Nut screwing machine of connecting rod

A nut machine and connecting rod technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult control of nut screw-in distance and low efficiency, and achieve low manufacturing cost, strong interchangeability, and easy length control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution is further elaborated in combination with specific implementation methods.

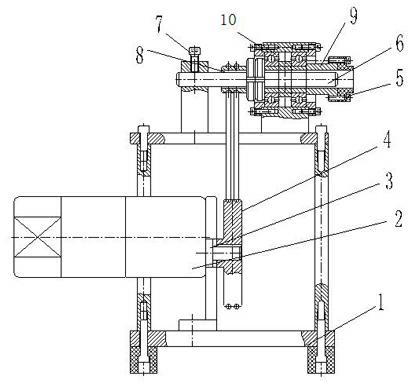

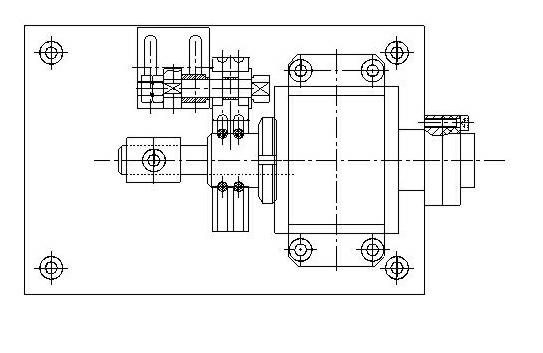

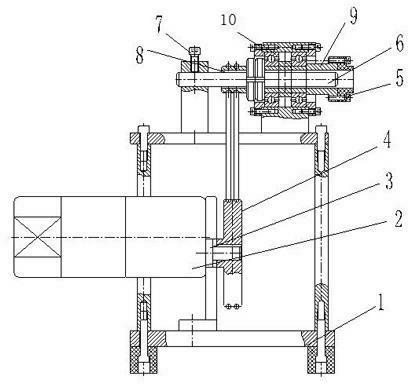

[0013] In the connecting rod nut screwing machine of the present invention, the motor 2 is fixed on the lower base plate 1, and the output side of the main shaft is equipped with a multi-ribbed pulley 3, which is transmitted to the multi-ribbed belt pulley 8 on the main shaft through the multi-ribbed belt 4, driving the main shaft 9 to rotate, and the main shaft The right side of 9 is equipped with a nut clamp 5, and the left side is equipped with a limit rod 6. Screw nuts of different specifications to replace different nut clamps 5, and the length of tightening is adjusted by the limit rod 6, and then the set screw 7 is locked. tight.

[0014] The connecting rod nut screwing machine of the present invention can replace nut clamps, can install connecting rod nuts of different specifications, has reliable screwing speed, adjustable screwing distance and high efficiency, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com