Organic-inorganic compound fluorescent powder, manufacturing method and application

An inorganic compounding and manufacturing method technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, luminescent materials, etc., can solve the problems of mismatching excitation wavelength LED chips, low light conversion efficiency and brightness, etc., to avoid non-radiation The effect of energy transfer, improving stability and improving quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

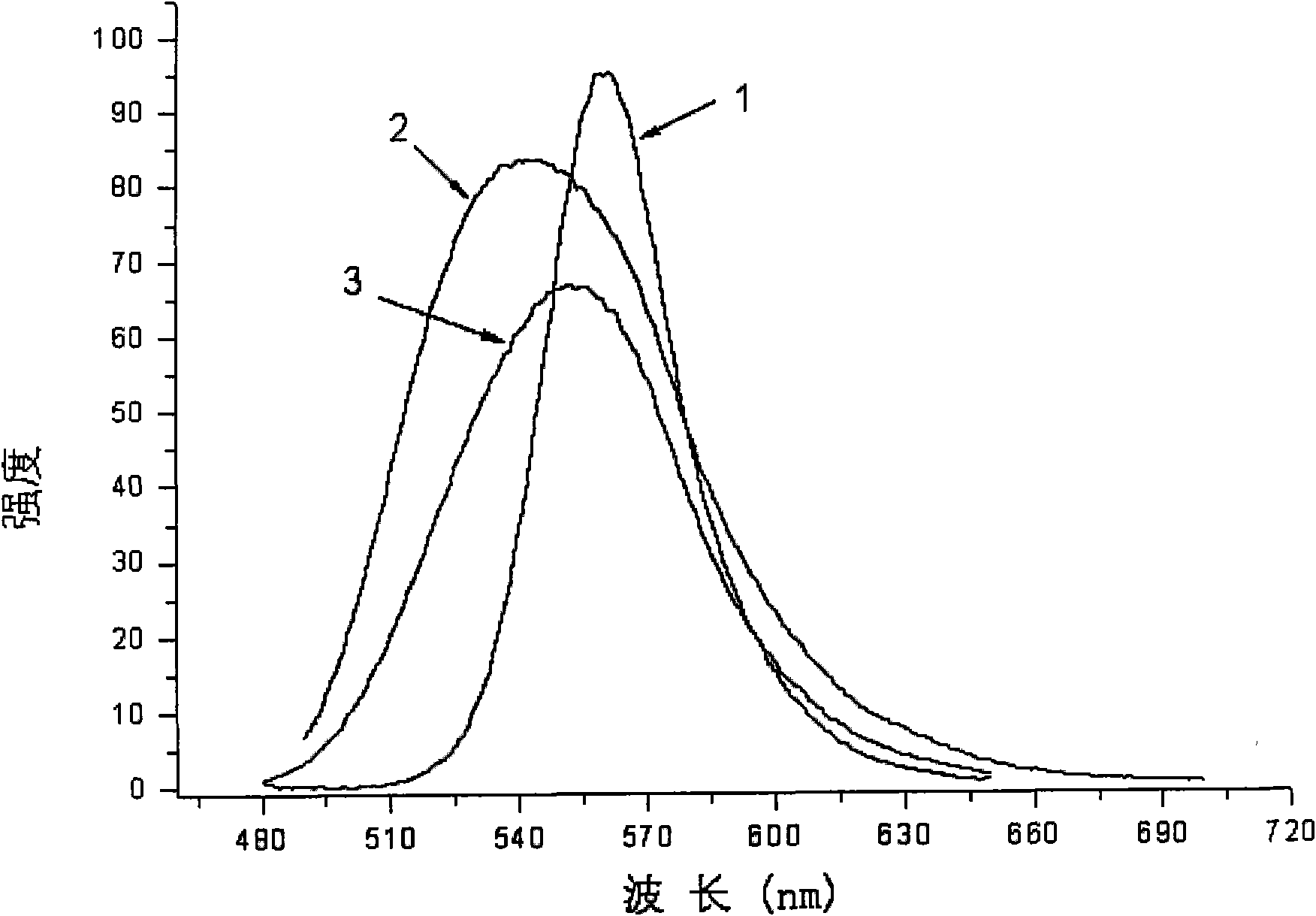

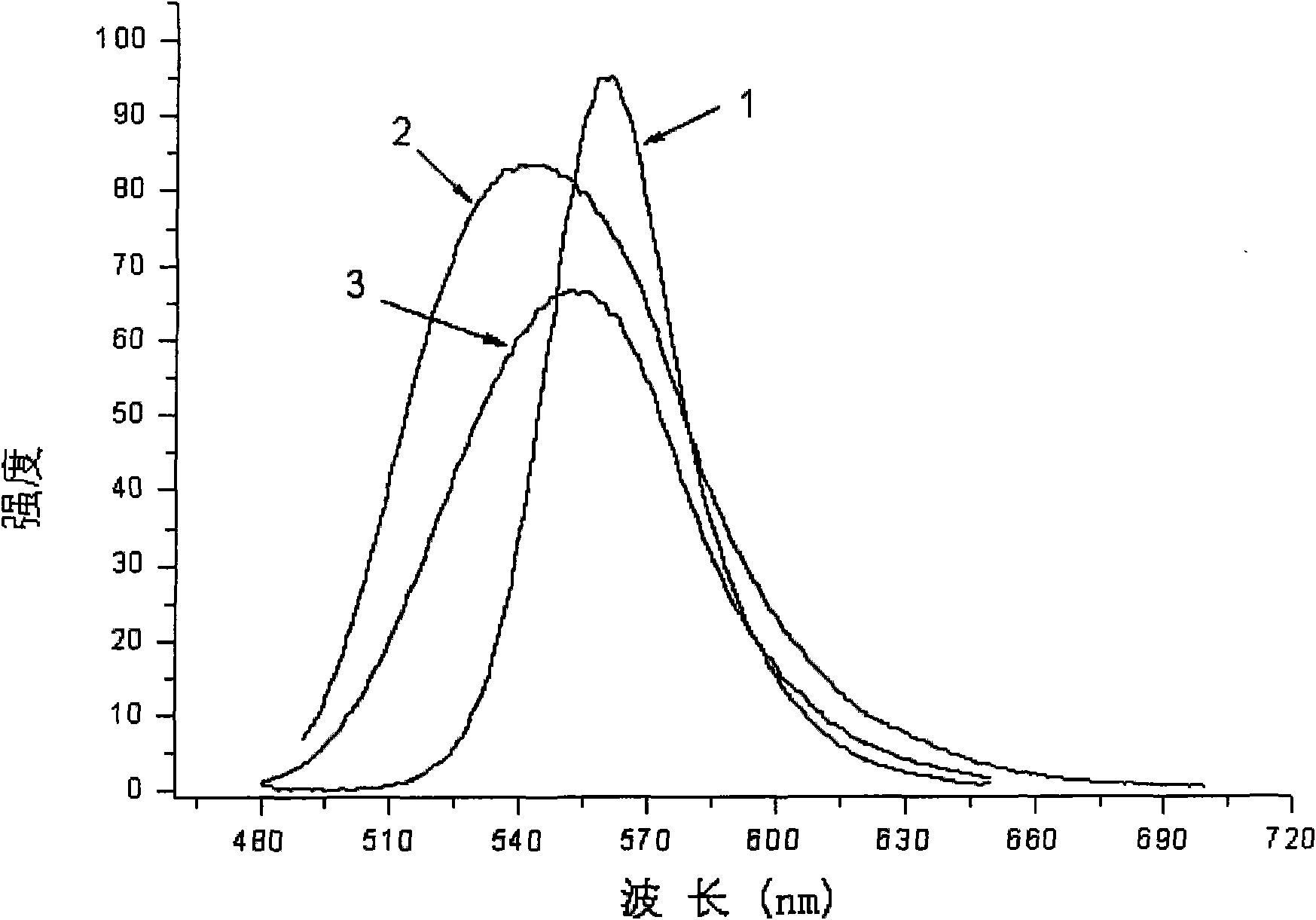

[0035] Get rhodamine compound rhodamine 6G (Acros company) 0.01mmol, be dissolved in the ethanol of 100ml, be mixed with 10 -4 mol / L solution, immerse porous glass whose pore volume accounts for 25% of the total volume of porous glass into the above solution for 8 hours, take it out, wash the surface with ethanol and dry it, then pulverize and grind it to obtain organic- Inorganic composite phosphor. figure 1 A comparison chart of the emission spectra of the organic-inorganic composite phosphor powder prepared in this example and commercially available phosphor powder is given, wherein curve 1 is the emission spectrum of the organic-inorganic composite phosphor powder prepared in this example 1 under the excitation of 475nm excitation light Spectrum; Curve 2 is commercially available YAG (yttrium aluminum garnet, yttrium aluminum garnet), a kind of Ce commercial fluorescent powder (Xi'an Rainbow Fluorescent Materials Co., Ltd.) emission spectrum under its optimal excitation wa...

