A silver-magnesium doped alumina nano-material covered with nitrogenized graphite doped nanometer silica, a preparing method thereof and applications of the material

A nanomaterial and nanotechnology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, nanotechnology, etc., can solve the problems of rare or disclosed invention patents, and achieve good catalytic selection. high yield, good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

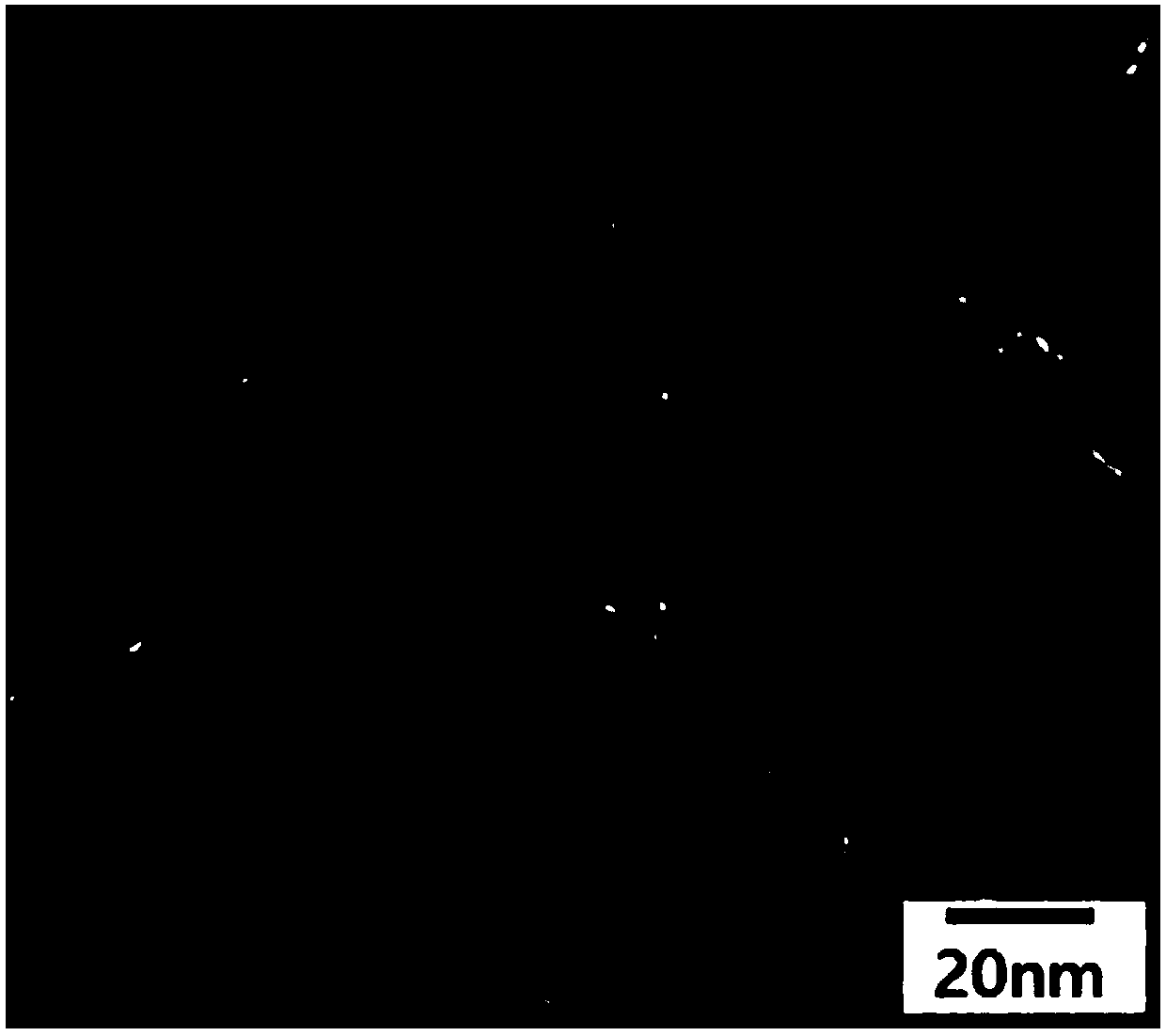

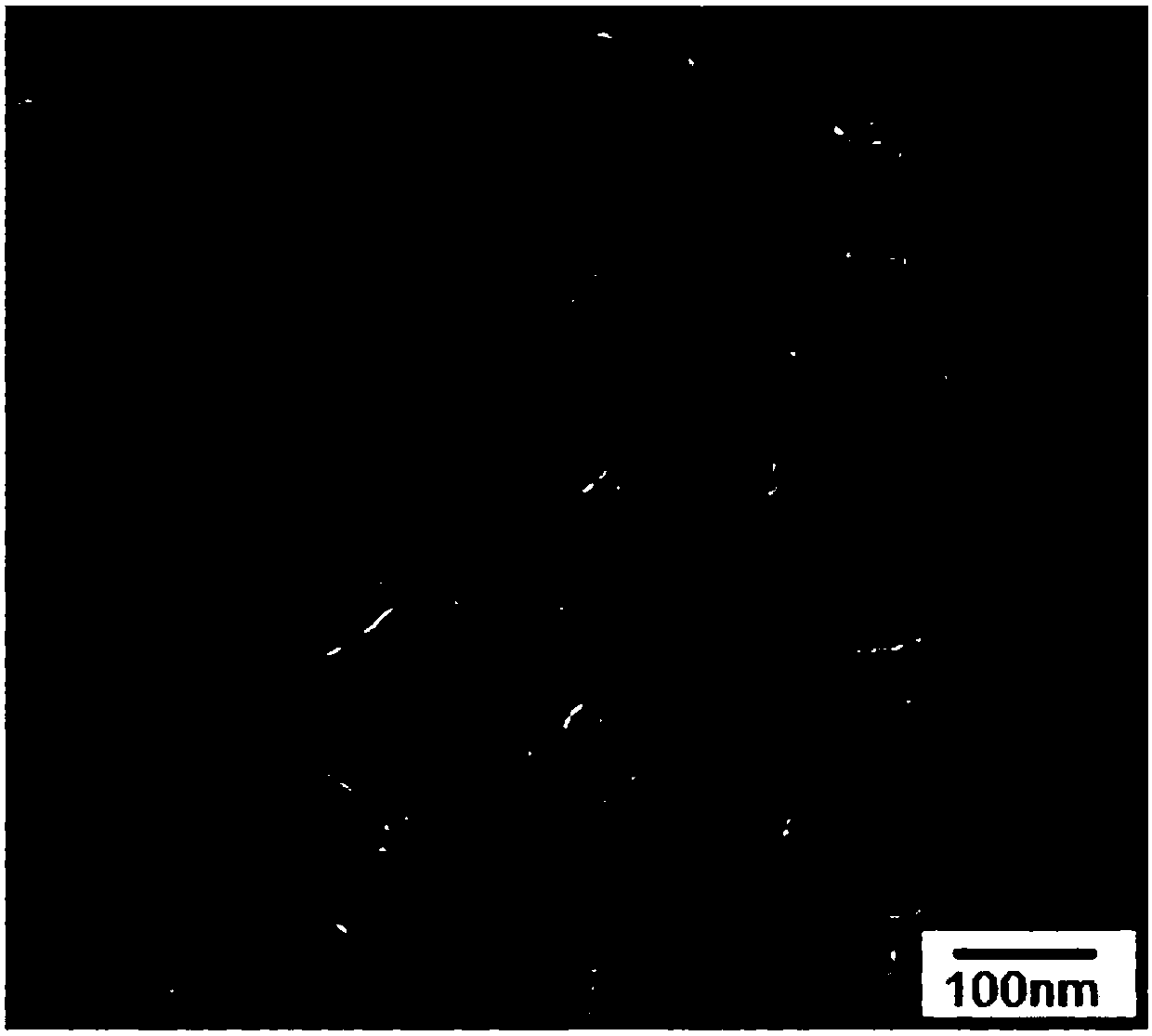

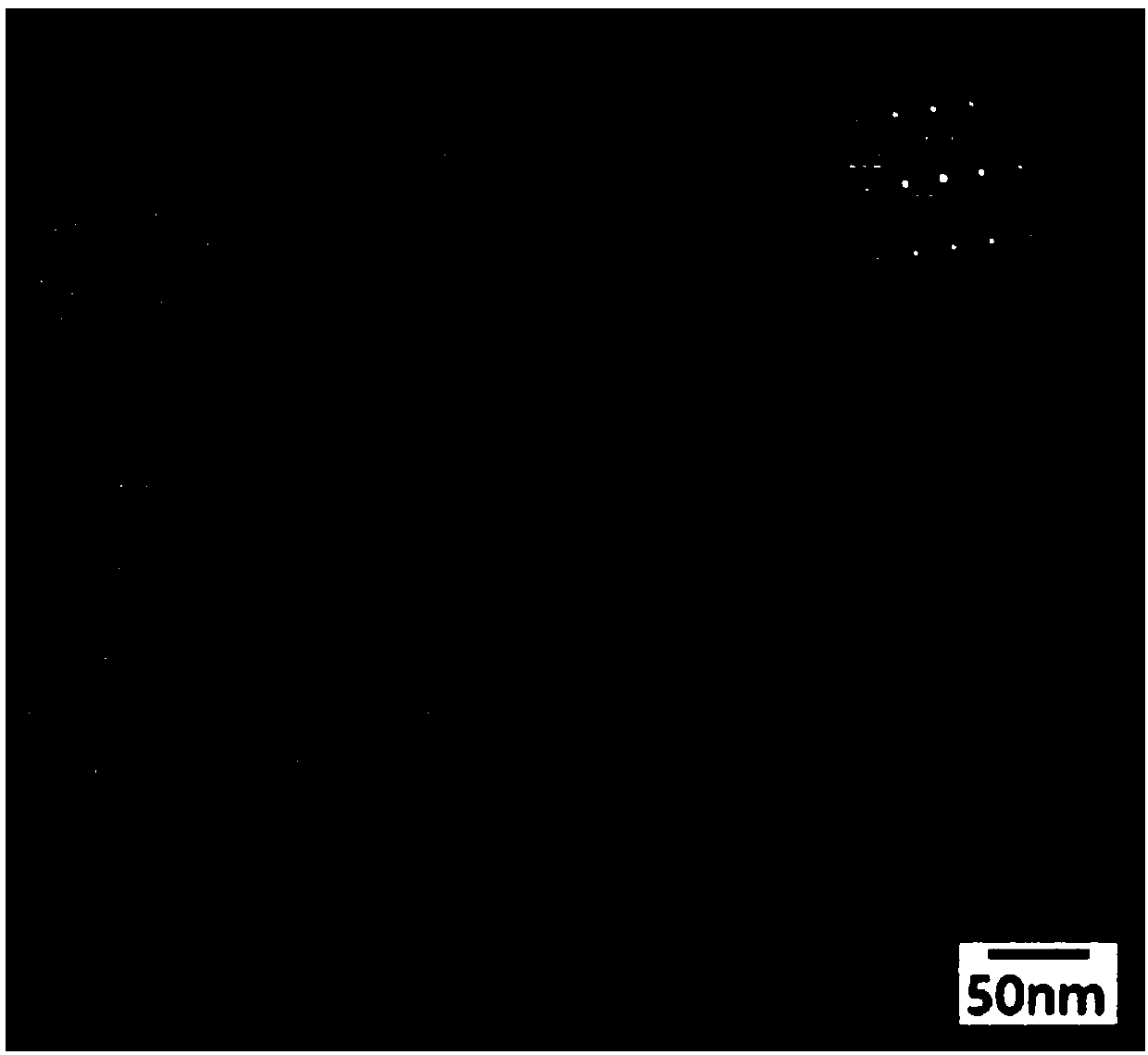

Image

Examples

Embodiment 1

[0056] Graphite Nitride Doped Nano-SiO 2 Coated Ag-Mg doped Al 2 o 3 Nanomaterial, its preparation method comprises the steps:

[0057] Step 1, under stirring condition, to the aluminum sulfate (Al 2 (SO 4 ) 3 ) and concentration are in the silver nitrate solution of 0.05mol / L, the mixed solution of 0.01mol / L magnesium sulfate, drip concentration is the sodium hydroxide solution of 0.1mol / L, the pH value of control reaction system is 8.5, reacts 30 minutes, Obtain gray or gray-black Ag-Mg doped aluminum hydroxide sol, dry at 85°C for 9 hours, grind, wash with distilled water until the pH of the eluate is about 6.8, and dry to obtain gray-white or gray Ag-Mg doped with hydrogen Alumina gel, calcined at 350°C for 12 hours, then off-white or gray Ag-Mg doped Al can be obtained 2 o 3 Nano powder;

[0058] Step 2, the Ag-Mg that the step 2 of 30g obtains is doped with Al 2 o 3 Nano-powder with a mass equivalent to Ag-Mg doped Al 2 o 3 Nano powder mass 5% soluble chitosa...

Embodiment 2

[0061] Graphite Nitride Doped Nano-SiO 2 Coated Ag-Mg doped Al 2 o 3 Nanomaterial, its preparation method comprises the steps:

[0062]Step 1. Under stirring conditions, in the aluminum nitrate with a concentration of 0.75mol / L, the silver nitrate solution with a concentration of 0.1mol / L, and the mixed solution of magnesium nitrate with a concentration of 0.15mol / L, add the carbonic acid with a concentration of 0.5mol / L dropwise. Sodium solution, control the pH value of the reaction system to 9.5, react for 25 minutes to obtain gray or gray black Ag-Mg doped aluminum hydroxide sol, dry at 95°C for 6 hours, grind, wash with distilled water to the pH of the eluate About 7.0, dry to get off-white or gray Ag-Mg doped aluminum hydroxide gel, calcined at 450°C for 10 hours to get off-white or gray Ag-Mg doped Al 2 o 3 Nano powder;

[0063] Step 2, the Ag-Mg that the step 2 of 50g obtains is doped Al 2 o 3 Nano-powder with a mass equivalent to Ag-Mg doped Al 2 o 3 Nano powd...

Embodiment 3

[0066] Graphite nitride doped nano-SiO 2 Coated Ag-Mg doped Al 2 o 3 Nanomaterial, its preparation method comprises the steps:

[0067] Step 1. Under stirring conditions, in the mixed solution of aluminum chloride with a concentration of 1.0mol / L, a silver nitrate solution with a concentration of 0.15mol / L, and a mixed solution of magnesium chloride with a concentration of 0.2mol / L, carbonic acid with a concentration of 1.0mol / L is added dropwise Sodium hydrogen solution, control the pH value of the reaction system to 10.5, react for 15 minutes to obtain gray or gray black Ag-Mg doped aluminum hydroxide sol, dry at 105°C for 3 hours, grind, and wash with distilled water until the eluate The pH is about 7.2, dried to obtain off-white or gray Ag-Mg doped aluminum hydroxide gel, calcined at 550°C for 8 hours to obtain off-white or gray Ag-Mg doped Al 2 o 3 Nano powder;

[0068] Step 2, the Ag-Mg that the step 2 of 100g obtains is doped with Al 2 o 3 Nano-powder with a mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com