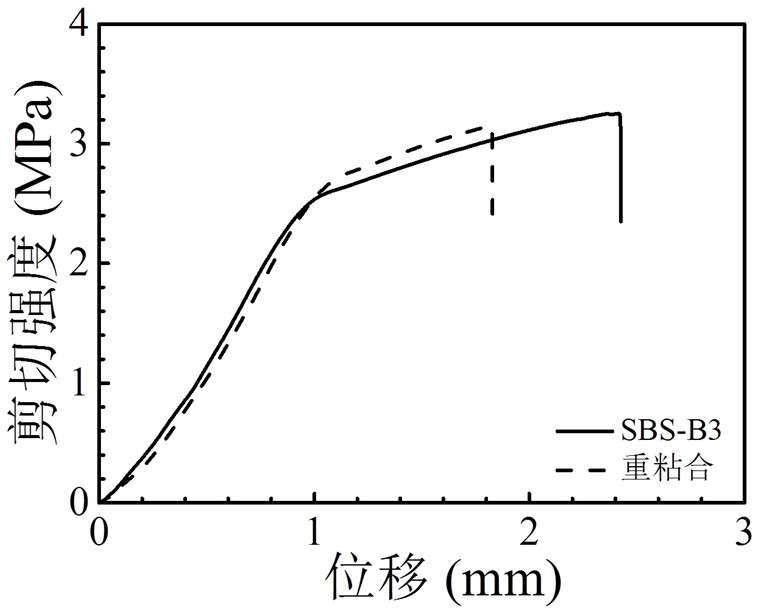

Dynamic cross-linked SBS hot-melt pressure-sensitive adhesive and preparation method thereof

ActiveCN113801615AHigh softening temperatureImprove heat resistanceNon-macromolecular adhesive additivesElastomerPhenylboronic acid

The invention discloses a dynamically cross-linked SBS hot-melt pressure-sensitive adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The adhesive comprises the following raw materials: an SBS thermoplastic elastomer, an antioxidant, an ultraviolet light initiator and a phenylboronic acid ester dynamic cross-linking agent. The phenylboronic acid ester dynamic cross-linking agent participates in construction of an SBS hot-melt pressure-sensitive adhesive cross-linked network through ultraviolet irradiation, so that the softening temperature of the SBS hot-melt pressure-sensitive adhesive is increased, and the heat resistance of the pressure-sensitive adhesive is improved. Due to the formation of a dynamic cross-linked network, the average molecular weight of the SBS hot-melt pressure-sensitive adhesive is increased, and the body viscosity and cohesive strength of the pressure-sensitive adhesive are obviously improved. Besides, the phenylboronic acid ester covalent bond has excellent ester exchange capacity, and the formed cross-linked network has dynamic characteristics, so that the phenylboronic acid ester covalent bond is fractured and recombined at high temperature, the cross-linked material is endowed with repeatable adhesive property, and the practicability of the material is improved.

Owner:HEFEI UNIV OF TECH

Preparation method of capacitive touch screen electro-conductive glass with shadow eliminating function

InactiveCN105819703AGood square resistance uniformityEasy to adjust performanceCoatingsCutting glassTransmittance

Owner:JIANGSU XINPU ELECTRONICS TECH CO LTD

Organic-inorganic compound fluorescent powder, manufacturing method and application

InactiveCN101962533AStrong chemical inertnessWide range of choicesSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceLight-emitting diode

The invention provides organic-inorganic compound fluorescent powder, a manufacturing method and application thereof. The method comprises the following steps of: immerging porous glass into the solution of an organic fluorescent material; taking the porous glass out after the porous glass absorbs the solution of the organic fluorescent material; and smashing the porous glass which absorbs the solution of the organic fluorescent material. The organic-inorganic compound fluorescent powder is prepared by the manufacturing method. The organic-inorganic compound fluorescent powder can be made into a light-emitting device by matching a semiconductor light-emitting diode in the range of between 200 and 550nm. The organic-inorganic compound fluorescent powder of the invention has a simple manufacturing process, can be doped into an encapsulating material of the semiconductor light-emitting diode, and solves the problem of a photochemical reaction between an organic light-emitting material and an organic encapsulating material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Hydrogenation protective agent and preparation method thereof

ActiveCN108855114AEffective protectionImprove protectionCatalyst protectionMetal/metal-oxides/metal-hydroxide catalystsActive componentThermal stability

The invention relates to a hydrogenation protective agent and a preparation method thereof. The catalyst contains an active component molybdenum, nickel-containing alumina is used as a carrier, a precursor of the nickel-containing alumina carrier is nickel-containing pseudo-boehmite, and the preparation process of the nickel-containing pseudo-boehmite includes acid-base neutralization and gellingprocesses. A specific carrier is used in the protective agent provided by the invention, and the specific carrier has the advantages that the nickel and the pseudo-boehmite can be organically combined, so that the active component nickel is effectively dispersed in the pspseudo-boehmite, and a specific crystal form of the nickel-containing alumina is formed; the method has a good regulation effecton a pore structure and acidity of the carrier, and has the advantages of simple process and easy of adjusting the performance of the carrier material compared with the preparation of the catalyst only through an impregnation method. The hydrogenation protective agent provided by the invention has better capacities of hydrogenation, containing gel and dirt and good chemical stability and thermalstability, and can effectively protect the primary hydrogenation catalyst and prolong the service life of the primary catalyst.

