Luminescent glass, making method and application thereof

A technology of luminescent glass and manufacturing method, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve problems such as complex manufacturing process, achieve simple process, wide wavelength tunable range, and improve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

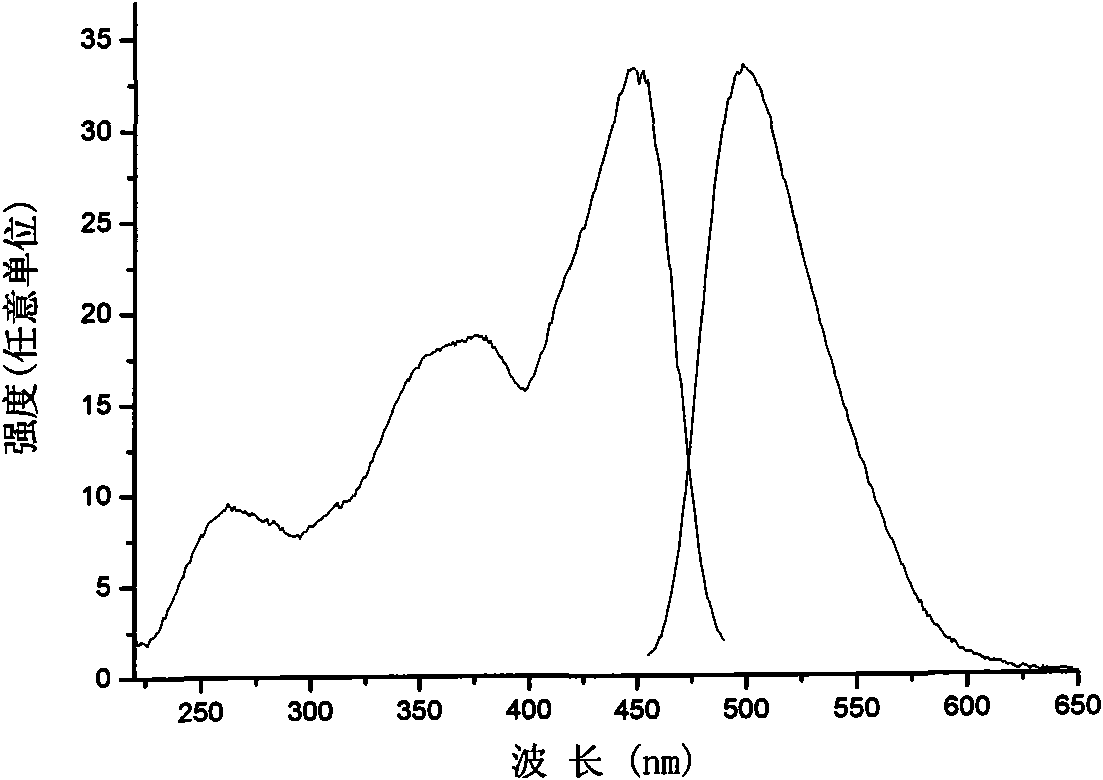

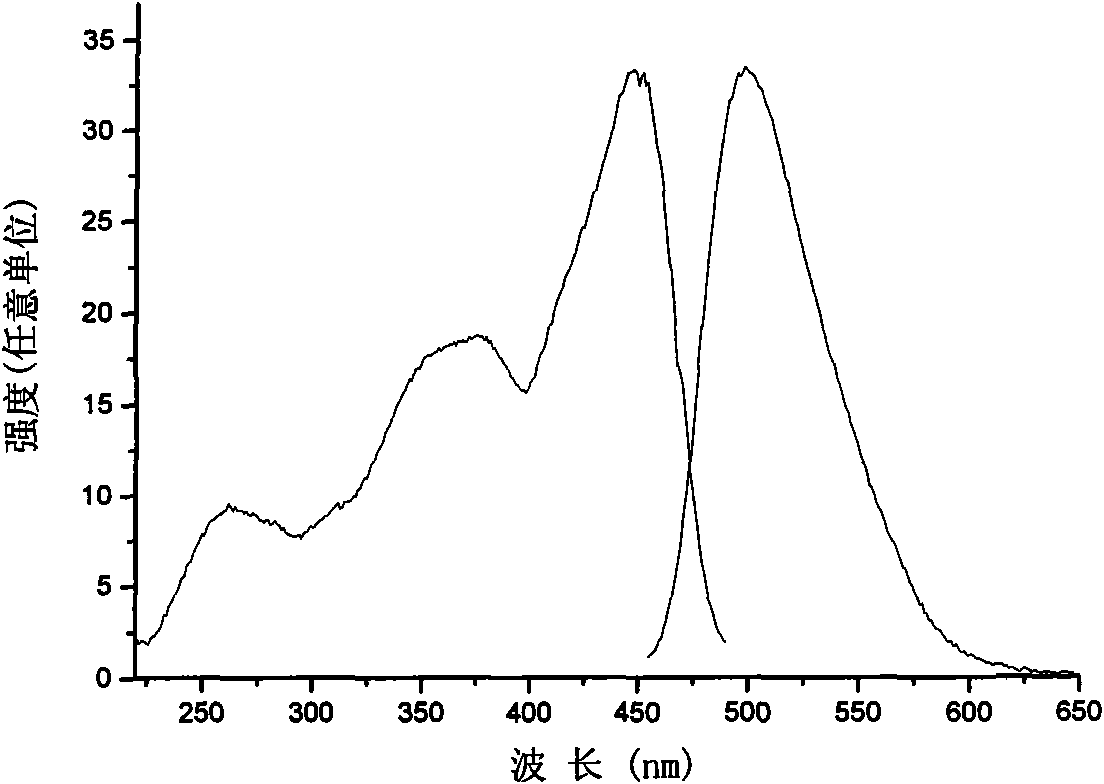

[0040] Get coumarin compound coumarin 307 (Acros company) 0.1mmol, be dissolved in the ethanol solution of 10ml, be mixed with 10 -2 mol / L solution, the porous glass whose pore volume accounts for 25% of the total volume of the luminescent glass is immersed in the above solution for 8 hours and then taken out, the surface is washed with ethanol solution and dried to obtain a porous luminescent material containing organic fluorescent materials. Glass. For the excitation and emission spectra of the porous luminescent glass prepared in this example, see figure 1 ,from figure 1 We can see that the material is suitable for 450nm blue LED excitation and can emit 500nm green light.

Embodiment 2

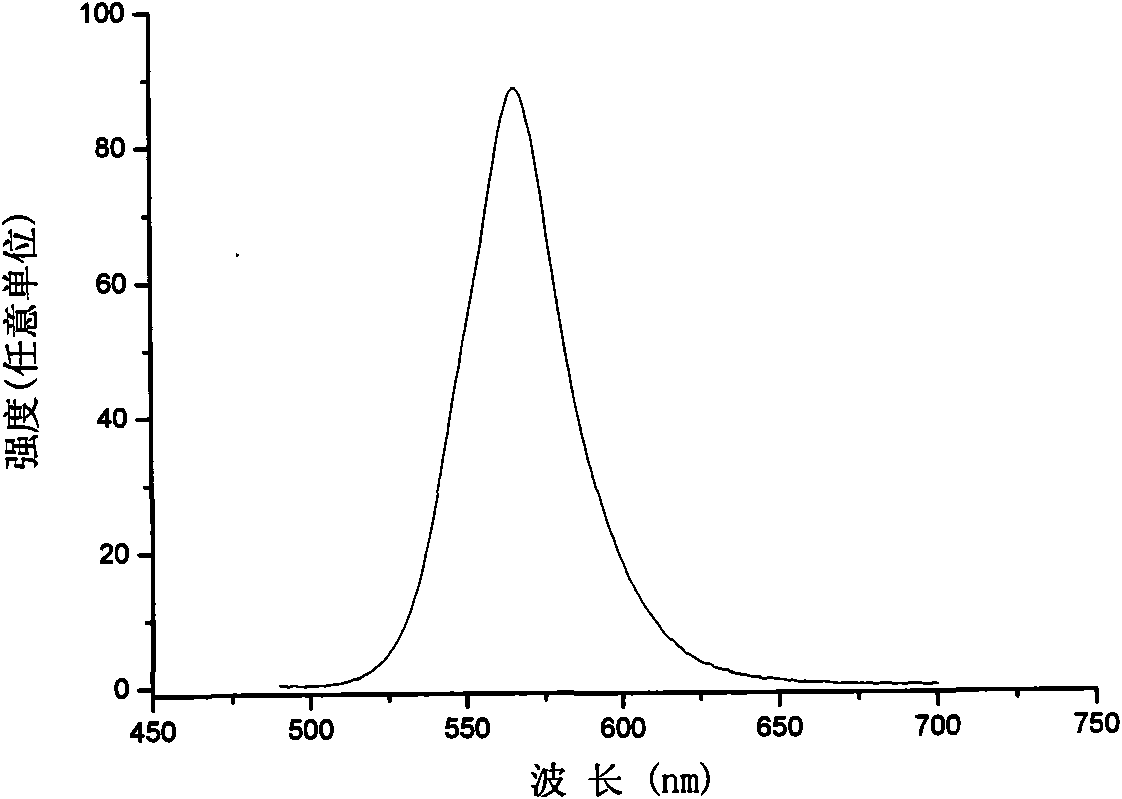

[0042] Get rhodamine compound rhodamine 6G (Acros company) 0.01mmol, be dissolved in the ethanol solution of 100ml, be mixed with 10 -4 mol / L solution, the porous glass whose pore volume accounts for 25% of the total volume of the luminescent glass is immersed in the above solution for 8 hours and then taken out, the surface is washed with ethanol solution and dried to obtain a porous luminescent material containing organic fluorescent materials. Glass. figure 2 The emission spectrum of the porous luminescent glass prepared in this example under the excitation of excitation light with a wavelength of 485nm is given, and yellow light of 565nm can be emitted under the excitation of light with a wavelength of 485nm. The test was carried out with Shimadzu RF-5301PC fluorescence spectrophotometer under the condition of 1.5nm slit and low sensitivity.

Embodiment 3

[0044] Get fluorene compound 9,9-bis(4-aminophenyl) fluorene (Acros company) 0.1mmol, be dissolved in the chloroform solution of 100ml, be mixed with 10 -3 mol / L solution, immerse the porous glass whose pore volume accounts for 40% of the total volume of the luminescent glass into the above solution for 8 hours, take it out, wash the surface with chloroform solution and dry it, then you can get porous luminescent glass containing organic fluorescent materials Glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com