Embodiment 2

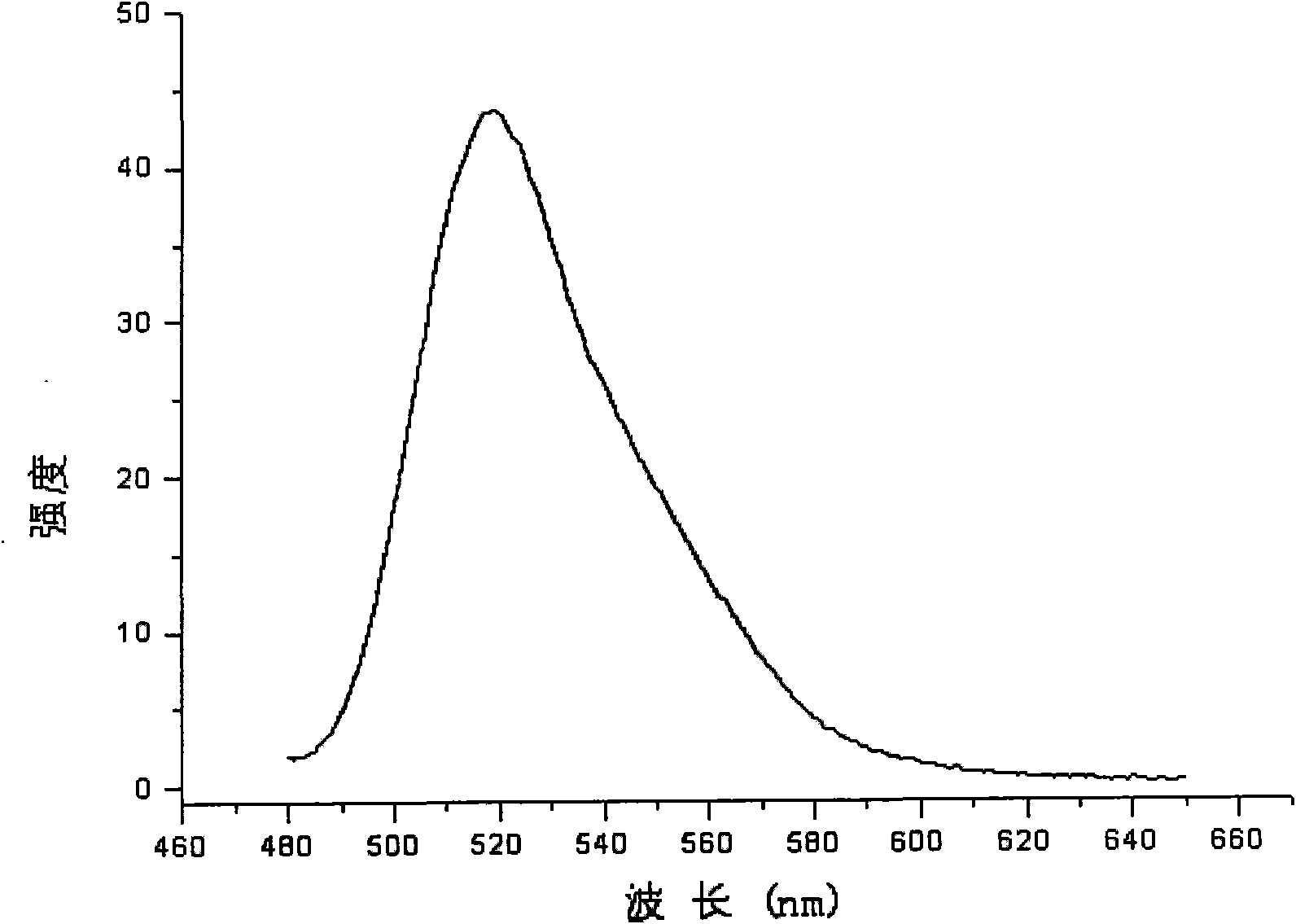

[0037] Get coumarin compound coumarin 307 (Acros company) 0.1mmol, be dissolved in the ethanol of 10ml, be mixed with 10 -2 mol / L solution, the porous glass whose pore volume accounts for 30% of the total volume of the porous glass is immersed in the above solution for 8 hours, taken out, cleaned with ethanol and dried, then pulverized and ground to obtain organic - Inorganic composite phosphor.

Embodiment 3

[0039] Get fluorene compound 9,9-bis(4-aminophenyl) fluorene (Acros company) 0.1mmol, be dissolved in the chloroform of 100ml, be mixed with 10 -3 mol / L solution, immerse porous glass whose pore volume accounts for 25% of the total volume of porous glass into the above solution for 8 hours, take it out, wash the surface with chloroform and dry it, then pulverize and grind it to obtain organic- Inorganic composite phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com