Method for producing metal nano wire based on DNA template

A metal nanometer and wire technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of difficult control of length, uncontrollable direction, severe twist of DNA template, etc., and achieve easy control of length and uniform and controllable diameter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

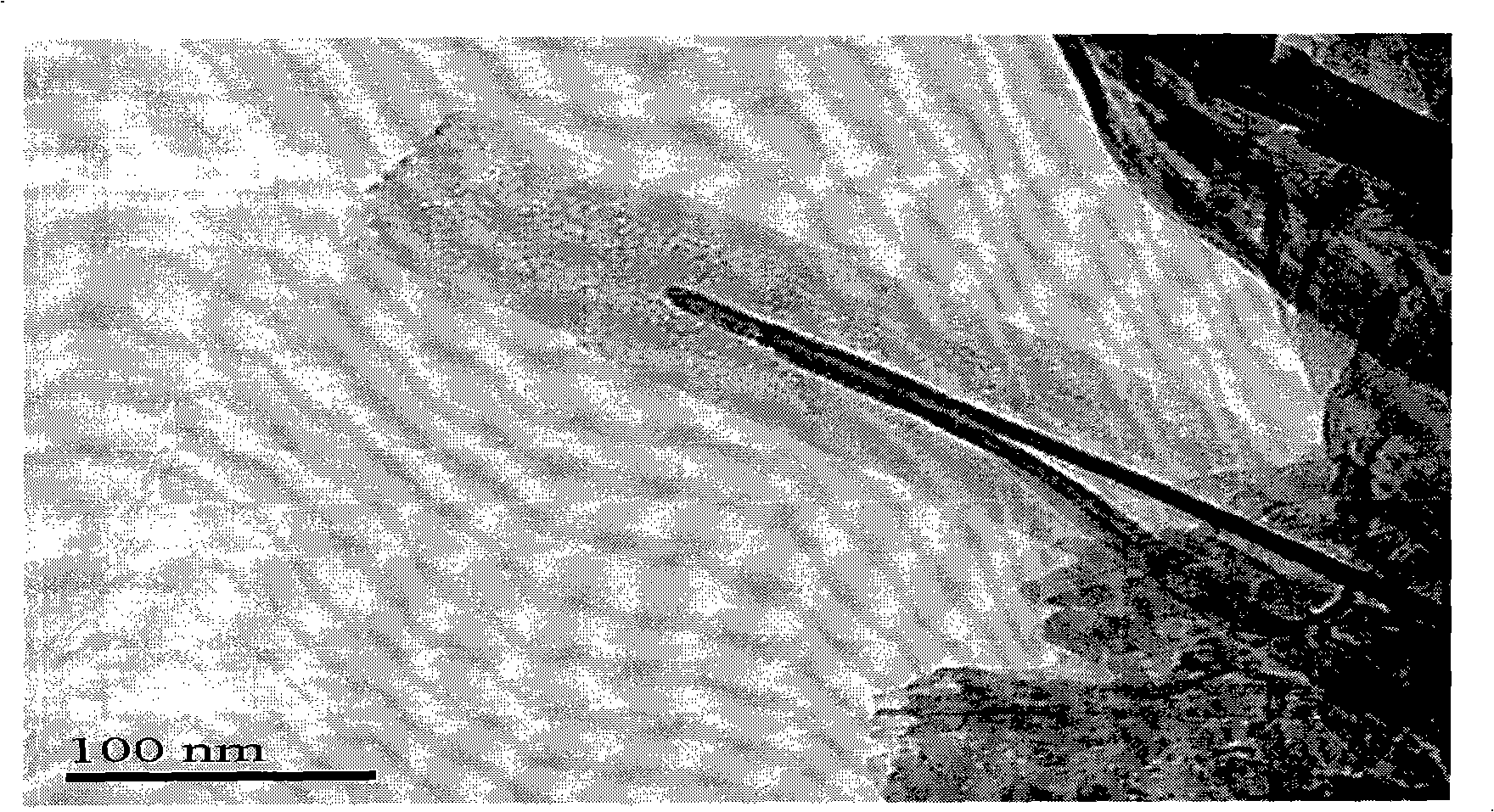

[0030] Soak the cleaned glass in 35% organic silanol for 25 minutes, take it out, wash and air-dry it for later use. Spread a mixed solution of 1.5 mg / ml DNA and 20 g / L magnesium chloride on the substrate with a micropipette, let it dry naturally for 2 hours, then use a peristaltic pump to rinse for 12 minutes at a speed of 25 rpm, and take out Air-dry naturally, then immerse in 10 g / L silver nitrate solution for 15 minutes, take it out and rinse it gently with pure water 3 times, then soak in 15 g / L sodium hydroxide plus 120 g / L formaldehyde solution for 10 minutes, Take it out and rinse it with pure water for 3 times, then air-dry to get the silver nano wire. The prepared nano-silver wire has a length of 600 nanometers and a width of 30 nanometers.

