Hydrothermal preparation method of shape-controllable titanium dioxide nano tube

A technology of titanium dioxide and hydrothermal method, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of controllability of nanotube morphology, achieve controllable length, high tube forming efficiency, The effect of uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

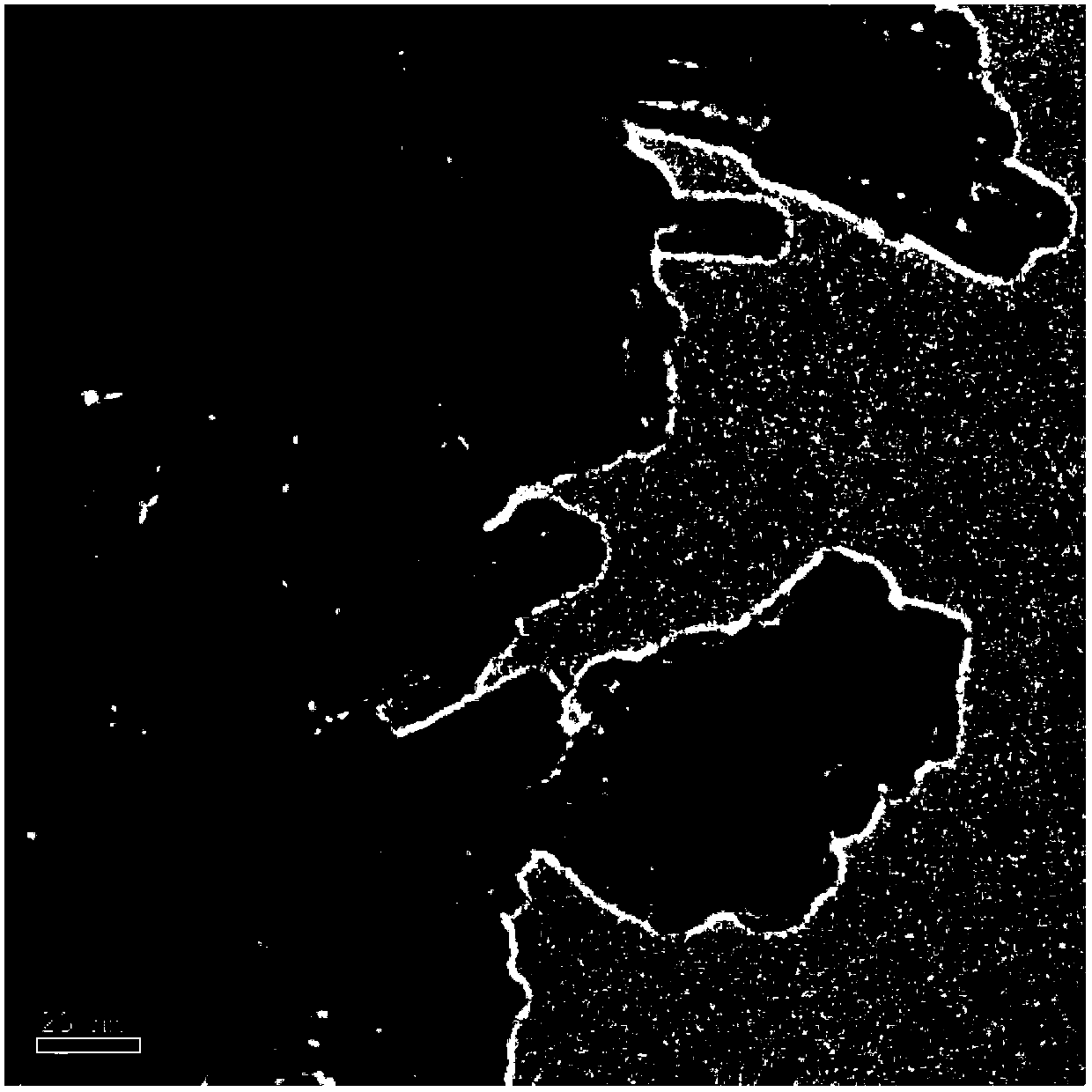

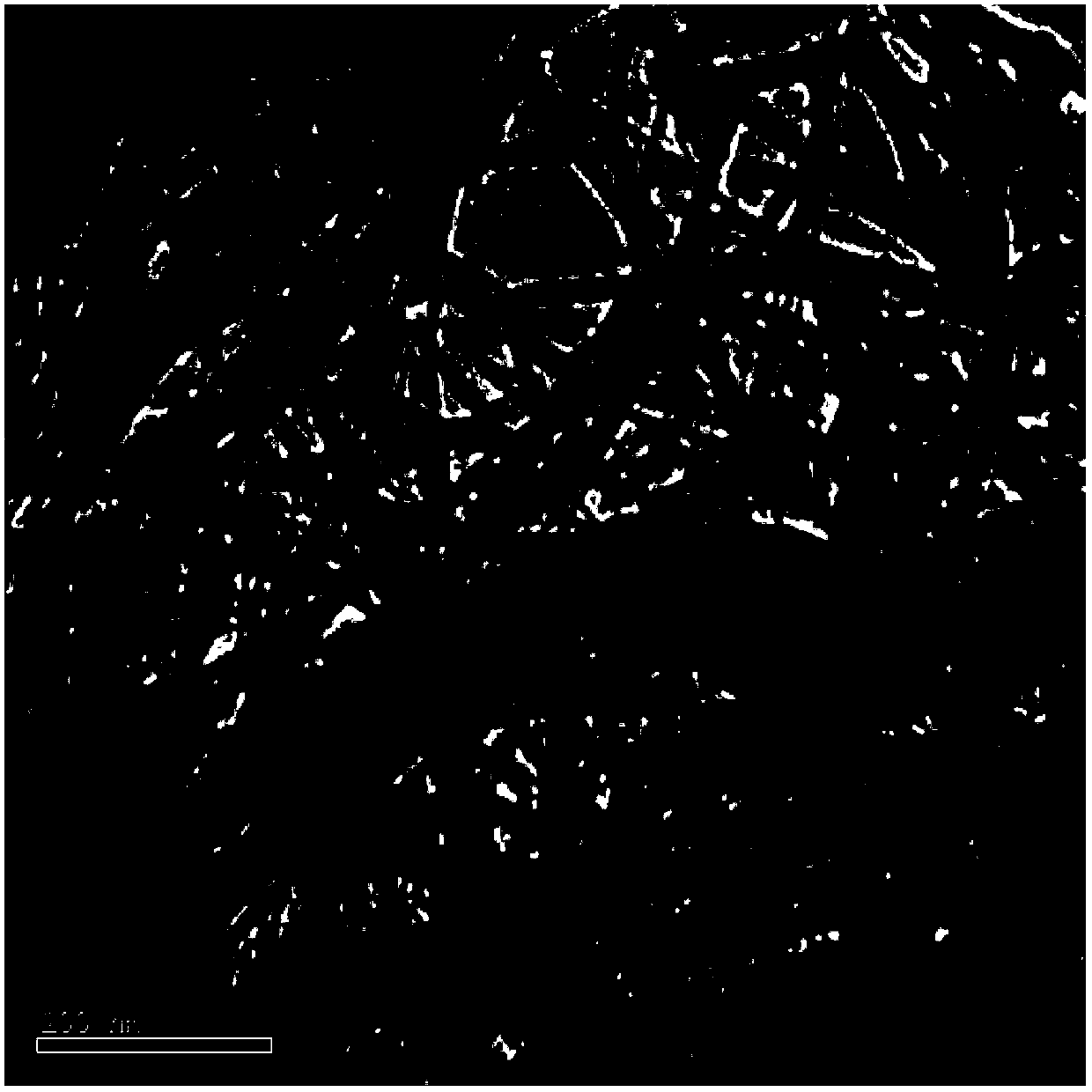

Image

Examples

Embodiment 1

[0023] Step 1: Prepare 20 mL of NaOH solution with a concentration of 10 mol / L and add it to the reaction kettle.

[0024] Step 2, weighing 3g of anatase phase titanium dioxide nanopowder with a particle size of 15nm, adding it into the prepared concentrated alkali solution and ultrasonically vibrating to make it evenly mixed.

[0025] Step 3: Put the reactor into an oven for hydrothermal reaction at 130° C. for 30 hours.

[0026] Step 4: After the hydrothermal reaction is completed, the supernatant is poured out, and the obtained solid powder is washed with water until neutral.

[0027] Step five, adding 0.1 mol / L nitric acid or hydrochloric acid to the obtained powder, and ultrasonicating at 50-100° C. for 1-3 hours.

[0028] In step six, the acid-treated sample is washed with water until it is nearly neutral.

[0029] Step seven, filter.

[0030] Step eight, fully dry the obtained powder.

[0031] Step 9, calcining the dried powder at 400° C. for 2 hours.

Embodiment 2

[0033] Step 1: Prepare 20 mL of NaOH solution with a concentration of 10 mol / L and add it to the reaction kettle.

[0034] Step 2, weighing 0.05g of cetyltrimethylammonium bromide and 3g of anatase phase titanium dioxide nanopowder with a particle size of 15nm, adding them into the prepared concentrated alkali solution and ultrasonically vibrating to mix them evenly.