Owner:PETROCHINA CO LTD

High-elastic antibacterial non-woven fabric with honeycomb structure and preparation method thereof

A high-elastic antibacterial non-woven fabric with a honeycomb structure comprises a plurality of compound fiber meshes sequentially stacked in a back-and-forth Z shape. Antibacterial agents are sprayed into the compound fiber meshes, the compound fiber meshes are sequentially in end-to-end connection, and hot melting fiber is clamped between the adjacent compound fiber meshes. When the high-elastic antibacterial non-woven fabric is manufactured, through preparation prior to mesh formation and a process of mesh formation through mechanical combing, an upper layer fiber mesh, an elastic fiber mesh and a lower layer fiber mesh are prepared respectively and then are overlaid into the compound fiber meshes through a fiber mesh compounding process; the upper layer fiber mesh and the lower layer fiber mesh are mixture of low melting point polyester short fiber and three-dimensional curly hollow polyester short fiber, and the elastic fiber mesh is mixture of low melting point polyester short fiber and elastic polyester short fiber. After the antibacterial agents are sprayed into the compound fiber meshes, the meshes are vertically laid through a vertical mesh laying process, the hot melting fiber is scattered between the compound fiber meshes, and then the high-elastic antibacterial non-woven fabric with the honeycomb structure is obtained through a drying, trimming and winding process.

