Turning tool device for turning narrow and deep end face groove with shaft

A technology with end faces and shafts, which is applied in the direction of lathe tools, turning equipment, manufacturing tools, etc. It can solve the problems of weakened tool strength and rigidity, low turning tool strength, and easily damaged parts, etc., and achieves blade regrinding Good, the strength and rigidity of the cutter bar are good, and the effect of convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

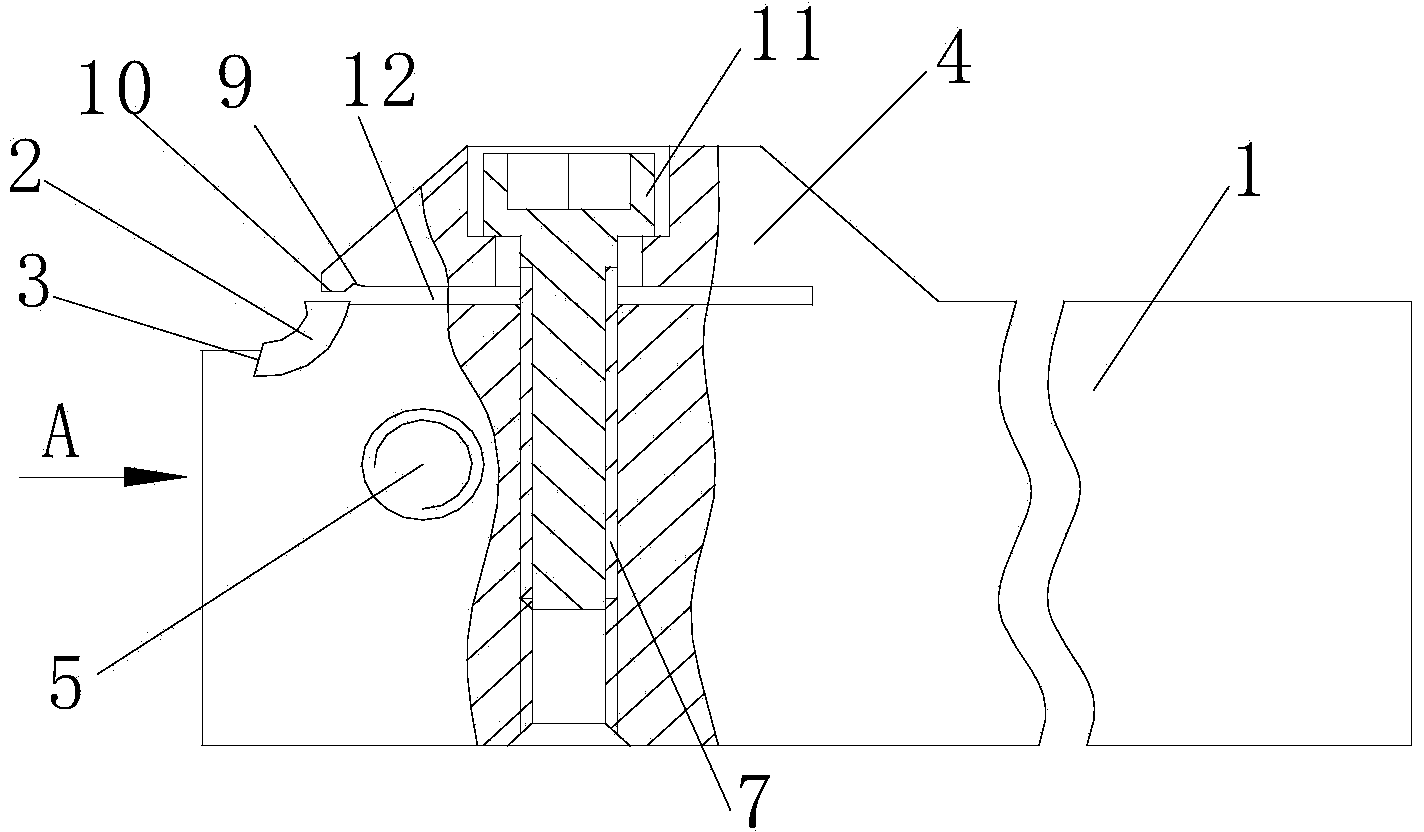

[0033] Attached below Figure 1-11 An embodiment of the present invention is described.

