White light diode and manufacturing method thereof

A manufacturing method and technology for diodes, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of short service life, unstable luminescence properties, and easy deterioration of white light diodes, and achieve the effect of prolonging service life and strengthening chemical inertness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

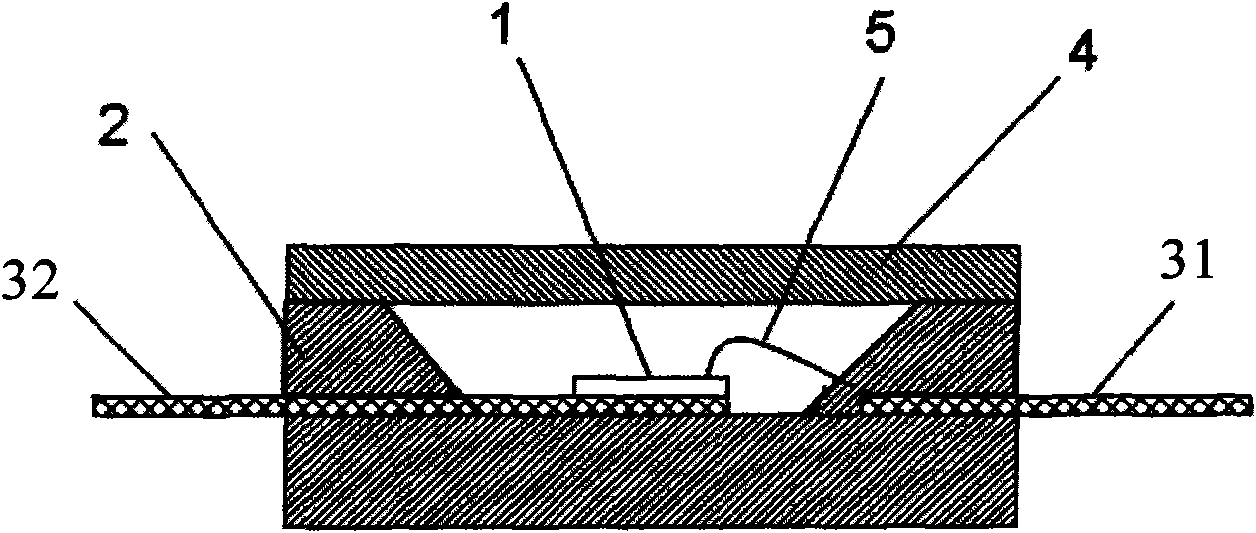

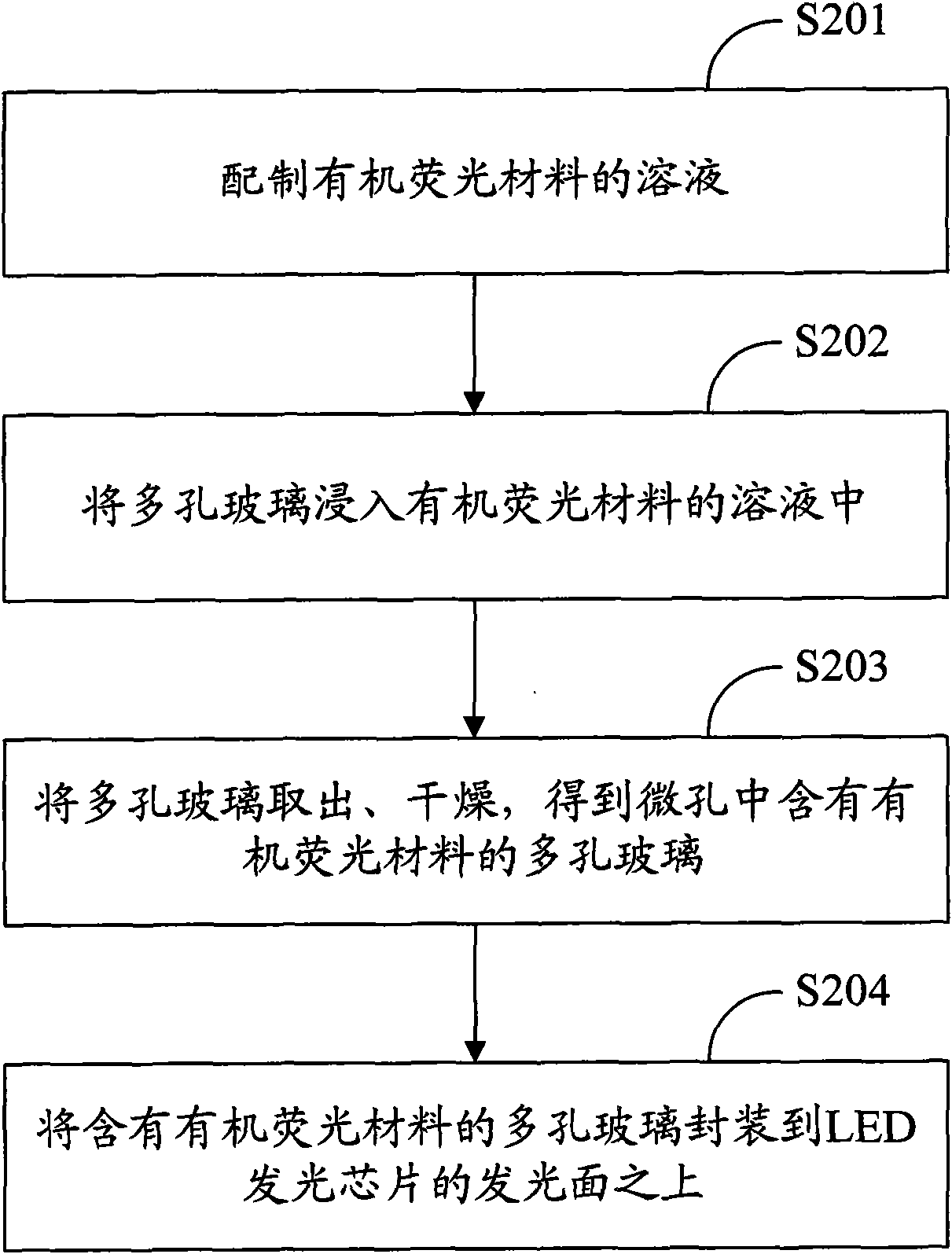

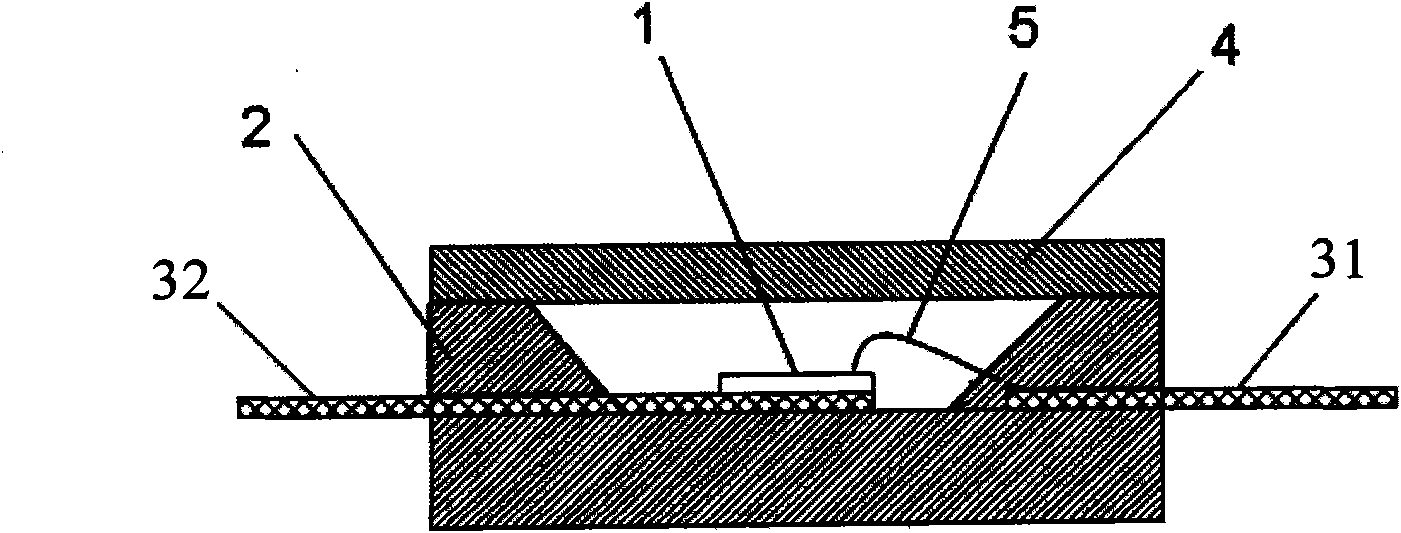

[0029] Dip fritted glass into 1×10 -4 mol / L rhodamine 6G ethanol solution, take out after fully absorbing this solution, dry, obtain porous glass, according to figure 1 The white light emitting diode is prepared by encapsulating in a manner, and the white light emitting diode of the present invention includes a semiconductor light emitting chip 1 , an insulating material 2 , an electrode 3 , a light emitting material 4 , and a lead 5 . In this embodiment, the main emission peak wavelength of the semiconductor light-emitting chip 1 is 468.7 nm, and the light-emitting material 4 is selected from the porous glass containing rhodamine 6G prepared in this embodiment. The porous glass is directly fixed on the semiconductor light-emitting chip with glue to obtain the white light-emitting diode provided by the embodiment of the present invention. The measured optical parameters of the white light emitting diode are shown in Table 1. The light efficiency is 55.07lm / W, the color coordi...

Embodiment 2