Owner:WUHAN TEXTILE UNIV

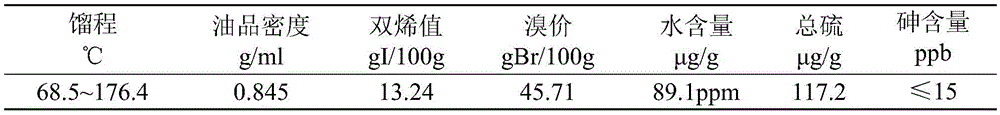

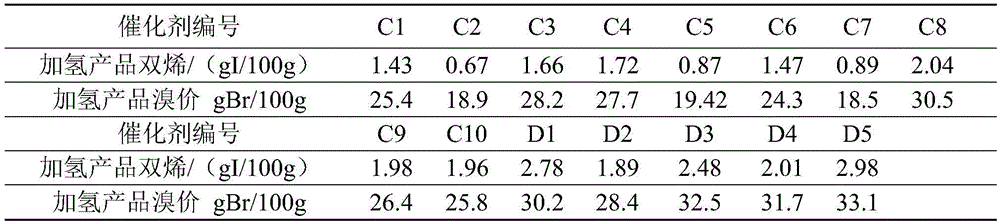

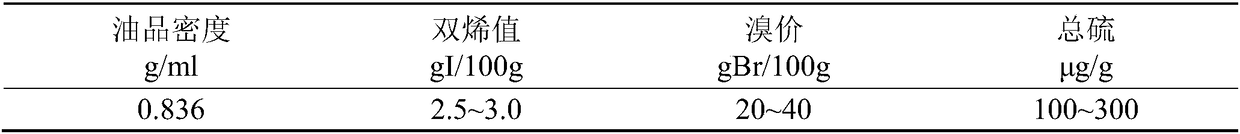

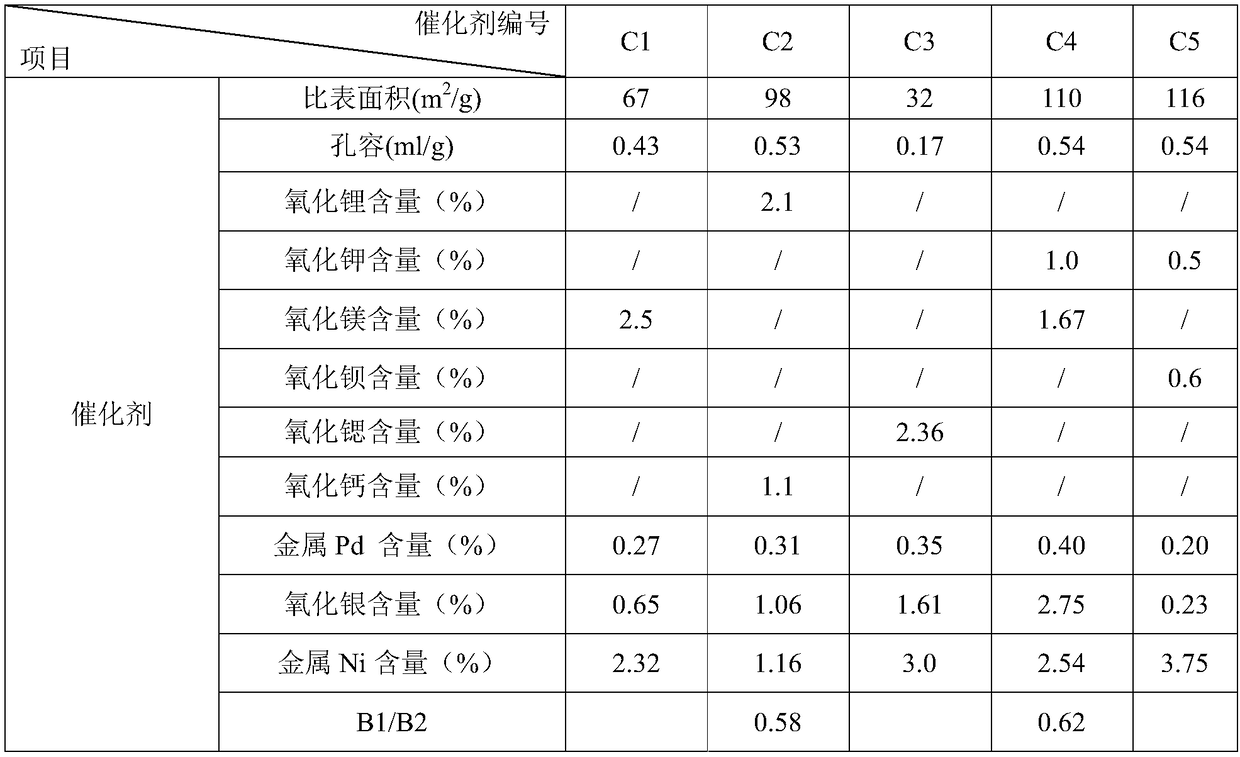

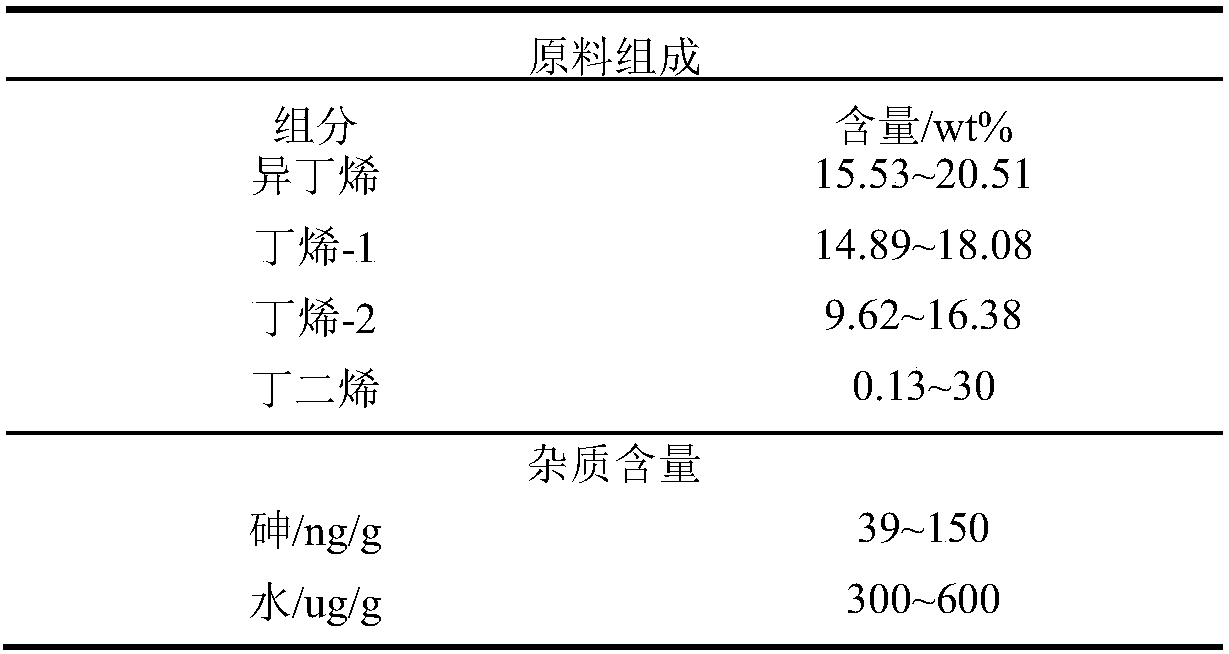

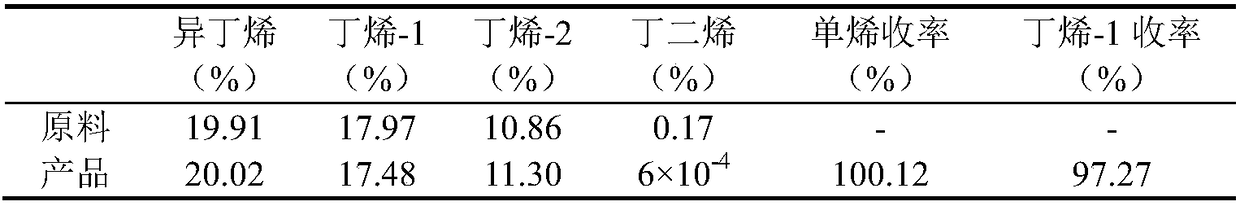

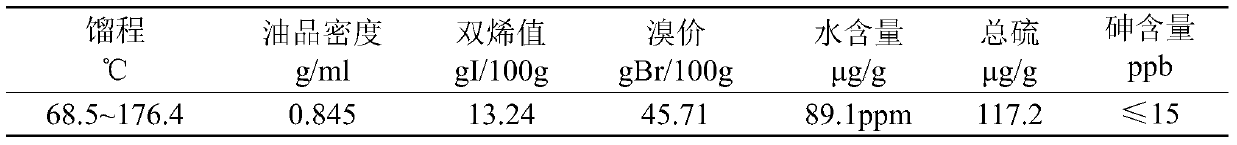