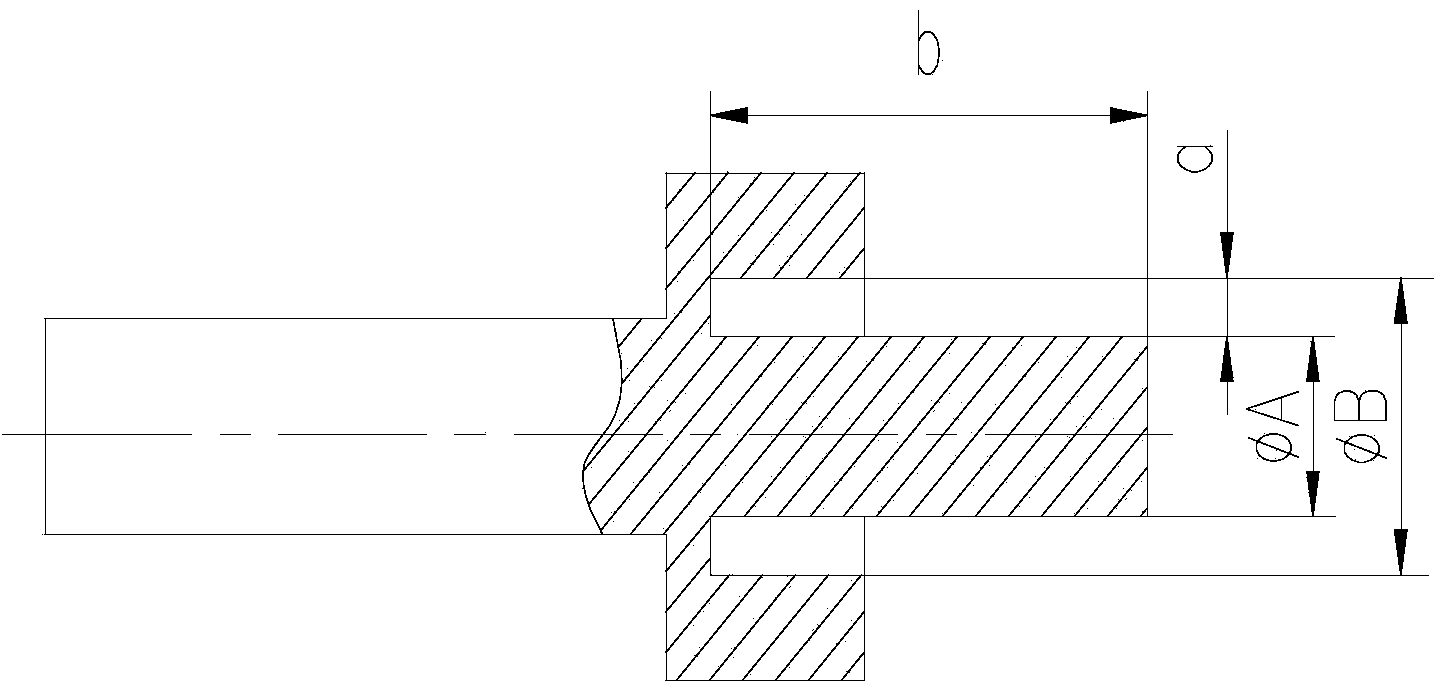

[0034] Turning tool device with narrow and deep grooves on the end surface of the shaft, which has a tool bar 1 and a blade 2. The tool bar 1 is in the shape of a cuboid as a whole. The rear end of the tool bar 1 is clamped with the tool holder as one. Groove 3, the overall shape of the blade 2 is a concave ring, the blade 2 is included in the groove 3 and both ends of the blade 2 protrude from the groove 3, the upper end surface of the knife rod 1 is shaped on a pressing plate 4, and the pressing plate 4 passes through the sinking The head screw 11 compresses the blade 2 in the groove 3. Specifically, the pressure plate 4 and the cutter bar 1 are of an integrated structure, and a pressure groove 12 is formed between the front end of the press plate 4 and the upper end surface of the cutter bar 1, wherein, The upper end surface of the cutter bar 1 is formed with a threaded hole II7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com