[0033] Dip the fritted glass into a 5×10 -5 mol / L rhodamine 6G ethanol solution, after fully absorbing the solution, take out and dry to obtain porous glass. The manufacturing method of the white light emitting diode of the present embodiment is the same as that of embodiment 1. The optical parameters of this white light emitting diode are shown in Table 1. Its luminous efficacy is 58.67lm / W, its color coordinates are (0.4138, 0.3619), and its color temperature is 3054K. Part of the blue light emitted by the blue chip excites the porous glass containing rhodamine 6G, causing the porous glass to emit yellow-red light, and the yellow-red light is combined with the remaining blue light emitted by the blue chip to form white light.

Embodiment 3

[0035] Dip the fritted glass into a 2×10 -5 mol / L rhodamine 6G ethanol solution, after fully absorbing the solution, take out and dry to obtain porous glass. The manufacturing method of the white light emitting diode of the present embodiment is the same as that of embodiment 1. The optical parameters of this white light-emitting diode are shown in Table 1. Its luminous efficacy is 55.77lm / W, its color coordinates are (0.3834, 0.3334), and its color temperature is 3515K. Part of the blue light emitted by the blue chip excites the porous glass containing rhodamine 6G, causing the porous glass to emit yellow-red light, and the yellow-red light is combined with the remaining blue light emitted by the blue chip to form white light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com