Epoxy functional group containing nano-reinforcer for hybrid polymer epoxy resin

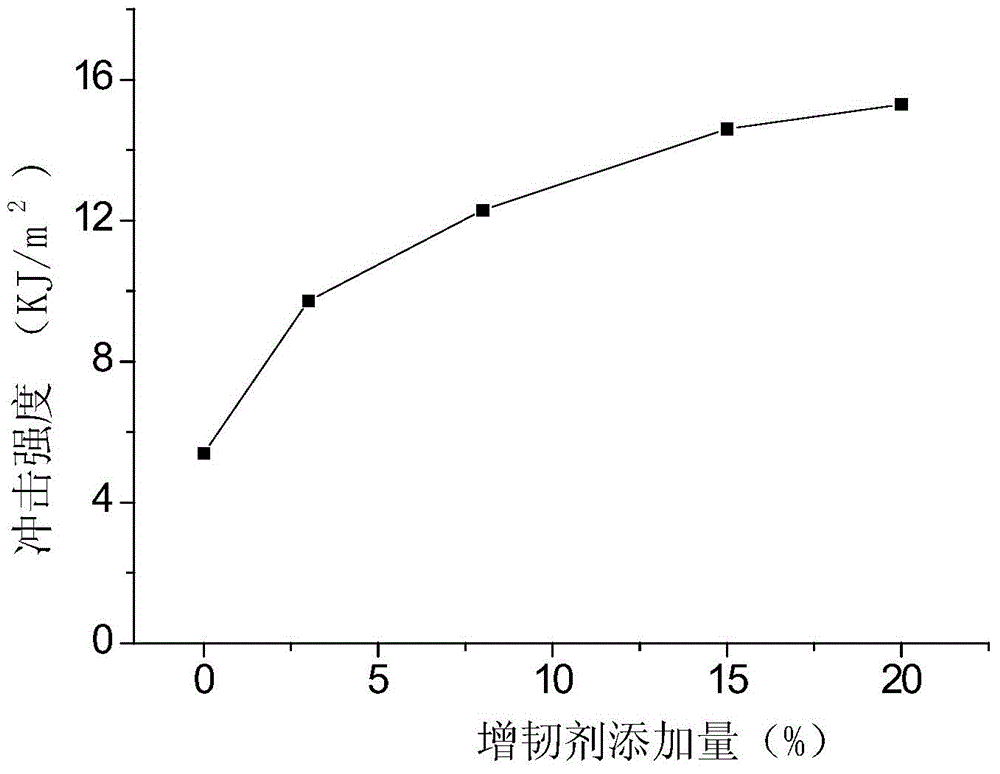

A technology of nano-reinforcing agent and epoxy resin, which is applied in the field of preparation of hybrid system of inorganic nanoparticles and high polymers, can solve problems such as high cross-linking density, poor impact resistance and weather resistance, and large internal stress, and achieve Easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

