Method for large-batch preparing overlength carbon nano pipe array and its apparatus

A technology of ultra-long carbon nanotubes and carbon nanotube arrays, which is applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of limited collection substrates and inability to match reactors, and achieves easy operation, simple device, Requires a loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

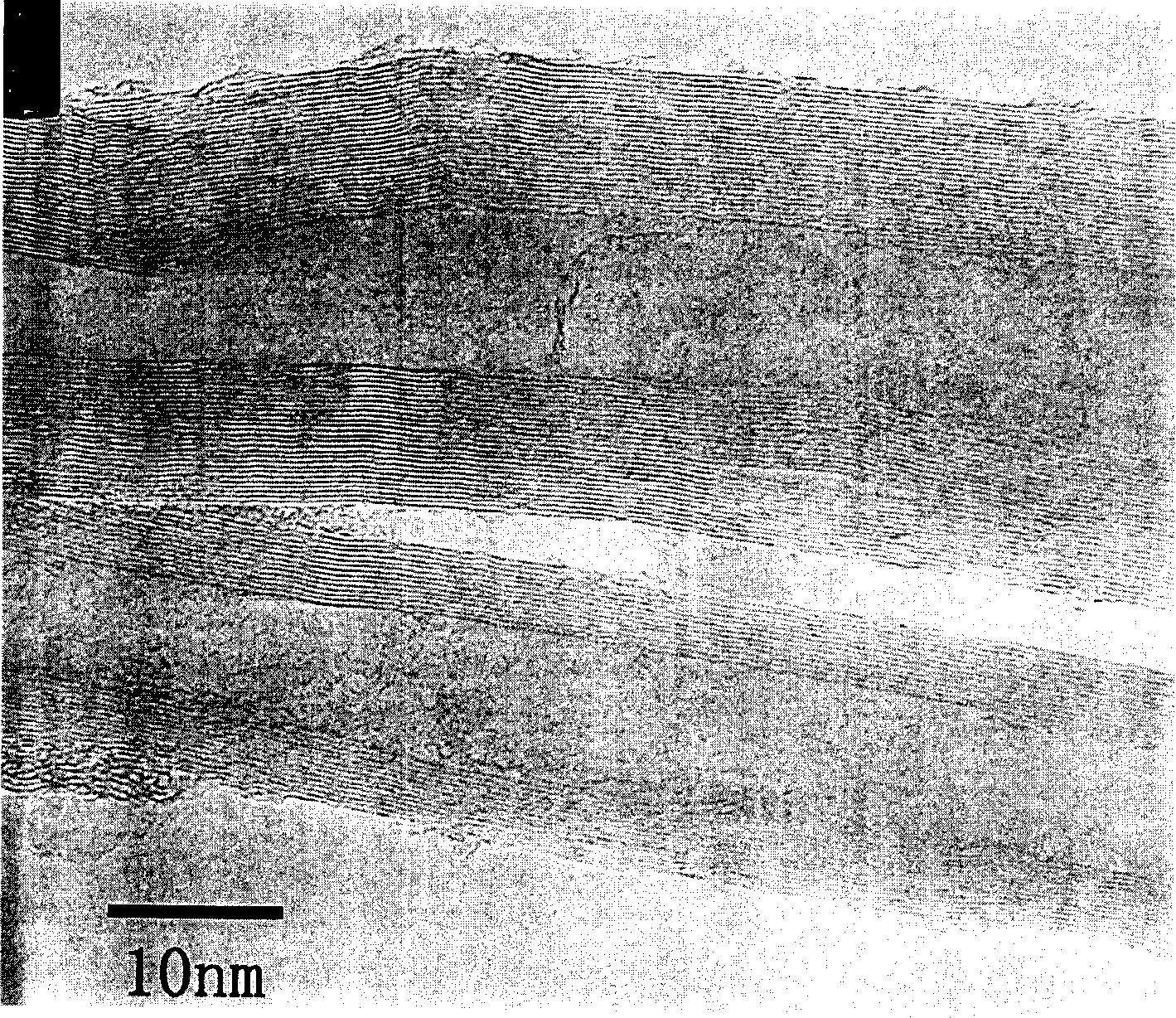

[0027] Fill the fixed-bed reactor with alumina spherical ceramic particles with a diameter of about 1 mm, and feed argon and hydrogen into the reactor from top to bottom (the airflow can also flow from top to bottom or from left to right), with a flow ratio of 5:1. Reaction temperature 850°C, 0.1 hour -1 Spray 5 mg / ml ferrocenebenzene solution into the reactor from the top of the reactor at a space velocity of 30 minutes, stop heating and cool to room temperature to take out the ceramic particles. The product on the particle surface is confirmed by scanning and transmission electron microscopy to be an array of multi-walled carbon nanotubes with a length of about 500 microns. figure 1 is the actual picture of the product, figure 2 , 3 The scanning and transmission electron microscope images respectively. Thermogravimetric analysis showed that the product did not contain any amorphous carbon, with a multi-walled tube content greater than 95%.

example 2

[0029] Zirconium dioxide spherical ceramic particles with an average particle size of about 50 microns are added to the reactor from the top of the moving bed, nitrogen and hydrogen are introduced from the bottom of the reactor, the flow rate is 20:1, the reaction temperature is 700 ° C, and the reaction time is 1 hour. -1 Add 100 mg / ml dicarbonylironcyclohexane solution from the bottom of the reactor at a space velocity of 100 mg / ml. After 30 minutes of reaction, open the valve, and the particles move into the separation section. This section strips the product array from the surface of the particles and collects them. The particles pass through the regeneration section at 600 ° C. After calcination, it is transported to the top of the reactor by the riser for recycling. The product is confirmed to be an array of multi-walled carbon nanotubes with a length of about 200 micrometers arranged by scanning and transmission electron microscopy.

example 3

[0031] Glass beads with an average particle size of about 100 microns are filled in a fluidized bed reactor, nitrogen and hydrogen protection gas are fed into the reactor from bottom to top at a flow ratio of 10:1, and the gas flow rate is adjusted to make the particles close to fluidization. Temperature 550°C, take 0.05 hours -1 Inject 20 mg / ml of ferrocene ethanol solution at a space velocity of 20 mg / ml, stop the supply of raw materials after 2 hours of reaction, increase the flow rate of the protective gas to completely fluidize the glass beads, and collect the product with a cyclone at the top of the reactor. After the product is completely released, switch The air valve is fed into the air to calcinate the remaining carbon deposits for 10 minutes and then return to the reaction conditions for the second cycle. The product is confirmed by scanning and transmission electron microscopy to be a neatly arranged array of multi-walled carbon nanotubes with a length of about 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com