Variable-diameter half grouting sleeve and construction method thereof

A technology of a semi-grouting sleeve and a construction method, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of difficult control of quality standards, complicated threading procedures, and difficult operations, and achieves reduced bearing capacity and quality standards. Ease of use and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

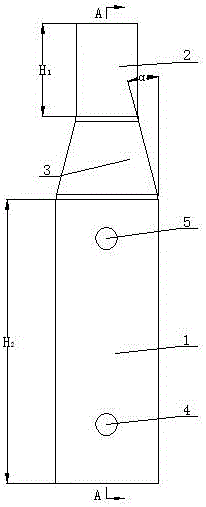

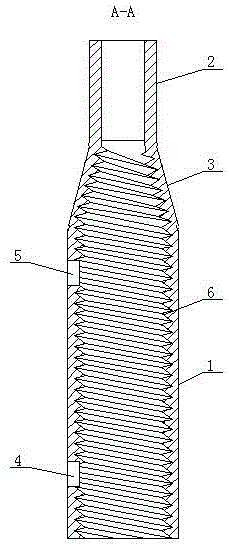

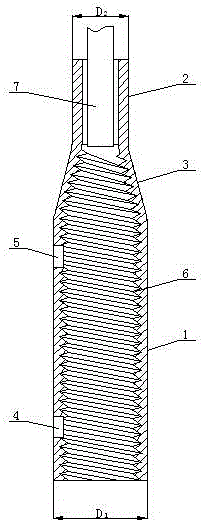

[0024] The present invention will be further described with reference to the accompanying drawings.

[0025] The variable-diameter semi-grouting sleeve of the present invention adopts seamless steel pipe as the main pipe 1, the inner wall of the main pipe 1 is a concave-convex surface, the upper end of the main pipe 1 is connected with the large diameter end of the conical pipe 3, and the small diameter of the conical pipe 3 The inner wall of the cylindrical pipe 2 is a smooth surface, the diameter of the main pipe 1 is equal, and the main pipe 1 is provided with a grouting hole 4 and a grouting hole 5. The variable-diameter semi-grouting sleeve of the present invention Cylindrical tube 2 is used to connect steel bars. Since the diameters of the two cylindrical tubes are equal, it can control the length of connecting steel bars inserted into the variable-diameter semi-grouting sleeve, which is easy to meet the national standard and easy to detect. At the same time, it can be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com