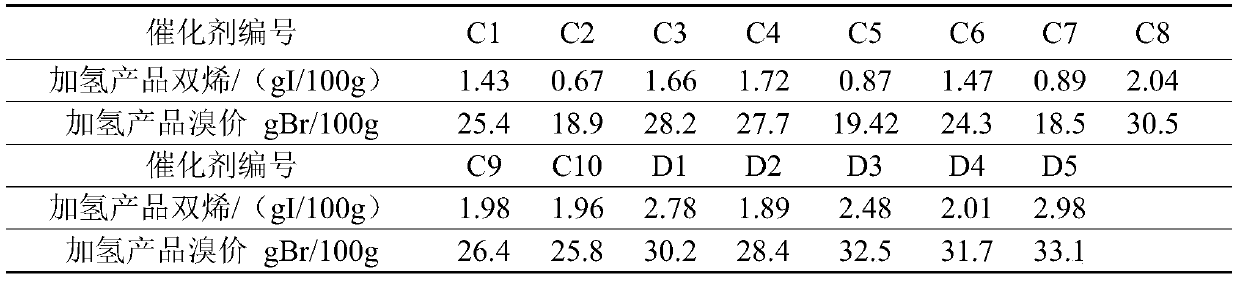

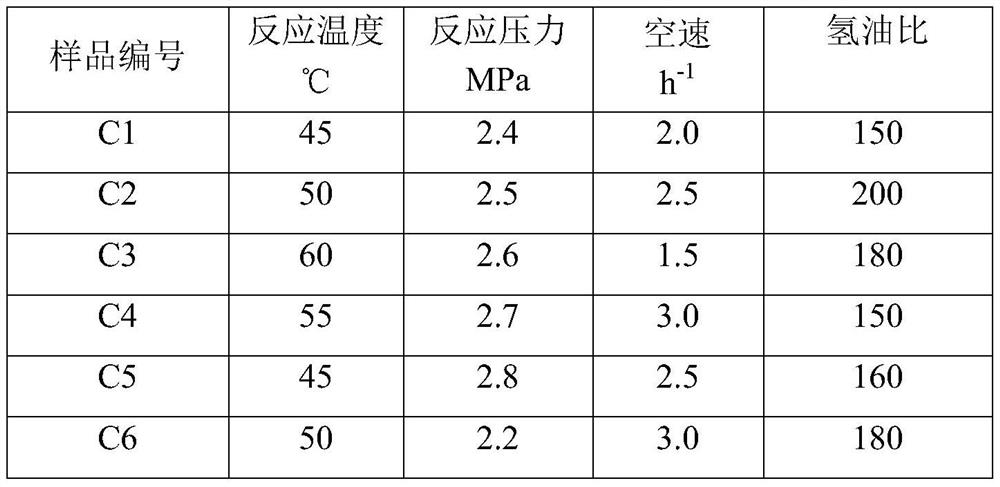

Hydrotreatment method of mixed C4 raw materials

ActiveCN108863695AImprove hydrogenation activityHigh selectivityHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsAlkaline earth metalBULK ACTIVE INGREDIENT