Embodiment 2

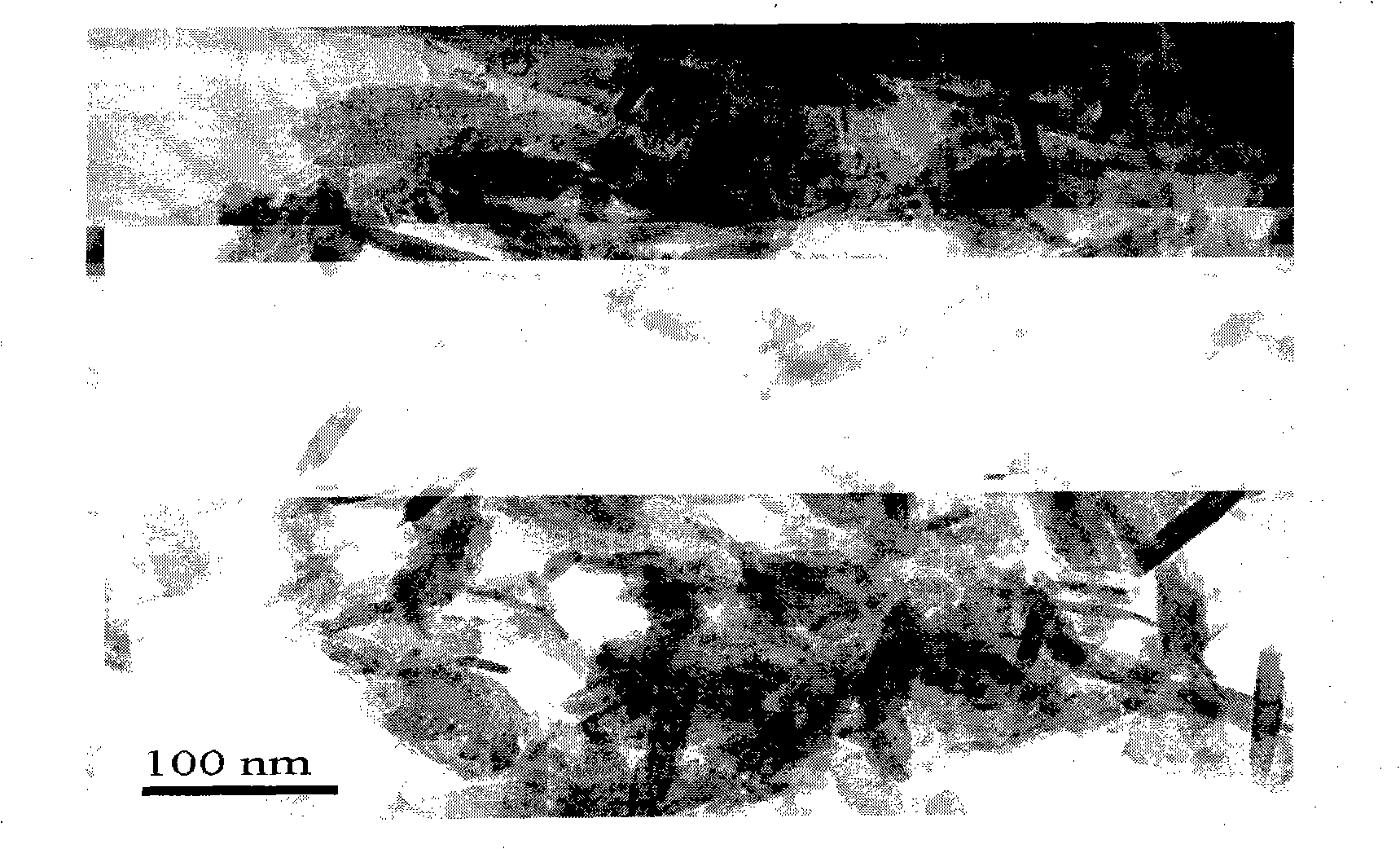

[0032] Soak the cleaned silicon wafer in 35% organic silanol for 10 minutes, take it out, wash and air dry it for later use. Then spread the mixed solution of 1.5 mg / ml DNA and 20 g / L magnesium chloride on the substrate with a micropipette, let it dry naturally for 2 hours, then use a peristaltic pump to rinse for 20 minutes at a speed of 10 rpm, and take out Naturally air-dry, then immerse in 20 g / L copper nitrate solution for 30 minutes, take it out and rinse it gently with pure water for 3 times, then put it in 25 g / L hypophosphite solution plus 140 g / L formaldehyde solution for 25 minutes , take it out and wash it with pure water for 3 times, then air-dry to get the copper nano wire. The prepared nano copper wire has a length of 100 nanometers and a width of 25 nanometers.

