Aluminum tape wrapping device and its operation method

A technology of winding device and operation method, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., which can solve the problems of cumbersome winding work, uneven construction technology, and loose winding of aluminum tape, so as to avoid excessive cutting length , large promotion and application value, and the effect of unified construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

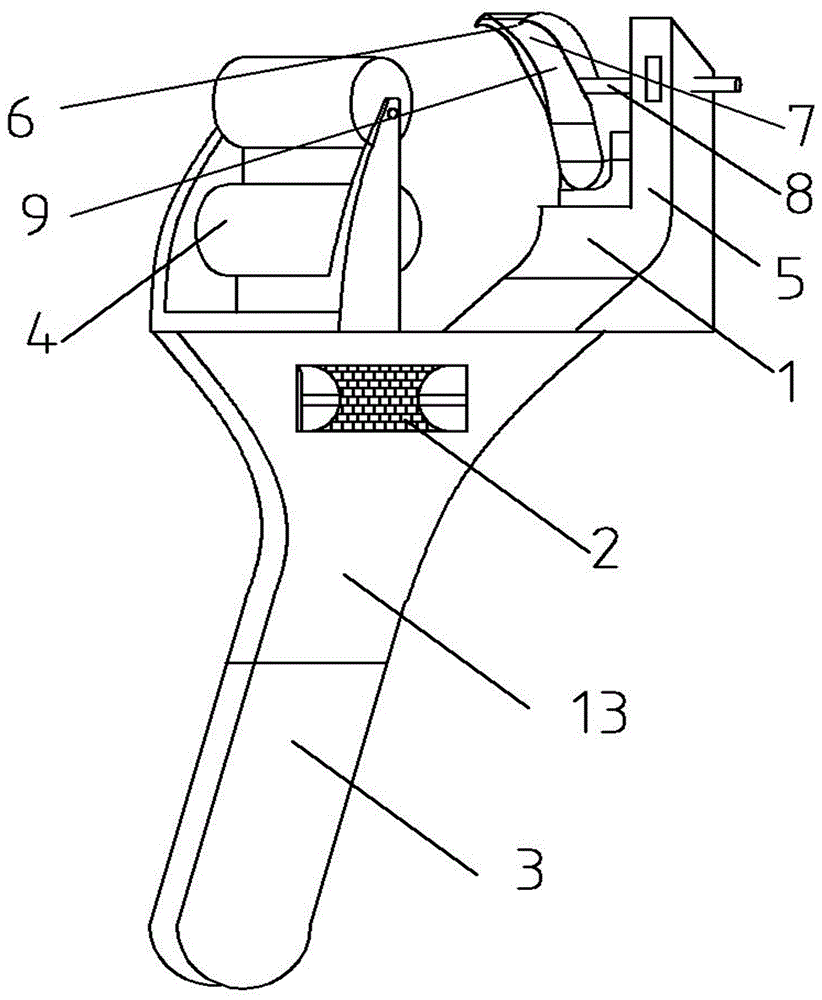

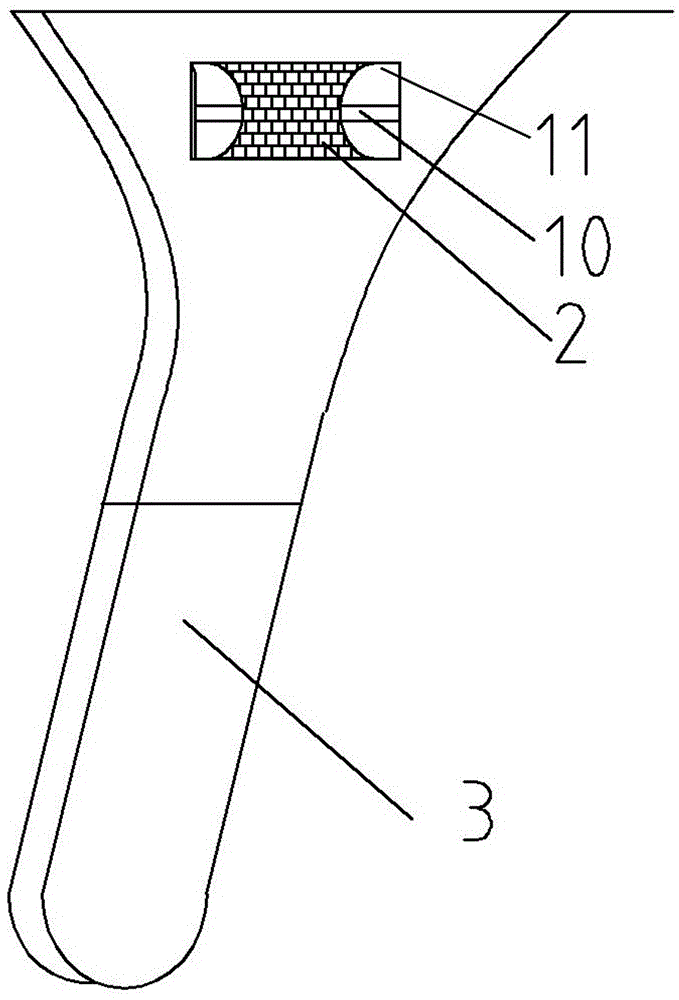

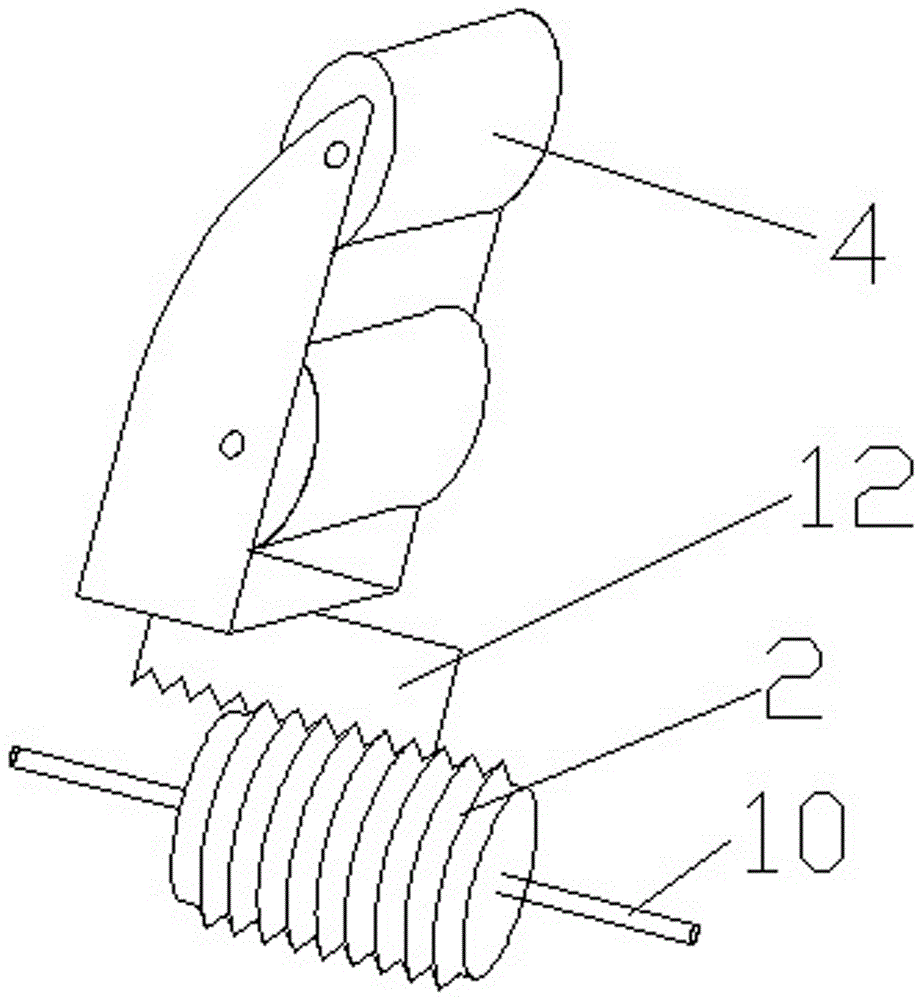

[0045] like Figures 1 to 3 As shown, an aluminum tape winding device includes a fixed jaw 1 and a movable jaw 4 that are oppositely arranged on the body 3. The inner side of the fixed jaw 1 is provided with an arc surface 5 that is adapted to the shape of the outer surface of the wire. The upper end of the fixed jaw 1 is provided with a movable notch 7, and one end of the movable notch 7 is fixed on the fixed jaw 1, and the other end of the movable notch 7 is provided with a notch 6 for clamping the aluminum strap.

[0046] Wherein, the fixed jaw 1 is connected with a screw rod 8 that can control the rotation of the movable notch 7 .

[0047] Wherein, the fixed jaw 1 is provided with an adjusting nut 9, one end of the screw rod 8 is connected with the movable notch 7, and the other end of the screw rod 8 is connected with the fixed jaw 1 through the adjusting nut 9.

[0048] Wherein, the radius of the arc surface 5 is 30mm-35mm.

[0049] Wherein, the shape of the movable no...

Embodiment 2

[0055] The operating method of the aluminum tape winding device described in embodiment 1 comprises the following steps:

[0056] Step 1), mark on the wrapped wire, the center position of the wire clip is marked as O, and the positions of the two ends of the wire clip are respectively extended by 5mm, respectively marked as A, B, and the distance between A and B is on the wire. The length D of the wrapped aluminum tape, according to the width of the clamp connecting the anti-vibration hammer and the wire, calculate the required length L of the aluminum tape;

[0057] Step 2), cut off the aluminum tape with a length of L, mark I at L / 2, the aluminum tape is divided into two parts a and b, and paste the two parts a and b on the surface of the wrapped wire respectively, so that the mark Point I coincides with point O;

[0058] Step 4), fix part a of the aluminum tape, make the aluminum tape close to the wire, use the aluminum tape winding device described in any one of claims 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com