The invention relates to a hydrotreatment method of refinery plant mixed C4 raw materials. A palladium-silver hydrogenation catalyst and a fixed bed reactor are used; the hydrogenation process conditions are as followings: the liquid volume airspeed is 2.0 to 10.0h<-1>; the inlet temperature of the reactor is 30 to 80 DEG C; the reaction pressure is 1.0 to 2.0 MPa; the mole ratio of hydrogen to butadiene is (1.1 to 3):1; the used palladium-silver hydrogenation catalyst uses nickel-containing aluminum oxide with specific crystal form as a carrier and palladium as an active ingredient; through being metered by using the catalyst weight as 100 percent, the palladium content (being metered by simple substances) is 0.05 to 0.5 weight percent; the nickel content (being metered by simple substances) is 1.0 to 4.0 weight percent; silver oxide accounts for 0.15 to 2.8 weight percent; alkali metal and / or alkaline-earth metal oxide accounts for 0.5 to 5.0 weight percent. Under the application method and process conditions, the catalyst has good butadiene hydrogenation activity and selectivity; the hydrogenation product can be used as raw materials for producing high-purity 1-butylene.

Owner:PETROCHINA CO LTD

Filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth and preparation method thereof

ActiveCN104911815AImprove adhesionAvoid distractionNon-woven fabricsAnti bacterialAntibacterial agent

The invention provides filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth. The filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth comprises a plurality of synthetic fiber nets sequentially stacked in a reciprocating Z shape, an antibacterial agent is sprayed inside the synthetic fiber nets, the synthetic fiber nets are sequentially connected in an end-to-end mode, the fiber net included angle between the adjacent synthetic fiber nets is an acute angle smaller than 2 degrees, hot melting filament yarns are arranged on the front surfaces and the back surfaces of the synthetic fiber nets in the width directions of the synthetic fiber nets at equal intervals in a side by side mode, and the hot melting filament yarns are folded in the reciprocating Z shape with the synthetic fiber nets. Each synthetic fiber net is a layer-shaped fiber net and formed by overlapping an upper layer fiber net, an elastic fiber net and a lower layer fiber net. The preparation method comprises the following steps that 1, preparation before net forming is conducted; 2, machinery carding for net forming is conducted; 3, fiber net synthetization is conducted; 4, the antibacterial agent is sprayed, 5, the nets are vertically laid; 6, drying is conducted; 7, edge cutting is conducted; 8, winding is conducted. The filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth has the advantages that not only is the high elasticity achieved, the antibacterial performance good, the structure simple, but also the cost is low, and the environment protection is achieved.

Owner:WUHAN TEXTILE UNIV

A kind of nickel-based hydrogenation catalyst and preparation method thereof

ActiveCN106732620BGood chemical stabilityImprove thermal stabilityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention provides a nickel-based hydrogenation catalyst and a preparation method thereof. The nickel-containing alumina carrier is impregnated with a nickel-containing solution, dried and roasted to obtain a catalyst; the nickel-containing alumina carrier is formed from nickel-containing pseudo-boehmite. It is obtained by roasting; the preparation process of nickel-containing pseudo-boehmite includes acid-base neutralization and gel-forming processes. The invention organically combines nickel and pseudo-boehmite, so that the active component nickel is effectively dispersed in the pseudo-boehmite and forms a specific crystal form of nickel-containing alumina carrier. At the same time, the pore structure and acidity of the carrier are improved. It has better regulating effect. The finally prepared catalyst has high hydrogenation activity and selectivity, and good chemical stability and thermal stability.

Owner:PETROCHINA CO LTD

A kind of highly elastic antibacterial nonwoven fabric with honeycomb structure and preparation method thereof