Embodiment 3

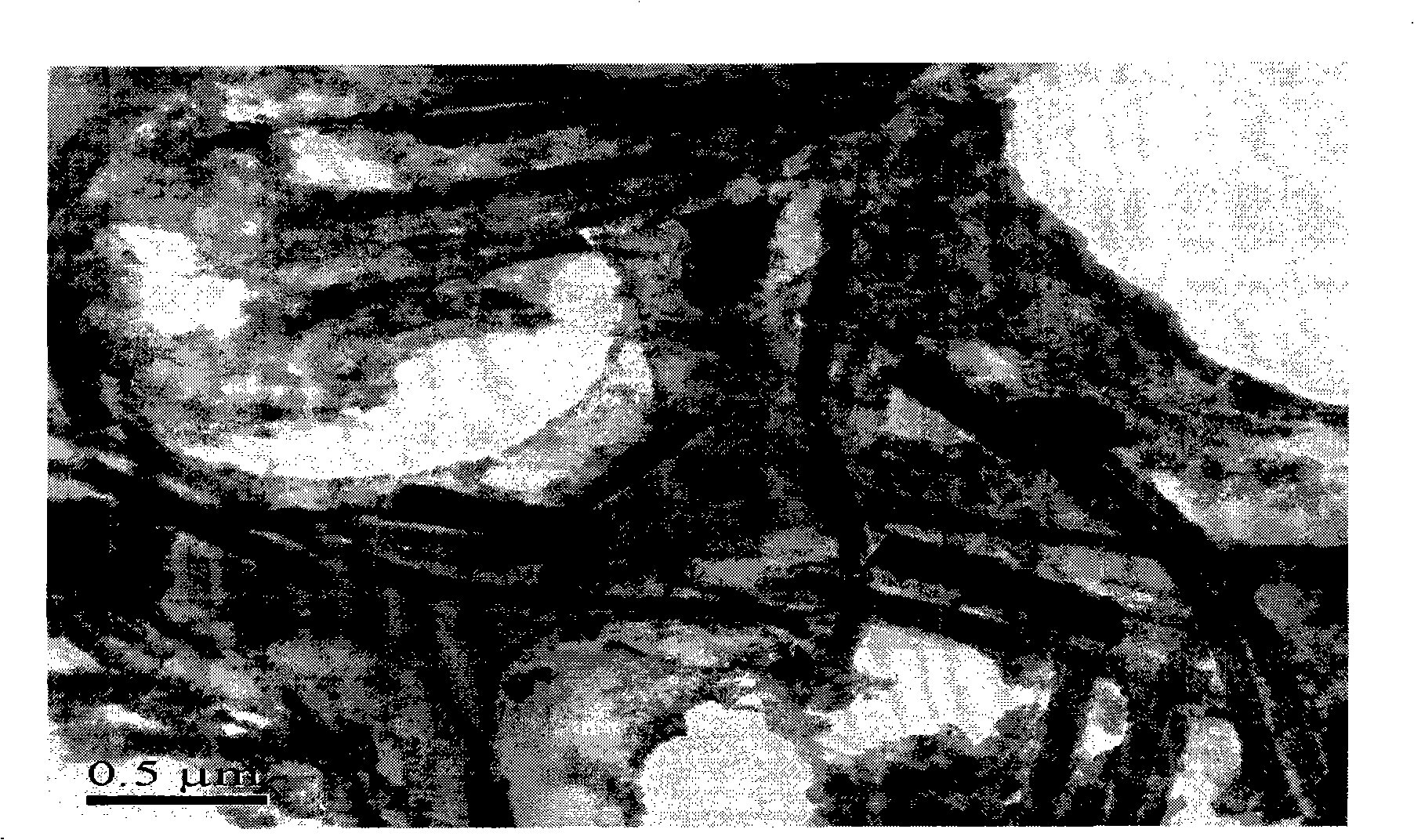

[0034] Soak the cleaned silicon wafer in 40% organic silanol for 20 minutes, take it out, wash and air dry it for later use. Spread a mixed solution of 0.5 mg / ml DNA and 20 g / L magnesium chloride on the substrate with a micropipette, let it dry naturally for 2 hours, then rinse it with a peristaltic pump at 20 rpm for 15 minutes, and take out Air-dry naturally, then immerse in 40 g / L ferric nitrate solution for 25 minutes, take it out and rinse gently with pure water 3 times, then put it into 25 g / L hypophosphite solution for 15 minutes, take it out and rinse with pure water for 3 The iron nanowires were obtained after air-drying for a few times. The prepared iron nanowire has a length of 2000-3000 nanometers and a width of 50 nanometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com