[0035] Step 3: Put the reactor into an oven for hydrothermal reaction at 130° C. for 30 hours.

[0036] Step 4: After the hydrothermal reaction is completed, the supernatant is poured out, and the obtained solid powder is washed with water until neutral.

[0037] Step five, adding 0.1 mol / L nitric acid or hydrochloric acid to the obtained powder, and ultrasonicating at 50-100° C. for 1-3 hours.

[0038] In step six, the acid-treated sample is washed with water until it is nearly neutral.

[0039] Step seven, filter.

[0040] Step eight, fully dry the obtained powder.

[0041] Step 9, calcining the dried powd...

Embodiment 3

[0043] Step 1: Prepare 20 mL of NaOH solution with a concentration of 10 mol / L and add it to the reaction kettle.

[0044] Step 2: Weigh 0.1 g of cetyltrimethylammonium bromide and 3 g of anatase phase titanium dioxide nanopowder with a particle size of 15 nm, and add them into the prepared concentrated alkali solution by ultrasonic vibration to mix them evenly.

[0045] Step 3: Put the reactor into an oven for hydrothermal reaction at 130° C. for 30 hours.

[0046] Step 4: After the hydrothermal reaction is completed, the supernatant is poured out, and the obtained solid powder is washed with water until neutral.

[0047] Step five, adding 0.1 mol / L nitric acid or hydrochloric acid to the obtained powder, and ultrasonicating at 50-100° C. for 1-3 hours.

[0048] In step six, the acid-treated sample is washed with water until it is nearly neutral.

[0049] Step seven, filter.

[0050] Step eight, fully dry the obtained powder.

[0051] Step 9, calcining the dried powder at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com