Owner:WUHAN TEXTILE UNIV

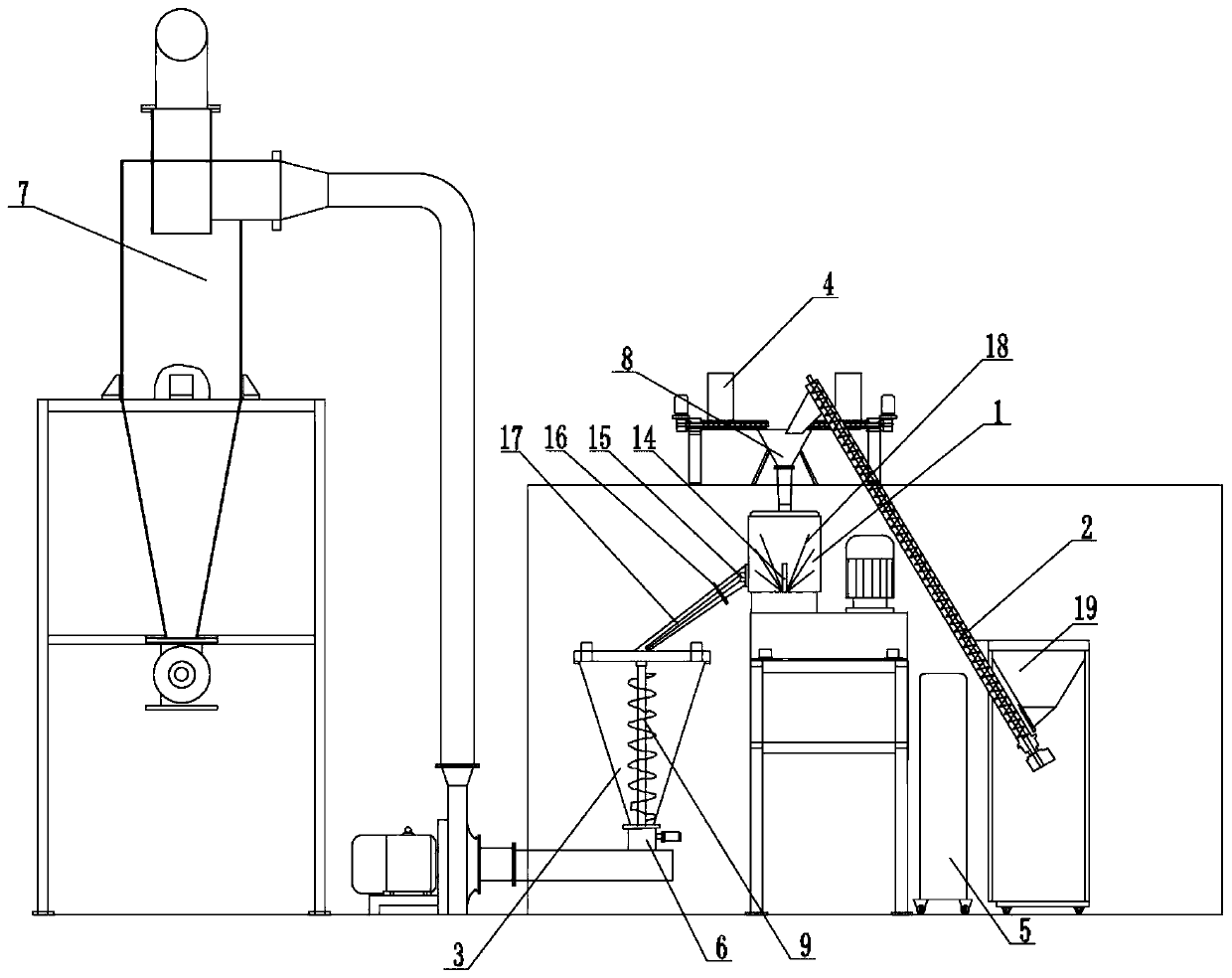

Polymer mixing system

The invention discloses a polymer mixing system. The polymer mixing system comprises a polymer mixing machine, wherein one side of the polymer mixing machine is provided with a feeding machine, a discharge port of the feeding machine communicates with a feeding port of the polymer mixing machine, one side of the polymer mixing machine is also provided with a stirring tank and a softener tank, thedischarging port of the polymer mixing machine communicates with the feeding port of the stirring tank, the discharging port of the softener tank communicates with the feeding port of the polymer mixing machine, and a screw feeding machine is arranged above the stirring tank, the discharging port of the screw feeding machine communicates with the feeding port of the polymer mixer, the bottom of the stirring tank communicates with a discharging pipe, one side of the discharging pipe communicates with a gas conveyor, and the gas conveyor is positioned at one side of the stirring tank. Accordingto the polymer mixing system, rapid transfer of materials can be realized, manual transfer is not needed, the contact time between operators and the materials is less in the production process, and the safety performance is high.

Owner:峨眉山市公平环保科技有限公司

Dual-polarized antenna and MIMO (multiple input multiple output) antenna with same

ActiveCN102810731BRadiation area is largeImprove performanceRadiating elements structural formsPolarised antenna unit combinationsCouplingMimo antenna