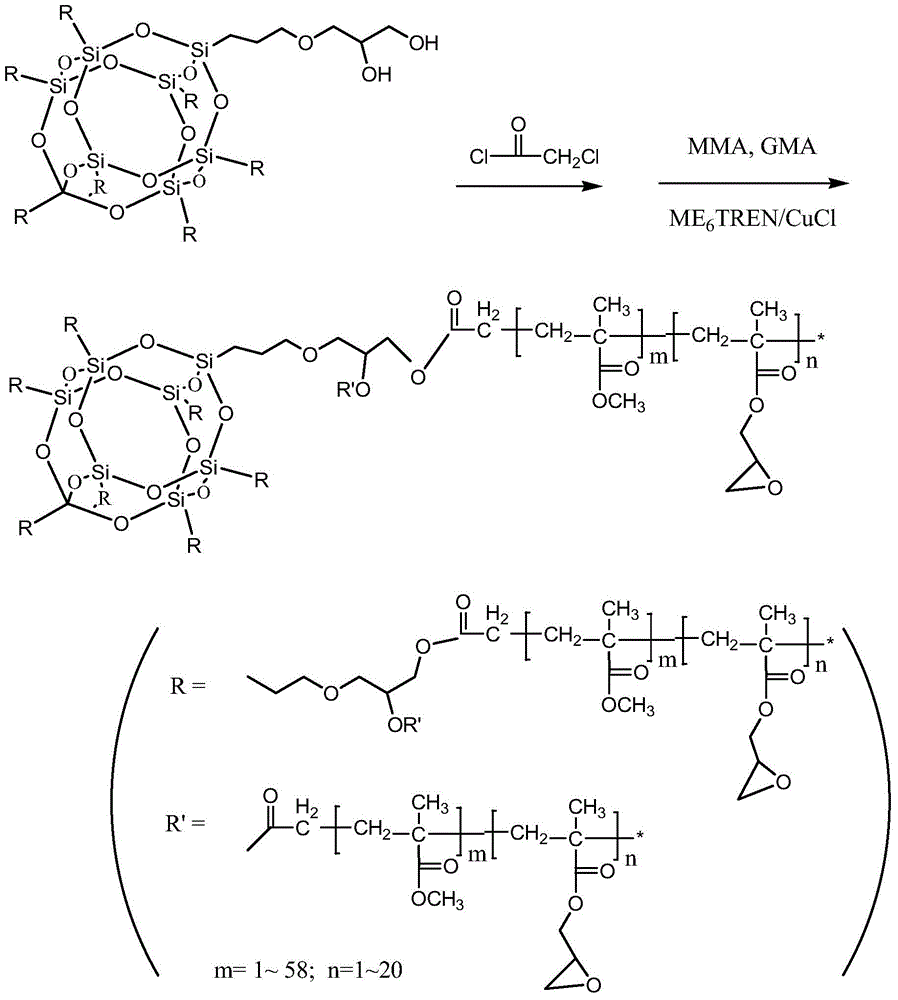

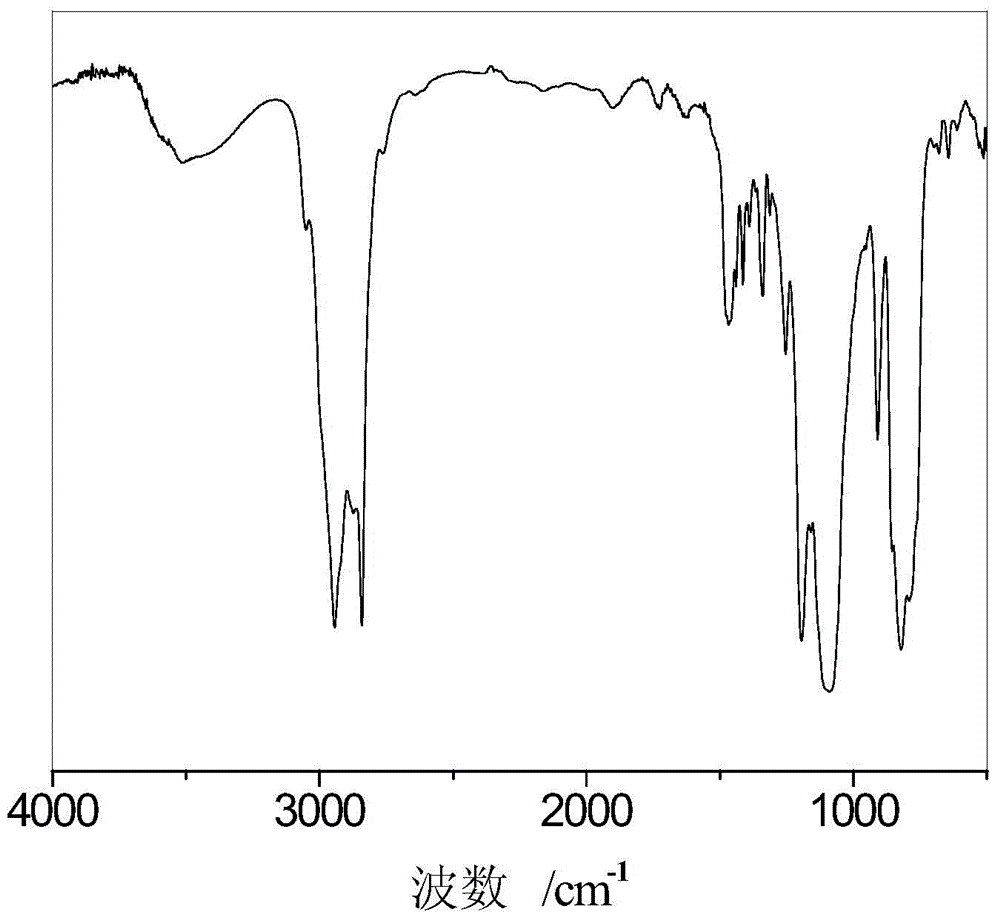

[0014] Add 80 ml of acetone and 120 ml of deionized water into a 500 ml three-neck flask, add 80 ml of KH-560 and 10 ml of hydrochloric acid under magnetic stirring, and heat to reflux at 70°C for 24 hours. The obtained product was evaporated with a rotary evaporator to remove the solvent, the precipitate was dissolved in tetrahydrofuran, dropped into water to re-precipitate under stirring, separated and purified through three cycles, and finally the product was put into a vacuum drying oven (40°C) and dried at a constant temperature for 24 hours to obtain Yellowish solid, the name is hydroxyoctapolysilsesquioxane. The sample was prepared by coating method, a small amount of product was dissolved in tetrahydrofuran, dried under infrared lamp, and its structure was analyzed by infrared spectrum test.

Embodiment 2

[0016] Take by weighing 14.72 grams of the hydroxyoctagonal silsesquioxane obtained in Example 1, add to 80 milliliters of N,N-dimethylformamide (DMF), stir in an ice bath for 1 hour and cool to 0 ℃, add 20 ml of triethylamine to the mixed solution, slowly add 18.08 g of 2-chloroacetyl chloride dropwise to the mixed solution while stirring, and react at room temperature for 24 hours after the dropwise addition is completed. After the reaction is over, the reaction solution is washed with 0.5mol / L sodium hydroxide solution, 0.5mol / L hydrochloric acid solution and a large amount of deionized water successively. The obtained macromolecular initiator was denoted as POSS-Cl after vacuum drying at ℃ for 48 hours.

Embodiment 3

[0018] Add 0.27 g (0.1 mmol) macroinitiator POSS-Cl in 50 ml reaction flask, dissolve in 15 ml DMF, add 2.72 g MMA and 3.86 g GMA and stir to dissolve, carry out vacuum pumping-nitrogen gas cycle three times. 0.33 g of CuCl and 0.77 g of tris[2-(dimethylamino)ethyl]amine (ME6TREN) were dissolved in DMF, and the solution was transferred into a reaction vial with a syringe, and reacted at 50° C. for 3 h under magnetic stirring. After the reaction, the reaction solution was diluted with DMF, separated by a neutral alumina separation column, dialyzed for 2 days, and the dialyzed aqueous solution was freeze-dried to obtain a product designated as POSS-P(MMA-co-GMA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com