Owner:KUANG CHI INST OF ADVANCED TECH

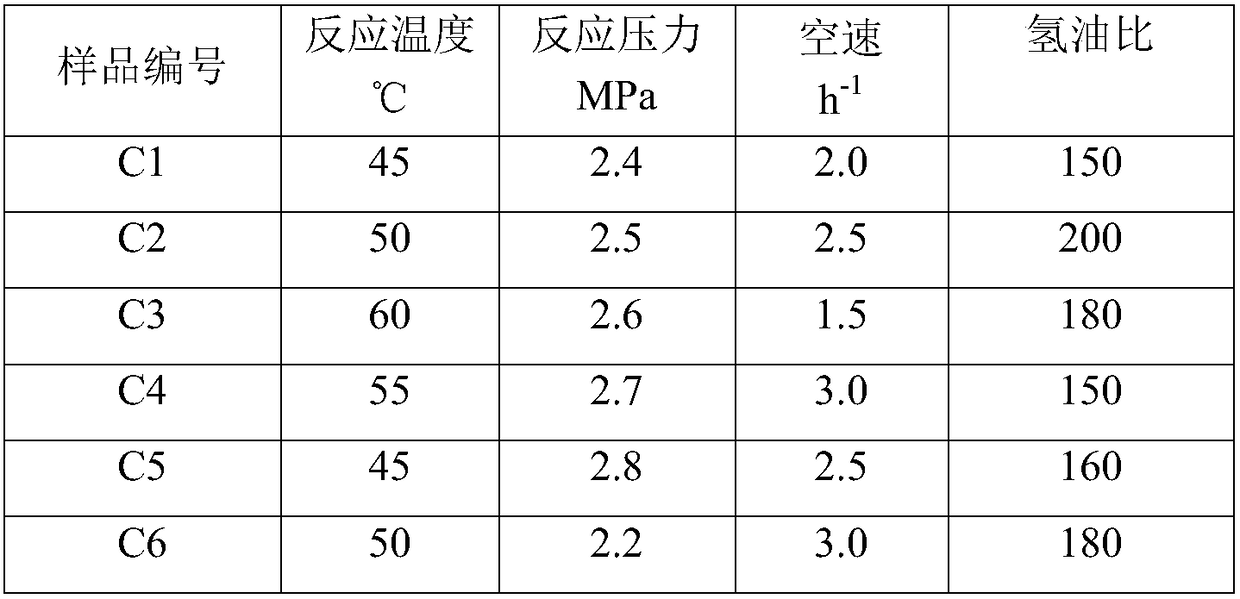

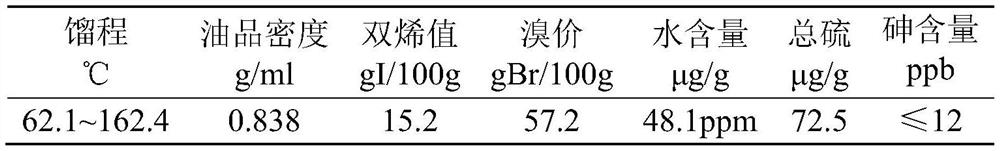

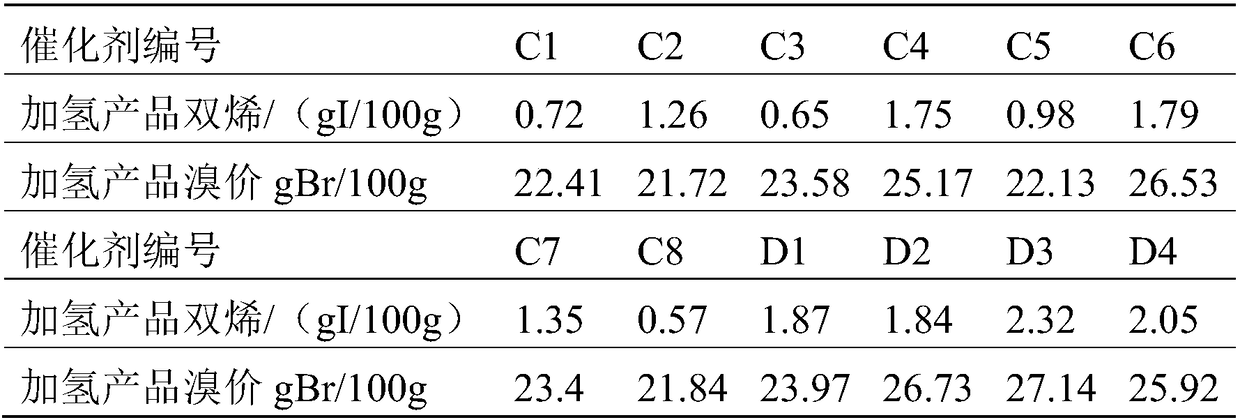

Hydrogenation method for pyrolysis gasoline

ActiveCN108865238AImprove hydrogenation activityEasy to adjust performanceHeterogenous catalyst chemical elementsRefining by selective hydrogenationActive componentHydrogenation reaction

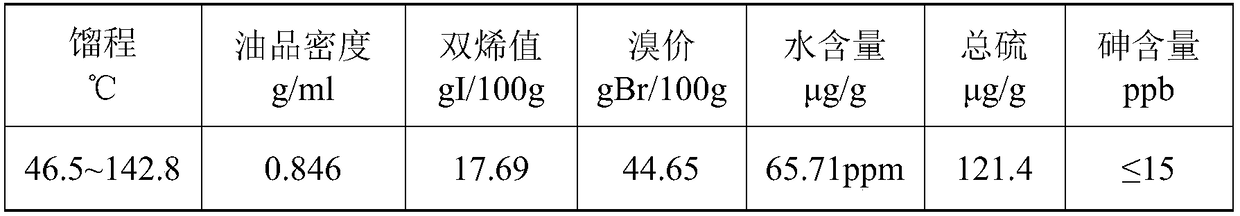

The invention provides a hydrogenation method for pyrolysis gasoline, wherein the pyrolysis gasoline which is by-produced in the ethylene production process is preheated and then enters a fixed bed hydrogenation reactor, the reactor is filled with nickel-molybdenum-zinc series hydrogenation catalysts, and after hydrogenation, the material is sent to the second-stage hydrogenation reactor; the catalysts prepared by using the nickel-containing carrier having the specific crystalline form prepared by the hydrogenation method for the pyrolysis gasoline can greatly improve the utilization ratio ofactive metal and reduce the preparation difficulty of the catalyst, and a synergistic action of selected active components can be added to play a synergistic effect to obtain active, selective and stable first-stage hydrogenation catalyst for the pyrolysis gasoline.

Owner:PETROCHINA CO LTD

A kind of hydrogenation method of pyrolysis gasoline

ActiveCN108865238BImprove hydrogenation activityEasy to adjust performanceHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogenation reaction

The invention provides a hydrogenation method for pyrolysis gasoline. The pyrolysis gasoline by-product in the ethylene production process is preheated and then enters a fixed-bed hydrogenation reactor. The reactor is equipped with a nickel-molybdenum-zinc hydrogenation catalyst. , the hydrogenated material is sent to the second-stage hydrogenation reactor. The catalyst prepared by using the nickel-containing carrier with a specific crystal form prepared by the present invention can greatly improve the utilization rate of active metals and reduce the difficulty of catalyst preparation. At the same time, the addition of selected active components has a synergistic effect and can produce active catalysts. , a one-stage hydrogenation catalyst for pyrolysis gasoline with good selectivity and stability.

Owner:PETROCHINA CO LTD

Organic-inorganic compound fluorescent powder, manufacturing method and application

InactiveCN101962533BStrong chemical inertnessWide range of choicesSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryLight emitting device

The invention provides organic-inorganic compound fluorescent powder, a manufacturing method and application thereof. The method comprises the following steps of: immerging porous glass into the solution of an organic fluorescent material; taking the porous glass out after the porous glass absorbs the solution of the organic fluorescent material; and smashing the porous glass which absorbs the solution of the organic fluorescent material. The organic-inorganic compound fluorescent powder is prepared by the manufacturing method. The organic-inorganic compound fluorescent powder can be made into a light-emitting device by matching a semiconductor light-emitting diode in the range of between 200 and 550nm. The organic-inorganic compound fluorescent powder of the invention has a simple manufacturing process, can be doped into an encapsulating material of the semiconductor light-emitting diode, and solves the problem of a photochemical reaction between an organic light-emitting material and an organic encapsulating material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

1-3 structure huge magnetoelectric material and preparing process thereof

InactiveCN100364129CImprove magnetoelectric propertiesEasy to makeDevice material selectionGalvano-magnetic material selectionElectricityConversion coefficients

This invention relates to a 1-3 structured huge magnet electric material and its preparation method. The material is composed of piezoelectric ceramics, magnetostriction materials and a high-molecular binding agent, among which, one of the dimension of the piezoelectric ceramics is greater than the other two shaped in a long column and distributed in a 3-D matrix composed of the magnetostriction materials powder and the high-molecular binding agent. This 1-3 structured material has high and stable magnetoelectric conversion coefficient, which can be regulated by altering contents of the piezoelectric ceramics.

Owner:TSINGHUA UNIV

Nickel-silver series hydrogenation catalysts and preparation method thereof

ActiveCN108855129AImprove hydrogenation activityEasy to adjust performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationActive componentThermal stability

The invention relates to a nickel-silver series catalysts and a preparation method thereof, in particular related to a preparation method of nickel-silver series hydrogenation catalysts using nickel-containing alumina as a carrier. The nickel-silver hydrogenation catalyst contains active components of nickel and copper, the nickel-containing alumina is used as the carrier, a precursor of the nickel-containing alumina carrier is nickel-containing pseudo-boehmite, and the preparation process of the nickel-containing pseudo-boehmite includes acid-base neutralization and gelling processes; a specific carrier is used in the catalysts provided by the invention, and the specific carrier has the advantages that nickel and the pseudo-boehmite can be organically combined, so that the active component nickel is effectively dispersed in the pspseudo-boehmite, and the nickel-containing alumina carrier swith a specific crystal form is formed; the method has a good regulation effect on a pore structure and acidity of the carrier, and has the advantages of simple process and easy to adjust the performance of the carrier material compared with the preparation of the catalyst by an impregnation method; The nickel-silver series hydrogenation catalysts provided by the invention have high hydrogenation activity and selectivity, with good chemical stability and thermal stability.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com